Professional Documents

Culture Documents

JG 5 - MMI Inspection Engineer (Facilities & Equipments)

Uploaded by

bintogeorgev862Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JG 5 - MMI Inspection Engineer (Facilities & Equipments)

Uploaded by

bintogeorgev862Copyright:

Available Formats

Document1Facilities & Equipments

Job Description

Date January 1, 2016

Business Finance

Division Finance Operations

Subdivision and Department

Data- Facilities & Equipments/Operational Excellence

(or other)

Job Title Process Data Engineer– Facilities & Equipments

Supervisor Job Title Senior Team Manager / Team Manager - Facilities & Equipments

Skill Pool Finance Operations

Job Purpose

Job Purpose Preparation of RBI data sheets, converting process flow diagram into

material selection diagrams, identifying corrosion loops, identifying

integrity operating windows and operating parameters from corrosion

monitoring framework, preparing corrosion loop descriptions and tags,

identification of dominant failure modes & damage mechanism,

knowledge of RBI procedures. Support Inspection supervision of static

equipment during asset Turnarounds.

Ensure Data validation of all the templates, create automation tools in

order to expedite the process and speedy implementation. Review error

log sheet, finding solutions and implement the same for maintaining high

quality data uploads in the system.

Analyze technical data, drawings, documents and processes for

Downstream businesses across the globe by working with engineering,

maintenance, operations and project teams& partners.

Creating equipment specific task lists for preventive, corrective and

shutdown maintenances of the static equipment like Vessels, Columns,

Heat Exchangers etc,

Support projects, maintenance& improvementsactivities performed at the

operating units, manufacturing sites, chemical plants, supply chain and

distribution locations.

Enable the assigned Downstream operating units, manufacturing sites,

chemical plants, supply chain and distribution locations and it’s on site

employees in producing and compiling high value maintenance

information and data, as measured by improvement trends in data

quality.

May be assigned as primary engineering analyst for smaller sites, plants

and locations.

Dimensions

Financial Dimensions In partnership with the Process Specialists and Process Managers,

is required to support Cost of Poor Quality Data (COPDQ) reduction

for assigned sites, plants and locations.

Business Dimensions Support the Process Specialistsand other engineers performing

primary functions, with scope covering technical data and

documentsof the operating units, manufacturing sites, chemical

plants, supply chain and distribution locations. This role is expected

tohelp ensure:

Data Maintenancefor the site is performed error-free and within

assigned controls (Clean the Stream).

Document1Facilities & Equipments

Assuranceprojects to extract, mine, clean, track, trend, analyze, or

report are agreed with the site within local quality

improvementplans.

Provision, as a process specialist, forTechnical Support that enables

the Site to leverage the benefits of utilizing the Engineering Tools to

the fullest extent.

Participation in Group and Operational Excellence(OE) team efforts

to Standardize processes, tools, benchmarks, standards and best

practices. The role may also be assigned as part of the Site Team or

Project Team working under anSenior Process Data Engineer .

Principal Accountabilities

Summarise in 5-7 statements the

principal results expected from the job Preparation of RBI data sheets, converting process flow

diagram into material selection diagrams, identifying corrosion

loops, identifying integrity operating windows and operating

parameters from corrosion monitoring framework, preparing

corrosion loop descriptions and tags, identification of dominant

failure modes & damage mechanism, knowledge of RBI

procedures. Support asset inspection activities during

Turnarounds and other Major maintenance activtiies.

Primary responsibility in Preperation, cleansing, validation of

inspection data for CIMS deployment in the

designated/assigned OUs, RBI data preparation, migrating

pacer data and explain the inspection engineers on how to use

CIMS tool and explain the analysis and results. Also provide the

post deployment support for CIMS.

End to End implementation experience of RBI data population

into RRM, Pacer and migrate the data into CIMS

Preparation Inspection reports, analyzing the corrosion

management framework, population of RRM templates.

Create the Preventive Maintenance (PM) tasklists and general

task lists based on the maintenance strategy and link it with

maintenance plans and items.Interact and communicate with

the site focals for Preventive Maintenance Libraries and

maintenance strategies, understanding the intricacies about

how the actual maintenance activities for static equipment,

rotating equipment and other machinery have been planned

and performed in various Downstream Operating Units of Shell.

Assist the Senior Process Data Engineer to develop, maintain

and manage the Site Reference Document. Communicate with

the site or locations, to know who are their contacts in Finance

Operations Data. Confirm who are the site or location

stakeholders and their responsibities. Understand their

interoperabilities, ERPs and processes migrated to the

SBO.Regularly report progress of work to site or location direct

contacts as Requestors and Approvers.

Assist the Senior Process Data Engineer in responding to

inquiries related to the data and its functionality or use in a

techncial support function; including training site staff in ERPs

or use of Request Tools, running pilot tests and

Document1Facilities & Equipments

demonstrations, increasing awareness of ERP functionality

(e.g. using Measurement Points more effectively.) This

Technical Support function includes supporting managers and

other staff on migration efforts.

Other back up accountabilities, as follows:

Engagement with the Site stakeholders such as Requestors

and Approvers to communicate plans, obtain feedback, and

solicit improvements.

Assist themanagers to standardize processes, tools, methods,

procedures as directed (Ex: Improving the data quality

standards and best practices).

Network with counterparts and other levels of organization

across the different data centers.

Key Challenges

Capture in 2-3 statements key Business knowledge and operational skills on activities at the

challenges to be faced in this job operating units, manufacturing site, chemical plant, supply

chain and distribution location. Includes specific methods,

software and hardware.

Confidence to work in virtual environment and managing

engagement across different levels of stakeholders. Includes

strong proficiency in using English for both spoken and

writtencommunication, as well as usingOffice Communciator,

Instant Messaging, Video Conferencing, Outlook, etc.

Shift work following operating hours of the Downstream

operation units, manufacturing site, chemical plant, supply

chain and distribution location across the globe.

Sound understanding of business/process workflow and having

mature mindset to deal and behave under tough/challenging

situations.

A self-starter leader and reliable deliverer, with very good verbal

and written skills in English, able to negotiate with senior or

difficult people, and able to resist undue influence that might

otherwise compromise integrity of data quality.

Exposes the individual to all cultural backgrounds and

organisational levels across the globe, across diverse

timezones.

Understanding the functions of the various equipments and

instruments and also thorough knowledge of reading/

interpreting the engineering drawings (P&IDs, PEFS, PFDs).

Although the role involves the remote support to the

Downstream operating units/sites. However, the candidate

should be willing to travel to various operating units/sites across

the globe as per requirements.

Job Knowledge, Skills & Experience

Educational background, qualifications Mandatory Education/Experience:

and experience typically required to

perform the job University Degree in Materials/Mechanical/ Industrial/ Metallurgical

Engineering.

Required at least 8 yrs.Ofexperience in Oil & Gas/

Document1Facilities & Equipments

Petrochemicals/Power Plants/degree in engineering /

technical/maintenance jobs from one or more of the followingfields: -

Experience working in Inspection Management systems

such as w-IMS and CMMS systems like SAP

ASNT LEVEL II is Mandatory

API 510 or API 570 (at least 1) certification is Mandatory

Field experience in inspection processes, corrosion

monitoring and related technical know-how, knowledge of

various NDT processes, inspection management plans,

piping integrity and maintenance of static equipment like

pressure vessels, heat exchangers etc,& knowledge in

Risk Based Inspection(RBI) Methodology – API 570, 580,

510, and 581.

Field experience in conducting corrosion monitoring

inspection, wall thickness measurements, CUI, and

experience in fabric maintenance/different types of

insulation and installation techniques. Preparation of work

packs and procedures related to MMI.

Industrial experience in operations and

maintenance/erection & commissioning of heavy rotating

equipment like engines, compressors, turbines, centrifugal

pumps, etc., with experience in maintenance planning,

preparing the maintenance work instructions, task lists,

maintenance plans, work and manpower estimation for

major maintenance of the rotary and static equipment.

Desirables/Added Value :-

Working knowledge/Experience in maintaining Downstream Asset

hierarchy/ Electronic Data Warehouse (EDW)/ AIM-EDMS/ SPI

Intools / IDMS/ Web Inspection Management System (WIMS) is

preferred.

Professional Engineering certification (API RBI-580/581/570/510

etc.,) is preferred.

Knowledge/Proficiency in SAP PM/MM module is an added value.

Knowledge/Proficiency in MS Excel, MS Access etc., is highly

desirable.

Knowledge/Proficiency in AutoCAD, AutoPlantand other design and

drafting software will be an added advantage.

Effective communication skill and stakeholder management is a

necessary skill for the job.

Knowledge of Lean Six Sigma CI methodology is an added value.

Virtual working experience highly desirable.

Other Skills, Competence and Behavior:Developed engagement

and communication skills. Knowledge or higher level awareness of

the context of use of technical data and documentation within

technical data processes, Shell’s physical processing assets

(hardware) and associated operating processes (Cat Crackers,

drilling ops, production and lube oil facilities).Ability to deal

Document1Facilities & Equipments

effectively with complexity and detail. Ability to prioritize and

ensuredelivery of priorities for the area of responsibility. Flexible and

adaptable to change, with track record of demonstrating initiative,

analytical capabilities and problem solving.

You might also like

- Radio Network Optimization Flow 20090429 A 4.0Document15 pagesRadio Network Optimization Flow 20090429 A 4.0Nguyen TrungNo ratings yet

- MSDS for Naphthenic Spent CausticDocument7 pagesMSDS for Naphthenic Spent Causticjbloggs2007No ratings yet

- MTU-DRL-CON-011-2018: Project: Client: ContractorDocument3 pagesMTU-DRL-CON-011-2018: Project: Client: ContractorSaddem HadfiNo ratings yet

- 2010 TAR Presentation - CalculationsDocument49 pages2010 TAR Presentation - CalculationsMikeGrabillNo ratings yet

- Nuts and Bolts of Project Management: Right Timing + Right Decision = SuccessFrom EverandNuts and Bolts of Project Management: Right Timing + Right Decision = SuccessRating: 5 out of 5 stars5/5 (1)

- Information Technology Audit A Complete Guide - 2020 EditionFrom EverandInformation Technology Audit A Complete Guide - 2020 EditionNo ratings yet

- TPIP ManualDocument53 pagesTPIP ManualMurugananthamParamasivamNo ratings yet

- 10 - PM - Communication ManagementDocument16 pages10 - PM - Communication ManagementEmran HossainNo ratings yet

- Senior Facilities Data Center Engineer in San Francisco CA Resume Fariq AliDocument2 pagesSenior Facilities Data Center Engineer in San Francisco CA Resume Fariq AliFariqAliNo ratings yet

- Initial Stages of EvolutionDocument5 pagesInitial Stages of EvolutionVivek MulchandaniNo ratings yet

- OilGas Brochure ViewDocument12 pagesOilGas Brochure ViewGeorge StaicuNo ratings yet

- P&ID LegendDocument29 pagesP&ID LegendEmmanuel Cervantes VelázquezNo ratings yet

- Exemplar 1:: Cardiff Metropolitan University Application For Ethics ApprovalDocument4 pagesExemplar 1:: Cardiff Metropolitan University Application For Ethics ApprovalSaptashwa MukherjeeNo ratings yet

- Advanced Backlog ManagementDocument17 pagesAdvanced Backlog Managementabid azizNo ratings yet

- Data Center Facility EngineerDocument12 pagesData Center Facility EngineerMAKENGO ELIASNo ratings yet

- Essential 7-point KPI framework for effective project managementDocument3 pagesEssential 7-point KPI framework for effective project managementBhaskar NandyNo ratings yet

- Project Control Manager Responsibilities and DutiesDocument4 pagesProject Control Manager Responsibilities and DutiesAris DaylagNo ratings yet

- Programs Overview MatrixDocument2 pagesPrograms Overview MatrixWeerapat Meng SittisuaNo ratings yet

- Data Encoding and TransmissionDocument67 pagesData Encoding and TransmissionGadaa AssebeNo ratings yet

- DC Ops Monitoring Policy Procedure r.2Document11 pagesDC Ops Monitoring Policy Procedure r.2aswendy wendyNo ratings yet

- Vehicle MaintenanceDocument17 pagesVehicle MaintenanceDipendra Sen50% (2)

- Change Control RegisterDocument12 pagesChange Control RegisterSunil BenedictNo ratings yet

- Manpower List - Aims HCMLDocument5 pagesManpower List - Aims HCMLJuliyanto STNo ratings yet

- QEHS ALERT 15-XXX - Class II Welding Requirements R0 - ScribdDocument2 pagesQEHS ALERT 15-XXX - Class II Welding Requirements R0 - ScribdLummersNo ratings yet

- Project Report ON "Tetra": in Partial Fulfillment For The Award of The Degree ofDocument64 pagesProject Report ON "Tetra": in Partial Fulfillment For The Award of The Degree ofKanika Khurana100% (2)

- FloVENT PDFDocument12 pagesFloVENT PDFVigiiNo ratings yet

- Reading Process DrawingDocument25 pagesReading Process DrawingArif VeyNo ratings yet

- Project Baseline Programme Rev 0Document8 pagesProject Baseline Programme Rev 0Rohit JaiswalNo ratings yet

- DesktopChecklist SystemsAdmins 2014 PDFDocument1 pageDesktopChecklist SystemsAdmins 2014 PDFBruce KraftNo ratings yet

- Project Charter Template 14Document27 pagesProject Charter Template 14Coffee MugNo ratings yet

- Shaft Alignment - Vibration Analysis - OutlineDocument4 pagesShaft Alignment - Vibration Analysis - OutlineElias RizkNo ratings yet

- Punch List: Guy Wire Support Flare Stack System Piping DetailDocument1 pagePunch List: Guy Wire Support Flare Stack System Piping DetailMuhammad SaifNo ratings yet

- 2 Leading Indicators of Turnaround Performance OutcomesDocument12 pages2 Leading Indicators of Turnaround Performance OutcomesPrettyAnnie51No ratings yet

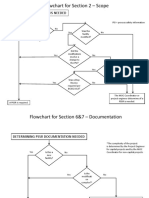

- Determining If A PSSR Is Needed: ModificationsDocument2 pagesDetermining If A PSSR Is Needed: ModificationsDave CNo ratings yet

- 10 Communication MGMT - Updated PDFDocument4 pages10 Communication MGMT - Updated PDFkishore13No ratings yet

- Controller CVDocument4 pagesController CVtdr184No ratings yet

- Maintain Asset IntegrityDocument35 pagesMaintain Asset Integrityhayder ahmedNo ratings yet

- 01 Mes Mep 002 Ms+for+Water+Supply+WorksDocument12 pages01 Mes Mep 002 Ms+for+Water+Supply+WorksJeffersonDeGuiaNo ratings yet

- ISO 18001 - Process Safety IndicatorsDocument22 pagesISO 18001 - Process Safety IndicatorsStephen Groves100% (1)

- Quality Documents and Their ControlDocument3 pagesQuality Documents and Their ControlVelmurugan BalasubramanianNo ratings yet

- Brochure Engineering TrainingDocument20 pagesBrochure Engineering TrainingAnonymous q9eCZHMuSNo ratings yet

- Nigeria Factories Act, 1987Document56 pagesNigeria Factories Act, 1987Ethelbert AkwuruahaNo ratings yet

- 430 Pipeline SecurityDocument39 pages430 Pipeline SecuritydmansoorNo ratings yet

- Preventative Maintenance PlanDocument2 pagesPreventative Maintenance Plan2slow_hrNo ratings yet

- Problem Solving FrameworkDocument2 pagesProblem Solving FrameworkGeoffNo ratings yet

- Main Tools and Techniques for Radio Network OptimizationDocument69 pagesMain Tools and Techniques for Radio Network Optimizationreza56mNo ratings yet

- Slide Email MemoDocument41 pagesSlide Email MemoAndina KusumawardaniNo ratings yet

- Asset and Maintenance Management (PM) : 14 August 2019 1Document7 pagesAsset and Maintenance Management (PM) : 14 August 2019 1amir1077No ratings yet

- Green Cloud ComputingDocument9 pagesGreen Cloud ComputingJohn SinghNo ratings yet

- Failure Mode and Effects AnalysisDocument3 pagesFailure Mode and Effects AnalysisMohd Mazhar Mohd MarzukiNo ratings yet

- Chevron AOA PresentationDocument18 pagesChevron AOA PresentationJahangir Malik0% (1)

- Case Study Reducing Project DurationDocument12 pagesCase Study Reducing Project DurationVarian ArdityaNo ratings yet

- Management of Project Communication Pub3711Document13 pagesManagement of Project Communication Pub3711Tsholofelo Majipos StlhanohNo ratings yet

- 6.2 Close-Out Report Template Mar 10Document4 pages6.2 Close-Out Report Template Mar 10Forbes KambaNo ratings yet

- EPISIOTOMYDocument17 pagesEPISIOTOMYKaye Arriane TenorioNo ratings yet

- Building Primitive Traps & SnaresDocument101 pagesBuilding Primitive Traps & SnaresJoseph Madr90% (10)

- Polygenic InheritanceDocument13 pagesPolygenic InheritanceSandeep Kumar RaghuvanshiNo ratings yet

- Evolution Packet FinalDocument24 pagesEvolution Packet FinalJoaquinNo ratings yet

- Pebc CompilationDocument14 pagesPebc CompilationAarti AroraNo ratings yet

- Getting the Most from Cattle Manure: Proper Application Rates and PracticesDocument4 pagesGetting the Most from Cattle Manure: Proper Application Rates and PracticesRamNocturnalNo ratings yet

- Types of NumbersDocument11 pagesTypes of NumbersbrajanosmaniNo ratings yet

- Galambos 1986Document18 pagesGalambos 1986gcoNo ratings yet

- Flexible Ductwork Report - November 2011v2Document69 pagesFlexible Ductwork Report - November 2011v2bommobNo ratings yet

- Liquid Analysis v3 Powell-Cumming 2010 StanfordgwDocument28 pagesLiquid Analysis v3 Powell-Cumming 2010 StanfordgwErfanNo ratings yet

- 20ME901 Automobile Engineering Unit 3Document74 pages20ME901 Automobile Engineering Unit 36044 sriramNo ratings yet

- Travis Walton Part 1 MUFON Case FileDocument346 pagesTravis Walton Part 1 MUFON Case FileClaudio Silva100% (1)

- Admission Procedure For International StudentsDocument8 pagesAdmission Procedure For International StudentsAndreea Anghel-DissanayakaNo ratings yet

- Oracle Apps Quality ModuleDocument17 pagesOracle Apps Quality ModuleSantOsh100% (2)

- Business Analysis FoundationsDocument39 pagesBusiness Analysis FoundationsPriyankaNo ratings yet

- Cell Selection ReselectionDocument35 pagesCell Selection ReselectionThiaguNo ratings yet

- Omobonike 1Document13 pagesOmobonike 1ODHIAMBO DENNISNo ratings yet

- Project Report On Evaporative CoolerDocument12 pagesProject Report On Evaporative Coolersourabh singh tomerNo ratings yet

- Aerospace Opportunities in SwitzerlandDocument5 pagesAerospace Opportunities in SwitzerlandBojana DekicNo ratings yet

- 10 Tips To Support ChildrenDocument20 pages10 Tips To Support ChildrenRhe jane AbucejoNo ratings yet

- Staining TechniquesDocument31 pagesStaining TechniquesKhadija JaraNo ratings yet

- Appendix 1 Application FormDocument13 pagesAppendix 1 Application FormSharifahrodiah SemaunNo ratings yet

- DCAD OverviewDocument9 pagesDCAD OverviewSue KimNo ratings yet

- Strategic Flexibility: The Evolving Paradigm of Strategic ManagementDocument3 pagesStrategic Flexibility: The Evolving Paradigm of Strategic Managementnanthini kanasanNo ratings yet

- Kennedy 1945 Bibliography of Indonesian Peoples and CulturesDocument12 pagesKennedy 1945 Bibliography of Indonesian Peoples and CulturesJennifer Williams NourseNo ratings yet

- Organic Facial Remedies Versus Inorganic Facial RemediesDocument13 pagesOrganic Facial Remedies Versus Inorganic Facial Remediesapi-271179911No ratings yet

- Icelandic Spells and SigilsDocument16 pagesIcelandic Spells and SigilsSimonida Mona Vulić83% (6)

- Act 1&2 and SAQ No - LawDocument4 pagesAct 1&2 and SAQ No - LawBududut BurnikNo ratings yet

- Starting A Business Candle Making 2009Document2 pagesStarting A Business Candle Making 2009Carlo Fabros Junio100% (4)

- Medicinal PlantDocument13 pagesMedicinal PlantNeelum iqbalNo ratings yet