Professional Documents

Culture Documents

Electronic Fuel Injection PDF

Electronic Fuel Injection PDF

Uploaded by

Alfianto HerakarsonoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electronic Fuel Injection PDF

Electronic Fuel Injection PDF

Uploaded by

Alfianto HerakarsonoCopyright:

Available Formats

ELECTRONIC FUEL INJECTION

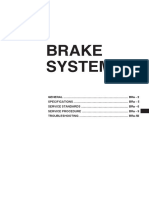

EFI SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . FI–1

FUEL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FI–5

FUEL PRESSURE REGULATOR . . . . . . . . . . . FI–15

INJECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FI–18

FUEL TANK AND LINE . . . . . . . . . . . . . . . . . . . FI–26

AIR FLOW METER . . . . . . . . . . . . . . . . . . . . . . . FI–28

THROTTLE BODY . . . . . . . . . . . . . . . . . . . . . . . FI–32

CAMSHAFT TIMING OIL

CONTROL VALVE . . . . . . . . . . . . . . . . . . . FI–39

IDLE SPEED CONTROL (ISC) VALVE . . . . . . FI–44

ACOUSTIC CONTROL INDUCTION

SYSTEM (ACIS) . . . . . . . . . . . . . . . . . . . . . FI–50

EFI MAIN RELAY . . . . . . . . . . . . . . . . . . . . . . . . FI–55

A/F SENSOR HEATER RELAY . . . . . . . . . . . . FI–56

CIRCUIT OPENING RELAY . . . . . . . . . . . . . . . FI–57

VSV FOR EVAPORATIVE

EMISSION (EVAP) . . . . . . . . . . . . . . . . . . . FI–58

VSV FOR ACOUSTIC CONTROL

INDUCTION SYSTEM (ACIS) . . . . . . . . . FI–60

WATER TEMPERATURE SENSOR . . . . . . . . FI–63

KNOCK SENSOR . . . . . . . . . . . . . . . . . . . . . . . . FI–64

AIR–FUEL RATIO (A/F) SENSOR . . . . . . . . . . FI–67

OXYGEN SENSOR (Bank 1 Sensor 2) . . . . . . FI–68

ENGINE ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . FI–70

FUEL CUT RPM . . . . . . . . . . . . . . . . . . . . . . . . . FI–72

FI–1

ELECTRONIC FUEL INJECTION – EFI SYSTEM

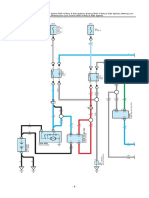

EFI SYSTEM FI0UO–01

PRECAUTION

1. BEFORE WORKINR ON FUEL SYSTEM, DISCON-

NECT NEGATIVE (–) TERMINAL CABLE FROM BAT-

TERY

HINT:

Any diagnostic trouble code retained by the engine ECU will be

erased when the negative (–) terminal cable is removed from

the battery. Therefore, if necessary, read the diagnosis before

removing the negative (–) terminal cable from the battery.

2. DO NOT SMOKE OR WORK NEAR AN OPEN FLAME

WHEN WORKING ON FUEL SYSTEM

3. KEEP GASOLINE AWAY FROM RUBBER OR LEATH-

ER PARTS

4. MAINTENANCE PRECAUTIONS

(a) In event of engine misfire, these precautions should be

taken.

(1) Check proper connection to battery terminals, etc.

(2) After repair work, check that the ignition coil termi-

nals and all other ignition system lines are recon-

nected securely.

(3) When cleaning the engine compartment, be espe-

cially careful to protect the electrical system from

water.

(b) Precautions when handling oxygen sensor.

(1) Do not allow oxygen sensor to drop or hit against an

object.

(2) Do not allow the sensor to come into contact with

water.

5. IF VEHICLE IS EQUIPPED WITH MOBILE RADIO

SYSTEM (HAM, CB, ETC.)

If the vehicle is equipped with a mobile communication system,

refer to the precaution in the IN section.

6. AIR INDUCTION SYSTEM

(a) Separation of the engine oil dipstick, oil filler cap, PCV

hose, etc. may cause the engine to run out of tune.

(b) Disconnection, looseness or cracks in the parts of the air

induction system between the throttle body and cylinder

head will allow air suction and cause the engine to run out

of tune.

7. ELECTRONIC CONTROL SYSTEM

(a) Before removing EFI wiring connectors, terminals, etc.,

first disconnect the power by either turning the ignition

switch to LOCK or disconnecting the negative (–) terminal

cable from the battery.

HINT:

Always check the diagnostic trouble code before disconnecting

the negative (–) terminal cable from the battery.

LEXUS RX300 (RM785E)

FI–2

ELECTRONIC FUEL INJECTION – EFI SYSTEM

(b) When installing the battery, be especially careful not to in-

correctly connect the positive (+) and negative (–) cables.

(c) Do not permit parts to receive a severe impact during re-

moval or installation. Handle all EFI parts carefully, espe-

cially the engine ECU.

(d) Be careful during troubleshooting as there are numerous

transistor circuit, and even slight terminal contact can

cause further troubles.

(e) Do not open the engine ECU cover.

(f) When inspecting during rainy weather, take care to pre-

vent entry of water. Also, when washing the engine

compartment, prevent water from getting on the EFI parts

and wiring connectors.

(g) Parts should be replaced as an assembly.

(h) Care should be taken when pulling out and inserting wir-

ing connectors.

(1) Release the lock and pull out the connector, pulling

on the connectors.

(2) Fully insert the connector and check that it is locked.

(i) Use SST for inspection or test of the injector or its wiring

connector.

SST 09842–30070

SST

FI2553

8. FUEL SYSTEM

(a) When disconnecting the high fuel pressure line, a large

amount of gasoline will spill out, so observe these proce-

dures.

(1) Disconnect the fuel pump connector.

Vinyl Bag (2) Start the engine. After the engine has stopped on

its own, turn the ignition switch to LOCK.

(3) Disconnect the fuel tube (See page FI–11).

B00679 (4) Drain the fuel remained inside the fuel tube.

(5) Prevent the disconnected fuel tube from damaging

and mixing foreign objects by covering them with a

vinyl bag.

LEXUS RX300 (RM785E)

FI–3

ELECTRONIC FUEL INJECTION – EFI SYSTEM

(6) Put a container under the connection.

B00347

New O–ring CORRECT (b) Observe these precautions when removing and installing

the injectors.

(1) Never reuse the O–ring.

(2) When placing a new O–ring on the injector, take

Delivery Pipe care not to damage it in any way.

Injector

(3) Coat a new O–ring with spindle oil or gasoline be-

WRONG fore installing–never use engine, gear or brake oil.

B00061

(c) Install the injector to the delivery pipe and intake manifold,

Delivery Pipe O–Ring as shown in the illustration.

Before installing the injector, must apply spindle oil or gas-

Grommet

oline on the place where a delivery pipe or an intake man-

Grommet ifold touches an O–ring of the injector.

Spacer

O–Ring

B05295

(d) Observe these precautions when disconnecting the fuel

tube connector.

Fuel Hose (1) Remove the fuel pipe clamp.

Clamp (2) Check if there is any dirt like mud on the pipe and

around the connector before disconnecting them

and clean the dirt away.

B12940

(3) Disconnect the connector from the hose while

A pinching part A with fingers as shown in the illustra-

tion.

B12941

LEXUS RX300 (RM785E)

FI–4

ELECTRONIC FUEL INJECTION – EFI SYSTEM

HINT:

When the connector and the pipe are stuck, pinch the fuel pipe

between the hands, push and pull the connector to free to dis-

connect and pull it out. Do not use any tool at this time.

(4) Inspect if there is any dirt or the likes on the seal sur-

face of the disconnected pipe and clean it away.

B12944

(5) Prevent the disconnected pipe and connector from

Vinyl Bag

damaging and mixing foreign objects by covering

them with a vinyl bag.

B09222

(e) Check that there are no fuel leaks after doing mainte-

Hand–Held Tester nance anywhere on the fuel system.

(1) Connect the hand–held tester to the DLC3.

(2) Turn the ignition switch ON and push hand–held

tester main switch ON.

NOTICE:

Do not start the engine.

(3) Select the active test mode on the hand–held tester.

DLC3 D09456 (4) Please refer to the hand–held tester operator’s

manual for further details.

(5) If you have no hand–held tester, connect the posi-

tive (+) and negative (–) leads from the battery to the

fuel pump connector.(See page FI–5)

(6) Check that there are no leaks from any part of the

fuel system.

(7) Turn the ignition switch to LOCK.

(8) Disconnect the hand–held tester from the

DLC3.

LEXUS RX300 (RM785E)

FI–5

ELECTRONIC FUEL INJECTION – FUEL PUMP

Hand–Held Tester

FUEL PUMP FI0UP–01

ON–VEHICLE INSPECTION

1. CHECK FUEL PUMP OPERATION

(a) Connect the hand–held tester to the DLC3.

(b) Turn the ignition switch ON and hand–held tester main

switch ON.

NOTICE:

DLC3 D09456

Do not start the engine.

(c) Select the active test mode on the hand–held tester.

(d) Please refer to the hand–held tester operator’s manual

for further details.

(e) If you have no hand–held tester, connect the positive (+)

and negative (–) leads from the battery to the fuel pump

connector. (See step 7)

(f) Check that there is pressure in the fuel inlet pipe from the

fuel filter.

HINT:

If there is fuel pressure, you will hear the sound of fuel flowing.

If there is no pressure, check the fusible link, fuses (AM2 30A,

IGN 5A), EFI main relay, fuel pump and wiring connections.

(g) Turn the ignition switch to LOCK.

(h) Disconnect the hand–held tester from the DLC3.

B12942 2. CHECK FUEL PRESSURE

(a) Check the battery positive voltage is above 12 V.

(b) Disconnect the negative (–) terminal cable from the bat-

tery.

(c) Purchase the new No.1 fuel pipe and take out the fuel

Fuel Tube Connector tube connector from its pipe.

Part No. 23801–20040

B09225

LEXUS RX300 (RM785E)

FI–6

ELECTRONIC FUEL INJECTION – FUEL PUMP

(d) Remove the fuel hose clamp.

Fuel

Hose

Clamp

B12940

(e) Disconnect the No.1 fuel pipe (fuel tube connector) from

the fuel filter outlet.

CAUTION:

S Perform disconnecting operations of the fuel tube

connector (quick type) after observing the precau-

tions.

S As there is retained pressure in the fuel pipe line, pre-

vent it from splashing inside the engine compart-

B12941 ment.

(f) Install SST (pressure gauge) as shown in the illustration

by using SST and fuel tube connector.

SST SST SST 09268–41047, 09268–41250, 09268–45012

(Hose) (Hose)

(g) Wipe off any splattered gasoline.

SST (h) Reconnect the negative (–) terminal cable to the battery.

No.1 Fuel (i) Connect the hand–held tester to the DLC3.

Pipe

(See step 1.)

(j) Measure the fuel pressure.

Fuel pressure:

301 – 347 kPa (3.1 – 3.5 kgf/cm2, 44 – 50 psi)

If pressure is high, replace the fuel pressure regulator.

If pressure is low, check the fuel hoses and connections, fuel

pump, fuel filter and fuel pressure regulator.

SST (k) Disconnect the hand–held tester from the DLC3.

(Hose)

(l) Start the engine.

(m) Measure the fuel pressure at idle.

Fuel pressure:

Fuel Tube 301 – 347 kPa (3.1 – 3.5 kgf/cm2, 44 – 50 psi)

Connector

B12975 (n) Stop the engine.

(o) Check that the fuel pressure remains as specified for 5

minutes after the engine has stopped.

Fuel pressure: 147 kPa (1.5 kgf/cm2, 21 psi) or more

If pressure is not as specified, check the fuel pump, pressure

regulator and/or injectors.

(p) After checking fuel pressure, disconnect the negative (–)

terminal cable from the battery and carefully remove the

SST and fuel tube connector to prevent gasoline from

splashing.

SST 09268–41047, 09268–41250, 09268–45012

LEXUS RX300 (RM785E)

FI–7

ELECTRONIC FUEL INJECTION – FUEL PUMP

(q) Reconnect the No.1 fuel pipe (fuel tube connector).

CAUTION:

Perform connecting operations of the fuel tube connector

(quick type) after observing the precautions.

B12944

(r) Install the fuel hose clamp to the fuel filter.

(s) Reconnect the negative (–) terminal cable to the battery.

Fuel (t) Check for fuel leakage.

Hose

Clamp

B12940

Ohmmeter 3. INSPECT FUEL PUMP

(a) Remove the LH rear seat.

(b) Remove the rear seat side garnish.

(c) Tarn over the floor carpet.

(d) Remove the floor service hole cover.

(e) Disconnect the fuel pump & sender gauge connector.

4

(f) Using an ohmmeter, measure the resistance between ter-

5 minals 4 and 5.

B08888 Resistance: 0.2 – 3.0 Ω at 20°C (68°F)

If the resistance is not as specified, replace the fuel pump.

(g) Inspect the fuel pump operation.

Connect the positive (+) lead from the battery to terminal

4 of the connector, and the negative (–) lead to terminal

5. Check that the fuel pump operates.

Battery

NOTICE:

S These tests must be done quickly (within 10 seconds)

to prevent the coil burning out.

5 S Keep the fuel pump as far away from the battery as

4 B08887 possible.

S Always do the switching at the battery side.

If operation is not as specified, replace the fuel pump or lead

wire.

(h) Reconnect the fuel pump & sender gauge connector.

(i) Reinstall the floor service hole cover.

(j) Install the floor carpet.

(k) Reinstall the rear seat side garnish.

(l) Reinstall the LH rear seat.

LEXUS RX300 (RM785E)

FI–8

ELECTRONIC FUEL INJECTION – FUEL PUMP

FI0UQ–01

COMPONENTS

Tonneau Cover

Rear Seat Side Garnish

Floor Carpet

Front Part of Deck

Board Assembly

Turn Over

LH Rear Seat

37 (375, 27)

Floor Service

Hole Cover

37 (375, 27)

37 (375, 27)

37 (375, 27)

N·m (kgf·cm, ft·lbf) : Specified torque

B08884

LEXUS RX300 (RM785E)

FI–9

ELECTRONIC FUEL INJECTION – FUEL PUMP

Floor Service Hole Cover

Fuel Pump & Sender

Gauge Coonector

3.5 (36, 31 in.·lbf) x8 Fuel Tank Main Tube

Fuel Tank Vent Tube Set Plate

Tube Joint Clip

Fuel Pump and Sendor

Gauge Assembly

z Gasket

Fuel Sub Suction Hose

N·m (kgf·cm, ft·lbf) : Specified torque

z Non–reusable part B12937

LEXUS RX300 (RM785E)

FI–10

ELECTRONIC FUEL INJECTION – FUEL PUMP

Fuel Suction Plate

with Sender Gauge

Fuel Filter

Fuel Pump

z O–Ring

Fuel Pressure

Regulator and Fuel

Return Jet Tube

Assembly

No.2 Fuel Suction Support

z Non–reusable part B12938

LEXUS RX300 (RM785E)

FI–11

ELECTRONIC FUEL INJECTION – FUEL PUMP

FI0UR–01

REMOVAL

CAUTION:

Do not smoke or work near an open frame when working

the fuel pump.

1. REMOVE LH REAR SEAT

2. REMOVE REAR SEAT SIDE GARNISH

3. TURN OVER FROOR CARPET

4. REMOVE FLOOR SERVICE HOLE COVER

B08891

Remove the 3 cap nuts and service hole cover.

5. DISCONNECT FUEL PUMP & SENDER GAUGE CON-

NECTOR

6. DISCONNECT FUEL TANK MAIN TUBE (FUEL TUBE

CONNECTOR) FROM FUEL SECTION PLATE

CAUTION:

S Perform disconnecting operation of the fuel tube con-

nector (quick type) after observing precaution (See

page FI–1).

S As there is retained pressure in the fuel line, prevent

it from splashing inside the vehicle compartment.

(a) Remove the tube joint clip.

(b) Pull out the fuel main tube.

(c) Plug the port of the fuel suction plate with a clean rubber

cap.

B08889

7. REMOVE FUEL PUMP AND SENDER GAUGE AS-

SEMBLY FROM FUEL TANK

(a) Remove the 8 bolts and fuel tank vent tube set plate.

B08890

(b) Lift up the fuel pump and sender gauge assembly, and

disconnect the fuel sub–suction hose from the fuel return

jet tube and remove the fuel pump, sender gauge assem-

bly and gasket.

8. REMOVE NO.2 FUEL SUCTION SUPPORT

9. REMOVE FUEL PRESSURE REGULATOR AND FUEL

Fuel RETURN JET TUBE ASSEMBLY

Sub–Suction

Hose B01874

LEXUS RX300 (RM785E)

FI–12

ELECTRONIC FUEL INJECTION – FUEL PUMP

10. REMOVE FUEL SUCTION FILTER

(a) Remove the clip.

(b) Pull out the suction filter.

B08893

11. REMOVE NO.1 FUEL SUCTION SUPPORT

(a) Using 2 screwdrivers, disconnect the 4 snap claws from

Pry the claw holes and remove the fuel suction support.

NOTICE:

Be careful not to damage the suction support and suction

plate.

Pry (b) Remove the No.2 fuel filter cushion.

B01889

12. REMOVE FUEL FILTER AND FUEL PUMP ASSEMBLY

(a) Disconnect the fuel pump connector from the fuel pump.

(b) Pull out the fuel filter and fuel pump assembly.

(c) Remove the No.1 fuel filter cushion.

(d) Remove the O–ring from the fuel port of the fuel suctiion

Pull plate.

B08894

13. REMOVE FUEL PUMP FROM FUEL FILTER

Pull out the fuel pump.

Pull

B01891

LEXUS RX300 (RM785E)

FI–13

ELECTRONIC FUEL INJECTION – FUEL PUMP

FI0US–01

INSTALLATION

1. INSTALL FUEL PUMP TO FUEL FILTER

Push in the fuel pump.

Push

B02037

2. INSTALL FUEL FILTER AND FUEL PUMP ASSEMBLY

Fuel Port Hole (a) Install the No.1 fuel filter cushion to the fuel suction plate.

New O–Ring (b) Apply a light coat of gasoline to a new O–ring, and install

it to the fuel port of the fuel suction plate.

(c) Align the fuel port of the fuel suction plate with the fuel port

hole of the fuel filter.

Fuel Port (d) Push in the fuel filter.

No.1 Fuel Filter (e) Connect the fuel pump connector.

Cushion B01892

3. INSTALL NO.1 FUEL SUCTION SUPPORT

(a) Install the No.2 fuel filter cushion the fuel filter.

B01893

Snap Claw (b) Push the fuel suction support, and attach the 4 snap

claws to the claw holes.

Push

B02038

4. INSTALL FUEL SUCTION FILTER

Install the suction filter with a new clip.

5. INSTALL FUEL PRESSURE REGULATOR AND FUEL

RETURN JET TUBE ASSEMBLY

New Clip 6. INSTALL NO.2 FUEL SUCTION SUPPORT

B08893

LEXUS RX300 (RM785E)

FI–14

ELECTRONIC FUEL INJECTION – FUEL PUMP

7. INSTALL FUEL PUMP AND SENDER GAUGE AS-

SEMBLY TO FUEL TANK

(a) Install a new gasket to the fuel suction plate.

(b) Connect the fuel sub–suction hose to the fuel return jet

tube.

(c) Attach the fuel pump and sender gauge assembly to the

Fuel fuel tank.

Sub–Suction

Hose

B08892

(d) Install the fuel tank vent tube set plate with the 8 bolts.

Torque: 3.5 N·m (36 kgf·cm, 31 in.·lbf)

B08890

8. CONNECT FUEL TANK MAIN TUBE (FUEL TUBE CON-

NECTOR) TO FUEL SUCTION PLATE

(a) Attach the fuel tube connector to the port of the fuel suc-

tion plate.

(b) Install the tube joint clip.

9. CONNECT FUEL PUMP & SENDER GAUGE CONNEC-

TOR

10. CHECK FOR FUEL LEAKS (See page FI–1)

B08889

11. INSTALL FLOOR SERVICE HOLE COVER

12. INSTALL FLOOR CARPET

13. INSTALL REAR SEAT SIDE GARNISH

14. INSTALL LH REAR SEAT CUSHION

B08891

LEXUS RX300 (RM785E)

FI–15

ELECTRONIC FUEL INJECTION – FUEL PRESSURE REGULATOR

FUEL PRESSURE REGULATOR

FI0UT–01

COMPONENTS

Rear Seat Cushion

Floor Service Hole cover

Fuel

Tube

Outlet

Fuel Pump & Sender

Gauge Connector

Clip

Fuel Tank Vent Tube

Set Plate X8

4 (40,35 in.·lbf)

Fuel Pump Assembly

Fuel Suction

Plate with

Sender Gauge

Fuel Filter

zGasket

Fuel zO–Ring

Pump

Fuel Pressure

Regulator

No.2 Fuel Suction Support

N·m (kgf·cm, ft·lbf) : Specified torque

zNon–reusable part B12939

LEXUS RX300 (RM785E)

FI–16

ELECTRONIC FUEL INJECTION – FUEL PRESSURE REGULATOR

FI0UU–01

REMOVAL

1. REMOVE FUEL PUMP ASSEMBLY FROM FUEL TANK

(See page FI–11)

2. REMOVE NO. 2 FUEL SUCTION SUPPORT

(See page FI–11)

Fuel

3. REMOVE FUEL PRESSURE REGULATOR

Pressure (a) Pull out the fuel pressure regulator.

Regulator (b) Remove the O–ring from the fuel pressure regulator.

B04948

LEXUS RX300 (RM785E)

FI–17

ELECTRONIC FUEL INJECTION – FUEL PRESSURE REGULATOR

FI0UV–01

New O–Ring INSTALLATION

1. INSTALL FUEL PRESSURE REGULATOR

(a) Install the O–ring to the fuel pressure regulator.

HINT:

Apply a light coat of gasoline to a new O–ring, and install it to

the fuel pressure regulator.

(b) Connect the fuel pressure regulator from the fuel filter.

2. INSTALL NO. 2 FUEL SUCTION SUPPORT

B00344

(See page FI–13)

3. INSTALL FUEL PUMP ASSEMBLY FROM FUEL TANK

(See page FI–13)

LEXUS RX300 (RM785E)

FI–18

ELECTRONIC FUEL INJECTION – INJECTOR

INJECTOR FI0UW–01

ON–VEHICLE INSPECTION

1. REMOVE V–BANK COVER

(a) Using a 5 mm hexagon wrench, remove the 2 cap nuts.

(b) Disconnect the 2 clips, and remove the V–bank cover.

5 mm

Hexagon

Wrench

A05071

Sound Scope 2. INSPECT INJECTOR OPERATION

Check operation sound from each injector.

(1) With the engine running or cranking, use a sound

scope to check that there is normal operating noise

in proportion to engine speed.

(2) If you have no sound scope, you can check the in-

jector operating vibration with your finger.

If no sound or unusual sound is heard, check the wiring connec-

B05296 tor, injector or injection signal from the engine ECU.

3. INSPECT INJECTOR RESISTANCE

(a) Disconnect the injector connector.

Ohmmeter (b) Using an ohmmeter, measure the resistance between the

terminals.

Resistance: 13.4 – 14.2 Ω at 20°C (68°F)

If the resistance is not as specified, replace the injector.

(c) Reconnect the injector connector.

4. REINSTALL V–BANK COVER

B05297 HINT:

For fixing the V–bank cover, push on the cover until a ”click” is

felt.

LEXUS RX300 (RM785E)

FI–19

ELECTRONIC FUEL INJECTION – INJECTOR

FI0UX–01

COMPONENTS

PS Pressure Tube 39 (400, 19)

19.5 (200, 14) V–Bank Cover

Air Intake Chamber Stay

Throttle Position

Sensor Connector

No.1 Engine

Hanger

43 (440, 32)

ISC Valve Accelerator Cable

Ground Cable Connector

Brake Booster

Vacuum Hose

Water Bypass Hose

Ground Cable

Vacuum

Ground Strap

Hose

PCV Hose Purge Hose

Air Intake Chamber No.1 VSV Connector for ASIC

Assembly

Air Assist Hose and Pipe

z Gasket 19.5 (200, 14)

10 (100, 7) Fuel Hose Clamp

Delivery Pipe

Spacer Injector Connector

z O–Ring

z Grommet

z Grommet

Injector z O–Ring

N·m (kgf·cm, ft·lbf) : Specified

zNon–reusable part B12945

LEXUS RX300 (RM785E)

FI–20

ELECTRONIC FUEL INJECTION – INJECTOR

FI0UY–01

REMOVAL

1. REMOVE AIR CLEANER HOSE

2. REMOVE AIR INTAKE CHAMBER ASSEMBLY

(See page EM–33)

3. DISCONNECT INJECTOR CONNECTORS

S04505

4. REMOVE AIR ASSIST HOSES AND PIPE

(a) Disconnect the air assist pipe from the bracket on the

No.1 fuel pipe.

(b) Remove the air assist hoses from the intake manifold.

B12951

5. DISCONNECT FUEL INLET PIPE

(a) Remove the fuel hose clamp.

B08887

(b) Disconnect the fuel inlet pipe (fuel tube connector) from

the fuel filter.

CAUTION:

S Perform disconnecting operations of the fuel tube

connector (quick type) after observing the precau-

tions.

S As there is retained pressure in the fuel pipe line, pre-

vent it from splashing inside the engine compart-

B12941 ment.

LEXUS RX300 (RM785E)

FI–21

ELECTRONIC FUEL INJECTION – INJECTOR

6. REMOVE DELIVERY PIPES AND INJECTORS

NOTICE:

S Be careful not to drop the injectors when removing

the delivery pipes.

S Pay attention to put any hung load on the injector to

and from the side direction.

(a) Remove the 5 bolts and delivery pipes together with the

6 injectors and fuel pipe.

B12949 (b) Remove the 4 spacers from the intake manifold.

(c) Pull out the 6 injectors from the delivery pipes.

(d) Remove the 2 O–rings and 2 grommets from each injec-

tor.

LEXUS RX300 (RM785E)

FI–22

ELECTRONIC FUEL INJECTION – INJECTOR

FI0UZ–01

INSPECTION

SST (Hose) 1. INSPECT INJECTOR INJECTION

CAUTION:

Keep injector clear of sparks during the test.

SST(Union)

Fuel Tube

Connector

SST (Clamp)

Injector B12946

(a) Purchase the new No. 1 fuel pipe and take out the fuel

Fuel Tube Connector tube connector from its pipe.

Part No. 23801–20040

B09225

(b) Connect SST (hose) and fuel tube connector to the fuel

Fuel Tube Connector filter outlet.

SST 09268–41047

SST CAUTION:

(Hose) Perform connecting operations of the fuel tube connector

(quick type) after observing the precautions.

HINT:

Use the vehicle’s fuel filter.

B12947

(c) Install the grommet and O–ring to the injector.

SST (Hose) (d) Connect SST (union and hose) to the injector, and hold

SST (Union) the injector and union with SST (clamp).

SST 09268–41047 (09268–41100, 09268–41300)

O–Ring (e) Put the injector into a graduated cylinder.

SST HINT:

(Clamp) Install a suitable vinyl hose onto the injector to prevent gasoline

from splashing out.

Vinyl Tube

B05298

(f) Connect the hand–held tester to the DLC3.

Hand–Held Tester (g) Turn the ignition switch ON and hand–held tester main

switch ON.

NOTICE:

Do not start the engine.

(h) Select the active test mode on the hand–held tester.

(i) Please refer to the hand–held tester operator’s manual

for further details.

DLC3 D09456

LEXUS RX300 (RM785E)

FI–23

ELECTRONIC FUEL INJECTION – INJECTOR

(j) If you have no hand–held tester, connect the positive (+)

and negative (–) leads from the battery to the fuel pump

connector (See page FI–5).

(k) Connect SST (wire) to the injector and battery for 15 se-

conds, and measure the injection volume with a gra-

duated cylinder. Test each injector 2 or 3 times.

SST 09842–30070

Volume: 60 – 73 cm3 (3.7 – 4.5 cu in.) per 15 sec.

SST Difference between each injector:

(Wire) 13 cm3 (0.8 cu in.) or less

If the injection volume is not as specified, replace the injector.

Battery

B05299

2. INSPECT LEAKAGE

(a) In the condition above, disconnect the test probes of SST

(wire) from the battery and check the fuel leakage from

the injector.

SST 09842–30070

Fuel drop: 1 drop or less per 12 minutes

(b) Turn the ignition switch to LOCK.

(c) Disconnect the negative (–) terminal cable from the bat-

B05331 tery.

(d) Remove the SST and fuel tube connector.

SST 09268–41047, 09842–30070

CAUTION:

S Perform disconnecting operations of the fuel tube

connector (quick type) after observing the precau-

tions.

S As there is retained pressure in the fuel pipe line, pre-

vent it from splashing inside the engine compart-

ment.

(e) Disconnect the hand–held tester from the DLC3.

LEXUS RX300 (RM785E)

FI–24

ELECTRONIC FUEL INJECTION – INJECTOR

FI0V0–01

INSTALLATION

New Insulator 1. INSTALL INJECTORS AND DELIVERY PIPES

(a) Install new insulator and grommet to each injector.

New

O–Ring (b) Apply a light coat of spindle oil or gasoline to 2 new O–

rings and install them to each injector.

New O–Ring

New Grommet B12948

(c) Apply a light coat of spindle oil or gasoline on the place

where a delivery pipe touches an O–ring of the injector.

Turn

(d) While turning the injector clockwise and counterclock-

Push

wise, push it to the delivery pipes. Install the 6 injectors.

(e) Position the injector connector outward.

Connector

S04511

(f) Place the 4 spacers in position on the intake manifold.

Spacer

Spacer S04510

(g) Apply a light coat of spindle oil or gasoline on the place

where a intake manifold touches an O–ring of the injector.

(h) Place the delivery pipes and fuel pipe together with the 6

injectors in position on the intake manifold.

(i) Temporarily install the 4 bolts holding the delivery pipes

to the intake manifold.

(j) Temporarily install the bolt holding the fuel pipe to the in-

take manifold.

B12949

(k) Check that the injectors rotate smoothly.

HINT:

If injectors do not rotate smoothly, the probable cause is incor-

Rotate rect installation of O–rings. Replace the O–rings.

(l) Position the injector connector outward.

Outward

S04728

LEXUS RX300 (RM785E)

FI–25

ELECTRONIC FUEL INJECTION – INJECTOR

(m) Tighten the 4 bolts holding the delivery pipes to the intake

manifold.

Torque: 10 N·m (100 kgf·cm, 7 ft·lbf)

(n) Tighten the bolt holding the fuel pipe to the intake man-

ifold.

Torque: 19.5 N·m (200 kgf·cm, 14 ft·lbf)

B12949

2. CONNECT FUEL INLET PIPE

(a) Align the alignment marks (white paint) on the fuel inlet

pipe.

Align

B12950

(b) Connect the fuel inlet pipe (fuel tube connector) to the fuel

filter.

CAUTION:

Perform connecting operations of the fuel tube connector

(quick type) after observing the precautions.

B12944

(c) Install the fuel hose clamp to the fuel filter.

Fuel

Hose

Clamp

B12940

3. INSTALL AIR ASSIST HOSES AND PIPE

(a) Connect the air assist hoses to the intake manifold.

(b) Install the air assist pipe to the bracket on the No. 1 fuel

pipe.

4. CONNECT INJECTOR CONNECTORS

5. INSTALL AIR INTAKE CHAMBER ASSEMBLY

(See page EM–60)

6. INSTALL AIR CLEANER HOSE

B12951 7. CHECK FOR FUEL LEAKS

LEXUS RX300 (RM785E)

FI–26

ELECTRONIC FUEL INJECTION – FUEL TANK AND LINE

FUEL TANK AND LINE

FI0V1–01

COMPONENTS

CAUTION:

S Always use new gaskets when replacing the fuel tank or component parts.

S Apply the proper torque to all parts tightened.

EVAP Hose

No.3 Fuel Tank protector

Vent Tube Set Plate Vapor Pressure Sensor Fuel Tank Cap

x4 Ring

z Gasket Vent Tube Set Plate

x5 Ring

EVAP Tube Support Plate

Fuel Sender z Gasket Shield

Gauge Clip

Fuel Cut Off Valve

z Gasket

Fuel Cut

Off Valve

Fuel Tank

z Gasket Breather Tube

z Gasket Fuel Inlet

Pipe

Fuel Tank Fuel Inlet Hose Fuel Tank

Main Tube

Fuel Sub–Suction Hose

x8 Tube Joint Clip

3.5 (36, 31 in.·lbf)

Fuel Tank

Vent Tube

RH Fuel Set Plate

Tank Band 39.2 (400, 29) Fuel Pump and

Sender Gauge

Assembly

z Gasket

39.2 (400, 29)

LH Fuel Tank Band

Location of Fuel Tank Cushion

Lower Center

Fuel Tank Protector

RH Fuel Tank Protector

N·m (kgf·cm, ft·lbf) : Specified torque

z Non–reusable part LH Fuel Tank Protector

B12175

LEXUS RX300 (RM785E)

FI–27

ELECTRONIC FUEL INJECTION – FUEL TANK AND LINE

FI0V2–01

INSPECTION

INSPECT FUEL TANK AND LINE

(a) Check the fuel lines for cracks or leakage, and all connec-

Crack Leakage tions for deformation.

(b) Check the fuel tank vapor vent system hoses and connec-

tions for looseness, sharp bends or damage.

(c) Check the fuel tank for deformation, cracks, fuel leakage

Deformation or tank band looseness.

BO0919

(d) Check the filler neck for damage or fuel leakage.

2 – 7 mm (0.08 – 0.28 in.) (e) Hose and pipe connections are as shown in the illustra-

Pipe Hose tion.

If a problem is found, repair or replace the parts as necessary.

Clip

0 – 3 mm (0 – 0.12 in.) FU0041

LEXUS RX300 (RM785E)

FI–28

ELECTRONIC FUEL INJECTION – AIR FLOW METER

AIR FLOW METER

FI0V3–01

COMPONENTS

Air Flow Meter Connector

Air Flow Meter

B08898

LEXUS RX300 (RM785E)

FI–29

ELECTRONIC FUEL INJECTION – AIR FLOW METER

FI0V4–01

REMOVAL

REMOVE AIR FLOW METER

(a) Disconnect the air flow meter connector.

(b) Remove the 2 screw, air flow meter and gasket.

HINT:

At the time of installation, please refer to the following items.

Use a new gasket.

B04946

LEXUS RX300 (RM785E)

FI–30

ELECTRONIC FUEL INJECTION – AIR FLOW METER

FI0V5–01

THA Ohmmeter INSPECTION

1. INSPECT AIR FLOW METER RESISTANCE

Using an ohmmeter, measure the resistance between terminals

E2 THA and E2.

Terminals Resistance Temperature

THA – E2 14.6 – 17.8 kΩ –20°C (–4°F)

THA – E2 2.21 – 2.69 kΩ 20°C (68°F)

B04947

THA – E2 0.29 – 0.35 kΩ 60°C (140°F)

E2G If the resistance is not as specified, replace the air flow meter.

2. INSPECT AIR FLOW METER OPERATION

VG

(a) Connect the air flow meter connector.

(b) Turn the ignition switch ON.

Air (c) Using a voltmeter, connect the positive (+) tester probe to

Voltmeter

terminal VG, and negative (–) tester probe to terminal

E2G.

(d) Blow air into the air flow meter, and check that the voltage

B04957 fluctuates.

If operation is not as specified, replace the air flow meter.

(e) Turn the ignition switch LOCK.

(f) Disconnect the air flow meter connector.

LEXUS RX300 (RM785E)

FI–31

ELECTRONIC FUEL INJECTION – AIR FLOW METER

FI0V6–01

INSTALLATION

Installation is in the reverse order of removal (See page FI–29).

LEXUS RX300 (RM785E)

FI–32

ELECTRONIC FUEL INJECTION – THROTTLE BODY

THROTTLE BODY FI0V7–01

ON–VEHICLE INSPECTION

1. INSPECT THROTTLE BODY

Check that the throttle linkage moves smoothly.

2. INSPECT THROTTLE POSITION SENSOR

(a) Check that there is no clearance between each throttle

Must Have Must Have stop screw and the throttle lever when applying the nega-

Clearance No Clearance B05129 tive pressure (53.3 kPa (400 mmHg)) to the throttle open-

er using the mighty pack.

(b) Apply vacuum to the throttle opener.

(c) Disconnect the sensor connector.

(d) Using an ohmmeter, measure the resistance between

each terminal.

Throttle valve Between

Resistance

condition terminals

Fully closed VTA – E2 0.2 – 6.3 kΩ

VTA E2 VC Fully open VTA – E2 2.0 – 10.2 kΩ

A06100

– VC – E2 2.5 – 5.9 kΩ

(e) Reconnect the sensor connector.

LEXUS RX300 (RM785E)

FI–33

ELECTRONIC FUEL INJECTION – THROTTLE BODY

FI0V8–01

COMPONENTS

z Gasket 19.5 (199, 14.4)

Surge Tank Stay

19.5 (199, 14.4)

Throttle Body

Air Hose

Vacuum Hose Water Bypass Hose

Accelerater Cable

Air Cleaner Hose

Connector

Air Cleaner Cap

Air Cleaner Case

N·m (kgf·cm, ft·lbf) : Specified torque

z Non–reusable part

B12952

LEXUS RX300 (RM785E)

FI–34

ELECTRONIC FUEL INJECTION – THROTTLE BODY

Throttle Body No.3

Protector

z O–Ring

Throttle Postion Senser

6.9 (70, 61 in.·lbf)

Throttle Body No.1

z Gasket

6.9 (70, 61 in.·lbf)

z O–Ring

z Gasket

Throttle Body No.2

ISC Valve

6.9 (70, 61 in.·lbf)

N·m (kgf·cm, ft·lbf) : Specified torque

z Non–reusable part

B05284

LEXUS RX300 (RM785E)

FI–35

ELECTRONIC FUEL INJECTION – THROTTLE BODY

FI0V9–01

REMOVAL

1. DRAIN ENGINE COOLANT

2. DISCONNECT ACCELERATOR CABLE

3. DISCONNECT THROTTLE CABLE

4. REMOVE AIR CLEANER HOSE

(a) Disconnect the PCV hose.

(b) Loosen the 2 hose clamps, and remove the air cleaner

hose.

A05687

5. REMOVE THROTTLE BODY

Throttle (a) Disconnect the throttle position sensor connector.

Position

Sensor

Connector

B04794

(e) ISC (b) Disconnect the ISC valve connector.

Valve (c) Disconnect the water bypass hosese.

Connector (d) Disconnect the air assist hose.

(e) Disconnect the 2 fuel vapor feed hosese.

(f)

(f) Disconnect the vacuum hose.

(c)

(d)

B04795

(g) Remove the 3 nuts,throttle body and gasket.

HINT:

At the time of installation, please refer to the following items.

Place a new gasket on the air intake chamber.

Torque: 19.5 N·m (200 kgf·cm, 14 ft·lbf)

B04793

LEXUS RX300 (RM785E)

FI–36

ELECTRONIC FUEL INJECTION – THROTTLE BODY

FI0VA–01

INSPECTION

NOTICE:

In case of changing, removing or installing the throttle

body or ISC valve, must do this.

1. THROTTLE BODY INSPECTION

(a) Check that there is no clearance between each throttle

stop screw and the throttle lever when applying the nega-

Must Have Must Have tive pressure (53.3 kPa (400 mmHg)) to the throttle open-

Clearance No Clearance B05129

er using the MITYVAC.

Throttle Stop Screw Standard: Must have no clearance.

Adjust Screw NOTICE:

(Close Side) As the throttle stop screw is precisely adjusted, so do not

adjust it.

Adjust Screw

(Open Side) B05130

(b) Under the condition of (1), check visually that there is a

clearance between each adjust screw and the throttle le-

ver on No. 1 side.

Adjust Screw Reference Value

Close Side Close Side About 0.13 mm

Open Side About 0.22 mm

Open Side B05131

Fully Opening Thickness (c) Measure the clearance between the adjust screw on the

Gauge close side when fully opening the throttle lever on No. 2

side by hand and the throttle lever on No. 1 side with a

thickness gauge.

Standard value: 0.25 – 0.45 mm

In case of being out of standard value, perform the ad-

justment of (2).

Adjust Screw

(Close Side) B05132

LEXUS RX300 (RM785E)

FI–37

ELECTRONIC FUEL INJECTION – THROTTLE BODY

Throttle Stop Screw 2. THROTTLE BODY (BALANCE) ADJUSTMENT

NOTICE:

Adjust Screw

(Close Side) Do not adjust the throttle stop screw and throttle opener.

(a) Beforehand checking

Recheck 1 – (1)

(b) Adjustment of the adjust screw on the open side

(1) Loosen the lock nut and screw using the hexagon

Adjust Screw wrench (width of two planes 2 mm), make clearance

(Open Side) B05133 between the screw tip and the throttle lever on No.

1 side.

(2) Turn the screw to the screw torque direction gradu-

ally, and stop it at the position where to touch the le-

ver at the very moment.

NOTICE:

If turning it too much to the torque direction, No. 1 lever

goes off from the throttle stop screw causing the adjust-

ment failure.

(3) Turn it back from the position where it touches the

lever to the screw loosing direction.

Standard:

Turn it back by rotating 1/4.

Close Side (4) Torque the lock nut.

(c) Adjustment of the adjust screw on the close side

(1) Loosen the lock nut and screw, and make clearance

between the screw tip and the throttle lever on No.

Open Side B05184 1 side.

(2) Turn the screw to the screw torque direction gradu-

ally, and stop it at the position where to touch the le-

ver at the very moment.

NOTICE:

If turning it too much to the torque direction. No. 2 lever

goes off from the throttle stop screw causing the adjust-

ment failure.

(3) Turn it back from the position where it touches the

lever to the screw loosing direction.

Standard:

Turn it back by rotating 1/2 – 3/4.

(4) Torque the lock nut.

(d) Completion checking

Check 1 – (3).

LEXUS RX300 (RM785E)

FI–38

ELECTRONIC FUEL INJECTION – THROTTLE BODY

FI0VB–01

INSTALLATION

NOTICE:

S Do not give a shock to the throttle position senor.

S Do not disassemble or adjust the throttle opener.

1. INSTALLATION OF THE THROTTLE POSITION SEN-

SOR

Installation is in the reverse order of removal

(See page FI–35).

B05127

(a) Check that the throttle valve is fully open.

(b) Insert the sensor to the throttle body with it turned clock-

wise by 30 to 60° against the fully – open valve position.

(c) By turning the sensor counterclockwise, torque the sen-

sor.

2. INSTALLATION OF THE THROTTLE BODY NO. 1 AND

Gasket Gasket NO. 2

Set the gasket and O–ring as shown in the illustration to the il-

lustration to the lift.

O–Ring O–Ring

B05128

LEXUS RX300 (RM785E)

FI–39

ELECTRONIC FUEL INJECTION – CAMSHAFT TIMING OIL CONTROL VALVE

Ohmmeter CAMSHAFT TIMING OIL CONTROL

VALVE FI0VC–01

ON–VEHICLE INSPECTION

INSPECT OIL CONTROL VALVE RESISTANCE

(a) Remove the V–bank cover.

(b) Remove the intake air connector.

(c) Disconnect the oil control valve connector.

A06082

(d) Using an Ohmmeter, measure the resistance between

the terminals.

Resistance:

6.9 – 7.9 Ω at 20°C (68°F)

If the resistance is not as specified, replace the valve.

(e) Reconnect the oil control valve connector.

(f) Reinstall the intake air connector.

(g) Reinstall the V–bank cover.

LEXUS RX300 (RM785E)

FI–40

ELECTRONIC FUEL INJECTION – CAMSHAFT TIMING OIL CONTROL VALVE

FI0VD–01

COMPONENTS

V–Bank Cover

Camshaft Timing

Oil Control Valve

A06081

LEXUS RX300 (RM785E)

FI–41

ELECTRONIC FUEL INJECTION – CAMSHAFT TIMING OIL CONTROL VALVE

FI0VE–01

REMOVAL

1. REMOVE V–BANK COVER

2. REMOVE INTAKE AIR CONNECTOR

3. DISCONNECT THROTTLE BODY FROM INTAKE

MANIFOLD (See page FI–52)

4. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

(a) Disconnect the engine wire from the wire clamp on the LH

timing belt rear plate.

(b) Disconnect the 2 camshaft oil control valve connectors.

(c) Remove the bolt, camshaft oil control valve and O–ring.

Remove the 2 camshaft oil control valves.

Torque: 8 N·m (80 kgf·cm, 66 in.·lbf)

(d) Remove the O–ring from the each camshaft oil control

B04940 valve.

HINT:

At the time of installation, please refer to the following items.

Use a new O–rings.

LEXUS RX300 (RM785E)

FI–42

ELECTRONIC FUEL INJECTION – CAMSHAFT TIMING OIL CONTROL VALVE

FI0VF–01

INSPECTION

INSPECT OIL CONTROL VALVE OPERATION

Connect positive ę lead to terminal 1 of connector and nega-

tive Ĝ lead to terminal 2, then check the movement of the valve.

1 2

When battery positive voltage is applied. Valve moves in direction.

When battery positive voltage is cut off. Valve moves in direction.

B01689

If operation is not as specified, replace the oil control valve.

LEXUS RX300 (RM785E)

FI–43

ELECTRONIC FUEL INJECTION – CAMSHAFT TIMING OIL CONTROL VALVE

FI0VG–01

INSTALLATION

Installation is in the reverse order of removal (See page FI–41).

LEXUS RX300 (RM785E)

FI–44

ELECTRONIC FUEL INJECTION – IDLE SPEED CONTROL (ISC) VALVE

IDLE SPEED CONTROL (ISC)

VALVE FI0VH–01

ON–VEHICLE INSPECTION

1. INSPECT ISC VALVE OPERATION

(a) Initial conditions:

S Engine at normal operating temperature

S Idle speed checked correctly

S Transmission in neutral position

S A/C switch OFF

(b) Using SST, connect terminals TE1 and E1 of the DLC1.

DLC1 SST

E1 SST 09843–18020

(c) After engine speed is kept at approx. 1,000 rpm for 5 se-

conds, check that it returns to idle speed.

If the engine speed operation is not as specified, check the ISC

TE1 valve, wiring and engine ECU.

(d) Remove the SST from the DLC1.

SST 09843–18020

DLC1

A05186

RSC 2. INSPECT ISC VALVE RESISTANCE

+B NOTICE:

RSO

Ohmmeter

”Cold” and ”Hot” in the following sentences express the

temperature of the coils themselves. ”Cold” is from –10°C

(14°F) to 50°C (122°F) and ”Hot” is from 50°C (122°F) to

100°C (212°F).

(a) Disconnect the ISC valve connector.

(b) Using an ohmmeter, measure the resistance between ter-

B04811 minal +B and other terminals (RSC, RSO).

Resistance:

Cold: 17.0 – 24.5 Ω

Hot: 21.5 – 28.5 Ω

If resistance is not as specified, replace the ISC valve.

(c) Reconnect the ISC valve connector.

3. INSPECT AIR ASSIST SYSTEM

(a) Initial conditions:

S Engine at normal operating temperature

S Idle speed checked correctly

S Transmission in neutral position

S A/C switch OFF

LEXUS RX300 (RM785E)

FI–45

ELECTRONIC FUEL INJECTION – IDLE SPEED CONTROL (ISC) VALVE

(b) Using SST, connect terminals TE1 and E1 of the DLC1.

DLC1 SST

E1 SST 09843–18020

(c) After engine speed is kept at 900 – 1,300 rpm for 10 se-

conds, check that it returns to idle speed.

(d) Stop the engine.

TE1 (e) Disconnect the air assist hose from the air pipe, and block

off the ISC valve exit and the entry to the pipe.

(f) Start the engine and check that the idle speed reaches

A05186 500 rpm or below (the engine may stall).

If the idle does not reach 500 rpm or below, check for a

leak between the air assist hoses, pipe and injectors.

(g) Remove the SST from the DLC1.

SST 09843–18020

(h) Reconnect the air assist hose to the ISC valve.

LEXUS RX300 (RM785E)

FI–46

ELECTRONIC FUEL INJECTION – IDLE SPEED CONTROL (ISC) VALVE

FI0VI–01

COMPONENTS

19.5 (199, 14)

z Gasket

Surge Tank Stay

19.5 (199, 14)

Throttle Body

Air Hose Connector

Accelerater Cable

Vacuum Hose Water Bypass Hose

Air Cleaner Hose

Connector

Throttle Body

Air Cleaner Cap

z Gasket

Air Cleaner Case

ISC Valve

N·m (kgf·cm, ft·lbf) : Specified torque B05283

z Non–reusable part

B12953

LEXUS RX300 (RM785E)

FI–47

ELECTRONIC FUEL INJECTION – IDLE SPEED CONTROL (ISC) VALVE

FI0VJ–01

REMOVAL

1. REMOVE THROTTLE BODY (See page FI–35)

2. REMOVE ISC VALVE

Remove the 4 screws, ISC valve and gasket.

HINT:

At the time of installation, please refer to the following items.

Place a new gasket on the throttle body.

B04798

LEXUS RX300 (RM785E)

FI–48

ELECTRONIC FUEL INJECTION – IDLE SPEED CONTROL (ISC) VALVE

FI0VK–01

INSPECTION

Open

INSPECT ISC VALVE OPERATION

Close

(a) Check that the ISC valve is halfly opened.

(b) Connect the ISC valve connecter to the ISC valve.

(c) Turn the ignition switch ON.

Valve (d) Check that the ISC valve moves in 0.5 seconds by order

of fully colse, fully open and halfly open.

If operation is not as specified, replace the ISC valve.

(e) Turn the ignition switch OFF.

(f) Disconnect the ISC valve connecter from the ISC valve.

Valve

B00341

LEXUS RX300 (RM785E)

FI–49

ELECTRONIC FUEL INJECTION – IDLE SPEED CONTROL (ISC) VALVE

FI0VL–01

INSTALLATION

Installation is in the reverse order of removal (See page FI–47).

LEXUS RX300 (RM785E)

FI–50

ELECTRONIC FUEL INJECTION – ACOUSTIC CONTROL INDUCTION SYSTEM (ACIS)

Vacuum Gauge ACOUSTIC CONTROL INDUCTION

SYSTEM (ACIS) FI0VM–01

ON–VEHICLE INSPECTION

INSPECT INTAKE AIR CONTROL VALVE

(a) Using a 3–way connector, connect vacuum gauge to the

actuator hose.

(b) Start the engine.

B04801

(c) While the engine is idling, check that the vacuum gauge

needle does not move.

(d) Rapidly depress the accelerator pedal to fully open posi-

tion and check that the vacuum gauge needle momentari-

Approx.

ly fluctuates up to approx. 26.7 kPa (200 mmHg, 7.9

26.7 kPa

in.Hg). (The actuator rod is pulled out.)

B04800

LEXUS RX300 (RM785E)

FI–51

ELECTRONIC FUEL INJECTION – ACOUSTIC CONTROL INDUCTION SYSTEM (ACIS)

FI0VN–01

COMPONENTS

Intake Air Control Valve

14.5 (145, 10)

z Gasket

Actuator Vacuum Hose

Ground Cable

Ground Strap

N·m (kgf·cm, ft·lbf) : Specified torque

z Non–reusable part B04799

LEXUS RX300 (RM785E)

FI–52

ELECTRONIC FUEL INJECTION – ACOUSTIC CONTROL INDUCTION SYSTEM (ACIS)

FI0VO–01

REMOVAL

1. DISCONNECT ACTUATOR VACUUM HOSE

2. DISCONNECT DLC1 FROM DLC1 BRACKET

3. REMOVE INTAKE AIR CONTROL VALVE

(a) Remove the 4 nuts and DLC1 bracket, and disconnect the

ground strap and cable.

(b) Remove the intake air control valve by prying a screwdriv-

er between the intake air control valve and air intake

chamber.

(c) Remove the gasket.

B04802

LEXUS RX300 (RM785E)

FI–53

ELECTRONIC FUEL INJECTION – ACOUSTIC CONTROL INDUCTION SYSTEM (ACIS)

FI0VP–01

INSPECTION

1. INSPECT INTAKE AIR CONTROL VALVE

(a) With 26.7 kPa (200 mmHg, 7.9 in.Hg) of vacuum applied

to the actuator, check that the actuator rod moves.

(b) One minute after applying the vacuum in (a), check that

the actuator rod does not return.

If the operation is not as specified, replace the intake air control

valve.

Vacuum

S05041

2. INSPECT VACUUM TANK

Air Air LOCATION: The LH side member under the battery tray.

(a) Check that air flows from port B to port A.

(b) Check that air does not flow from port A to port B.

S05689

Vacuum (c) Plug port B with your finger, and apply 26.7 kPa (200

mmHg, 7.9 in.Hg) of vacuum to port A, and check that

there is no change is vacuum after one minute.

If the operation is not as specified, replace the vacuum tank.

3. INSPECT VSV (See page FI–62)

S05688

LEXUS RX300 (RM785E)

FI–54

ELECTRONIC FUEL INJECTION – ACOUSTIC CONTROL INDUCTION SYSTEM (ACIS)

FI0VQ–01

INSTALLATION

1. INSTALL INTAKE AIR CONTROL VALVE

(a) Install a new gasket to the air intake chamber.

New Gasket

B04803

(b) Apply a light coat of engine oil to the rubber portions.

Seal

Packing Seal (c) Apply seal packing to the positions of the intake air control

Packing valve shown in the illustration.

Seal packing: Part No. 08826–00080 or equivalent

(d) Install the intake air control valve, DLC1 bracket, ground

strap and cable with the 4 nuts.

Torque: 14.5 N·m (145 kgf·cm, 10 ft·lbf)

Rubber 2. CONNECT DLC1

S05052 3. CONNECT ACTUATOR VACUUM HOSE

LEXUS RX300 (RM785E)

FI–55

ELECTRONIC FUEL INJECTION – EFI MAIN RELAY

EFI MAIN RELAY FI0VR–01

INSPECTION

1. REMOVE EFI MAIN RELAY (Marking: EFI)

EFI Main

Relay

I06870

Continuity 2. INSPECT EFI MAIN RELAY CONTINUITY

(a) Using an ohmmeter, check that there is continuity be-

Ohmmeter 2 Ohmmeter

1 tween terminals 1 and 2.

If there is no continuity, replace the relay.

5

(b) Check that there is no continuity between terminals 3 and

5.

3 If there is continuity, replace the relay.

No Continuity

S04947

3. INSPECT EFI MAIN RELAY OPERATION

2 (a) Apply battery voltage across terminals 1 and 2.

Ohmmeter

1 (b) Using an ohmmeter, check that there is continuity be-

tween terminals 3 and 5.

5

If there is no continuity, replace the relay.

4. REINSTALL EFI MAIN RELAY

3

Battery

Continuity

S04946

LEXUS RX300 (RM785E)

FI–56

ELECTRONIC FUEL INJECTION – A/F SENSOR HEATER RELAY

A/F SENSOR HEATER RELAY FI0VS–01

INSPECTION

1. REMOVE RELAY BOX COVER

2. REMOVE A/F SENSOR HEATER RELAY (Marking: A/F

HTR)

A/F Sensor

Heater

Relay

B09976

Continuity 3. INSPECT A/F SENSOR HEATER RELAY CONTINUITY

(a) Using an ohmmeter, check that there is continuity be-

Ohmmeter 2 Ohmmeter

1 tween terminals 1 and 2.

If there is no continuity, replace the relay.

5

(b) Check that there is no continuity between terminals 3 and

5.

3 If there is continuity, replace the relay.

No Continuity

S04947

4. INSPECT A/F SENSOR HEATER RELAY OPERATION

2

(a) Apply battery voltage across terminals 1 and 2.

Ohmmeter

1 (b) Using an ohmmeter, check that there is continuity be-

tween terminals 3 and 5.

5

If there is no continuity, replace the relay.

5. REINSTALL A/F SENSOR HEATER RELAY

3 6. REINSTALL RELAY BOX COVER

Battery

Continuity

S04946

LEXUS RX300 (RM785E)

FI–57

ELECTRONIC FUEL INJECTION – CIRCUIT OPENING RELAY

CIRCUIT OPENING RELAY FI0VT–01

INSPECTION

1. REMOVE CIRCUIT OPENING RELAY (Marking: CIR

OPN)

Remove the circuit opening relay from R/B No.1.

Circuit Opening Relay I19409

Continuity 2. INSPECT CIRCUIT OPENING RELAY CONTINUITY

2 (a) Using an ohmmeter, check that there is continuity be-

Ohmmeter Ohmmeter

1 tween terminals 1 and 2.

If there is no continuity, replace the relay.

5 (b) Check that there is no continuity between terminals 3 and

5.

If there is continuity, replace the relay.

3

No Continuity

S04947

3. INSPECT CIRCUIT OPENING RELAY OPERATION

2 (a) Apply battery voltage across terminals 1 and 2.

1 Ohmmeter

(b) Using an ohmmeter, check that there is continuity be-

tween terminals 3 and 5.

5 If there is no continuity, replace the relay.

4. REINSTALL CIRCUIT OPENING RELAY

3

Battery

Continuity

S04946

LEXUS RX300 (RM785E)

FI–58

ELECTRONIC FUEL INJECTION – VSV FOR EVAPORATIVE EMISSION (EVAP)

VSV FOR EVAPORATIVE EMISSION (EVAP)

FI0VU–01

COMPONENTS

V–Bank Cover EVAP Hose

VSV for EVAP

VSV for EVAP Connector

VSV for ACIS NO.2

VSV for ACIS NO.2

Connector

VSV for ACIS NO.1

Connector

B04805

LEXUS RX300 (RM785E)

FI–59

ELECTRONIC FUEL INJECTION – VSV FOR EVAPORATIVE EMISSION (EVAP)

FI0VV–01

INSPECTION

1. REMOVE V–BANK COVER, COVER AND EMISSION

CONTROL VALVE SET

2. REMOVE VSV

(a) Disconnect the 2 EVAP hoses from the VSV.

(b) Remove the screw and VSV.

Ohmmeter 3. INSPECT VSV FOR OPEN CIRCUIT

Using an ohmmeter, check that there is continuity between the

terminals.

Resistance: 27 – 33 Ω at 20°C (68°F)

If there is no continuity, replace the VSV.

Continuity

S04522

Ohmmeter 4. INSPECT VSV FOR GROUND

Using an ohmmeter, check that there is no continuity between

each terminal and the body.

If there is continuity, replace the VSV.

No Continuity

S04521

Air 5. INSPECT VSV OPERATION

(a) Check that air flows with difficulty from port E to port F.

E

F

P18857

(b) Apply battery voltage across the terminals.

Air

(c) Check that air flows from port E to port F.

If operation is not as specified, replace the VSV.

6. REINSTALL VSV

(a) Install the VSV with the screw.

E

(b) Connect the 2 EVAP hoses to the VSV.

7. REINSTALL EMISSION CONTROL VALVE SET

F Battery 8. REINSTALL V–BANK COVER

S04520

LEXUS RX300 (RM785E)

FI–60 ELECTRONIC FUEL INJECTION – VSV FOR ACOUSTIC CONTROL INDUCTION

SYSTEM (ACIS)

VSV FOR ACOUSTIC CONTROL INDUCTION SYSTEM (ACIS)

FI0VW–01

COMPONENTS

NO. 1

V–Bank Cover Vacuum Hose

VSV for ACIS NO. 1

VSV for EVAP Connector

VSV for ACIS NO. 2

Connector

VSV for ACIS NO. 1

Connector

Emission Control Valve Set

B04804

LEXUS RX300 (RM785E)

ELECTRONIC FUEL INJECTION – VSV FOR ACOUSTIC CONTROL INDUCTION FI–61

SYSTEM (ACIS)

NO. 2

V–Bank Cover

VSV for EVAP Connector

VSV for ACIS NO. 2

Connector

Vacuum Hose VSV for ACIS NO. 1

Connector

VSV for ACIS NO. 2

B04806

S05515

LEXUS RX300 (RM785E)

FI–62 ELECTRONIC FUEL INJECTION – VSV FOR ACOUSTIC CONTROL INDUCTION

SYSTEM (ACIS)

FI0VX–01

INSPECTION

1. REMOVE V–BANK COVER, AND EMISSION CON-

TROL VALVE SET

2. REMOVE VSV

(a) Disconnect the 2 vacuum hoses from the VSV.

(b) Remove the screw and VSV.

Ohmmeter Continuity 3. INSPECT VSV FOR OPEN CIRCUIT

Using an ohmmeter, check that there is continuity between

each terminals.

Resistance: 33 – 39 Ω at 20°C (68°F)

If there is no continuity, replace the VSV.

S04525

Ohmmeter 4. INSPECT VSV FOR GROUND

No Continuity

Using an ohmmeter, check that there is no continuity between

each terminal and the body.

If there is continuity, replace the VSV.

S04524

Air

5. INSPECT VSV OPERATION

(a) Check that air flows from port E to the filter.

Filter

FI6393

(b) Apply battery voltage across the terminals.

Air (c) Check that air flows from port E to port F.

If operation is not as specified, replace the VSV.

6. REINSTALL VSV

(a) Install the VSV with the screw.

E

(b) Connect the 2 vacuum to the VSV.

7. REINSTALL EMISSION CONTROL VALVE SET

F 8. REINSTALL V–BANK COVER

Battery

S04523

LEXUS RX300 (RM785E)

FI–63

ELECTRONIC FUEL INJECTION – WATER TEMPERATURE SENSOR

WATER TEMPERATURE SENSOR FI0VY–01

INSPECTION

1. DRAIN ENGINE COOLANT

2. REMOVE WATER TEMPERATURE SENSOR

(a) Disconnect the water temperature sensor connector.

ECT Switch 19 mm

Deep Socket (b) Using a 19 mm deep socket wrench, remove the water

Wrench temperature sensor and gasket.

Gasket S04759

3. INSPECT WATER TEMPERATURE SENSOR

Using an ohmmeter, measure the resistance between the ter-

Ohmmeter minals.

Resistance: Refer to the graph

If the resistance is not as specified, replace the water tempera-

ture sensor.

4. REINSTALL WATER TEMPERATURE SENSOR

(a) Install a new gasket to the water temperature sensor.

Acceptable (b) Using a 19 mm deep socket, install the water temperature

RESISTANCE kΩ

sensor.

Torque: 20 N·m (200 kgf·cm, 14 ft·lbf)

(c) Connect the water temperature sensor connector.

5. REFILL WITH ENGINE COOLANT

TEMPERATURE °C (°F)

S04982

LEXUS RX300 (RM785E)

FI–64

ELECTRONIC FUEL INJECTION – KNOCK SENSOR

KNOCK SENSOR

FI0VZ–01

COMPONENTS

Hood to Cowl Top Seal

24 (245, 18)

LH Wiper Arm and Blade Assembly

RH Wiper Arm and Blade Assembly

RH Cowl Top

Ventilator Louver LH Cowl Top Ventilator Louver

Wiper Motor with Wiper Link

Wiper Motor Connector

x6

Outer Cowl Top Panel

N·m (kgf·cm, ft·lbf) : Specified torque

B13138

LEXUS RX300 (RM785E)

FI–65

ELECTRONIC FUEL INJECTION – KNOCK SENSOR

19.5 (200, 14)

PS Pressure 39 (400, 19)

Tube

V–Bank Cover Fastener

Air Intake Chamber Stay V–Vank Cover

Throttle Position

No. 1 Engine Sensor Connector

Hanger

43 (440, 32)

VSV Connector

for EVAP

Ground Cable IAC Valve Accelerator Cable

Connector

Brake Booster

Vacuum Hose

Ground Cable Cruise Control Cable

Water Bypass Hose

Ground Strap

PCV Hose Vacuum Hose

Air Intake Chamber Purge Hose

Assembly

z Gasket Fuel Hose Clamp

15 (150, 11)

No. 1 VSV Connector for ASIC

Water Bypass x9

Upper Radiator Hose

Water Temperature Heater Hose

Hose

Sensor Connector

Ground Strap Intake Manifold

Connector Assembly

15 (150, 11)

Injector Connector

Water Outlet

Knock Sensor

z Gasket Connector

z Gasket

Knock Sensor

39 (400, 29)

N·m (kgf·cm, ft·lbf) : Specified torque

z Non–reusable part B12954

LEXUS RX300 (RM785E)

FI–66

ELECTRONIC FUEL INJECTION – KNOCK SENSOR

FI0W0–01

INSPECTION

1. REMOVE AIR CLEANER HOSE

2. REMOVE RH ENGINE MOUNTING STAY

3. REMOVE INTAKE MANIFOLD ASSEMBLY AND

WATER OUTLET (See page EM–33)

4. REMOVE KNOCK SENSORS

(a) Disconnect the knock sensor connector.

Knock Sensor 1 (b) Using SST, remove the knock sensor.

SST

SST 09817–16011

Knock Sensor 2

P20115

5. INSPECT KNOCK SENSORS

Using an ohmmeter, check that there is no continuity between

Ohmmeter

the terminal and body.

If there is continuity, replace the sensor.

6. REINSTALL KNOCK SENSORS

(a) Using SST, install the knock sensor.

SST 09817–16011

Torque: 39 N·m (400 kgf·cm, 29 ft·lbf)

P01630 (b) Connect the knock sensor connector.

7. REINSTALL WATER OUTLET AND INTAKE

MANIFOLD ASSEMBLY (See page EM–60)

8. REINSTALL RH ENGINE MOUNTING STAY

9. REINSTALL AIR CLEANER HOSE

LEXUS RX300 (RM785E)

FI–67

ELECTRONIC FUEL INJECTION – AIR–FUEL RATIO (A/F) SENSOR

Bank 1 Sensor 1

Ohmmeter

AIR–FUEL RATIO (A/F) SENSOR FI0W1–01

+B HT INSPECTION

INSPECT HEATER RESISTANCE OF A/F SENSORS

(a) Disconnect the A/F sensor connector.

(b) Using an ohmmeter measure the resistance between ter-

minals +B and HT.

Resistance: 0.8 – 1.4 Ω at 20°C (68°F)

If the resistance is not as specified, replace the sensor.

Bank 2 Sensor 1 Torque: 44 N·m (440 kgf·cm, 31 ft·lbf)

(c) Reconnect the A/F sensor connector.

Ohmmeter

+B HT

B00738

LEXUS RX300 (RM785E)

FI–68

ELECTRONIC FUEL INJECTION – OXYGEN SENSOR (Bank 1 Sensor 2)

OXYGEN SENSOR (Bank 1 Sensor 2)

FI0W2–01

COMPONENTS

Passenger’s Seat

37 (375,27)

Connector

for Seat

Heated Oxygen Sensor

Connector

(Bank 1 Sensor 2)

B05024

LEXUS RX300 (RM785E)

FI–69

ELECTRONIC FUEL INJECTION – OXYGEN SENSOR (Bank 1 Sensor 2)

FI0W3–01

Bank 1 Sensor 2 Ohmmeter INSPECTION

+B HT INSPECT HEATER RESISTANCE OF HEATED OXYGEN

SENSOR (Bank 1 Sensor 2)

(a) Remove the driver’s seat.

(b) Take out the floor carpet.

(c) Disconnect the oxygen sensor connector.

(d) Using an ohmmeter, measure the resistance between the

terminals +B and HT.

B05022

Resistance: 11 – 16 Ω at 20°C (68°F)

If the resistance is not as specified, replace the sensor.

Torque: 44 N·m (440 kgf·cm, 31 ft·lbf)

(e) Reconnect the oxygen sensor connector.

(f) Reinstall the floor carpet.

(g) Reinstall the driver’s seat.

LEXUS RX300 (RM785E)

FI–70

ELECTRONIC FUEL INJECTION – ENGINE ECU

ENGINE ECU

FI0W4–01

COMPONENTS

Engine ECU

Engine ECU Connector

No.2 Instrument

Lower Panel

Under Cover

B04961

LEXUS RX300 (RM785E)

FI–71

ELECTRONIC FUEL INJECTION – ENGINE ECU

FI0W5–01

INSPECTION

1. REMOVE ENGINE ECU

2. INSPECT ENGINE ECU (See page DI–19)

3. REINSTALL ENGINE ECU

LEXUS RX300 (RM785E)

FI–72

ELECTRONIC FUEL INJECTION – FUEL CUT RPM

FUEL CUT RPM FI0W6–01

INSPECTION

1. REMOVE V–BANK COVER

(a) Using a 5 mm hexagon wrench, remove the 2 cap nuts.

(b) Disconnect the 2 clips, and remove the V–bank cover.

2. WARM UP ENGINE

Allow the engine to warm up to normal operating temperature.

A05071

3. CONNECT HAND–HELD TESTER OR OBDII SCAN

Hand–Held Tester TOOL

(a) Connect the hand–held tester or OBDII scan tool to the

DLC3.

(b) Please refer to the hand–held tester or OBDII scan tool

operator’s manual for further details.

DLC3 D09456

Sound Scope 4. INSPECT FUEL CUT OFF PRM

(a) Increase the engine speed to at least 3,500 rpm.

(b) Use a sound scope to check for injector operating noise.

(c) Check that when the throttle lever is released, injector op-

eration noise stops momentarily and then resumes.

HINT:

Measure with the A/C OFF.

Fuel return rpm: 1,200 rpm

B04808 5. DISCONNECT HAND–HELD TESTER OR

OBDII SCAN TOOL

6. REINSTALL V–BANK COVER

HINT:

For fixing the V–bank cover, push on the cover until a ”click” is

felt.

LEXUS RX300 (RM785E)

You might also like

- P1656 PDFDocument3 pagesP1656 PDFTalleban TalNo ratings yet

- Sfi System: PrecautionDocument60 pagesSfi System: PrecautionChristian Linares AbreuNo ratings yet

- 1NZ-FE Engine Control System PDFDocument12 pages1NZ-FE Engine Control System PDFjuan100% (1)

- Motores 4H Series MT-OrG (150-170)Document21 pagesMotores 4H Series MT-OrG (150-170)VictorNo ratings yet

- Efi 1az-Fse PDFDocument60 pagesEfi 1az-Fse PDFfrank mutale93% (30)

- 1996-2001 Fuso - Electrical-Sm78Document251 pages1996-2001 Fuso - Electrical-Sm78Poon Electronic Training CentreNo ratings yet

- Subaru 2004 Forester XT Transmission TCM IO PinoutDocument3 pagesSubaru 2004 Forester XT Transmission TCM IO PinoutMarco Cisternas100% (3)

- 2AZ-FE FuelDocument43 pages2AZ-FE FuelAdedeji OluwatobilobaNo ratings yet

- Ex CAT 390Document4 pagesEx CAT 390Rhyan FF100% (1)

- The Making of Japanese Manchuria, 1904-1932 (Etc.)Document550 pagesThe Making of Japanese Manchuria, 1904-1932 (Etc.)Parqui Vilca FringsNo ratings yet

- Chapter5 Efi SystemDocument74 pagesChapter5 Efi SystemDavid Perez NavarroNo ratings yet

- EWD595EDocument272 pagesEWD595Empecha80% (5)

- Removing Mitsubishi Pajero ECUDocument2 pagesRemoving Mitsubishi Pajero ECUJose GilmerNo ratings yet

- Ecs 1KDDocument33 pagesEcs 1KDNguyễn Văn ƬhanhNo ratings yet

- MGA Workshop ManualDocument296 pagesMGA Workshop ManualTony CapuanoNo ratings yet

- SCMDocument181 pagesSCMJeremy Taylor50% (2)

- English Visit Visa Form v7Document4 pagesEnglish Visit Visa Form v7Tabish BhatNo ratings yet

- Checking VVT Sensor PDFDocument6 pagesChecking VVT Sensor PDFDoDuyBacNo ratings yet

- Electrical Wiring Diagram: TOYOTA: Hilux Sport RiderDocument60 pagesElectrical Wiring Diagram: TOYOTA: Hilux Sport RiderThiri HlaingNo ratings yet

- Automatic Transaxle Manual PDFDocument429 pagesAutomatic Transaxle Manual PDFJeff UptagrafftNo ratings yet

- A Day at The AirportDocument22 pagesA Day at The AirportBiblioteca Contadero100% (1)

- 1G FUEL SYSTEM (DOHC) - Service Adjustment ProceduresDocument40 pages1G FUEL SYSTEM (DOHC) - Service Adjustment ProceduresAgus Prasetyanto100% (1)

- MM ConfigDocument37 pagesMM Configsaifrahman1234No ratings yet

- 4JVP44 We 0111Document238 pages4JVP44 We 0111Elkin Martínez SilvaNo ratings yet

- Control System 1Document34 pagesControl System 1Shrinivas Prabhu100% (4)

- Acoustic Emission PDFDocument17 pagesAcoustic Emission PDFAMIGO100% (1)

- Engine ControlDocument4 pagesEngine ControlJoné Jaquay100% (1)

- NISSAN Note (E11) 1.4 16V CR14DE: Timing Chain: Removal/installationDocument13 pagesNISSAN Note (E11) 1.4 16V CR14DE: Timing Chain: Removal/installationmanuel arturo ralda de leonNo ratings yet

- 830e Ac PDFDocument4 pages830e Ac PDFwhmidi7331No ratings yet

- Coaching - Miscellaneous Topics - Part 1 - 30 April 2022Document50 pagesCoaching - Miscellaneous Topics - Part 1 - 30 April 2022Mayya Bona100% (1)

- Electronic Engine Controls TDV6 2.7Document10 pagesElectronic Engine Controls TDV6 2.7elisei sorinNo ratings yet

- Insp Valve Clearance 2.7 3rz PDFDocument5 pagesInsp Valve Clearance 2.7 3rz PDFEdwin Versteeg100% (1)

- Technical File - Yuchai - YC6T 540 C BEURSMOTOR PDFDocument2 pagesTechnical File - Yuchai - YC6T 540 C BEURSMOTOR PDFanto starlinNo ratings yet

- cx5 MitsubichiDocument554 pagescx5 MitsubichiJULIAN VALDERRAMA50% (2)

- C1201 DTC TroubleshootingDocument2 pagesC1201 DTC TroubleshootingMelvineJSTemple100% (3)

- Electronic Diesel Control Is A Diesel Engine Fuel InjectionDocument4 pagesElectronic Diesel Control Is A Diesel Engine Fuel InjectionRoberto Ortega MicalizziNo ratings yet

- Merchant Ship StabilityDocument212 pagesMerchant Ship StabilityJosé Ramón Devan Devan100% (1)

- w58 RebuildDocument49 pagesw58 RebuildtfphoenixNo ratings yet

- Deed of Absolute Sale of A Motor Vehicle - Lorenzo & SelduraDocument1 pageDeed of Absolute Sale of A Motor Vehicle - Lorenzo & SelduraJinJiShinNo ratings yet

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Sequential Fuel Injection SystemDocument66 pagesSequential Fuel Injection SystemCậu TúNo ratings yet

- DiagramaDocument38 pagesDiagramaEdik Bonifacio MamaniNo ratings yet

- Transmission Fluid PDFDocument5 pagesTransmission Fluid PDFLv2mack0% (1)

- Pajero 4WD Flashing Light Fix and TroubleshootingDocument13 pagesPajero 4WD Flashing Light Fix and TroubleshootingAren MendozaNo ratings yet

- Toyota Tercel 1999 Repair Manual..Engine and ChassisDocument10 pagesToyota Tercel 1999 Repair Manual..Engine and Chassisjenlo8338No ratings yet

- Harrop Lc200-1ur InstallDocument22 pagesHarrop Lc200-1ur InstallArtur ElectroMecânicoNo ratings yet

- DTC P1128 Throttle Control Motor Lock Malfunction: Circuit DescriptionDocument1 pageDTC P1128 Throttle Control Motor Lock Malfunction: Circuit DescriptionWillian Jane100% (1)

- Mazda 5 EngineDocument143 pagesMazda 5 EngineAngel CastNo ratings yet

- 2 2az Fe+coolingDocument36 pages2 2az Fe+coolingfredypezNo ratings yet

- 1KD EduDocument5 pages1KD EduMakokha Mumelo100% (1)

- VVT-i (Variable Valve Timing-Intelligent) System: GS430/300 - NEW FEATURES 41Document5 pagesVVT-i (Variable Valve Timing-Intelligent) System: GS430/300 - NEW FEATURES 41Luqman AzamNo ratings yet

- Automatic Transmission Unit (1Hd Fte) : ComponentsDocument1 pageAutomatic Transmission Unit (1Hd Fte) : Componentsjoe nathanNo ratings yet

- Ford Ranger Mazda BT-50 Oil Pump PrimingDocument1 pageFord Ranger Mazda BT-50 Oil Pump PrimingMaster XeotoNo ratings yet

- 3RZ Engine TimingDocument1 page3RZ Engine TimingRoberto RizzaNo ratings yet

- 03 Oct 16 Isuzu KB My16 SpecsDocument3 pages03 Oct 16 Isuzu KB My16 SpecsDieu PhamNo ratings yet

- Repair Manual - 2AR-FE (Engine Control) - SFI System - P1603, P1605Document67 pagesRepair Manual - 2AR-FE (Engine Control) - SFI System - P1603, P1605hoàng gia bùiNo ratings yet

- Electronically Controlled Transmission Communication CircuitDocument3 pagesElectronically Controlled Transmission Communication CircuitErln Lima100% (1)

- Workshop Manual: N SeriesDocument5 pagesWorkshop Manual: N SeriesAlexander NeyraNo ratings yet

- Tormoza HD-120 PDFDocument91 pagesTormoza HD-120 PDFанджелаNo ratings yet

- Ecuf HelpDocument22 pagesEcuf HelpАндрей МихайловичNo ratings yet

- Mitsubichi Minicab SpecificationDocument5 pagesMitsubichi Minicab SpecificationstdsaaNo ratings yet

- DTC P0120/41 Throttle/Pedal Position Sensor/Switch "A" Circuit MalfunctionDocument6 pagesDTC P0120/41 Throttle/Pedal Position Sensor/Switch "A" Circuit MalfunctionMiguel ruizNo ratings yet

- CS9153Document9 pagesCS9153Antony BurgersNo ratings yet

- EMISSION CONTROL SYSTEM (2AZ FE) CamryDocument30 pagesEMISSION CONTROL SYSTEM (2AZ FE) CamryRahmat HidayatNo ratings yet

- Кардан Передний Задний Мосты LGPRO-WE-0554 - 1st - WSMW - 05 - N - G.Exp - 729Document188 pagesКардан Передний Задний Мосты LGPRO-WE-0554 - 1st - WSMW - 05 - N - G.Exp - 729Dmitry BondarNo ratings yet

- Newrexton Ewd Cewd05009Document6 pagesNewrexton Ewd Cewd05009nicamarcosNo ratings yet

- Service Manual Hyundai h35-45d-7 Brake SystemDocument9 pagesService Manual Hyundai h35-45d-7 Brake SystemПетрNo ratings yet

- Fault Codes: Diesel (1KD-FTV - D-4D)Document2 pagesFault Codes: Diesel (1KD-FTV - D-4D)Oliver LealNo ratings yet

- Swift Dzire 2012 Service ManualDocument3 pagesSwift Dzire 2012 Service Manualshamim khanNo ratings yet

- 013 - Engine - Throttle - Pedal Position Sensor - Switch A Circuit MalfunctionDocument4 pages013 - Engine - Throttle - Pedal Position Sensor - Switch A Circuit MalfunctionMortada AlsonniNo ratings yet

- Engine Control SectionDocument65 pagesEngine Control SectionNguyễn Thanh NhànNo ratings yet

- Crystal ModelsDocument6 pagesCrystal ModelsupenderNo ratings yet

- Gupta 2007Document18 pagesGupta 2007upenderNo ratings yet

- Pages From CH 3Document6 pagesPages From CH 3upenderNo ratings yet

- Pages From CH 3Document6 pagesPages From CH 3upenderNo ratings yet

- MF7203-Dec 16 THEORY-OF-METAL-FORMINGDocument3 pagesMF7203-Dec 16 THEORY-OF-METAL-FORMINGupender100% (1)

- Anna UniversityDocument3 pagesAnna UniversityupenderNo ratings yet

- Papet ID (IE507) : Roll No. ......................... (Total No. of Pages: 02Document2 pagesPapet ID (IE507) : Roll No. ......................... (Total No. of Pages: 02upenderNo ratings yet

- (WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Metal Forming Sample Paper 3 PDFDocument2 pages(WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Metal Forming Sample Paper 3 PDFupenderNo ratings yet

- Siemens Articles On SN Crve Fatigue and Stress StrainDocument37 pagesSiemens Articles On SN Crve Fatigue and Stress StrainupenderNo ratings yet

- Examination Schedule For B.Tech 1 & 5 Semester and M.Tech 1 Semester (Regular & Backlog) December, 2018Document3 pagesExamination Schedule For B.Tech 1 & 5 Semester and M.Tech 1 Semester (Regular & Backlog) December, 2018upenderNo ratings yet

- Creep Strength: Definitions: Creep Is The Tendency of A Solid Material To Move Slowly or Deform Permanently UnderDocument13 pagesCreep Strength: Definitions: Creep Is The Tendency of A Solid Material To Move Slowly or Deform Permanently UnderupenderNo ratings yet

- Different Types of PlagiarismDocument4 pagesDifferent Types of Plagiarismupender100% (1)

- Research Approach: Deductive Research Approach Inductive Research Approach Abductive Research ApproachDocument10 pagesResearch Approach: Deductive Research Approach Inductive Research Approach Abductive Research ApproachupenderNo ratings yet

- Research Lecture 2Document17 pagesResearch Lecture 2upenderNo ratings yet

- Research Lecture 1Document15 pagesResearch Lecture 1upenderNo ratings yet

- Research Methodology: (BUMA-331)Document103 pagesResearch Methodology: (BUMA-331)upenderNo ratings yet

- Intellectual Property Rights: CSCI 327 Social Implications of ComputingDocument22 pagesIntellectual Property Rights: CSCI 327 Social Implications of ComputingupenderNo ratings yet

- I. Types and ContentDocument4 pagesI. Types and ContentupenderNo ratings yet

- RM SyllabusDocument1 pageRM SyllabusupenderNo ratings yet

- 2 Material Science EE S4 B.Tech KTU 2017 PDFDocument1 page2 Material Science EE S4 B.Tech KTU 2017 PDFupenderNo ratings yet

- Combustion in Spark-Ignition EnginesDocument46 pagesCombustion in Spark-Ignition EnginesupenderNo ratings yet

- Maha Booklet LD DesignDocument6 pagesMaha Booklet LD DesignM S GokulNo ratings yet

- Timing Belt, Gear and Pulleys Opel Zafira-BDocument4 pagesTiming Belt, Gear and Pulleys Opel Zafira-Bmr & mrsNo ratings yet

- OLADE, Palcee - Latin American and Caribbean Energy Efficiency Program, July 2013Document65 pagesOLADE, Palcee - Latin American and Caribbean Energy Efficiency Program, July 2013Detlef LoyNo ratings yet

- Fuel Additive System Filling and BleedingDocument4 pagesFuel Additive System Filling and Bleedingaalin14No ratings yet

- List TT DevicesDocument102 pagesList TT DevicesAhmetović Sabahudin0% (1)

- TER36055 - V3.0 SG Ed1 CE PDFDocument914 pagesTER36055 - V3.0 SG Ed1 CE PDFDragos ComanNo ratings yet

- Tracing The Development of Mediterranean Medieval Warships From The 11th To 15th CenturyDocument14 pagesTracing The Development of Mediterranean Medieval Warships From The 11th To 15th Centuryموسى رجبNo ratings yet