Professional Documents

Culture Documents

AEC Bell Type Furnaces

Uploaded by

aecsuresh35100%(1)100% found this document useful (1 vote)

177 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

177 views2 pagesAEC Bell Type Furnaces

Uploaded by

aecsuresh35Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

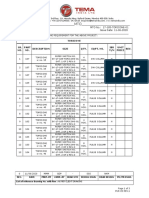

BELL TYPE FURNACE

BELL ANNEALING FURNACE is widely used for annealing of Ferrous

and Non-Ferrous(Copper, Brass, Alum., Tin, Zinc etc.,) coils. The coils can be

of strips, wire or any other shape which can be loaded in the furnace. The

furnace can be electrically heated, oil fired or gas fired. It can also be used for

de-carburising of Stampings.

Bell Type Furnace is be a versatile furnace suitable for black, bright

and spherodized annealing of steel and non-ferrous strips, wires and general

heat treatment processes upto 1200°c.

AEC offers a standalone application wide Bell Furnaces which gives

more efficiency and less Process Cost. The Construction and Operation of

AEC Bell Furnaces differs with any other manufacturers. So that AEC

Furnaces are called ‘Third Generation Furnaces’. It overcomes all troubles

faced with traditional type of Bell Furnaces in industries which are Hooking &

Picking up the Furnace shell and placing it on another stage for process and

also keeping it in right position for leak proof sealing becomes very difficult in

previous days. But AEC made Automatic – almost all operations, even AEC

made to no use of Over Head Crane itself.

Construction & Operation:

The furnace is of cylindrical furnace in top hood design, that is the

furnace kept on the Up and Down Sliding Hydraulic Piston at it two sides in

the inverted position and Hence Total Inverted Furnace is able to move up

unto the working height of Furnace. The Furnace shell will be of robust

construction suitably reinforced with rolled sections. The furnace rests on the

inner cover with ceramic fibre sealing in between. The inner cover rests on

the Indexing Bed with neoprene seal in between for making the inner chamber

gas tight. There are two Indexing Beds at the bottom of furnace can be moved

to and fro by Hydraulic Indexing System. By this ability of Indexing Beds, Heat

Treatment process is carried out by one Indexing Head and other Head can

be loaded for next Batch Process.

Once the Pre- Programmed process by PLC is completed, the Alarm

will be given by Control System followed by (opening) lifting up of furnace.

Then Preloaded material is indexed to the Furnace bottom and taken into the

next process cycle. The Processed Material is freely available outside now

and it can be unloaded & reloaded with new material opting to process. Hence

continuous Process without loosing Heat inside Furnace and with less

process cost, many of Heat Treatment Process are done by this Bell

Furnaces.

Applications:

Bell furnace are used for heat treatment of following materials:

• Coils of gold, Silver, Brass, Tin Ti, Pt, Cu, Zn, Al, GI etc.

• Rolled steel tape

• Middle and thick hot - rolled plates, bars and wire bundles.

• Annealing / Bright Annealing

• Carburizing

• Hardening

• Martempering

• Stress Relieving

• Preheating

• Solution treating

Contact Us :

AEC,

AGUSTHIESWARAN EQUIPMENTS CORPORATION,

AEC CAMPUS, TS-93,

SIDCO INDUSTRIAL ESTATE, TELEFAX : +91 422 267

COIMBATORE – 641 021. PHONE : +91 97 875 96 996

TAMIL NADU, EMAIL : aecsuresh@gmail.com

INDIA. WEB : www.aecgroup.co.in

You might also like

- Unit 1 Metals and Melting Practices: StructureDocument45 pagesUnit 1 Metals and Melting Practices: StructureTapas BanerjeeNo ratings yet

- Tilting Rotary FurnaceDocument8 pagesTilting Rotary FurnaceErnane MagalhãesNo ratings yet

- BDA30603 Tutorial 4Document7 pagesBDA30603 Tutorial 4Firdaus JannahNo ratings yet

- SG Iron Castings GuideDocument4 pagesSG Iron Castings Guidebbaskaran100% (2)

- Scrap Metal Sources:: Using Scrap Aluminum For Sand CastingsDocument2 pagesScrap Metal Sources:: Using Scrap Aluminum For Sand CastingsAnonymous mKdAfWifNo ratings yet

- Presentation ON Steel Melting Shop: Rupendra Naik 3203810037Document19 pagesPresentation ON Steel Melting Shop: Rupendra Naik 3203810037Rahul PandeyNo ratings yet

- Carbon Pick-Up IF Steels PDFDocument3 pagesCarbon Pick-Up IF Steels PDFAnonymous jYdzzw6No ratings yet

- HK 40 SSDocument3 pagesHK 40 SSsonara mansukhNo ratings yet

- Rr411802 Steel MakingDocument4 pagesRr411802 Steel MakingSrinivasa Rao GNo ratings yet

- DF M1Document2 pagesDF M1plj0001No ratings yet

- SLR Brochure 2017 2Document13 pagesSLR Brochure 2017 2Jyotirmoy BarmanNo ratings yet

- Sintering ProcessDocument4 pagesSintering ProcessNicollas Matheus100% (1)

- Development of a new hydraulic mold oscillator model for continuous casting processesDocument5 pagesDevelopment of a new hydraulic mold oscillator model for continuous casting processesM M HossainNo ratings yet

- Feeding Systems Product DatasheetDocument6 pagesFeeding Systems Product DatasheetSachin KumbharNo ratings yet

- Nippon Steel & Sumikin Engineering's Blast FurnaceDocument4 pagesNippon Steel & Sumikin Engineering's Blast Furnacekalai100% (1)

- Salt Bath FurnaceDocument7 pagesSalt Bath FurnacehavejsnjNo ratings yet

- Electric and Automation - Ladle Management A-323eDocument4 pagesElectric and Automation - Ladle Management A-323eSantosh UpadhyayNo ratings yet

- Design and Operating Features of New 27.6 Mva Furnace at Nava Bharat Ventures Limited, PalonchaDocument4 pagesDesign and Operating Features of New 27.6 Mva Furnace at Nava Bharat Ventures Limited, PalonchaKvvPrasadNo ratings yet

- Aluminium Alloys GuideDocument74 pagesAluminium Alloys GuideAladdin AdelNo ratings yet

- Astm hk40 Chemical Composition Astm hk40 Mechanica 2 PDFDocument2 pagesAstm hk40 Chemical Composition Astm hk40 Mechanica 2 PDFprashant mishraNo ratings yet

- Is Codes For Structural EngineeringDocument13 pagesIs Codes For Structural EngineeringChetan ParmarNo ratings yet

- Progress of Special Steel-Making Process in Japan: Yoshio IshiharaDocument15 pagesProgress of Special Steel-Making Process in Japan: Yoshio IshiharaChandra Shekar EmaniNo ratings yet

- Resilient Sealed Gate Valve: Leadership in Product DesignsDocument2 pagesResilient Sealed Gate Valve: Leadership in Product DesignspeetholNo ratings yet

- Gunmetal Melting ProcessDocument3 pagesGunmetal Melting Processdom250% (2)

- TMT ProcesesDocument39 pagesTMT ProcesesVikrant HanwatNo ratings yet

- MillDocument15 pagesMillChandan KumarNo ratings yet

- ESSC Magnetic Steering DeviceDocument12 pagesESSC Magnetic Steering DeviceRakesh AhlawatNo ratings yet

- Er308l PDFDocument1 pageEr308l PDFnargissuhailNo ratings yet

- Zircon Sand: Milling MatterDocument2 pagesZircon Sand: Milling MatterLe Hoang LongNo ratings yet

- TongHeer Brouchure)Document10 pagesTongHeer Brouchure)bkprodhNo ratings yet

- 03HighSpeedCastingNucor DanieliDocument29 pages03HighSpeedCastingNucor DanielialfonsomendietaNo ratings yet

- Thermal Processing of MetalsDocument63 pagesThermal Processing of MetalsNagaVenkateshGNo ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationTennis Mathew100% (1)

- Hot Dip Galvanizing of Sheet Metal-SpangleDocument6 pagesHot Dip Galvanizing of Sheet Metal-SpangleAgustine SetiawanNo ratings yet

- Nano CuODocument9 pagesNano CuOcanilkumarrichithaNo ratings yet

- Strollberg LEO WorkshopDocument54 pagesStrollberg LEO WorkshopBinod Kumar PadhiNo ratings yet

- A Bell-Type Annealing Furnac PDFDocument9 pagesA Bell-Type Annealing Furnac PDFfercho-kun satochiNo ratings yet

- Vacuum Moulding (V-Process)Document13 pagesVacuum Moulding (V-Process)okicirdarNo ratings yet

- Environmental Issues Management: C P C BDocument79 pagesEnvironmental Issues Management: C P C BGanesh N KNo ratings yet

- Compensation To Opening BC BhattacharyaDocument18 pagesCompensation To Opening BC BhattacharyaRADHE GRAPHICSNo ratings yet

- KTR Pin Bush CouplingDocument8 pagesKTR Pin Bush CouplingVarun MalhotraNo ratings yet

- Arun SNH 500Document3 pagesArun SNH 500Parmasamy SubramaniNo ratings yet

- FGD PresentationDocument32 pagesFGD PresentationSaravanan RagupathyNo ratings yet

- Vật liệu học và xử lý: +AnnealingDocument13 pagesVật liệu học và xử lý: +AnnealingĐinh Gia HuyNo ratings yet

- Induction Furnace SparesDocument3 pagesInduction Furnace SparesskluxNo ratings yet

- Report on steel melting shop processesDocument18 pagesReport on steel melting shop processesRahul PandeyNo ratings yet

- AlloyDocument12 pagesAlloyMani MaranNo ratings yet

- 46 1080 Steel DegassingDocument2 pages46 1080 Steel DegassingAjiNo ratings yet

- Project Report On ZIRCONIUM SILICATE POWDERDocument7 pagesProject Report On ZIRCONIUM SILICATE POWDEREIRI Board of Consultants and PublishersNo ratings yet

- Price List MRP 20-Dec-2018-2Document42 pagesPrice List MRP 20-Dec-2018-2Happy JainNo ratings yet

- Energy Saving Strategy For Tunnel & Shuttle Kilnd PDFDocument18 pagesEnergy Saving Strategy For Tunnel & Shuttle Kilnd PDFBRYAN ANDRADENo ratings yet

- Q245R PDFDocument2 pagesQ245R PDFAnonymous 9zykaX6T100% (1)

- Rotary Furnace Air Pollution ControlDocument10 pagesRotary Furnace Air Pollution Controlagbajelola idrisNo ratings yet

- Liquid NitridingDocument7 pagesLiquid NitridingSenthil_kumar_palaniNo ratings yet

- INDUSTRIAL FURNACES Nutec BickleyDocument17 pagesINDUSTRIAL FURNACES Nutec Bickleyfercho-kun satochiNo ratings yet

- 1973 BACKER Shaped Heat 20111009Document50 pages1973 BACKER Shaped Heat 20111009Hank MarvinNo ratings yet

- Electric Melting FurnaceDocument2 pagesElectric Melting FurnaceRodrigo GarcíaNo ratings yet

- Furnaces ReportDocument10 pagesFurnaces ReportMay FadlNo ratings yet

- Induction Heating Tecnology - VerDocument8 pagesInduction Heating Tecnology - Verdenivaldo2009No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- FishNet Catalog19-01Document2 pagesFishNet Catalog19-01aecsuresh35No ratings yet

- Autotron Instruments& Automation CatalogDocument21 pagesAutotron Instruments& Automation Catalogaecsuresh35No ratings yet

- Guidelines Healthcare For Bio Medical Waste Management June 2016Document80 pagesGuidelines Healthcare For Bio Medical Waste Management June 2016samarth25100% (1)

- Autotherm's SteriClave SeriesDocument4 pagesAutotherm's SteriClave Seriesaecsuresh35No ratings yet

- Wood Vacuum Impregnation Plant - CatalogDocument7 pagesWood Vacuum Impregnation Plant - CatalogaecsureshNo ratings yet

- Autotherm Full Catalog2017 A4 PDFDocument16 pagesAutotherm Full Catalog2017 A4 PDFaecsuresh35No ratings yet

- Things To Mind To Avoid Boiler BlastDocument1 pageThings To Mind To Avoid Boiler Blastaecsuresh35No ratings yet

- Autotherm's SteriClave SeriesDocument4 pagesAutotherm's SteriClave Seriesaecsuresh35No ratings yet

- Autotron Instruments& Automation CatalogDocument21 pagesAutotron Instruments& Automation Catalogaecsuresh35No ratings yet

- Wood Vacuum Impregnation Plant - CatalogDocument7 pagesWood Vacuum Impregnation Plant - CatalogaecsureshNo ratings yet

- Autotherm Full Catalog2017 A4 PDFDocument16 pagesAutotherm Full Catalog2017 A4 PDFaecsuresh35No ratings yet

- Autotherm's SteriClave SeriesDocument4 pagesAutotherm's SteriClave Seriesaecsuresh35No ratings yet

- Aerospace Composite AutoclaveDocument7 pagesAerospace Composite Autoclaveaecsuresh35No ratings yet

- AutoBrick - AAC Block Plant CatalogDocument14 pagesAutoBrick - AAC Block Plant Catalogaecsuresh35No ratings yet

- Engineering Design Guidelines - Compressors Rev02 KLM Technology GroupDocument32 pagesEngineering Design Guidelines - Compressors Rev02 KLM Technology GroupAhmed Fgt Kaasehg0% (1)

- Type of Pressure SensorsDocument3 pagesType of Pressure Sensorsaecsuresh35No ratings yet

- AutoBrick - AAC Block Plant CatalogDocument14 pagesAutoBrick - AAC Block Plant Catalogaecsuresh35No ratings yet

- Asme CodesDocument11 pagesAsme Codesaecsuresh35No ratings yet

- 10 Ways To Better Manage Sales Leads - Sales ManagementDocument3 pages10 Ways To Better Manage Sales Leads - Sales Managementaecsuresh35No ratings yet

- Steam Engineering TutorialsDocument208 pagesSteam Engineering Tutorialsaecsuresh35No ratings yet

- Energy Efficient Type of BoilersDocument6 pagesEnergy Efficient Type of Boilersaecsuresh35No ratings yet

- 10 Best Oil & Gas Industry Consultants in Singapore (Updated) - Yellow PagesDocument3 pages10 Best Oil & Gas Industry Consultants in Singapore (Updated) - Yellow Pagesaecsuresh35No ratings yet

- Heat Exchanger Type SelectionDocument2 pagesHeat Exchanger Type Selectionaecsuresh35No ratings yet

- Wolverine Heat Transfer Data Book IIIDocument0 pagesWolverine Heat Transfer Data Book IIImonsterh5No ratings yet

- Boiler TypesDocument14 pagesBoiler Typesaecsuresh35No ratings yet

- 1.2 Basic Heat Exchangers EquationsDocument0 pages1.2 Basic Heat Exchangers EquationsViñu LittleMonkeyNo ratings yet

- Piping Flange Class SelectionDocument2 pagesPiping Flange Class Selectionaecsuresh35No ratings yet

- Energy Conversion TableDocument4 pagesEnergy Conversion Tableaecsuresh35No ratings yet

- Steam Table Properties MetricDocument5 pagesSteam Table Properties Metricaecsuresh35No ratings yet

- What Is The Difference Between LTCS and Carbon SteelDocument2 pagesWhat Is The Difference Between LTCS and Carbon Steelarianna_001No ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingPutry NHy Saya0% (1)

- Nptel: Technology of Surface Coating - Video CourseDocument3 pagesNptel: Technology of Surface Coating - Video CourseRajeev vermaNo ratings yet

- 17 185 Toricone 01 - R0Document5 pages17 185 Toricone 01 - R0Agni DuttaNo ratings yet

- Outokumpu Forta Range DatasheetDocument16 pagesOutokumpu Forta Range DatasheetIgnacio DavilaNo ratings yet

- Notes For Material Selection Philosophy (Methodology)Document2 pagesNotes For Material Selection Philosophy (Methodology)SMAHMADI100% (1)

- IS 319 - 2007 - Reff2022Document11 pagesIS 319 - 2007 - Reff2022k27571No ratings yet

- Mounting System For Photovoltaic and Solar Cells 2012Document136 pagesMounting System For Photovoltaic and Solar Cells 2012salkan_rahmanovic810No ratings yet

- Fatigue Analysis of A Tension Leg Platform: Fatigue Life ImprovementDocument17 pagesFatigue Analysis of A Tension Leg Platform: Fatigue Life ImprovementFoyez AhmadNo ratings yet

- SOP Galvanized Repair ProcessDocument4 pagesSOP Galvanized Repair ProcessMohamed Reda Hussein SengarNo ratings yet

- AMS4016MDocument5 pagesAMS4016M黄当甲No ratings yet

- Quench CrackDocument8 pagesQuench Crackdarwin_huaNo ratings yet

- Casting HandbookDocument18 pagesCasting HandbookGaurav NarulaNo ratings yet

- Guide To Fixings For GRC CladdingDocument55 pagesGuide To Fixings For GRC CladdingThompson Lai100% (4)

- BASIC MANUFACTURING PROCESSES: MOLDING, CASTING, ROLLINGDocument46 pagesBASIC MANUFACTURING PROCESSES: MOLDING, CASTING, ROLLINGmantra2010No ratings yet

- TP54 January2020 Temacoat GPL-S+Temathane 50 2022Document3 pagesTP54 January2020 Temacoat GPL-S+Temathane 50 2022Virintojas Welding ConstructionsNo ratings yet

- 05 Hardware March2012Document98 pages05 Hardware March2012stress11_11No ratings yet

- Influence of SiC Nanoparticles and Saccharin On The StructuDocument5 pagesInfluence of SiC Nanoparticles and Saccharin On The StructumomenziNo ratings yet

- Anodize AluminiumDocument200 pagesAnodize AluminiumYunus LorrNo ratings yet

- A370-14 Standard Test Methods and Definitions For Mechanical Testing of Steel ProductsDocument7 pagesA370-14 Standard Test Methods and Definitions For Mechanical Testing of Steel ProductsChutha100% (2)

- LCP K RIB SpecificationDocument2 pagesLCP K RIB SpecificationGarfieldNo ratings yet

- Esab, Ok 309L (29.12.16)Document1 pageEsab, Ok 309L (29.12.16)RodrigoNo ratings yet

- Foundry and Heat TreatmentDocument26 pagesFoundry and Heat TreatmentAcerz VillagraciaNo ratings yet

- IND SHELL CAST PRIVATE LTD PROCESS FLOW CHART FOR CAT SWL INLET MACHINEDDocument2 pagesIND SHELL CAST PRIVATE LTD PROCESS FLOW CHART FOR CAT SWL INLET MACHINEDMONISHRAJNo ratings yet

- Bof Lab Daily Production Report: TotalDocument2 pagesBof Lab Daily Production Report: TotalBinod Kumar PadhiNo ratings yet

- Titanium Alloys and Its PropertiesDocument26 pagesTitanium Alloys and Its PropertiesAnand Prabhu100% (1)

- Design and Construction Guide: Hi-Vi Vibratory Feeder TraysDocument8 pagesDesign and Construction Guide: Hi-Vi Vibratory Feeder TraysBryan ScofieldNo ratings yet

- Wikipedia - FoundaryDocument7 pagesWikipedia - Foundaryshovit singh100% (1)

- Jawapan Galus Periodic TableDocument2 pagesJawapan Galus Periodic TableismalindaNo ratings yet

- Graphitization of Steels in Elevated-Temperature Service: Introduction and BackgroundDocument2 pagesGraphitization of Steels in Elevated-Temperature Service: Introduction and BackgroundMuhammad Noman ButtNo ratings yet