Professional Documents

Culture Documents

(Food) Procedure For Food Facility Inspection

Uploaded by

Rakesh MishraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Food) Procedure For Food Facility Inspection

Uploaded by

Rakesh MishraCopyright:

Available Formats

WI/INSP/01(Food)/

00

Effective date:

Oct, 2012

Work Instruction-Food facility inspection INDIA

TUV NORD

G GROUP

G

Page 1 of 4

Purpose:

The intention of this work instruction is to provide a generic procedure for Food facility inspection.

Scope:

This work instruction is applicable to all food facility inspection activities undertaken by TUV India Private Limited.

Reference documents:

Codex standard CAC/RAP/2003 and IS 16020:2012.

1) Responsibilities:

1.1) Head - Food Safety

He/She is responsible for:

the selection of the GMP inspectors/Inspectors and those entitled to grant approvals

ensuring that inspectors/inspectors are trained and assessed

Monitoring of Compliance with the requirements of GMP requirement as per CODEX

Alimentarius CAC/RCP/2003.

inspection decision

1.2) Branch offices

At specified branch offices of TUV India certain specified functions like marketing can be carried

out independently. The relevant rules are laid down in the individual TÜV offices.

1.3) Inspectors

The FSMS inspectors are responsible for conducting the inspection process properly in

accordance with the specifications of.

This includes:

Inspection planning with the company to be inspectioned

Examination and evaluation of the applied system in practice (in the inspection)

Documentation of the results of the inspection and submitting them complete and on time to

the head office for decision on Inspection

Conduct of a follow-up inspection as required

2) Procedure for performance of inspection

2.1) Preparation of quotation:

Applicant organization is asked to provide detailed information on concerning process lines,

HACCP studies and number of shifts and other general information, outsourced process,

seasonal products etc.

The application from client is reviewed by qualified FSMS Inspectors/Auditors at the regional

offices & inspection effort is calculated on basis of procedure A22VA02A3e for HACCP

This must take into consideration the minimum time required on site.

The Calculation is documented in (TUVI/Cal/03/2008).The quotation (QF 03) is prepared on the

basis of the calculation and is sent to the client along with other Terms and conditions.

Preparedby: Vaibhav Wagh Reviewedby: Asha Sridhar Approvedby: Asha Sridhar

Date : October, 2012 Date : October, 2012 Date : October, 2012

WI/INSP/01(Food)/

00

Effective date:

Oct, 2012

Work Instruction-Food facility inspection INDIA

TUV NORD

G GROUP

G

Page 2 of 4

2.2) Contract review:

The contract is reviewed by Head Food safety for:

Scope shall not exclude part of the processes, sectors, products or services which have an

influence on the food safety of the end product.

The inspection team approval with the questionnaire and proposal is reviewed by equally trained

personnel at the H.O by Head Food safety.

3) Inspection Planning & Preparation

3.1) Inspectioning time, & team selection

The inspection time is computed using the table from the procedure A22VA02A3e.

The inspections are planned by ensuring the qualified lead inspectionor is leading the team, and

competent inspectionor / expert are part of the inspection team.

The surveillance inspections are normally carried out by the inspector/Auditors employed for the

previous inspection.

Note: If an inspection does not have the relevant product knowledge for the product and service

category, experts can be employed as necessary.

3.2) Appointment of inspectors for the inspection

The inspectors are selected from the pool. As required, a team of inspectors can be employed.

The inspector receives information of the client, and relevant assignment details, documents prior

to the inspection.

3.3) Inspection planning

The client is informed about the composition of the inspection team including experts, if any;

well in advance so that any objection to any member of the inspection team may be brought

to the notice of Certification Manager for appropriate action.

3.4) Pre-inspection

Pre-inspection (optional)

As an option a pre-inspection shall be conducted before the main site Inspection

The inspection agrees with the company to be certified those areas which should be looked at in

greater depth in the pre-inspection.

The results and subsequent procedure will be notified to the company to be inspectioned in a final

discussion.

The company to be inspected will receive a report of the pre-inspection.

The range of the pre-inspection will be decided in consultation with the company to be

inspected/certified and will not exceed the duration of the certification inspection. The cost of the

pre-inspection may not be deducted from the cost of the certification /inspection.

The inspection findings shall be conveyed in the similar manner in the inspection report.

3.5) Performance of inspection

scope

Preparedby: Vaibhav Wagh Reviewedby: Asha Sridhar Approvedby: Asha Sridhar

Date : October, 2012 Date : October, 2012 Date : October, 2012

WI/INSP/01(Food)/

00

Effective date:

Oct, 2012

Work Instruction-Food facility inspection INDIA

TUV NORD

G GROUP

G

Page 3 of 4

Identification of regulatory and statutory requirements

Appropriateness of food safety policy and system set to achieve.

System design to include organisational structure, reviews, internal inspections, CAPA etc.

Identification of food safety hazards and determination of their significance

state of knowledge / status

Identification of PRPs,

Relevant legislation in place as applicable for relevant sector.

the improvement programs conform to the requirements of relevant codex standard of

CAC/RAP/2003 and IS 16020:2012.

documentation and arrangements to communicate internally and with relevant suppliers,

customers and interested parties.

The inspection procedure is discussed in an introductory meeting. Following this individual employees are

interviewed and relevant documents, records, contracts, policies, etc are examined with the focus on food

safety inspection shall take place at the site(s) of the client. It shall also include

Information and evidence about conformity to all requirements the applicable codex CAC –RCP

1996, 2003/ relevant standard and IS 16020:2012.

The client’s legal compliance

Operational control of the client’s process

Internal inspections (layout, infrastructure facility, utility, etc)

Maintenance of equipment

Water supply

Drainage

Pre Requisite program like pest control, personal hygiene Storage etc.

links between any applicable legal requirements, responsibilities, operations, procedures,

performance data and internal inspection findings and conclusion .

Ref document: Inspection checklist QP/FOOD/02

A final meeting is held to conclude the inspection. Positive and negative inspection findings are discussed

verbally and inspection conclusion is verbally reported to the client. The conclusion shall clearly specify

whether the organisation has been recommended or not, including the forward path. In case fresh

explanation differing from those observed earlier is presented to the inspectors during the closing

meeting, such explanation shall be recorded in inspection report.

Any non conformity shall be raise in prescribed format and has to be agreed with the client including time

frame and methodology for closure during the closing meeting.

4) Release note: a release note F/INSP(Food)/03 is given to conclude the inspection, where the

conclusion of Pass/Fail is conveyed.

5) Certificate: A certificate with 1 year validity is given if the client desires certification.

6) Conformance

Preparedby: Vaibhav Wagh Reviewedby: Asha Sridhar Approvedby: Asha Sridhar

Date : October, 2012 Date : October, 2012 Date : October, 2012

WI/INSP/01(Food)/

00

Effective date:

Oct, 2012

Work Instruction-Food facility inspection INDIA

TUV NORD

G GROUP

G

Page 4 of 4

Critical non- A single or continuous non-conformance in meeting the requirement for product safety

conformance in relation to consumer health or an non-conformity in relation to compliance with

statutory requirements.

Major non- A failure or partial failure in relation to the requirements of the IS 16020:2012.with

conformance possible effect on product safety.

Minor non- A failure or partial failure in relation to the requirements of the IS 16020:2012.without

conformance possible effect on product safety.

7) Termination of inspection

If non conformities become evident in any stage of inspection which is so serious that the inspectors

cannot recommend the issuance of a TÜV India certificate, the inspection can be terminated, the

organization inspected is notified of the termination of the certification inspection and is given the

recommendation that it be turned into a pre inspection. If the company decides in favour of a pre–

inspection.

The complete inspection is carried out again once the client has taken necessary actions to eliminate

such non –conformities

8) Handling of Non-Conformance

Initial inspection / surveillance inspection / repeat inspection

Client shall analyze the cause & describe the specific correction and corrective actions taken, or planned

to be taken, to eliminate detected non-conformities, within a defined time. The client shall be informed for

the further course of action based on the nature of non-conformities and the action plan submitted. The

inspection team shall review the corrections and corrective actions by having appropriate evidence

presented or by a follow-up inspection within a maximum period of 3 months.

9) Follow-up inspection

In a follow-up inspection the corrective measures for Non-Conformances are examined and evaluated.

Preparedby: Vaibhav Wagh Reviewedby: Asha Sridhar Approvedby: Asha Sridhar

Date : October, 2012 Date : October, 2012 Date : October, 2012

You might also like

- Haccp Audit ChecklistDocument8 pagesHaccp Audit Checklistkarthikeyan G100% (1)

- Clause 11Document6 pagesClause 11Nor Adila Norhasmie hassanNo ratings yet

- FsmsDocument9 pagesFsmsEngr Muhammad Asim IqbalNo ratings yet

- Bureau of Indian Standards Conformity Assessment Scheme For Milk and Milk ProductsDocument51 pagesBureau of Indian Standards Conformity Assessment Scheme For Milk and Milk Productsatvenu16160No ratings yet

- Qa QC ProcedureDocument5 pagesQa QC ProcedureRodel B. AradaNo ratings yet

- SamplemanualDocument7 pagesSamplemanualisrael afolayan mayomiNo ratings yet

- QA Personnel Should Prepare List of Auditors From Every Department WithDocument4 pagesQA Personnel Should Prepare List of Auditors From Every Department WithjaimurugeshNo ratings yet

- Procedure For Internal AuditingDocument4 pagesProcedure For Internal AuditingQuality Unit 1 Ajay Pandey67% (3)

- Sucofindo SBU HMPMDocument4 pagesSucofindo SBU HMPMlaili qadariahNo ratings yet

- Lecture 5 (Audit) PDFDocument18 pagesLecture 5 (Audit) PDFrana mokbelNo ratings yet

- Sac-Singlas 002 (15 Feb 2017)Document13 pagesSac-Singlas 002 (15 Feb 2017)JeganeswaranNo ratings yet

- Audit Planning Conducting and ReportingDocument49 pagesAudit Planning Conducting and ReportingjackhanNo ratings yet

- Validation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyDocument26 pagesValidation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyAfdal Naim100% (1)

- FSSC 22000 GUIDELINE - FSSC CertificationDocument14 pagesFSSC 22000 GUIDELINE - FSSC CertificationFelix MwandukaNo ratings yet

- GP 4161 FSSC FSMS AnnexDocument4 pagesGP 4161 FSSC FSMS AnnexRagesh PawarNo ratings yet

- Inspection and Testing of ValveDocument5 pagesInspection and Testing of ValveCandy Kendee100% (2)

- Internal Audits - Guidance For Laboratories and Inspection BodiesDocument12 pagesInternal Audits - Guidance For Laboratories and Inspection BodiesRoyal BimhahNo ratings yet

- EA 4 09 Rev03Document19 pagesEA 4 09 Rev03TanChantreaNo ratings yet

- Certification Process Overview Tuv IndiaDocument8 pagesCertification Process Overview Tuv IndiaDarshit VyasNo ratings yet

- An Updated and Modern Concept of ValidatDocument5 pagesAn Updated and Modern Concept of ValidatlobakNo ratings yet

- Iso 17020Document34 pagesIso 17020Samir ChaudharyNo ratings yet

- Chapter 5.0 HALAL INTERNAL AUDIT FACILITATIONDocument88 pagesChapter 5.0 HALAL INTERNAL AUDIT FACILITATIONprincess sabbyNo ratings yet

- Auditing in Food Processing IndustriesDocument28 pagesAuditing in Food Processing Industriesabdul qudoosNo ratings yet

- QMS Internal External AuditDocument5 pagesQMS Internal External AuditNesanNo ratings yet

- CSWIP-PED-2-01, 2nd Edition, February 2009Document5 pagesCSWIP-PED-2-01, 2nd Edition, February 2009AndréMenezesNo ratings yet

- 13 Procedure For QADocument8 pages13 Procedure For QASasi Kss100% (1)

- CERT-SC-F 01-G Self Assessment Checklist GMP GHPDocument23 pagesCERT-SC-F 01-G Self Assessment Checklist GMP GHPAsma DahaboNo ratings yet

- Short Term Training Course (STTC) "Safety and Quality in Innovative Food Production Systems"Document29 pagesShort Term Training Course (STTC) "Safety and Quality in Innovative Food Production Systems"Linda Setya WatiNo ratings yet

- 1.procedure For Incoming Material. Customer Products (6 Files Merged)Document16 pages1.procedure For Incoming Material. Customer Products (6 Files Merged)Valentine GaneshNo ratings yet

- Questions and Answers About The FSSC 22000 CertificationDocument4 pagesQuestions and Answers About The FSSC 22000 CertificationediasianagriNo ratings yet

- Validation Master PlanDocument33 pagesValidation Master PlanisralmayoorNo ratings yet

- Tuev Nord Cert GMP Service DescriptionDocument10 pagesTuev Nord Cert GMP Service DescriptionMohamed HafezNo ratings yet

- ISO 9001 Quality Manual-WOLSTDocument29 pagesISO 9001 Quality Manual-WOLSTSergioNo ratings yet

- AC7109 Rev D - Nadcap Audit Criteria For Coatings (To Be Used On or AFTER 18-Aug-13)Document9 pagesAC7109 Rev D - Nadcap Audit Criteria For Coatings (To Be Used On or AFTER 18-Aug-13)Ravi Kumar100% (1)

- Is 14489 1998Document19 pagesIs 14489 1998Imran Bagwan100% (1)

- Quality ControlDocument15 pagesQuality Controlحسام الدين الحيفيNo ratings yet

- G Sundar Pharmqa Compliance Services IndiaDocument26 pagesG Sundar Pharmqa Compliance Services IndiaTarikNo ratings yet

- Iqoqpq RMGDocument11 pagesIqoqpq RMGjpmaurya7750% (4)

- Iso-20807-2013 GenDocument7 pagesIso-20807-2013 GenHarleyAGNo ratings yet

- CookBook 09 Internal Audits - 09-2018Document2 pagesCookBook 09 Internal Audits - 09-2018Jacek SobczykNo ratings yet

- Preliminary Report: (GPS Coordinates Obtained From SMF)Document6 pagesPreliminary Report: (GPS Coordinates Obtained From SMF)Michael BonettNo ratings yet

- KSA-POP-010-General Guidelines For Sampling For Laboratory TestingDocument7 pagesKSA-POP-010-General Guidelines For Sampling For Laboratory TestingASHJANNo ratings yet

- TOR - BAI ISO CertificationDocument5 pagesTOR - BAI ISO CertificationDM BertisNo ratings yet

- Cases HD 2011 Including Answers PDFDocument11 pagesCases HD 2011 Including Answers PDFAhmedElSayedNo ratings yet

- QCPR08 - Internal Audit Rev 7Document3 pagesQCPR08 - Internal Audit Rev 7FAIRUZ IZYAN BINTI IBRAHIMNo ratings yet

- Ur w35 PDFDocument5 pagesUr w35 PDFBala MuruganNo ratings yet

- 1 Objective: Packaging Validation Packaging Line/packaging RoomDocument13 pages1 Objective: Packaging Validation Packaging Line/packaging RoomAngel CvetanovNo ratings yet

- Environmental AuditDocument12 pagesEnvironmental AuditOmkarNo ratings yet

- Tuev Nord Cert Iscc Plus and Redcert2 Service DescriptionDocument3 pagesTuev Nord Cert Iscc Plus and Redcert2 Service DescriptionMohamed HafezNo ratings yet

- APLAC Internal AuditDocument17 pagesAPLAC Internal Auditsofia tunishaNo ratings yet

- ISO 9001 Process Procedure QPP-092-1 Internal AuditDocument4 pagesISO 9001 Process Procedure QPP-092-1 Internal Auditmahm.tahaNo ratings yet

- ISO14010Document7 pagesISO14010Bilal QasimNo ratings yet

- Quality Programs IP 20-1-3: ScopeDocument2 pagesQuality Programs IP 20-1-3: ScopeDhanushNo ratings yet

- CookBook 09 Internal Audits - 09-2018Document2 pagesCookBook 09 Internal Audits - 09-2018Retno NovvitasariNo ratings yet

- QAQCDocument15 pagesQAQCflawlessy2k100% (1)

- Informe 40Document104 pagesInforme 40HOSMANECHEVERRIANo ratings yet

- Solar Keymark Specific Scheme Rules: SKN - N0106 - Annexe - R0Document6 pagesSolar Keymark Specific Scheme Rules: SKN - N0106 - Annexe - R0Adnan KaraahmetovicNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Wi-Expd-01 Rev.00 Work Instruction - Expediting Report Contents GuidelinesDocument19 pagesWi-Expd-01 Rev.00 Work Instruction - Expediting Report Contents GuidelinesRakesh MishraNo ratings yet

- LE Quality Assurance Plan: Lachhman Electronics New DelhiDocument3 pagesLE Quality Assurance Plan: Lachhman Electronics New DelhiRakesh MishraNo ratings yet

- Astm A262 Igc Test PPTDocument50 pagesAstm A262 Igc Test PPTRakesh Mishra100% (3)

- WI-INSP-11 R0 Work Instruction-Fastener InspDocument3 pagesWI-INSP-11 R0 Work Instruction-Fastener InspRakesh MishraNo ratings yet

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocument5 pagesWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNo ratings yet

- WI-INSP-05 R0 Work Instruction-Skid Mounted Unit InspDocument3 pagesWI-INSP-05 R0 Work Instruction-Skid Mounted Unit InspRakesh MishraNo ratings yet

- WI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionDocument5 pagesWI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionRakesh MishraNo ratings yet

- WI-INSP-01 R2 Work Instruction-Pressure Vessel InspDocument8 pagesWI-INSP-01 R2 Work Instruction-Pressure Vessel InspRakesh Mishra100% (1)

- WI-INSP-04 R0 Work Instruction-Agitator InspDocument2 pagesWI-INSP-04 R0 Work Instruction-Agitator InspRakesh MishraNo ratings yet

- WI-INSP-05 R0 Work Instruction-Skid Mounted Unit InspDocument3 pagesWI-INSP-05 R0 Work Instruction-Skid Mounted Unit InspRakesh MishraNo ratings yet

- Instructions - How To Apply For ASNT NDT Level - II RenewalDocument1 pageInstructions - How To Apply For ASNT NDT Level - II RenewalRakesh MishraNo ratings yet

- Heat Exchanger Type On Flow Basis by Rakesh Mishra 01.04.2020Document23 pagesHeat Exchanger Type On Flow Basis by Rakesh Mishra 01.04.2020Rakesh MishraNo ratings yet

- Heat Exchanger As Per TEMA Design PPT by Rakesh Mishra 31.03.2020Document34 pagesHeat Exchanger As Per TEMA Design PPT by Rakesh Mishra 31.03.2020Rakesh Mishra100% (1)

- WI-INSP-01 R2 Work Instruction-Pressure Vessel InspDocument8 pagesWI-INSP-01 R2 Work Instruction-Pressure Vessel InspRakesh Mishra100% (1)

- Recomended Filling ElectrodesDocument1 pageRecomended Filling ElectrodesRakesh MishraNo ratings yet

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- Ideate Product Keys PDFDocument2 pagesIdeate Product Keys PDFMohammed Zuber InamdarNo ratings yet

- Air France Internet Marketing-Karan Aggarwal EPGC11mm-020Document4 pagesAir France Internet Marketing-Karan Aggarwal EPGC11mm-020karan aggarwal100% (1)

- Auditing and Assurance ServicesDocument12 pagesAuditing and Assurance ServicesAlysha Harvey EANo ratings yet

- Event Plan MemoDocument4 pagesEvent Plan MemoAnn StimsonNo ratings yet

- General Reference RISA-Tekla LinkDocument31 pagesGeneral Reference RISA-Tekla LinkKelebogile K. MonnaatshipiNo ratings yet

- Member - Client Agreement (Between A Trader Member and The Client)Document3 pagesMember - Client Agreement (Between A Trader Member and The Client)Viyena KhalkoNo ratings yet

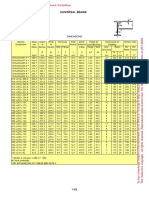

- Section TableDocument44 pagesSection TableMohammed BarniNo ratings yet

- Silver Anvil CloroxDocument11 pagesSilver Anvil Cloroxcassandraspicer100% (2)

- IGCSE Accounting So PDF New Incl Feature SpreadDocument16 pagesIGCSE Accounting So PDF New Incl Feature Spreadtunlinoo.06743367% (3)

- Switch UtilitiesDocument83 pagesSwitch Utilitiesapi-225367524No ratings yet

- Cost Accounting Jobs: The Role of A Cost AccountantDocument2 pagesCost Accounting Jobs: The Role of A Cost AccountantchokieNo ratings yet

- Answerdash CaseDocument20 pagesAnswerdash CaseTathagataNo ratings yet

- Business Blue PrintDocument65 pagesBusiness Blue PrintRahul100% (1)

- Bsa 200Document11 pagesBsa 200Tara Vora RateNo ratings yet

- ERPCh 3Document49 pagesERPCh 3Novia Damayanti ArifahNo ratings yet

- Business Strategy + ModelsDocument109 pagesBusiness Strategy + ModelsMegan Cook100% (6)

- Tax Audit ManualDocument314 pagesTax Audit ManualVigneshVigneshNo ratings yet

- 2 Sight Word SentencesDocument48 pages2 Sight Word SentencesFaiza Mohd Jais100% (1)

- Marketing Final Project Report1Document10 pagesMarketing Final Project Report1walter chahwetaNo ratings yet

- JVA Cost CalculationsDocument7 pagesJVA Cost CalculationsChanitra Witvaranugoon100% (1)

- SGX-Listed ECS Holdings Huawei Expands Distributorship With ECS Computers in SingaporeDocument3 pagesSGX-Listed ECS Holdings Huawei Expands Distributorship With ECS Computers in SingaporeWeR1 Consultants Pte LtdNo ratings yet

- CRM Toyota Synopsis FinalDocument11 pagesCRM Toyota Synopsis FinalKanna LyNo ratings yet

- The State and Impact of Content Consistency Benchmark ReportDocument34 pagesThe State and Impact of Content Consistency Benchmark ReportDemand Metric100% (1)

- How Are McKinsey, BCG, Bain, at Kearney and The Likes Playing The Game in India - Page 2 - Timesofindia-EconomictimesDocument3 pagesHow Are McKinsey, BCG, Bain, at Kearney and The Likes Playing The Game in India - Page 2 - Timesofindia-EconomictimesHarrish MurugesanNo ratings yet

- Forwarded Message - From: Date: Mon, Jun 23, 2014 at 3:17 PM Subject: Rechargeitnow - Successful Recharge ToDocument2 pagesForwarded Message - From: Date: Mon, Jun 23, 2014 at 3:17 PM Subject: Rechargeitnow - Successful Recharge Todd12420007358No ratings yet

- Conflict of Interest PolicyDocument4 pagesConflict of Interest PolicyPradeep KumarNo ratings yet

- Difference Minor and Major Non ConformityDocument1 pageDifference Minor and Major Non Conformitychrisn786No ratings yet

- Implementing and Using Tax Recovery in R12 E-Business Tax (EBTax) PDFDocument14 pagesImplementing and Using Tax Recovery in R12 E-Business Tax (EBTax) PDFMustafa SLlamNo ratings yet

- Renub Research: Singapore Medical Tourist Arrivals, Medical Tourism Market & Forecast To 2015Document13 pagesRenub Research: Singapore Medical Tourist Arrivals, Medical Tourism Market & Forecast To 2015api-114525849No ratings yet

- Marketing Strategy of AirtelDocument59 pagesMarketing Strategy of AirtelgeetapurshotamaniNo ratings yet