0% found this document useful (0 votes)

406 views21 pagesControlling Vibration in Machining Operations

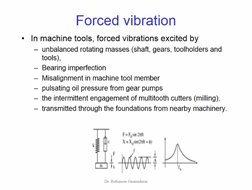

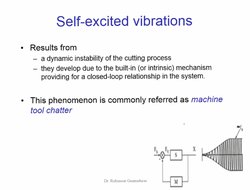

Vibration is common in machining and must be controlled to improve accuracy and productivity. There are three main types of vibration: free vibration caused by impulses, forced vibration excited by unbalanced masses or imperfections, and self-excited or chatter vibration resulting from a dynamic instability in the cutting process. Forced vibration can cause surface irregularities while chatter is more difficult to control and influences surface finish, accuracy, tool life, and machining rates. Chatter occurs due to variability in cutting forces and work hardening and can be destructive.

Uploaded by

Leo Dev WinsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

406 views21 pagesControlling Vibration in Machining Operations

Vibration is common in machining and must be controlled to improve accuracy and productivity. There are three main types of vibration: free vibration caused by impulses, forced vibration excited by unbalanced masses or imperfections, and self-excited or chatter vibration resulting from a dynamic instability in the cutting process. Forced vibration can cause surface irregularities while chatter is more difficult to control and influences surface finish, accuracy, tool life, and machining rates. Chatter occurs due to variability in cutting forces and work hardening and can be destructive.

Uploaded by

Leo Dev WinsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Chatter: Introduces the concept of chatter in machining, setting the context for subsequent sections.

- Vibration: Describes the role of vibration in machining operations and its impact on accuracy and productivity.

- Types of Vibration: Outlines different vibration types: free, forced, and self-excited vibrations.

- Free Vibration: Explains the characteristics of free vibrations and their decay over time.

- Forced Vibration: Discusses the causes and consequences of forced vibrations in machine tools.

- Self-Excited Vibrations: Focuses on self-excited vibrations, also known as machine tool chatter, and their causes.

- Mechanism of Chatter: Describes the mechanisms behind chatter, including regenerative and mode coupling effects.

- Effect of Chatter: Examines the detrimental effects of chatter on tools and machining processes.

- Factors Affecting Chatter: Identifies factors contributing to chatter, such as machine rigidity and cutting speed.

- Elimination of Chatter: Provides strategies for eliminating chatter through optimal parameter selection and damping techniques.