Professional Documents

Culture Documents

Q 32004

Uploaded by

Pradeep Kumar BowmarajuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Q 32004

Uploaded by

Pradeep Kumar BowmarajuCopyright:

Available Formats

Material Selection Questions from Fontana 3 hrs.

1. 2% Ni cast iron is superior than unalloyed cast iron.

2. Acid brick is made from fire clay with 10% silica.

3. Acid rain causes soluble patina on copper

4. Adsorption inhibitor affect both anodic and cathodic processes.

5. Al alloys lose strength rapidly above 350 deg F. but good at low temp.

6. Aluminium is good for ammonia and refrigerant application.

7. Antifouling paints contains copper compounds

8. Armco iron is pure iron.

9. Arsenic and antimony are hydrogen evolution poisons.

10. Austenitic st. steel are essentially non magnetic and cannot be hardened by heat

treatment.

11. Carbon steel is used for containing mercury upto 540 deg.C

12. Cathodic inhibitors are not dangerous as anodic inhibitors even if they are present

in small quantities.

13. Cathodic protection is achieved by supplying electrons to metal structures to be

protected.

14. Chlorimet and hastealloy can withstand hydrochloric acid up to boiling

temperature.

15. Chromate and nitrate are examples of anodic inhibitors.

16. Chromate and nitrite act as inhibitors.(anodic)

17. Corrosion prevention is achieved by good design.

18. Ductile iron contains nodular graphite due to magnesium addition.

19. Durimet is good for sulphuric acid service.

20. Duriron is good for glacial acetic acid.

21. Ferric stainless steel is resistant to stress cracking in chloride.

22. Film formers decrease the effective area of corrosion reaction.

23. Fungus and mold attack leather and fabrics

24. Give equation for % inhibition.

25. Give equation to calculate cost by conc.ppm.

26. Give four test procedures for evaluating a new inhibitor.

27. Grey cast iron contains 2 to 4% carbon and 1 to 3% silicon.

28. High silicon cast iron contains about 14.5 Si.

29. Hydrazine and sodium sulphite act as oxidizers.

30. In stainless steel minimum chromium content is 11%

31. In strong reducing condition copper alloys are better than St.Steel up to 300 to

400 Deg.C.

32. In tubing displacement the well is shut for 2 to 15 hours.

33. In wrought st. steel silicon is 1% max.

34. Inhibitors retard corrosion by altering the environment.

35. Lead is resistant to HF up to 60% conc.

36. Magnesium alloy are not attacked by HF and chromic acid.

Metallurgy:

37. Metals have stress corrosion cracking when exposed to molten lead and tin.

38. Monel is good for HF acid.

39. MR 0175 is material selection guide for oilfield services.

40. Ni alloys are embrittled by sulphur bearing gases at elevated temp.

41. Ni hard is white cast iron containing 4% Ni and 2% Chromium.

42. Ni is not resistant to strong oxidizing solutions and ammonia.

43. Ordinary carbon steel is widely used for containing sulphuric acid above 70%

conc.

44. Scavengers are most effective in neutral and weak acid solutions.

45. Scavengers remove oxygen from corrosive reagents.

46. Silicates and benzoate are examples of film formers.

47. Soft rubber is best for abrasion resistance.

48. Squeeze treatment may be effective for 3 to 18 months.

49. Standard batch treatment may last for few days to few months.

50. Strong acids and alkalies attack wood.

51. Sulphate reducing bacteria are prevalent under anaerobic condition.

52. Teflon is poly tetra fluoro ethylene.

53. The oxide coating on Al is stable to acid but attacked by alkali.

54. Thermo setting plastics harden when heated.

55. Ti absorbs gases at high temp. becomes brittle.

56. Ti is not resistant to pure H2SO4 and HCI or dry CI

57. TM O1- 77 is for sour services of metals.

58. Ultra high molecular weight polyethylene is very resistant to abrasion and erosion

59. Vapour phase inhibitors are good only in closed.atmospheres.

60. Vitreous silica is corrosion resistant at high temperature.

61. White cast iron is produced by quick chilling.

62. Write equation for mpy using W,D,A,T.

63. Write equation for penetration rate using k,a,I,n,D.

64. Write equation for stress using Euler’s equation.

65. Write Tafel’s equation using E, i. I corr.

You might also like

- RT11 PDFDocument20 pagesRT11 PDFPradeep Kumar BowmarajuNo ratings yet

- Q2Document2 pagesQ2Pradeep Kumar Bowmaraju100% (1)

- Q 2ansDocument2 pagesQ 2ansPradeep Kumar BowmarajuNo ratings yet

- Qa Ans1Document6 pagesQa Ans1Pradeep Kumar Bowmaraju100% (1)

- RT13 PDFDocument34 pagesRT13 PDFPradeep Kumar BowmarajuNo ratings yet

- RT07 PDFDocument45 pagesRT07 PDFPradeep Kumar BowmarajuNo ratings yet

- EXTRUSIONDocument14 pagesEXTRUSIONPradeep Kumar BowmarajuNo ratings yet

- ROLLINGDocument9 pagesROLLINGPradeep Kumar BowmarajuNo ratings yet

- RT15Document33 pagesRT15Pradeep Kumar BowmarajuNo ratings yet

- RT-L3 Q&aDocument8 pagesRT-L3 Q&aPradeep Kumar Bowmaraju100% (1)

- ASNT - Materials & Process For NDT Technology ASNT Specific Questions - LavenderDocument39 pagesASNT - Materials & Process For NDT Technology ASNT Specific Questions - LavenderMiguel Angel Aguilar Mena100% (1)

- Painting HandoutDocument49 pagesPainting HandoutPradeep Kumar BowmarajuNo ratings yet

- Infra Red ThermographyDocument4 pagesInfra Red ThermographyPradeep Kumar Bowmaraju100% (2)

- Metal Forming Process and DefectsDocument7 pagesMetal Forming Process and DefectsPradeep Kumar BowmarajuNo ratings yet

- 1 Basic Metallurgy 1Document8 pages1 Basic Metallurgy 1Salauddin ShaikhNo ratings yet

- Basic91 EtDocument5 pagesBasic91 EtPradeep Kumar BowmarajuNo ratings yet

- Basic 2Document5 pagesBasic 2JithuJohnNo ratings yet

- HOT FORGING OF METALS: ORIGIN AND REMEDIES FOR MISMATCH DEFECTDocument7 pagesHOT FORGING OF METALS: ORIGIN AND REMEDIES FOR MISMATCH DEFECTPradeep Kumar BowmarajuNo ratings yet

- Basic9 UtDocument5 pagesBasic9 UtPradeep Kumar BowmarajuNo ratings yet

- Basic 5Document8 pagesBasic 5Pradeep Kumar BowmarajuNo ratings yet

- Basic92 PTDocument4 pagesBasic92 PTPradeep Kumar BowmarajuNo ratings yet

- Basic1 PDFDocument3 pagesBasic1 PDFSooraj RajanNo ratings yet

- Basic 4Document8 pagesBasic 4Pradeep Kumar BowmarajuNo ratings yet

- Basic 3Document8 pagesBasic 3JithuJohnNo ratings yet

- PTIntroDocument3 pagesPTIntroPradeep Kumar BowmarajuNo ratings yet

- PT17Document30 pagesPT17Pradeep Kumar BowmarajuNo ratings yet

- Basic8 RTDocument4 pagesBasic8 RTPradeep Kumar BowmarajuNo ratings yet

- PTIndexDocument12 pagesPTIndexPradeep Kumar BowmarajuNo ratings yet

- PT16Document19 pagesPT16Pradeep Kumar BowmarajuNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Gypsum Board FRDocument2 pagesGypsum Board FRKhaled Abdel SalamNo ratings yet

- Cleanroom air conditioning unitsDocument8 pagesCleanroom air conditioning unitsmacanipharoldf6220No ratings yet

- Dynaflow Vs Stay Silv 15Document2 pagesDynaflow Vs Stay Silv 15Zeljko RisticNo ratings yet

- Air Liquide BS 50-3-2,5Document1 pageAir Liquide BS 50-3-2,5kuraimundNo ratings yet

- LE10-Aulas 14 e 15-Escoamento Viscoso em Condutos-PME3238 PDFDocument3 pagesLE10-Aulas 14 e 15-Escoamento Viscoso em Condutos-PME3238 PDFMalu NevesNo ratings yet

- Piping Class DGS New PDFDocument54 pagesPiping Class DGS New PDFعلي احمدNo ratings yet

- Self-lubricating bearings guideDocument39 pagesSelf-lubricating bearings guideDevang RathodNo ratings yet

- Rig Grip Safety MatsDocument4 pagesRig Grip Safety Matsromerov240% (1)

- GALVANIZED STEEL SHEETS (Kobelco)Document28 pagesGALVANIZED STEEL SHEETS (Kobelco)Towkir AhmmadNo ratings yet

- Application of Bamboo For Flexural and Shear Reinforcement in Con PDFDocument271 pagesApplication of Bamboo For Flexural and Shear Reinforcement in Con PDFKarthik MHNo ratings yet

- T2785 1U Glamo HousingDocument12 pagesT2785 1U Glamo HousingLiesa StoneNo ratings yet

- Resume LaukeshDocument5 pagesResume LaukeshlaukkeasNo ratings yet

- Properties of Linear Poly (Lactic Acid) /polyethylene Glycol BlendsDocument9 pagesProperties of Linear Poly (Lactic Acid) /polyethylene Glycol BlendsZeynep BurakNo ratings yet

- 35.02 21Document10 pages35.02 21tesfayNo ratings yet

- Lab Report 2 - Cooling TowerDocument14 pagesLab Report 2 - Cooling TowerSeng Kong0% (2)

- Foam ConcreteDocument16 pagesFoam ConcreteManvitha GNo ratings yet

- 2024 - MTRL 494 - Assignment 4Document3 pages2024 - MTRL 494 - Assignment 4vjscricNo ratings yet

- Early Thermal Cracking ConcreteDocument13 pagesEarly Thermal Cracking ConcreteOttawa Canada100% (2)

- Advanced Ceramics - The New Frontier in Modern-Day Technology: Part IDocument9 pagesAdvanced Ceramics - The New Frontier in Modern-Day Technology: Part IAbdi EphremNo ratings yet

- Evonik-Ancamine 2726 EUDocument7 pagesEvonik-Ancamine 2726 EUkishanptlNo ratings yet

- 2502 Filtri HFA Dic2014Document8 pages2502 Filtri HFA Dic2014John F Diaz HNo ratings yet

- Experimental and CFD Analysis of Aluminium Heat Sinks For Avionics ApplicationsDocument7 pagesExperimental and CFD Analysis of Aluminium Heat Sinks For Avionics ApplicationsIJIRSTNo ratings yet

- Spare Parts List STORM 15 20180000 XDocument4 pagesSpare Parts List STORM 15 20180000 XFati ZoraNo ratings yet

- Punching Strength of Reinforced Concrete Flat Slabs Without Shear ReinforcementDocument16 pagesPunching Strength of Reinforced Concrete Flat Slabs Without Shear ReinforcementWael KassemNo ratings yet

- Community services department standards for residential piles and grade beamsDocument1 pageCommunity services department standards for residential piles and grade beamsaiplNo ratings yet

- Courtyard As A Building Component ChettiarDocument7 pagesCourtyard As A Building Component ChettiarAkshaya MayakrishnanNo ratings yet

- Surge CalculationsDocument21 pagesSurge CalculationsHieuNo ratings yet

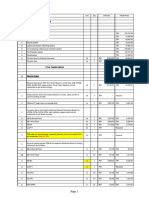

- Peter Lindemann, Aaron Murakami - Save On Home Energy-A&P Electronic Media (2009)Document94 pagesPeter Lindemann, Aaron Murakami - Save On Home Energy-A&P Electronic Media (2009)Ganugio MirianiNo ratings yet

- 2022-23 AP SyllabusDocument2 pages2022-23 AP SyllabusThrishaNo ratings yet

- Detail Cost Estimate For Renovation and Reconstruction of Beri Sri Sri Ramakrishna AshramaDocument11 pagesDetail Cost Estimate For Renovation and Reconstruction of Beri Sri Sri Ramakrishna Ashramariya paul100% (4)