Professional Documents

Culture Documents

Hanging and Supports PDF

Uploaded by

martin.rubenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hanging and Supports PDF

Uploaded by

martin.rubenCopyright:

Available Formats

Anchoring, Hanging & Supports B-20

.

ANCHORING, HANGING AND SUPPORTS Hangers for straight runs

Shurjoint grooved couplings are designed to hold axial For straight runs, you can use both flexible and rigid

thrusts 4–5 times their rated working pressure, though the couplings. When rigid couplings are used, the same hanger

strength against bending movements is less than that of spacing as other piping methods can be applied. You can

steel pipe. The joint may be damaged when a bending refer to the hanger spacing standards of ANSI B31.1 Power

movement greater than the allowed deflection occurs. Piping Code, B31.9 Building Services Piping Code, NFPA

System designers should provide anchors (main and 13 Sprinkler Systems, or Mechanical Equipment

intermediate) and pipe guides with proper spacing to Construction Guide (Japan). See the table below.

protect the system from unexpected large bending

movements. Suggested Max. Span between Supports

(steel pipe)

These illustrations are examples only, and are not intended Water Service Gas or Air Service

to be used for all installations as conditions and Nominal

requirements vary from job to job. Reliance on general data Pipe Size (feet/meters) (feet/meters)

in/mm 1) 2) 3) 4) 1) 2) 3)

or information contained herein shall be at the user's sole

risk and without obligation to Shurjoint. 1 / 25 7/2.1 9/2.7 12/3.7 6.6/2.0 9/2.7 9/2.7 9/2.7

1¼ / 32 7/2.1 11/3.4 12/3.7 6.6/2.0 9/2.7 9/2.7 11/3.4

Hangers shall be designed to support five times the weight

1½ / 40 7/2.1 12/3.7 15/4.6 6.6/2.0 9/2.7 9/2.7 13/4.0

of water-filled pipe plus 250 lb (115 kgs) at each point of

pipe support (NFPA 13 9.1.1.1.). The following illustrations 2 / 50 10/3.1 13/4.0 15/4.6 6.6/2.0 13/4.0 13/4.0 15/4.6

are examples of acceptable hanger types and sizes per 3 / 80 12/3.7 15/4.6 15/4.6 6.6/2.0 15/4.6 15/4.6 17/5.2

NFPA 13. 4 / 100 14/4.3 17/5.2 15/4.6 6.6/2.0 17/5.2 17/5.2 21/6.4

6 / 150 17/5.2 20/6.1 15/4.6 10/3.0 21/6.4 21/6.4 25/7.6

8 / 200 19/5.8 21/6.4 15/4.6 10/3.0 24/7.3 24/7.3 28/8.5

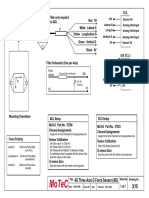

U-Hook Size 10 / 250 19/5.8 21/6.4 10/3.0 24/7.3 24/7.3 31/9.5

Pipe D dimension 12 / 300 23/7.0 21/6.4 10/3.0 30/9.1 30/9.1 33/10.1

Size in/mm

14 / 350 23/7.0 21/6.4 30/9.1 30/9.1 33/10.1

~2" 5/16 (7.9)

2½ ~ 6" ⅜ (9.5) 16 /400 27/8.2 21/6.4 35/10.7 35/10.7 33/10.1

8" ~ ½ (12.7) 18 /450 27/8.2 21/6.4 35/10.7 35/10.7 33/10.1

20 /500 30/9.1 21/6.4 39/11.9 39/11.9 33/10.1

24 / 600 32/9.8 216.4 42/12.8 42/12.8 33/10.1

Wraparound 1) ANSI B31.1 Power Piping Code

U-hook 2) ANSI B31.9 Building Services Piping Code

3) NFPA 13 Sprinkler systems

4) Ministry of Land & Transportation of Japan: Mechanical

Equipment Construction Guide

Rod Size Hanger locations on straight runs where

Pipe D dimension

Size in/mm

flexible couplings are used

~4" ⅜ (9.5)

5 ~ 8" ½ (12.7)

When flexible couplings are used on straight runs, location

10 ~ 12" ⅝ (12.9)

of hangers shall be designed as close to each coupling as

possible, or within a distance of less than 1/6 the span.

Adjustable swivel

Ring - rod tight

to pipe

D

dimension

Eye rod sizes

Pipe D dimension

Size in/mm

~4" ⅜ (9.5)

5 ~ 8" ½ (12.7)

10 ~ 12" ¾ (15.1)

B-20-1/3 Rev.D 20160314

Anchoring, Hanging & Supports B-20

Hanger locations on curved pipe runs and Additional hangers or supports shall be provided where

branch lines Runs are curved, connected to a branch line or on short

risers or drops

Typical designs of hangers and sway braces

for pipe runs

Pipe runs shall be adequately suspended by rod hangers

or steel angles that are directly attached to the building

structure to restrict the movement of the piping. Hangers

and their components shall be ferrous. The maximum

distance between hangers shall not exceed that specified

in the table of previous page.

A trapeze hanger suspended from ceiling

A rod hanger for a single ipe run

A trapeze hanger for multiple pipe runs

B-20-2/3 Rev.D 20160314

Anchoring, Hanging & Supports B-20

Supports for risers

In multi-story buildings, risers shall be fixed (or anchored)

at the lowest level and at the top of the riser and shall be

supported by riser clamps or U-bolts at each floor level to

prevent the risers from swaying. If risers are braced by the

penetration floors, the number of riser clamps or U bolts

may be reduced to one at each three stories. For risers,

either flexible or rigid

couplings can be used as

long as proper anchoring

and support is provided.

Anchors should be sufficient to hold the weight of

waterfilled pipe and pressure thrusts.

Pipe guides (sway braces) should be such as to brace

lateral movement of the system.

B-20-3/3 Rev.D 20160314

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- HS PumpDocument1 pageHS Pumpmartin.rubenNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Durco Iso PDFDocument28 pagesDurco Iso PDFmartin.rubenNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Closecoupled Pump PDFDocument4 pagesClosecoupled Pump PDFmartin.rubenNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- HS PumpDocument1 pageHS Pumpmartin.rubenNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Liquid Ring PumpDocument12 pagesLiquid Ring PumpAnonymous CMS3dL1T100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- EN 1092-1-Flange PDFDocument18 pagesEN 1092-1-Flange PDFSimona Adriana100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Fire PumpDocument24 pagesFire Pumpmartin.rubenNo ratings yet

- Lineshaft and Submersible Turbine PumpsDocument16 pagesLineshaft and Submersible Turbine PumpsRheoserveNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Split Case LRDocument8 pagesSplit Case LRmartin.rubenNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Multistage Pump PDFDocument8 pagesMultistage Pump PDFmartin.ruben100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Anillo Rasca AceiteDocument16 pagesAnillo Rasca Aceitemartin.rubenNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Liquid Ring PumpDocument12 pagesLiquid Ring PumpAnonymous CMS3dL1T100% (1)

- Fluido Barrera SeleccionDocument20 pagesFluido Barrera Seleccionmartin.rubenNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Tad 1641 GeDocument2 pagesTad 1641 Gemartin.rubenNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Vacum PumpDocument12 pagesVacum Pumpmartin.rubenNo ratings yet

- Ebsray Pumps: G SeriesDocument4 pagesEbsray Pumps: G Seriesmartin.rubenNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Foundations For CompressorsDocument7 pagesFoundations For Compressorsv100% (1)

- Oring PDFDocument225 pagesOring PDFmartin.rubenNo ratings yet

- Mark PumpDocument71 pagesMark Pumpmartin.rubenNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Pressure DropDocument4 pagesPressure Dropmartin.rubenNo ratings yet

- WDXDocument4 pagesWDXmartin.rubenNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Pump Intake PDFDocument13 pagesPump Intake PDFmartin.rubenNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Durco Iso PDFDocument28 pagesDurco Iso PDFmartin.rubenNo ratings yet

- 22 945GCT-MDocument54 pages22 945GCT-Mmartin.rubenNo ratings yet

- Pump Intake PDFDocument13 pagesPump Intake PDFmartin.rubenNo ratings yet

- Generating Set Installation ManualDocument33 pagesGenerating Set Installation Manualmartin.rubenNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Pump Foundations PDFDocument9 pagesPump Foundations PDFmartin.ruben100% (1)

- SilencerDocument20 pagesSilencermartin.rubenNo ratings yet

- Mechanical Considerations in Pump DesignDocument5 pagesMechanical Considerations in Pump Designmartin.rubenNo ratings yet

- Fertilization to Implantation StagesDocument18 pagesFertilization to Implantation StagesNurulAqilahZulkifliNo ratings yet

- Heat Transfer Surfaces Guide PDFDocument8 pagesHeat Transfer Surfaces Guide PDFJohan ConradieNo ratings yet

- Refrigeration and Air Conditioning Laboratory: Lab Session 3 Absorption Refrigeration Demonstrator 816 ObjectivesDocument10 pagesRefrigeration and Air Conditioning Laboratory: Lab Session 3 Absorption Refrigeration Demonstrator 816 Objectivesjhon milliNo ratings yet

- RS9923 - Grade 12 Compulsory Subjects - Test Specification Chart and Model Questions - FinalDocument32 pagesRS9923 - Grade 12 Compulsory Subjects - Test Specification Chart and Model Questions - FinalPrince JaiswalNo ratings yet

- Dissertation - December 2022Document71 pagesDissertation - December 2022Musasa TinasheNo ratings yet

- TS68Document52 pagesTS68finandariefNo ratings yet

- Rear Derailleur: Important Notice Names of PartsDocument1 pageRear Derailleur: Important Notice Names of PartsRyan MulyanaNo ratings yet

- Recommended Abma & Asme Boiler Water Limits Drum Operating Pressure (Psig) SteamDocument9 pagesRecommended Abma & Asme Boiler Water Limits Drum Operating Pressure (Psig) Steammaoc4vnNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Filter and wiring schematic for 3-axis ADL G-force sensorDocument1 pageFilter and wiring schematic for 3-axis ADL G-force sensorJuan Ramón Pérez LorenzoNo ratings yet

- Vrs PresentationDocument24 pagesVrs PresentationshrutipalkarNo ratings yet

- Traits and BehaviorDocument8 pagesTraits and BehaviorNorwafa Cariga EspinosaNo ratings yet

- Cast Resin Planning Guidelines GEAFOL PDFDocument24 pagesCast Resin Planning Guidelines GEAFOL PDFtenk_man100% (1)

- Honey & Bee Product Recipes: November 2007Document29 pagesHoney & Bee Product Recipes: November 2007Kyra ThomasNo ratings yet

- Exxonmobil High Density Polyethylene Product Guide: Extrusion MoldingDocument6 pagesExxonmobil High Density Polyethylene Product Guide: Extrusion MoldingDaikinllcNo ratings yet

- 0210 Pop Labels BSDocument1 page0210 Pop Labels BSThe London Free PressNo ratings yet

- 2 Way 3 Way Piping DiagramDocument1 page2 Way 3 Way Piping DiagrammarrukhjNo ratings yet

- Neonatal Ventilation, Step by StepDocument99 pagesNeonatal Ventilation, Step by StepMarely Ovando Castillo93% (14)

- Stanley - Your Voice (1957) PDFDocument396 pagesStanley - Your Voice (1957) PDFŠašavi Sam MajmunNo ratings yet

- Section - A: Holiday Homework For Grade XiDocument7 pagesSection - A: Holiday Homework For Grade XiGM Ali KawsarNo ratings yet

- A Study On Satisfaction Level of Employees With Special Reference Textile IndustryDocument12 pagesA Study On Satisfaction Level of Employees With Special Reference Textile Industrysai kiran bade100% (1)

- Master FormDocument62 pagesMaster FormsamsulNo ratings yet

- CHEMDocument20 pagesCHEMValli RamalingamNo ratings yet

- SpaceX ProposalDocument6 pagesSpaceX ProposalTexas WatchdogNo ratings yet

- Ecl7000 enDocument2 pagesEcl7000 ensuchaya tupyangNo ratings yet

- EXERCISE - (JEE Main) Chemical Equilibrium - CombinedDocument24 pagesEXERCISE - (JEE Main) Chemical Equilibrium - CombinedKeerthana Reddy DomaNo ratings yet

- Innogy Invitation For Seminar PCODocument6 pagesInnogy Invitation For Seminar PCOTivorshio MacabodbodNo ratings yet

- Simplex 4100ES 5 Days Customer TrainingDocument1 pageSimplex 4100ES 5 Days Customer TrainingBrahmantyo HadiprasetyoNo ratings yet

- 4-Ingredient Vegan Easy Brownies - Minimalist Baker RecipesDocument2 pages4-Ingredient Vegan Easy Brownies - Minimalist Baker RecipespeteNo ratings yet

- Method of Statement For Pipeline WorkDocument15 pagesMethod of Statement For Pipeline WorkHalil Güney100% (3)

- Lab Report (Experiment 5)Document2 pagesLab Report (Experiment 5)Adrian FlorinNo ratings yet