Professional Documents

Culture Documents

Saic LPT 2006

Uploaded by

jerinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic LPT 2006

Uploaded by

jerinCopyright:

Available Formats

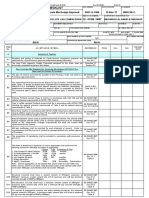

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.

00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Verification of Water Washable Color Contrast

SAIC-LPT-2006 30-Apr-17 MECH-

(Visible Dye) Penetrant Examination

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Safety & Supervision Check (Utilize Attachments with this Checklist) ... CLOSELY MONITOR NEW TECHS ON JOB SITES.

Pre-Work Safety Check* was made first, then the following:

A) Procedure is SA approved & See Note 1

Controlled Field Copy is at site. B) Certified

NDE Personnel performing exams were evaluated and accepted by (Safety Check)

A1 Project Quality Mgr or NDE Supervisor & their names appear on the As

approved roster of NDE Technicians for the Project. Referenced

C) LPT Matls & Test Equipment were checked &

accepted before use Verify SAIC-LPT- Checklists

2001, 2002 & 2003 requirements were met. As Referenced

Technicians for NDT Service Providers are properly supervised and

A2 are following approved NDE Process Control Procedure for site work

NDE

relative to the detailed requirements of SAIC-LPT-2010.

Process

Control

B Surface Preparation, Cleaning & Dry* Times ... 5 Minute Minimum Drying Time Required

The surface to be inspected is in the as-welded condition.

Note: Surface SAEP-1145,

B1

preparation by grinding, machining, or other methods may be used if Para. 4.7.1

surface condition could mask indications of defects.

In the event that a mechanical method of cleaning (e.g., grinding,

machining, wire brushing and sanding) is necessary, it may be SAEP-1145,

B2

necessary to acid etch the surface prior to penetrant examination. Para. 4.7.1

(Refer to ASME SEC V, Article 24, SE-165.)

Welds or areas to be examined & 1 inch on either side of the weld or

area, shall be dry and free of all dirt, grease, lint, scale, weld spatter, SAEP-1145,

B3

welding flux, paint, oil & any other matl that could obscure surface Para. 4.7.2

openings or otherwise interfere with the exam. (25mm rule)

Cleaning of surface is done using the approved cleaning solvent.

Note: Cleaning agents are detergents, organic solvents, descaling SAEP-1145,

B4

solutions and other paint removers. UT and degreasing methods may Para. 4.7.3

also be used to clean surfaces prior to examination.

Following pre-cleaning, evaporation time of cleaners shall be 5 (Five)

minutes minimum. Note:Where indications of retained moisture exist, SAEP-1145,

B5

evaporation time shall be increased until no evidence of moisture in Para. 4.8

test areas can be detected. 5 MINUTE DRY TIME!

The minimum and maximum temperatures of the penetrant and

surface to be tested depends on the type of penetrant used. The

SAEP-1145,

B6 permissible test surface temperature for Penetrant Testing is 50° to

Para. 5.1

125°F (10° to 52°C).Calibrated surface thermometer or digital

pyrometer used

C Application of penetrant:

Saudi Aramco: Company General Use

Penetrant materials shall be:

SAEP-1145,

C1 Para. 4.3 &

Appendix V

Saudi Aramco: Company General Use

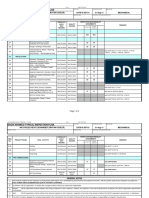

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Verification of Water Washable Color Contrast

SAIC-LPT-2006 30-Apr-17 MECH-

(Visible Dye) Penetrant Examination

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

Intermixing of penetrant materials from different manufacturers is not

SAEP-1145,

C2 permitted. Manufacturer's recommendation for compatible penetrant

Para. 4.4.2

systems shall be followed.

Penetrant is applied either by dipping, brushing or spraying.

Extreme caution is taken to prevent

SAEP-1145,

C3 overspray & fouling of sensitive equipment and components.

Para. 5.2

Good Workmanship!

Dwell time (length of time the penetrant must remain on the part to

allow proper penetration) shall be as recommended by Penetrant

manufacturer. If manufacturers' recommendations are not available,

SAEP-1145, Table 1 shall be used [See Attachment 1].

Note: Select dwell times carefully. Although Table 1 lists various

recommended dwell times, some circumstances may exist where the

required dwell times are significantly greater. For example, one

manufacturer recommends a dwell time of 240 minutes for detection SAEP-1145,

C4 of stress corrosion cracking. Where dwell times exceed 20 minutes, Para. 5.3

additional penetrant must be applied at least every 20 minutes or as

needed to keep the surface wet. If the penetrant is allowed to dry

during the examination the part must be recleaned and the entire

examination repeated. Check the Mfg data sheet!

D Removal of Excess Penetrant & Drying Time

WATER WASHABLE: Excess penetrant can be removed by coarse

SAEP-1145,

water spray with pressure not exceeding 50 psi & water temp not

Para. 5.4.3

exceeding 110°F. A nozzle specifically designed (droplet sprayer) for

D1 &

this application shall be used in lieu of a typical garden nozzle.

App.III

Great care shall be given to avoid over washing

(Procedure B1)

test areas.

When drying surfaces after excess penetrant removal, ensure the

SAEP-1145,

shortest time possible occurs between the penetrant removal and

Para. 5.5.1 &

developer application steps, but not to exceed 30 minutes.

D2

Surfaces may be dried by blotting or

Para. 5.5.3

circulating air. Typical Procedure

(Procedure)

time is 2 - 5 minutes.

E Developing (Wet Developers ONLY with Color Contrast Penetrant Method SAEP-1145, Para. 5.6.1)

Developers shall be lightly applied. It is OK to add additional

SAEP-1145,

E1 developer to aide in interpretation, as needed. If it is necessary to

Section 5.6

remove developer determined to be excessive, tests are restarted.

Color contrast LPT uses:

A) Only a wet developer (Water based or solvent based) SAEP-1145,

E2

B) Thoroughly Section 5.6

agitated prior to application.

Nonaqueous (solvent based) Developer is applied only to a dry

SAEP-1145,

E3 surface (sprayed at spray at 250mm to 300mm (10" to 12") from the

Section 5.6

surface. Drying shall be by normal evaporation.

Water Based Developer may be applied to either a wet or dry

SAEP-1145,

surface & may be applied by dipping, spraying, immersion, etc.

Section 5.6

Note 1: The surface shall be flooded and allowed

E4 & Appendix 1

to dry. Note 2: Drying time may be

accelerated with warm air provided surface temps does not exceed

(Procedure)

maximum allowed. (125 F or 52C)

Saudi Aramco: Company General Use

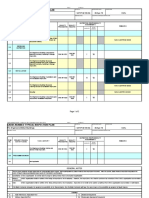

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Verification of Water Washable Color Contrast

SAIC-LPT-2006 30-Apr-17 MECH-

(Visible Dye) Penetrant Examination

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

F Lighting Requirements (Color Contrast Methods)

SAEP-1145,

Visible penetrant indications can be examined in either natural or

Section 5.7

artificial white light. Adequate illumination is required to ensure no

loss of sensitivity of the examination. It is recommended that,

F1 ASME Section

wherever possible, white light intensity levels be maintained at 100

V

ftc (1076 lux) or greater. The minimum permissible light intensity at

the examination site is 32.5 ftc (350 lux).

T676.3

G Interpretation/Evaluation ... Utilize Attachment 1

SAEP-1145,

G1 Final interpretation is within 7 to 30 mins of applying the developer.

Para. 5.8.1

All indications shall be evaluated in accordance with referencing

Code or Specification. These shall be on site & available at all times. SAEP-1145,

G2

Note: For Code Para. 6.1

Acceptance Criteria, See Attachment 1.

Any indication that is believed to be nonrelevant shall be regarded as

relevant until re-examined to verify whether or not an actual

discontinuity is present. Note: Machine marks, surface roughness,

SAEP-1145,

G3 mechanical conditions & other surface conditions can cause or

Para. 6.2

produce false indications. Supervising Inspectors shall allow

supplemental method of NDT by following the appropriate SAIC

for common repairs (grinding to remove indications).

Broad areas of pigmentation that mask indications of discontinuities

are unacceptable and require corrective action by cleaning or other

SAEP-1145,

G4 suitable means of surface preparation as described herein.The Area

Para. 6.3

must be re-tested.This is overlooked by vast majority of NDE Techs

(rushing work).

Interpretation of indications found & determined to be rejectable are

based on the apparent size of the indication as follows:

A) Linear indications - length is greater SAEP-1145,

G5

than three x width. B) Rounded indications - Para. 6.4

circular or elliptical in shape with length equal to or less than

three times the width.

Findings & Results of Liquid Penetrant Tests are documented in the SAEP-1145,

F6

SATR-NDE-2002 (modified SA Form 4719 or SAEP-1145 App VIII). Para. 6.5

H Post Cleaning

Post cleaning shall be performed on all components that have been

PT tested. Suitable cleaning techniques include machine wash, vapor

degreasing, solvent soak and ultrasonic cleaning. Caution shall be

SAEP-1145,

H1 exercised to remove all developer prior to vapor degreasing as vapor

Sec. 7

degreasing can bake the developer on parts.

Post cleaned LPT surfaces with residual developer are

identifed for recleaning. Workmanship = Do it right once!

REMARKS:

Saudi Aramco: Company General Use

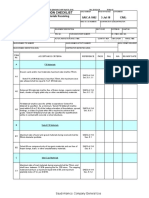

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Verification of Water Washable Color Contrast

SAIC-LPT-2006 30-Apr-17 MECH-

(Visible Dye) Penetrant Examination

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

NOTES: 1. THE APPLICATION IS SAFE (SAFETY FIRST):

A) Applicable safety rules in handling & use of LPT matls & equip are followed (work permit, GFCI extension cords, etc).

B) Adequate ventilation shall be provided when performing LPT exams in confined areas to prevent inhalation of harmful materials.

C) Wet method solutions with petroleum distillates are highly volatile, relatively toxic, skin irritants. Use gloves (avoid skin contact).

D) Flammable inspection materials such as solutions with a petroleum distillate base shall not be used in an area where they may be

exposed to open flame or sparks. NEVER ALLOW MATERIALS TO BE LEFT LYING AROUND (CLOSE STORAGE BOXES).

ATTACHMENTS: Attachment 1 - LPT Procedures, Forms & Code Criteria (SAEP-1145, Appendices)

REFERENCE DOCUMENTS: 1. SAEP-1145, Liquid Penetrant Examination, (8 May 2011)

2. ASME Section V, Article 6, Liquid Penetrant Examination (Ed 2013)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Verification of Water Washable Color Contrast

SAIC-LPT-2006 30-Apr-17 MECH-

(Visible Dye) Penetrant Examination

Attachment 1 - LPT Procedures, Forms & Code Criteria (SAEP-1145 Appendices)

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387No ratings yet

- Saic A 1017Document1 pageSaic A 1017jerinNo ratings yet

- SAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewDocument7 pagesSAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewAbdul HannanNo ratings yet

- Saic H 2060Document11 pagesSaic H 2060jerinNo ratings yet

- Saic LPT 2004Document13 pagesSaic LPT 2004jerinNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002Sajid ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- SAIC L 2031 (Comments)Document2 pagesSAIC L 2031 (Comments)Anton Thomas PunzalanNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Satip e 007 01Document2 pagesSatip e 007 01Anonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- SAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionDocument10 pagesSAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionAbdul HannanNo ratings yet

- GI-0002.600 (Unit Accpetance After T&I Shut DownDocument4 pagesGI-0002.600 (Unit Accpetance After T&I Shut DownSanthoshNo ratings yet

- Schedule B - Attachment IVDocument29 pagesSchedule B - Attachment IVAbdul Ahad LoneNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- QMIS RFI RaisedDocument2 pagesQMIS RFI RaisedSulman YounasNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- Satip F 001 04Document4 pagesSatip F 001 04Anonymous 4e7GNjzGWNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechDocument27 pagesSaudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechNaushad AlamNo ratings yet

- Saic B 1002Document3 pagesSaic B 1002jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJagdishNo ratings yet

- SAIC-W-2043 Rev 0Document3 pagesSAIC-W-2043 Rev 0philipyapNo ratings yet

- SATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementDocument2 pagesSATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Sampling, Testing & Placement Inspection SAIC-Q-1060 15-Nov-17 MAH-SA-CDocument3 pagesSaudi Aramco Inspection Checklist: Concrete Sampling, Testing & Placement Inspection SAIC-Q-1060 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- SATIP-Q-001-04rev4 (Structural Precast-Prestressed Conc.) PDFDocument2 pagesSATIP-Q-001-04rev4 (Structural Precast-Prestressed Conc.) PDFRamziAhmedNo ratings yet

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNo ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechDocument6 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritNo ratings yet

- Saic RT 2007Document9 pagesSaic RT 2007munnaNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSelvakpm06No ratings yet

- SATIP-P-104-05 Rev 8 Final Above Grade Conduits PDFDocument2 pagesSATIP-P-104-05 Rev 8 Final Above Grade Conduits PDFSabheeh AliNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Document1 pageSaudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Zia ur RehmanNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Neelam AhmadNo ratings yet

- Saic A 2001Document21 pagesSaic A 2001Dilshad AhemadNo ratings yet

- Saic A 1008Document4 pagesSaic A 1008jerinNo ratings yet

- Saep 1105 PDFDocument7 pagesSaep 1105 PDFbalajiNo ratings yet

- Saic W 2003Document14 pagesSaic W 2003Mohammed IlliasuddinNo ratings yet

- RFI (Blank)Document1 pageRFI (Blank)SajjadPervaizNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- Saic B 1004Document2 pagesSaic B 1004jerinNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Saudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacDocument1 pageSaudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacmohamadNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzNo ratings yet

- SAIC-D-2005 Rev 2Document4 pagesSAIC-D-2005 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- SATIP-K-001-11 - AC Split Systems DX TypeDocument3 pagesSATIP-K-001-11 - AC Split Systems DX TypeRAMAKRISHNANo ratings yet

- Saic H 2015Document4 pagesSaic H 2015jerinNo ratings yet

- Saic H 2060Document11 pagesSaic H 2060jerinNo ratings yet

- Saic LPT 2004Document13 pagesSaic LPT 2004jerinNo ratings yet

- Saic Gi 2102Document3 pagesSaic Gi 2102jerin100% (3)

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Saic LPT 2001Document22 pagesSaic LPT 2001jerinNo ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saic H 2033Document6 pagesSaic H 2033jerinNo ratings yet

- Saic M 1004Document2 pagesSaic M 1004jerinNo ratings yet

- Saic B 1002Document3 pagesSaic B 1002jerinNo ratings yet

- Saic B 1004Document2 pagesSaic B 1004jerinNo ratings yet

- Saic A 2013Document6 pagesSaic A 2013jerinNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- Saic D 2017Document2 pagesSaic D 2017jerinNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- Satip N 110 01Document11 pagesSatip N 110 01jerinNo ratings yet

- Saic N 2026Document3 pagesSaic N 2026jerinNo ratings yet

- Satr M 1063Document3 pagesSatr M 1063jerin100% (1)

- API 1104 Question 1Document9 pagesAPI 1104 Question 1Anonymous 4e7GNjzGW0% (1)

- Organograma ASME IX Art. I PDFDocument4 pagesOrganograma ASME IX Art. I PDFfabiocorreasilvaNo ratings yet

- Clna15786enc 001Document68 pagesClna15786enc 001Raka AjaNo ratings yet

- MMC New ProfileDocument17 pagesMMC New ProfileFanie NelNo ratings yet

- API 570 Mock Exam Closed BookDocument17 pagesAPI 570 Mock Exam Closed Bookaasatti100% (1)

- BS en 440-95 PDFDocument14 pagesBS en 440-95 PDFAhmet Memiş100% (2)

- Module - IntroductioninMetalWorkDocument19 pagesModule - IntroductioninMetalWorkDaniel Daryl CalingNo ratings yet

- Wear Plate SpecsDocument4 pagesWear Plate SpecsJuan Carlos EspinozaNo ratings yet

- Astm B148 09 PDFDocument5 pagesAstm B148 09 PDFRamana NatesanNo ratings yet

- Api 653Document1 pageApi 653BashMohandesssNo ratings yet

- Lincoln Strip Cladding Presentation April 2011Document26 pagesLincoln Strip Cladding Presentation April 2011Renny DevassyNo ratings yet

- Mumetal Permimphy Supermimphy EngDocument10 pagesMumetal Permimphy Supermimphy Englemco7777No ratings yet

- (32"-Sawl Bare Pipe) : Quality Assurance Plan / Inspection Test Plan (For Sour Service Application)Document18 pages(32"-Sawl Bare Pipe) : Quality Assurance Plan / Inspection Test Plan (For Sour Service Application)Gordon LongforganNo ratings yet

- New Microsoft Word DocumentDocument10 pagesNew Microsoft Word Documentkisan singhNo ratings yet

- Plastic Welding: We Know HowDocument125 pagesPlastic Welding: We Know Howprabal rayNo ratings yet

- Hardox 450 Uk Data SheetDocument2 pagesHardox 450 Uk Data SheetNenad BozicNo ratings yet

- Under Water WeldingDocument19 pagesUnder Water WeldingKIRAN KUMAR DNo ratings yet

- API 1104 SummaryDocument7 pagesAPI 1104 Summarymohamedqc100% (1)

- Astm A216-A216m-08Document4 pagesAstm A216-A216m-08selcukxNo ratings yet

- Peikko Terajoint and Teradowel InstallationDocument47 pagesPeikko Terajoint and Teradowel InstallationGilbert Escolano AnchetaNo ratings yet

- Aws Cwi Part B Practical Question rv0 PDF FreeDocument5 pagesAws Cwi Part B Practical Question rv0 PDF Freealexbv10100% (1)

- Electrode Weight CalculationDocument1 pageElectrode Weight CalculationBiginchNo ratings yet

- Saep 11Document29 pagesSaep 11Anonymous 4IpmN7On100% (1)

- Steel ConstructionDocument46 pagesSteel ConstructionKhadeeja AslamNo ratings yet

- Kuwait 20" Pipeline: OilstoneDocument3 pagesKuwait 20" Pipeline: OilstoneShravan ThangallapalliNo ratings yet

- Hazardous Chemicals & Toxic Substances ListDocument20 pagesHazardous Chemicals & Toxic Substances ListCalvin Jr. WongNo ratings yet

- As 3545-2004 Welding PositionsDocument7 pagesAs 3545-2004 Welding PositionsSAI Global - APACNo ratings yet

- Welding Equipment Catalogue 2008-English 13.08Document52 pagesWelding Equipment Catalogue 2008-English 13.08gogotigNo ratings yet

- Escotilhas - KnappcoDocument12 pagesEscotilhas - KnappcoRenato CorrêaNo ratings yet

- Corrosion Prevent at Ion TechnologyDocument12 pagesCorrosion Prevent at Ion TechnologyandraspappNo ratings yet