Professional Documents

Culture Documents

Crane ds2

Uploaded by

Nurcahyo Djati W0 ratings0% found this document useful (0 votes)

10 views2 pagesok

Original Title

crane ds2

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentok

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesCrane ds2

Uploaded by

Nurcahyo Djati Wok

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

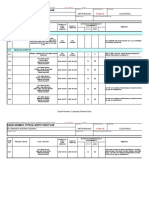

DATA SHEET FOR OVERHEAD CRANE 3 of 3

CLIENT : PT. PERUSAHAAN GAS NEGARA (Persero) Tbk. REV B 0 1

PROJECT : SOUTH SUMATRA - WEST JAVA GAS PIPELINE PROJECT BY TG TG

JOB NO. : C22H2G5018 / 05-1307 CHKD SA SA

ITEM NO. : 20-M-1114 APVD SYF SYF

DOC. NO. : 005-20-M-DS-213 DATE Jan 22, '07 Feb 19, '07 May 28, '07

1 SITE : CP No. 5 COMPRESSOR STATION LOCATION : o OUTDOOR n INDOOR o UNDER SHELTER

2 SERVICE : OHC FOR GENERATOR SET BUILDING MFR. #5.

3 NO. REQUIRED : 1 MODEL NO.: #5. DRIVER : o ELECTRIC MOTOR o AIR MOTOR n MANUAL

4 OPERATING CONDITIONS UTILITY

5 ELECTRICAL

6 USAGE n MAINTENANCE o WAREHOUSE o ______________________ POWER

7 MAIN HOOK AUXILIARY HOOK CONTROL

8 MAX. CAPACITY 5 #4. TONS N/A TONS AIR

9 _____________ psig _____________ F

10 LIFT 7.5 #4. m N/A m CONSUMPTION _______ MMSCFD

11 SPAN 1 13 #4. m DRIVER

12 TRAVERSING DISTANCE : 0 8.5 #4. m AMBIENT TEMPERATURE MIN. : 72 o

F HOISTING TRAVERS'G TRAVELLING

13 TRAVELLING DISTANCE : 28 #4. m MAX. : 93 o

F NO. REQ'D

14 OPERATING HOURS _______________ hr/day RELATIVE HUMIDITY MIN. : 81.5 % MOTOR MFR.

15 CODE & STD. n FEM n AGMA n MIGAS o MAX. : 90.2 % POWER (KW)

16 AREA CLASS n NON HAZARDOUS o HAZARDOUS: ENCLOSURE

17 OPERATING METHOD #1. INSULATION

18 HOISTING n MANUAL o PENDANT o CABIN o TIME RATING

19 TRAVERSING n MANUAL o PENDANT o CABIN o

20 TRAVELLING n MANUAL o PENDANT o CABIN o INSPECTION AND TEST

21 LOCATION OF CONTROL o END OF CRANE o CENTER o ALONG SIDE FABRICATION n REQ'D o WITNESS

22 MATERIAL HANDLED : MAINTENANCE PART OF ENGINE GENERATOR MATERIAL INSP. n REQ'D o WITNESS

23 CONSTRUCTION FEATURES APPEARANCE CHK n REQ'D n WITNESS

24 DIMENSION CHECK n REQ'D n WITNESS

25 DESIGN TEMPERATURE : 104 O

F RATED LOAD TEST n REQ'D n WITNESS #3

26 TYPE n OVERHEAD o SUSPENSION o GANTRY o JIB o WALL o PILLAR STATIC LOAD TEST n REQ'D n WITNESS #3

27 o MONORAIL o SINGLE GIRDER o DOUBLE GIRDER SHIPPING PREP. n REQ'D o WITNESS

28 PERFORMANCE DATA MAIN HOOK AUXILIARY HOOK WPS / PQR n REQ'D o WITNESS

29 LIFTING SPEED NORMAL m/min. m/min.

30 LOW m/min. m/min. OTHER SPECIFICATION

31 TRAVERSING SPEED MAXIMUM : m/min. LOW : m/min.

32 TRAVELLING SPEED MAXIMUM : m/min. LOW : m/min. PAINTING Refer to painting spec

33 WINCH TYPE o CRAB n HOIST o FINISH COLOR (HOLD)

34 HOOK TYPE n SINGLE o RAM HORN o LUBRICANT SPEC. Grease

35 OPERATING SWITCH o ON OFF o UP DOWN o EAST WEST o SOUTH NORTH LUBRICANT Q'TY lb

36 o NORMAL - LOW SPEED CONSTRUCTION MATERIAL #2

37 CHAIN SPECIFICATION #5.

38 GRADE : _______________________________________________________ GIRDER CARBON STEEL

39 DIAMETER x PITCH __________________________________________________________ mm WHEEL CARBON STEEL

40 POWER FEEDING SYSTEM SPROCKET CARBON STEEL

41 HOISTING o FLEXIBLE CABLE o CABLE REEL o COLLECTOR HOOK CARBON STEEL

42 TRAVERSING o FLEXIBLE CABLE o CABLE REEL o COLLECTOR

43 TRAVELLING o FLEXIBLE CABLE o CABLE REEL o COLLECTOR 1 ACCESSORIES AND SPARE PARTS

44 BUILDING / STRUCTURE INFORMATION

0

45 COLUMN CENTER SPAN 10000 mm RAIL SPAN 9200 mm MAINTENANCE STAGE n YES o NO

46 LONGITUDINAL LENGTH 1 20000 1

mm MAIN SWITCH BOX o YES n NO

47 CLEARANCE BETWEEN RAIL AND EAVES #5. mm ALARM EQUIPMENT o YES n NO

0 0

48 RAIL SPECIFICATION #5. OVERLOAD CUT-OFF DEVICE o YES n NO

49 ALLOWABLE WHEEL LOAD #5. kN/wheel RUNWAY RAIL AND CLAMP n YES o NO

50 REMARKS SUPPORT FOR CABLE o YES n NO

51 #1: Manual by chain POWER INDICATOR LAMP o YES n NO

52 #2: ASTM grade material or eq. to be specified by Vendor END STOPPERS W/BOLT & NUT n YES o NO

53 #3: To be done at site. Test load and other necessary equipment and material TRAVEL LIMIT SWITCH o YES n NO

53 for load test shall be provided by Vendor. CABLE/WIRING o YES n NO

53 #4: For reference and will be finalized when maintenance requirement is fixed SPACE HEATER o YES n NO

53 #5: By Vendor SPARE PARTS FOR 1-YEAR n YES o NO

54 #6. This data sheet shall refer to General Specification No. 005-20-M-SP-211

53 NET WEIGHT : #5. kg GROSS WEIGHT #5. kg SHIPPING VOLUME #5. m3

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Case 788-988 Service ManualDocument1,146 pagesCase 788-988 Service ManualVinnichuk OlesNo ratings yet

- DATA SHEET FOR OVERHEAD CRANEDocument2 pagesDATA SHEET FOR OVERHEAD CRANENurcahyo Djati WNo ratings yet

- Diesel Tank SizingDocument7 pagesDiesel Tank SizingNurcahyo Djati W100% (2)

- 2002 Arctic Cat Pantera 600 EFI SNOWMOBILE Service Repair Manual PDFDocument65 pages2002 Arctic Cat Pantera 600 EFI SNOWMOBILE Service Repair Manual PDFusekjdmmNo ratings yet

- Engine DiagnosticsDocument462 pagesEngine Diagnosticswillyhua100% (1)

- NC250 Engine ManualDocument60 pagesNC250 Engine ManualTallerSoldaduraAluminioInoxidable67% (3)

- CNG O&MDocument15 pagesCNG O&MNurcahyo Djati W0% (1)

- Capex OpexDocument5 pagesCapex OpexNurcahyo Djati WNo ratings yet

- Capex OpexDocument5 pagesCapex OpexNurcahyo Djati WNo ratings yet

- ANT AMB4520R0 1433 DatasheetDocument2 pagesANT AMB4520R0 1433 DatasheetDeiz Sovie100% (1)

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- Load List 1Document2 pagesLoad List 1Nurcahyo Djati WNo ratings yet

- Blanket Gas DemandDocument2 pagesBlanket Gas DemandNurcahyo Djati W100% (2)

- Gas - Pneumatic StarterDocument2 pagesGas - Pneumatic StarterNurcahyo Djati WNo ratings yet

- Data CompresorDocument2 pagesData CompresorNurcahyo Djati WNo ratings yet

- Vessel VolumeDocument5 pagesVessel VolumeNurcahyo Djati W100% (1)

- VENDOR LIST CNG As 100510Document4 pagesVENDOR LIST CNG As 100510Nurcahyo Djati WNo ratings yet

- Deliverable List ElectricalDocument8 pagesDeliverable List ElectricalNurcahyo Djati WNo ratings yet

- Choosing A Compressed Air DryerDocument7 pagesChoosing A Compressed Air DryerNurcahyo Djati WNo ratings yet

- One Year Spare Parts and OPEX for CNG StationDocument6 pagesOne Year Spare Parts and OPEX for CNG StationNurcahyo Djati WNo ratings yet

- Ariel Non LubeDocument2 pagesAriel Non LubeNurcahyo Djati WNo ratings yet

- Dryer NewDocument9 pagesDryer NewNurcahyo Djati WNo ratings yet

- Deliverable List ElectricalDocument8 pagesDeliverable List ElectricalNurcahyo Djati WNo ratings yet

- CNG Bussiness DevelopmentDocument4 pagesCNG Bussiness DevelopmentNurcahyo Djati WNo ratings yet

- Deliverable List ElectricalDocument8 pagesDeliverable List ElectricalNurcahyo Djati WNo ratings yet

- Air Compressor DWGDocument1 pageAir Compressor DWGNurcahyo Djati WNo ratings yet

- ACestimateDocument4 pagesACestimateNurcahyo Djati WNo ratings yet

- Crane DsDocument2 pagesCrane DsNurcahyo Djati WNo ratings yet

- Sheet A - 1 Volume CalculationDocument3 pagesSheet A - 1 Volume CalculationNurcahyo Djati WNo ratings yet

- Crane DsDocument2 pagesCrane DsNurcahyo Djati WNo ratings yet

- CommDocument31 pagesCommNurcahyo Djati WNo ratings yet

- Crane DsDocument2 pagesCrane DsNurcahyo Djati WNo ratings yet

- APIseparator SizDocument10 pagesAPIseparator SizNurcahyo Djati WNo ratings yet

- Sheet A - 1 Volume CalculationDocument3 pagesSheet A - 1 Volume CalculationNurcahyo Djati WNo ratings yet

- PBD655 DatasheetDocument2 pagesPBD655 DatasheetSergeyNo ratings yet

- Fluke Pm6304 ManualDocument160 pagesFluke Pm6304 ManualYung SangNo ratings yet

- (2011) Rail-to-Rail IO AmpsDocument71 pages(2011) Rail-to-Rail IO AmpsMostafa M. SamiNo ratings yet

- Datalogic tl46 A Manual - 230104 - 140343Document2 pagesDatalogic tl46 A Manual - 230104 - 140343Emmanuel Baldenegro PadillaNo ratings yet

- C1162 OkiDocument14 pagesC1162 Okipedro torresNo ratings yet

- Philips 42pfl3312 42 LCD HD Ready Widescreen Flat TV 42pfl3312 10 User ManualDocument3 pagesPhilips 42pfl3312 42 LCD HD Ready Widescreen Flat TV 42pfl3312 10 User ManualLa perrritaaaNo ratings yet

- Catalogo Transmision PartsDocument125 pagesCatalogo Transmision PartsJhon PalominoNo ratings yet

- Supply Voltage: Current Rating:: 1 1/4" Pressure SwitchesDocument1 pageSupply Voltage: Current Rating:: 1 1/4" Pressure Switchesalex castroNo ratings yet

- Saudi Aramco Typical Inspection Plan: Fire Detection and Alarm Systems SATIP-B-014-01 ElectricalDocument18 pagesSaudi Aramco Typical Inspection Plan: Fire Detection and Alarm Systems SATIP-B-014-01 ElectricalSajid ShaikhNo ratings yet

- 3DS Hardware InventoryDocument27 pages3DS Hardware InventoryMeeNo ratings yet

- Jiangsu Eastern 37500 DWT 004Document17 pagesJiangsu Eastern 37500 DWT 004Nikos LevogiannisNo ratings yet

- DeWalt Rotary SurfacerDocument2 pagesDeWalt Rotary SurfacerDanNo ratings yet

- 2mbi50n 060Document4 pages2mbi50n 060yunaschtNo ratings yet

- MR J2S A Instruction ManualDocument385 pagesMR J2S A Instruction ManualEdwin Abinguna100% (4)

- Title: Speed Control of Adjustable Frequency DriveDocument64 pagesTitle: Speed Control of Adjustable Frequency DriveMehroz FatimaNo ratings yet

- Anritsu MS2700A Interference Hunter Datasheet 11410-00692JDocument6 pagesAnritsu MS2700A Interference Hunter Datasheet 11410-00692JsergiolrmaiaNo ratings yet

- Compactor With Vibratory Smooth Roller Drum - Compactor With Vibratory Smooth Roller DrumDocument2 pagesCompactor With Vibratory Smooth Roller Drum - Compactor With Vibratory Smooth Roller DrumMdk MakineNo ratings yet

- 262 15ME753 Mechatronics and Microprocessor (10me65) PDFDocument69 pages262 15ME753 Mechatronics and Microprocessor (10me65) PDFthayu manavan100% (1)

- AI858CTX: Model TypeDocument43 pagesAI858CTX: Model TypesaptacNo ratings yet

- Citizen Cl-s621 UputstvoDocument66 pagesCitizen Cl-s621 UputstvoBoris StankovićNo ratings yet

- Katalog BONT-Full Lift Safety ValveDocument8 pagesKatalog BONT-Full Lift Safety ValveAnwar MohammadNo ratings yet

- Tinkering and Fiddling - Hacking On A Digital Lightwave ASA-PKG-OC12 - Part 1 PDFDocument2 pagesTinkering and Fiddling - Hacking On A Digital Lightwave ASA-PKG-OC12 - Part 1 PDFPeter RenhultNo ratings yet

- Mindray BC 2800 Service ManualDocument108 pagesMindray BC 2800 Service Manualcarlos enriquezNo ratings yet

- Lithium Battery Vehicles CargoDocument2 pagesLithium Battery Vehicles CargoMarlo TinaNo ratings yet