Professional Documents

Culture Documents

UNIT 4 (Suppositories)

Uploaded by

Prashant307100%(5)100% found this document useful (5 votes)

3K views17 pagesSuppositories are solid or semi-solid dosage forms that are inserted into body orifices to dissolve or melt and exert local or systemic drug effects. They have advantages like direct drug delivery to the rectum, use in unconscious patients, and avoidance of first-pass metabolism. Common suppository bases include cocoa butter and glycerol gelatin. Suppositories are manufactured via various methods like hand molding, compression molding, and pouring melted base into molds. Quality is evaluated based on appearance, weight uniformity, and melting range.

Original Description:

As per PCI syllabus

Original Title

UNIT 4(Suppositories)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSuppositories are solid or semi-solid dosage forms that are inserted into body orifices to dissolve or melt and exert local or systemic drug effects. They have advantages like direct drug delivery to the rectum, use in unconscious patients, and avoidance of first-pass metabolism. Common suppository bases include cocoa butter and glycerol gelatin. Suppositories are manufactured via various methods like hand molding, compression molding, and pouring melted base into molds. Quality is evaluated based on appearance, weight uniformity, and melting range.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(5)100% found this document useful (5 votes)

3K views17 pagesUNIT 4 (Suppositories)

Uploaded by

Prashant307Suppositories are solid or semi-solid dosage forms that are inserted into body orifices to dissolve or melt and exert local or systemic drug effects. They have advantages like direct drug delivery to the rectum, use in unconscious patients, and avoidance of first-pass metabolism. Common suppository bases include cocoa butter and glycerol gelatin. Suppositories are manufactured via various methods like hand molding, compression molding, and pouring melted base into molds. Quality is evaluated based on appearance, weight uniformity, and melting range.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 17

SUPPOSITORIES

Suppositories are semisolid or solid

dosage forms intended for insertion

into body orifices where they melt,

soften, or dissolve and exert localized

or systemic effects.

ADVANTAGES

1. Can exert local effect on rectal mucosa.

2. Used to promote evacuation of bowel.

3. Avoid any gastrointestinal irritation.

4. Can be used in unconscious patients (e.g. during

fitting).

5. Can be used for systemic absorption of drugs and

avoid first-pass metabolism.

6. Babies or old people who cannot swallow oral

medication.

7. Post operative people who cannot be administered

oral medication.

8. People suffering from severe nausea or vomiting.

DISADVANTAGE

1. The problem of patient acceptability.

2. Suppositories are not suitable for patients

suffering from diarrhea.

3. In some cases the total amount of the drug

must be given will be either too irritating or in

greater amount than reasonably can be

placed into suppository.

Ideal Suppository Base

1. Melts at body temperature or dissolves in

body fluids.

2. Non-toxic and non-irritant.

3. Compatible with any medicament.

4. Releases any medicament readily.

5. Easily moulded and removed from the mould.

6. Stable to heating above the melting point.

7. Easy to handle.

8. Stable on storage.

Types of Suppository Base

1. Fatty Bases (Cocoa butter)

2. Water-soluble and water-

miscible bases(Glycero-gelatin)

1. Fatty Bases: designed to melt at body temperature.

• Theobroma oil (Cocoa butter)

It is a yellowish-white solid with an odour of chocolate

and is a mixture of glyceryl esters of different

unsaturated fatty acids.

Advantages:

a- A melting range of 30 - 36°C (solid at room temperature but

melts in the body).

b- Readily melted on warming, rapid setting on cooling.

c- Miscible with many ingredients.

d- Non-irritating.

Disadvantage

a- Polymorphism b- Rancidity on storage c- Expensive

d- Poor water-absorbing ability e- Adherence to the

mould f- Softening point too low for hot climates.

g- Melting point reduced by soluble ingredients

2. Water-soluble and water-miscible bases:

A- Glycero-gelatin:

The commonest is Glycerol Suppositories

Base B.P., which has 14% w/w gelatin, and

70% w/w glycerol & water Q.S. to 100%. .

The glycerol-gelatin base U.S.P. consisted

of 20% w/w gelatin, and 70% w/w glycerol

& water Q.S. to 100%.

B- Macrogols (polyethylene glycols):

Polyethylene glycols (PEGs) having

average molecular weights of 300, 400,

and 600 are clear, colorless liquids,

while those with molecular weights of

600-1000 are semisolids.

•Molecular weights of greater than

1000 are wax-like.

Preparation of Suppositories

1. Hand moulding:

Hand molding is useful when we are preparing a small number of

suppositories:

1. The drug is made into a fine powder.

2. It is incorporated into the suppository base by triturating in a

mortar.

3. The triturated mass is rolled between fingers into rod shaped

units.

4. The rods are cut into pieces and then one end is pointed.

2. Compression moulding:

The cold mass of the base containing the drug is

compressed into suppositories using a hand operated

machine.

Advantages:

1. It is a simple method.

2. It gives more elegant suppositories than hand moulded.

3. In this method sedimentation of solids in the base is

prevented.

4. Suitable for heat labile medicaments.

Disadvantages:

1. Air entrapment may take place.

2. This air may cause weight variation.

3. The drug and/or the base may be oxidized by this air.

3. Pour moulding:

Using a suppository mould which is made of

metal or plastic. Traditional metal moulds are in

two halves which are clamped together with a

screw.

Steps:

1. The base is melted (no overheat ).

2. The drug is incorporated in it.

3. The melted liquid mass is poured into pre-

lubricated(water soluble for fatty base/ oily for

water soluble base) chilled moulds.

4. After solidification with fairly stiff brush

suppositories are removed.

4. Automatic Moulding machine:

All the operations in pour moulding are done by

automatic machines. Using this machine, up to

about 10,000 suppositories per hour can be

produced.

Displacement Value (DV)

The no. of parts of medicament (DRUG) that

displaces one part by weight of the base is known

as the displacement value of the drug.

Or

Displacement value is defined as “the quantity of

the drug which displaces one part of the base".

The DV of given medicament may be determined as follows:-

i. Prepare & weigh 6 suppositories containing Theobroma oil= a gm

ii. Prepare & weigh 6 suppositories containing , say 40% of DRUG= b gm

iii. Calculate the amount of theobroma oil present in medicated suppositories= (60/100)×b=c gm

iv. Calculate the amount of medicament present in medicated suppositories= (40/100)×b= d gm

v. Calculate the amount of theobroma oil displaced by ‘d gm’ of medicament= (a-c) gm

vi. Displacement value of medicament= d/(a-c)

Evaluation of suppository

1- Appearance: This includes odour, colour, surface condition and

shape.

2- Weight Uniformity: -

Weigh 20 suppositories individually. w1, w2, w3….w20

Weigh all the suppositories together = W.

Calculate the average weight = W/20.

Limit: Not more than 2 suppositories differ from the average

weight by more than 5%, and no suppository differs from the

average weight by more than 10%.

i.e., NMT 2 Suppositories (out of 20) should be-MT 5% wt.

NO Suppositories (out of 20) should be- MT 10%.

3. Melting range test

• The suppository is completely immersed in the constant

temperature water bath, and the time for the entire suppository

to melt or disperse in the surrounding water is measured.

•The suppository is considered disintegrated when:

A- It is completely dissolved or

B- Dispersed into its component part.

C- Become soft “change in shape” with formation of core which is

not resistant to pressure with glass rod

You might also like

- Experiment No 7 MicromeriticsDocument6 pagesExperiment No 7 MicromeriticsLyka TamarayNo ratings yet

- QC Tests For Ointments and CreamsDocument3 pagesQC Tests For Ointments and CreamsHumzaMasoom100% (1)

- pHARMACEUTICALTechNOLOGY Lab ManualDocument5 pagespHARMACEUTICALTechNOLOGY Lab Manualjunaidniazi188% (8)

- MICROMERITICSDocument33 pagesMICROMERITICSsandymh67% (3)

- 6a. QC of Suppositories2Document8 pages6a. QC of Suppositories2Muhammad Masoom Akhtar100% (1)

- Experiment No: Date: Determination of Bulk Density, True Density and PorosityDocument6 pagesExperiment No: Date: Determination of Bulk Density, True Density and PorosityVishwajeet Ghorpade67% (3)

- Instrumental Methods of Drug AnalysisFrom EverandInstrumental Methods of Drug AnalysisRating: 3 out of 5 stars3/5 (3)

- Topic 9 - SuppositoriesDocument21 pagesTopic 9 - SuppositoriesFilip IlievskiNo ratings yet

- Tablet and Capsule ManufacturingDocument28 pagesTablet and Capsule ManufacturingShibaprasad DandapatNo ratings yet

- Tablets NotesDocument56 pagesTablets NotesLakshmi Kumari100% (1)

- CapsulesDocument100 pagesCapsulesprinceamit100% (1)

- Selection & Evaluation of Pharmaceutical Packaging MaterialsDocument35 pagesSelection & Evaluation of Pharmaceutical Packaging MaterialsTushar Naik50% (2)

- Unit 5 Packaging MaterialsDocument15 pagesUnit 5 Packaging MaterialsRevathiNo ratings yet

- Biphasic Liquid Dosage FromDocument8 pagesBiphasic Liquid Dosage FromSwaroopSinghJakhar100% (1)

- TabletsDocument28 pagesTabletsMuhammad sheraz67% (3)

- Chapter 1 PPT 2 (Container and Closures)Document15 pagesChapter 1 PPT 2 (Container and Closures)Shumaila Qadir100% (2)

- CapsulesDocument84 pagesCapsuleskarthikeyan V100% (1)

- Rheology of Suspensions and EmulsionsDocument17 pagesRheology of Suspensions and EmulsionsHaroon Rahim100% (3)

- Monophasic Liquid Dosage Forms PDFDocument25 pagesMonophasic Liquid Dosage Forms PDFAamir KhanNo ratings yet

- QC of SuppositoriesDocument36 pagesQC of Suppositoriesroma imtiazNo ratings yet

- Quality Control Tests For Tablets and CapsulesDocument27 pagesQuality Control Tests For Tablets and Capsulesasksankar7857100% (2)

- Formulation Consideration of Buccal Delivery System: Presented By: Diwya Kumar Lal 7 Sem/B. PharmacyDocument11 pagesFormulation Consideration of Buccal Delivery System: Presented By: Diwya Kumar Lal 7 Sem/B. PharmacyDiwya KumarNo ratings yet

- Monophasic Liquid Dosage FormDocument20 pagesMonophasic Liquid Dosage FormAkhil Sharma100% (2)

- Regulatory Provisions Related To CosmeticsDocument21 pagesRegulatory Provisions Related To CosmeticsShashidhar Reddy Bodha100% (1)

- Pilot Scale Up Techniques For Semi Dolid Dosage FormsDocument7 pagesPilot Scale Up Techniques For Semi Dolid Dosage FormsNidhiNo ratings yet

- Evaluation of ParenteralsDocument31 pagesEvaluation of ParenteralsDeepak50% (2)

- Factors Affecting Drug Absorption: List of Content: - IDocument13 pagesFactors Affecting Drug Absorption: List of Content: - IMD REFATNo ratings yet

- SOP of D. Pharm Lab. ApparatusDocument8 pagesSOP of D. Pharm Lab. Apparatusramesh joshiNo ratings yet

- Investigational New Drug Application (IND)Document48 pagesInvestigational New Drug Application (IND)Divya100% (1)

- Semisolid Dosage FormsDocument200 pagesSemisolid Dosage Formsved.g007100% (8)

- Physics of Tablet Comp ActionDocument25 pagesPhysics of Tablet Comp ActionPraanav DaNo ratings yet

- Glassware Used in Pharmaceutical Analysis Laboratory: PrinciplesDocument4 pagesGlassware Used in Pharmaceutical Analysis Laboratory: Principlesqueeny75% (4)

- Swelling Index of IspagholDocument2 pagesSwelling Index of Ispagholzero content50% (2)

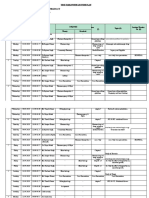

- Unit - I: Solubility of Drugs: Mahatma Gandhi Institute of Pharmacy, LucknowDocument23 pagesUnit - I: Solubility of Drugs: Mahatma Gandhi Institute of Pharmacy, LucknowMukesh TiwariNo ratings yet

- Swami Vivekanand College of Pharmacy, IndoreDocument3 pagesSwami Vivekanand College of Pharmacy, IndoreShubham wani100% (2)

- Different SpeciesDocument16 pagesDifferent SpeciesArchana Pawar0% (1)

- PowdersDocument16 pagesPowdersShumaila Qadir100% (2)

- HCP MCQsDocument2 pagesHCP MCQsRohit GodaseNo ratings yet

- Thin Layer ChromatographyDocument30 pagesThin Layer ChromatographySamson RajNo ratings yet

- Dispensing ProcessDocument39 pagesDispensing ProcessLyca Salarda100% (3)

- Dispensing Pharmacy MCQSDocument25 pagesDispensing Pharmacy MCQSraju narayana padala100% (1)

- Micromeritics (Science of Particles)Document5 pagesMicromeritics (Science of Particles)SwaroopSinghJakhar100% (1)

- Pellets Unit III Part-BDocument44 pagesPellets Unit III Part-BKrishna PrasadNo ratings yet

- Rotary Die ProcessDocument5 pagesRotary Die ProcessM AfanNo ratings yet

- SAR of Aminoglycoside Antibiotics With ExamplesDocument3 pagesSAR of Aminoglycoside Antibiotics With ExamplesSimran SidhuNo ratings yet

- D7 Quality Control Tests For Suspension & Emulsions Finalized OkDocument36 pagesD7 Quality Control Tests For Suspension & Emulsions Finalized OkAlishba Mushtaq100% (3)

- Pharmaceutical AidsDocument3 pagesPharmaceutical AidsAjinkya Jagtap100% (2)

- Quality Control of Sterile ProductsDocument10 pagesQuality Control of Sterile ProductsMuhammad Masoom AkhtarNo ratings yet

- Vehiles For ParentralDocument9 pagesVehiles For ParentralEnamul HasanNo ratings yet

- UNIT 2 ELIMINATION and BIOAVAILABILITY & BIOEQUIVALENCE PDFDocument207 pagesUNIT 2 ELIMINATION and BIOAVAILABILITY & BIOEQUIVALENCE PDFMamta Pant100% (4)

- Question Bank of Pharmaceutics I: Multiple Choice Questions (1 Marks Each)Document6 pagesQuestion Bank of Pharmaceutics I: Multiple Choice Questions (1 Marks Each)Khushboo Dhaval KatharotiyaNo ratings yet

- DISINFECTIONDocument39 pagesDISINFECTIONSaravanan Rajagopal50% (2)

- Tute SuppositoriesDocument4 pagesTute Suppositoriesshaf.shiyamNo ratings yet

- Pharmaceutical Suppositories & PessariesDocument34 pagesPharmaceutical Suppositories & PessariesAh Boon100% (1)

- Suppositories & PessariesDocument26 pagesSuppositories & PessariesHamdiNo ratings yet

- Suppositories and PessariesDocument31 pagesSuppositories and PessariesMAHALAKSHMI SNo ratings yet

- SuppositoriesDocument14 pagesSuppositoriesESTHER WONG TZE YIING -No ratings yet

- Pharmaceutical Dosage Forms: Mscs in Pharmaceutical SciencesDocument77 pagesPharmaceutical Dosage Forms: Mscs in Pharmaceutical SciencesObada Sibai100% (1)

- 2 Practical Lab Manual BIOCHEMISTRY2Document66 pages2 Practical Lab Manual BIOCHEMISTRY2Prashant307No ratings yet

- Posology: Factors Affecting Drug DosageDocument11 pagesPosology: Factors Affecting Drug DosagePrashant307100% (1)

- UNIT 2 (Pharmaceutics I) PDFDocument46 pagesUNIT 2 (Pharmaceutics I) PDFPrashant307100% (1)

- Period:: Classification of MicrobesDocument7 pagesPeriod:: Classification of MicrobesPrashant307No ratings yet

- UNIT 2 (Pharmaceutics I)Document46 pagesUNIT 2 (Pharmaceutics I)Prashant307No ratings yet

- First-Order Kinetics: Whose I.E. Greater The Concentration, Faster The ReactionDocument12 pagesFirst-Order Kinetics: Whose I.E. Greater The Concentration, Faster The ReactionPrashant307No ratings yet

- First-Order Kinetics: Whose I.E. Greater The Concentration, Faster The ReactionDocument12 pagesFirst-Order Kinetics: Whose I.E. Greater The Concentration, Faster The ReactionPrashant307No ratings yet

- Unit 1 (Pharmaceutics I) PDFDocument27 pagesUnit 1 (Pharmaceutics I) PDFPrashant307100% (2)