Professional Documents

Culture Documents

Ago 19 PDF

Ago 19 PDF

Uploaded by

Danay ChOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ago 19 PDF

Ago 19 PDF

Uploaded by

Danay ChCopyright:

Available Formats

Canada

Reclamation of Canmore Creek;

Example of a successful walk away pit lake closure

by H. Gerry Stephenson and Devin Castendyk

Quarry Lake at

Canmore Creek is

O ne of the most important environmental

issues associated with contemporary openpit

mining is the closure of mine pit lakes, and the

Peer-reviewed publications of successful walk

away, pit lake closure provide mining companies

with the ability to address public concerns

a former openpit perpetual legacy these lakes can potentially regarding the safety of pit lakes which commonly

coal mine that is generate. Ideally, successful pit lake closure occur during the permitting, operations, and

now a popular includes the following: closure phases of mining. To date, most published

tourist site. work on walk away, pit lake closure work has

•

The water quality within the pit lake, occurred in the coal mining sector in Germany

plus surface water and ground water and Australia (McCullough et al., 2009; Jones and

discharging from the pit lake, meets pre- McCullough, 2011; Kumar et al., 2013; Schultz et

mining or other acceptable water quality al., 2013). In North America, examples of walk

conditions of the receiving environment. away, pit lake closure are not widely discussed

• The termination of all active treatment in the literature despite there being excellent

processes. examples from the coal mining sector in Alberta,

• The return of the pit lake to the Canada (e.g. Pleasure Island, Black Diamond,

government for long-term care and East Pit, Sphynx, Robb, Lovette, Siltstone and

maintenance. Sterling), and from the iron mining sector in

• The release of the mining company from Minnesota in the United States (e.g. Portsmouth

all future liabilities associated with the pit Lake, see MNDNR, 2018). Although seldom

lake. included in discussions of pit lakes from the

• The return of the environmental bond to metal and coal mining sectors, the aggregate and

the mining company. fabricated-stone mining sectors also produce

• The reuse of the pit pit lakes, and there are numerous examples

H. Gerry Stephenson is owner of lake for some post-closure, throughout North America where these pit lakes

Terra Cognita Resource Consultant beneficial purpose. have been successfully closed and transformed

and Devin Castendyk, member into post-mining resources (Vandenberg, 2018;

SME, is senior geochemist, Golder, The achievement of these Crossman, 2019). The difficulty of finding

respectively, email devin_casten- goals is known as walk away these good examples in the literature makes

dyk@golder.com. pit lake closure. it challenging for companies to respond to

20 august 2019 Mınıng engıneerıng www.miningengineeringmagazine.com

Canada

Figure 1

Canmore Creek in 1968 with mine waste covering the stream bank.

examples and can better address public concerns.

This article provides a first-person account by

Gerry Stephenson, who was chief mining engineer

of Canmore Mines, who was instrumental in the

planning and reclamation of Canmore Creek

Mine pit lakes into sustainable, post-closure

resources, which are highly valued today by the

local community and tourists. If proposed today,

mining activities in this area — Canmore, AB,

Canada, immediately south of Banff National Park

— would likely generate intense public scrutiny.

The purpose of this article is to raise awareness of

an outstanding example of mine pit lake closure

and reuse and to highlight the vision, planning and

decades-long effort that led to this success.

Site description and history

Mining of semi-anthracite coal in the Bow

River valley near Canmore, Alberta began in

public and regulatory questions regarding 1886. Nine different coal seams were mined

pit lake closure and reuse. As such, there is a by underground methods until the Canmore

pressing need to document the motivations and Mines Ltd. closed down in 1979. The operations

approaches used in examples of successful, walk were always extremely complex with gradients

away, pit lake closure in North America so that between 15° and 90°, very complicated geology

the mining industry, at large, can learn from these and methane emissions up to 2,300 cu ft/st of

22 august 2019 Mınıng engıneerıng www.miningengineeringmagazine.com

Canada

Figure 2

Canmore Creek in 1972 following bank stabilization and revegetation.

in 1968 where he had observed some remarkable

reclamation of land seriously damaged by

coal mining going back to the early years of

the industrial revolution. He took over as the

company’s chief mining engineer and found a

small, but efficient, surface mining operation with

several small pits exhausted and two operating.

The openpits, Canmore Creek Numbers One and

Two, were extracting 3.6-m (12-ft) thick seams

dipping at 80°.

At this time, 1968 to 1974, there were few

regulatory, public or corporate requirements for

reclamation. Obtaining a permit for opening a

surface or underground mine was not difficult.

Bureaucrats with provincial energy, lands and

forests, environment and water departments were

relatively new to their respective fields. There

were no hard and fast provincial mine reclamation

coal produced. In 1966, the company opened standards, water quality standards for mined

several small openpits to boost production for the lands, or monitoring requirements. From a public

Japanese market. Extreme faulting and folding perspective, Canmore had been a mining town

of seams created opportunities for pits with for 90 years, and the whole of the population

economic stripping ratios, though gradients up to depended directly or indirectly on mining. There

90° limited the depth of openpit mining to 37 m was a huge area of undisturbed land, rivers, lakes

(120 ft). and streams surrounding the mine. As such, there

Stephenson arrived from Northern England was very little thought given to the damage being

IDLERS PULLEYS IMPACT BEDS ACCESSORIES

IT TAKES GUTS

to Increase Your Conveying Performance

Luff’s Triple Labyrinth Seal & High Moisture Seal

are standard on all CEMA E rollers.

Combined with a sealed for life SKF Ball Bearing,

Luff provides the ultimate sealing protection for

longer roller life in the toughest applications.

Luff Industries has partnered with SKF

to provide its customers with the best

components available.

Please contact us today for more

information on SKF Equipped Rollers

Toll-free: 1.888.349.LUFF (5833)

Luff Industries Ltd. Email: info@luffindustries.com

Calgary, AB | Orillia, ON | Rancho Cucamonga, CA | Nashville, TN www.luffindustries.com

24 august 2019 Mınıng engıneerıng www.miningengineeringmagazine.com

Canada

Figure 3

Canmore Creek in 2018 with 9 m (30 ft) high trees. The triangular boul-

der in the stream is the same boulder shown in Figs. 1 and 2.

site. No separation of overburden had been

attempted so, spoil heaps contained a mixture of

soil, gravel, rock and coal waste, spiced up with

wire rope and spilled oil. Although water quality

was not analyzed in a laboratory before, during or

after mining, water pollution was evident based

on qualitative, visual inspection of turbidity and

aquatic life. Overburden was being dumped over

the bank of Canmore Creek where vegetation

had been destroyed, heavy siltation had occurred,

and the cutthroat trout had disappeared as had

all insect life (Fig. 1). No reclamation had been

attempted and the mining plans had omitted

any procedures to facilitate remedial work. This

was accepted practice in the Rocky Mountains

of Alberta at the time, where coal was being

mined at elevations up to 1,370 m (4,500 ft), with

temperatures down to -31 °C (-25 °F) in winter

and very short summers. Locals described the

done by coal mining. Likewise, the company had climate as seven months of winter and five months

no policy on reclamation partly because, at that of poor skiing.

time, surface mining had recently started and the The Canmore mines were operating adjacent

problems were not seen to be very serious. to Banff National Park and wildlife was abundant,

Consequently, the mines were not a pretty with bighorn sheep using abandoned highwalls

UNIQUE PROBLEMS

REQUIRE UNIQUE SOLUTIONS

Polydeck’s custom SVR

panels solve blinding

and boost throughput at

Canadian gold mine.

Download the complete case

study at: polydeck.com/bellcreek

26 august 2019 Mınıng engıneerıng www.miningengineeringmagazine.com

Canada

Figure 4

Canmore Creek Mine Number 2 during backfilling in 1972.

for refuge and as salt licks. Deer and elk were

numerous, and predators included cougars, wolves,

wolverines and black and grizzly bears. It was

clear that, unless steps were taken to develop

and apply methods of reclamation designed

for the climate and the landscape, with serious

consideration given to the impact on wildlife,

applications for future mine permits were not

going to be enthusiastically received by the

provincial government. The future of the company

was tenuous.

Creek bank stabilization and revegetation

Clearly the priority was to clean up the mess

caused by past mining. The first task was to

rehabilitate the bank of Canmore Creek. This

would provide an opportunity to experiment silt were available and were mixed 50/50, the

with a variety of procedures for stabilizing silt providing weight and the peat, moisture

spoil, finding soil, formulating appropriate seed retention. This mixture was poured down

mixtures and seasonal timing. The mine waste the terraced bank covering 80 percent of the

was lying at the natural angle of repose, about slope with 15 to 25 cm (6 to 10 in.) of soil.

40°, and stabilization without further damage to Hydro seeding with seed, water and fertilizer

the creek was needed. Backhoes were used to went ahead using various seed mixtures.

create terraces on the 12-m (40-ft) high pile but Each mixture contained native seeds which

of course, there was no soil. However, peat and included:

28 august 2019 Mınıng engıneerıng www.miningengineeringmagazine.com

Canada

• Grasses with a short life capable of very successful. An area of approximately 1.6

rooting quickly to stabilize the soil. ha (4 acres) between the pond and Canmore

• Grasses with a long life capable of self- Creek was covered with gravel which filtered the

seeding. overflow from the pond to remove silt before

• Legumes such as clover. the water entered the rehabilitated Canmore

Creek (Fig. 5). The revegetation of the area was

A proven system of mulching was employed carried out in similar fashion to the creek bank

using a mixture of chopped straw and a small with some modifications based on the previous

amount of asphalt to bind the straw together. A experiment at that location. For example, it was

layer of mulch approximately 10 cm (4 in.) thick important to hydroseed and mulch late in the year

was laid down creating a micro climate

over the seeded soil below. The creek

bank was completed in 1970 and, within

two years, there was a healthy crop of

grasses up to 30 cm (12 in.) high covering

A Full Line of

the river bank (Fig. 2). The soil layer and

the vegetation held firm over most of the Conveyor Belt

bank. This experiment, the first attempt

at remediation of an industrial site in the Fasteners

area, had been successful. A great deal

had been learned which could be applied

to the subsequent reclamation of openpit

mine sites.

Since this work was done, the bank

has been completely rehabilitated by

nature with native shrubs and 9-m (30-

ft) high trees growing on the original

soil and the weathered rock (Fig. 3).

The stream runs clear, and trout and

invertebrates have returned.

Reclamation of Canmore Creek Mines

Numbers 1 and 2

These two openpits were completed

in 1972 but without any plans for

reclamation. There were two parallel

pits, each about 37 m (120 ft) deep with

spoil piles of gravel, soil and rock mixed

together along both sides of the two pits,

plus a spoil pile extending down and

into the creek at the west end. The area

affected by mining was approximately

MS® Fasteners

610 m by 365 m (2,000 ft by 1,200 ft) —

not a large area, but one with plenty of

problems. There was a small, spring-fed

stream discharging into the area from

the east end. Approximately 60 percent

of the waste was bulldozed back into

the openpits (Fig. 4), with an attempt

being made to keep gravel for use during

contouring. The waste remaining in the

spoil pile was contoured to create stable Innovative products, easy to install !

slopes.

A small dam was built across the 2011 Nuggett Rd, High Point, NC 27263

area which it was hoped would form a Phone 336.434.0363 • Fax 336.434.2263

pond with an area of 1.2 ha (3 acres)

and a depth of 3 m (10 ft). This was MLTNorthAmerica.com

www.miningengineeringmagazine.com Mınıng engıneerıng august 2019 29

MLT ME ad_4.5x7_halfpageisland.indd 1 7/9/19 8:34 PM

Canada

Figure 5

Canmore Creek Mine Number 2 after backfilling in 1972.

before winter arrived. This encouraged seed to

germinate in spring when the air warmed up and

the snow melted.

Within two years, there was a healthy

vegetative cover of grasses and legumes as well

as some small transplanted trees (Fig. 6). The

pond quickly became a home for brook trout and

salamanders, hence the new name, Salamander

Pond. Today, it is difficult to see any scars left

by mining. The 1.2-m (4-ft) tall trees that were

planted are now 9-m (30-ft) tall, while Salamander

Pond looks absolutely natural.

Development and operation of Canmore Creek

Mine Number 3

In 1972, a new openpit began producing coal

in an area where the folding of seams 3 to 3.6 m

Figure 6 (10 to 12 ft) in thickness had resulted in doubling

of the coal thickness on anticlinal and synclinal

Canmore Creek Mine Number 2 after reclamation in 1974, renamed

folds with seams dipping at up to 70°. The openpit

Salamander Pond.

was designed for a depth of 37 m (120 ft) at a

low stripping ratio. For the first time, a new pit

was planned with the benefit of experience in

the rehabilitation and revegetation of mined

land (Stephenson, 1974), and, equally important,

the capability to include measures that would

facilitate the rehabilitation process as part of the

mining operation. These included:

• Excavating the soil, gravel and rock

separately.

• Placing these materials in locations

convenient for creating a new landscape.

• Incorporating springfed streams into the

finished landscape, and creating a lake.

Coal extraction was completed in early 1973,

and created a rectangular pit 365-m (1,200-ft)

long, 150-m (500-ft) wide and 36-m (120-ft)

Figure 7 deep (Fig. 7). The perimeter had almost vertical

Canmore Creek Mine Number 3 after mining in 1973. cliffs along the two longer sides with slopes of

20° to 30° elsewhere. A gravel bed extended up

the lower slopes of the 2,743-m (9,000-ft) high

mountain range alongside the pit to an elevation

of 1,980 m (6,500 ft) where the thickness of

gravel was 31 m (100 ft) or more. Every spring,

melting ice and snow from the mountainside

fed a large aquifer in the gravel. This aquifer,

in turn, discharged clear water into the openpit

at the interface of the bedrock and the gravel

throughout the year, even in the middle of winter.

During mining, this water had been a problem. In

closure, it became an asset valued for its quality

and uniform flow, for here was the essential

element that would allow the development of

a water body in the openpit excavation which

might, someday, be worthy of being called a

lake. And, with the 2,743-m (9,000-ft) high Three

30 august 2019 Mınıng engıneerıng www.miningengineeringmagazine.com

Canada

Figure 8

Canmore Creek Mine Number 3 after mining in 1974.

Sisters Peaks towering over the area, this lake could

become a very special place.

The creation of Quarry Lake

In 1974, some of the rock began to be

moved from the spoil piles back into parts of

the excavation. Water from the gravel beds had

filled the excavation to a depth of about 6 m (20

ft). However, the level of the water would go no

higher because the old haul road, which allowed

coal to be trucked from the bottom of the pit,

created an overflow point that limited the depth to

6 m (20 ft) and the size of the water body to about

0.8 ha (2 acres) surrounded by highwalls 15- to

18-m (50- to 60-ft) high. This was a small water

body, but not, by any stretch of the imagination, a

lake. To achieve this, the overflow point needed Figure 9

to be raised. Locating some material with a high Canmore Creek Mine Number 3 after recontouring the land surface in

clay content, a dam was created in the overflow 1976 and creating the water body.

location at the same elevation as the point where

water from the gravel aquifer entered the water

body.

At this point, the province of Alberta took

back control of an area of more than 80 ha (200

acres). This included the mined and reclaimed

land described earlier together with the land that

encompassed the Canmore Creek Number 3 Mine

that had been partially reclaimed. This acquisition

was part of a strategy by the ruling Conservative

Party, led by Premier Peter Lougheed, to develop

Alberta’s mountainous areas, and required far

less regulatory sign off than by today’s standards.

Meanwhile, Stephenson had left his position with

Canmore Mines Ltd. and, with his long-suffering

wife Avice, formed a consulting company based

in Canmore. The provincial government engaged

him to design the completion of reclamation The inflow from the gravel bed aquifer, as

and rehabilitation of the area. Importantly, they anticipated, caused the water level to rise to

encouraged Stephenson to continue with the the perimeter of the pit. The dam successfully

development of a waterbody, hopefully a lake. A blocked the outflow and two years later, there

new reclamation plan was prepared that included: was a water body 24 m (80 ft) deep and 4 ha (10

acres) in area surrounded by gently sloping hills

• Completion of backfilling rock into the (Fig. 8). Still there was not a lake. The water was

excavation designed to leave 40 percent heavily silted from exposed coal and rock in the

of the perimeter as steep cliffs adjacent to bottom of the pit. Methane gas from the exposed

water 6 m (20 ft) deep. coal seams at the bottom of the pit was bubbling

• Reduction of the maximum lake depth to to the surface, and floating debris, mostly logs

24 m (80 ft). and roots, covered much of the surface. It was

• Two shallow beach areas, one at each end expected that the silt would settle over time and

of the water body. that the coal seam would drain of gas very quickly

• Retention of material in the existing spoil as the coal was very gassy but very permeable.

heaps to create gently sloping features 9 m Still, some brave souls, Stephenson not being

(30 ft) high surrounding the water body. one of them, began swimming in the bitingly

• Spreading of gravel and soil from the cold water undeterred by the floating logs and

storage areas on the area affected by the methane gas. Fortunately, over the next two

mining. years, the silt settled, and the water became clear

• Hydroseeding and mulching using enough to give 1 m (3 ft) of visibility (Fig. 9). The

techniques proven by previous experience. coal seams became depleted of methane, and the

www.miningengineeringmagazine.com Mınıng engıneerıng august 2019 31

Canada

Figure 10

Canmore Creek Mine No. 3 was renamed Quarry Lake in 1982 following

reclamation.

Wildlife with small rainbow trout, which did not

work out well as most of them finished up in local

cooking pots. A later planting of arctic grayling

worked well, as these fish can thrive and breed

in the lake (Fig. 11). Today, no more stocking is

necessary, and the eggs are collected and added to

three other Alberta lakes (Stelfox et al., 2005).

At this time, the chairman, Walter Trost,

and vice chairman, Stuart Smith, of Alberta’s

Environment Conservation Authority, visited

the site. They were very impressed, stating that

the work being done in Canmore was the best

they had seen in Western Canada. The 1988

Winter Olympics were centered in Calgary and

the Nordic events were held at Canmore, with

many of the trails built on areas that had been

mined and reclaimed. Visitors began to arrive,

and the Town of Canmore began to develop a

Figure 11 picnic area at the lake with toilets, more trees and

Aerial view of Quarry Lake Park showing the surrounding forested land- enhancement of the beach area. A hiking trail was

scape and adjacent neighborhood. established around the lake and connected to the

Canmore trail system with more than 40 km (25

miles) of trails for hiking and cycling.

In 1999, Hollywood came to Canmore to make

Mystery Alaska, a film about a small-town hockey

team taking on the New York Rangers of the

National Hockey League, starring Russell Crowe

and Burt Reynolds. Consulted about filming

the hockey game on Quarry Lake, Stephenson

suggested that the fractured lake ice might create

more of an action movie than they expected. The

game was filmed on a different lake nearby, but

no Oscars were awarded.

In 2002, a major step was taken when the

Rocky Mountain Heritage Foundation and the

Town of Canmore joined together to obtain

96 ha (239 acres) from the Crown (i.e. the

Province of Alberta) for the sum of one dollar

bubbles stopped forming after two years, while the (Canadian) to form Quarry Lake Park. The land

debris was cleared from the surface, much of it by included the area surrounding Quarry Lake,

local volunteers. No water-quality monitoring was Salamander Pond, Canmore Creek, reclaimed

performed over this period other than qualitative land from several other smaller openpits, and

visual inspections of turbidity, gas bubbles and the thickly forested areas that had not been affected

development of fish populations. by mining (Fig. 12). In fact, almost two thirds

of the park is forest. In many areas, stands of

Continued restoration: A community effort mature trees had been left to screen the mining

Public interest in reclamation had begun operations and to provide shelter for ungulates

during the correction of the problems caused by from predators. This combination of grassland

mining. Once the population began to see that and forest works well as the revegetated areas

land could be reclaimed to enhance recreational continue to attract herbivores. Thanks to funds

opportunities and wildlife habitat, they came provided by the Foundation, chaired by Stan

onboard as did the mine’s owners. By the late Milner, and by Canmore taxpayers, the facilities

1970s, although there was still no lake, the gradual have been greatly improved while still retaining

improvement in conditions created optimism. a natural look which was an essential part of the

Sand was brought in for the beaches and miners design for the lake. In fact, many first-time visitors

helped to clean up the surroundings, put in oil are amazed when they see the photos of mining

drums for garbage, and built picnic tables (Fig. 10). operations in the 1970s (Fig. 1 and 4) and find

The lake had been stocked by Alberta Fish and that the lake they now enjoy was once an ugly

32 august 2019 Mınıng engıneerıng www.miningengineeringmagazine.com

Canada

Figure 12

Quarry Lake on a crowded July day in 2015.

openpit (Fig. 7). The whole park now forms a

very attractive location for outdoor activities with

Quarry Lake its center piece.

Today, the lake is a hive of activity especially

on summer weekends, with as many as 400

people on the shores of the lake and on the

trails running through the park (Fig. 13). Every

type of unpowered watercraft imaginable is on

the lake from inflatable mattresses to canoes,

kayaks and paddle boards. Other facilities

included in the park are an area for exercising

dogs off leash and two car parks with space

for 150 vehicles. The popular tourism website

TripAdvisor rates Quarry Lake as “#8 of 39 things

to do in Canmore,” (https://www.tripadvisor. (Fig. 13). The goal was to create a landscape that

com/Attraction_Review-g181727-d6966809- would provide a memorable outdoor experience,

Reviews-Quarry_Lake-Canmore_Kananaskis_ was nonpolluting, beneficial to residents and

Country_Alberta.html). Since 2011, the Town visitors alike, and would preserve wildlife habitat.

of Canmore and Alberta Health Services have It has succeeded in all except the last, and

monitored fecal coliform and E. coli colonies on perhaps the most important, of those objectives.

a weekly basis between June 1 and September Canmore is proud of its park.

15. These data provide an indication of public

swimming safety and, to date, Quarry Lake has Conclusions

not exceeded recreational guidelines. No other The reclamation carried out on Canmore

water quality data are monitored (Lisa Guest, Creek No. 1 and 2 mines was much more difficult

Town of Canmore, personal communication, June than on Canmore Creek No. 3 and other later

26, 2019). mines. There was much more damage from the

However, the park is now in danger of being former, for example the destruction of Canmore

loved to death. Wildlife are becoming notable for

their absence as more activities are introduced.

A regrettable example in Stephenson’s opinion

is a section of a mountain bike trail that is being

built to traverse an untouched section of the

park. While not a wildlife corridor or an official

habitat patch, this section was undisturbed forest

AirBlast

and had no trails. A well-known grizzly bear

(#148) used this area while coming to the lake

in the evenings to drink. Subsequently, this bear

bluff charged several people and was removed

to a remote location on the Alberta/ B.C. border belt wiper

where, tragically, it was shot by a hunter. The

balance between people and wildlife has become

a huge problem throughout the Bow Valley and

systems

unfortunately, wildlife is rapidly losing ground. Using heavy-duty low-

maintenance direct-drive

Evaluating success: Was it worthwhile? blowers, Air Blast belt wiper

It absolutely was. The creation of Quarry systems remove carry back

Lake was, over the years, a community effort by material off of the bottom side of your conveyor.

engineers, miners, a coal company, the residents

and Council of Canmore, and a not-for-profit Use it alongside primary/secondary scrapers, or by itself

agency devoted to land preservation. They have, in the case of a pleated belt.

collectively, beaten back an ill-advised attempt by Available in a range of pressures

a developer to build a golf course and, even more and widths to accommodate

astounding, to develop the land around the lake various sizes of belts and

for residences. The effort involved in creating types of carry back material.

Quarry Lake Heritage Park began 49 years ago

as an attempt to restore mined land, not to its www.airblastinc.com

former natural state but to something beautiful toll-free: (866) 424-7252 ■ sales@airblastinc.com

www.miningengineeringmagazine.com Mınıng engıneerıng august 2019 33

Canada

Figure 13

Canmore Creek Mine No. 3, renamed Quarry Lake, in 1982 following

reclamation.

largest openpits in the Alberta oil sands. Forty-

five managers and engineers attended and were

impressed. Stephenson was asked, “What is

the most important factor in successful openpit

reclamation?” His reply, “To have a senior

decision-maker who personally insists on a

high standard of reclamation, not because of

regulations or public relations but because it is the

right thing to do.” n

Acknowledgments

Gerry Stephenson would like to acknowledge

the efforts made by so many people and

organizations to enhance the area that was

reclaimed, and to encourage recreational

developments which in most, but not all cases,

have been appropriate for the park. In particular,

Creek and the failure to separate spoil into soil, he would like to recognize the residents of

gravel and rock. No thought was given to a vision Canmore, retired miners Andy Shellian and Lud

of what the reclaimed pit could become. Planning Kamenka, Town Councils between 1968 and the

and experience helped to resolve these issues. present, and Stan Milner’s “Rocky Mountain

These were all corrected and less time was spent Heritage Foundation.” Stephenson particularly

on Canmore Creek No. 3 to create a beautiful wishes to thank Devin Castendyck of Golder for

recreational/wildlife habitat. his help with this article.

As artfully described by Gerry Stephenson,

Quarry Lake is an outstanding example References:

Crossman, P. (2019), “An Islander’s Vinalhaven,” Yankee

of successful, walk away, pit lake closure, Magazine, July/August, pp. 96-97.

and post-mining pit lake reuse. In today’s Jones, H. and C. McCullough (2011), “Regulatory

environmentally conscious and politically Guidance and Legislation Relevant to Pit Lakes,” in Mine Pit

charged climate, it is challenging to permit new Lakes: Closure and Management, C. McCullough, ed., Perth,

mines in equally close proximity to a national Australia, Australian Centre for Geomechanics, pp. 137-152.

Kumar, R.N., C. McCullough, and M. Lund (2013), “Pit

park anywhere in North America, in part, due Lakes in Australia”, in Acid Pit Lakes: The Legacy of Coal and

to concerns that the post-mining environment Metal Surface Mining, W. Geller, M. Schultze, R. Kleinmann,

would be devoid of life with unusable, and C. Wolkersdorfer ed., Heidelberg, Germany, Springer, pp.

undesirable land and water resources. Quarry 342-362.

McCullough, C., D. Hunt and L. Evans (2009),

Lake provides one example where a sustainable, “Sustainable Development of Open Pit Mines: Creating

highly valued, post-mining resource was Beneficial End Uses for Pit Lakes”, in Mine Pit Lakes:

generated through careful planning, government Characteristics, Predictive Modeling, and Sustainability, D.

support and end-user participation. Castendyk and L.E. Eary, ed., Littleton, Colorado, Society for

Other examples of walk away pit lakes Mining, Metallurgy, and Exploration, pp. 249-273.

MNDNR (2018), “Cuyuna County State Recreation

exist in North America but too often remain Area”, Minnesota Department of Natural Resources

undocumented. The publication and public (MNDNR) website, accessed October 31, 2018, www.dnr.state.

dissemination of similar case studies could greatly mn.us/state_parks/park.html?id=sra00302#homepage

aid the mining industry in the following ways: Schultz, M., M. Hemm, W. Geller and F.C. Benthaus

(2013), “Pit Lakes in Germany: Hydrography, Water Chemistry,

(1) identifying, documenting and remembering and Management”, in Acid Pit Lakes: The Legacy of Coal and

previous successful strategies used in pit lake Metal Surface Mining, W. Geller, M. Schultze, R. Kleinmann

closure; (2) inspiring companies and stakeholders and C. Wolkersdorfer, ed., Heidelberg, Germany, Springer, pp.

to set higher goals for mine closure and pit 265-291.

lake reuse; (3) informing the public, which, Stelfox, J.D., G.E. Shumaker and D.M. Baayens (2005),

“Voluntary Creel Survey of High Mountain Lakes in

lacking access to better examples, frequently Kananaski Country, 1982-2002”, Alberta Sustainable Resource

cites negative examples of pit lakes that foment Development, Natural Resources Service, Fish and Wildlife

concerns over future pit lakes, and (4) accelerating Division, Cochrane, Alberta.

the approval of a social license for future Stephenson, H.G. (1974), “Problems of Reclamation in

High Altitude Mountainous Areas”, Canmore Mines Ltd.,

responsible mining. Canmore, Alberta.

Three years ago, Stephenson was asked Vandenberg, J. (2018), “The Story of Alberta’s Pit

to provide one of his history tours of Quarry Lakes,” You Tube, accessed June 30, 2019, www.youtube.com/

Lake park for Suncor Ltd., Canada’s largest oil watch?v=HIbq_0siUYY&t=17s

company, which operates some of the world’s

34 august 2019 Mınıng engıneerıng www.miningengineeringmagazine.com

You might also like

- TenCate Geotubes Global Marine - USA PDFDocument7 pagesTenCate Geotubes Global Marine - USA PDFpjgomezd100% (1)

- Barmm Mindanao or BARMM (Filipino: Rehiyong Awtonomo NG Bangsamoro Sa MuslimDocument8 pagesBarmm Mindanao or BARMM (Filipino: Rehiyong Awtonomo NG Bangsamoro Sa MuslimMylaCambriNo ratings yet

- 1st Summative Test in Science 6 - 4th QTRDocument5 pages1st Summative Test in Science 6 - 4th QTRBenj Alejo71% (14)

- Earth - S Internal Heat Source & MagmatismDocument26 pagesEarth - S Internal Heat Source & MagmatismAngela Nicole Nobleta80% (5)

- Pushover Analysis of A 19 Story Concrete Shear Wall BuildingDocument6 pagesPushover Analysis of A 19 Story Concrete Shear Wall BuildingGirish DeshmukhNo ratings yet

- Evaluating CarbonatesDocument20 pagesEvaluating CarbonatesIván VelázquezNo ratings yet

- New Perspectives on Deep-water Sandstones: Origin, Recognition, Initiation, and Reservoir QualityFrom EverandNew Perspectives on Deep-water Sandstones: Origin, Recognition, Initiation, and Reservoir QualityNo ratings yet

- An Investigation of The Brumadinho Dam Break With HEC-RASDocument16 pagesAn Investigation of The Brumadinho Dam Break With HEC-RASMart MugoniNo ratings yet

- Dinosaurs Alive Educator Guide2Document8 pagesDinosaurs Alive Educator Guide2Faten Hamamah Mohamed100% (1)

- CE 374 K - Hydrology CE 374 K Hydrology: Hydrologic DesignDocument19 pagesCE 374 K - Hydrology CE 374 K Hydrology: Hydrologic DesignEdwar ForeroNo ratings yet

- The Mud Logging Process - GeoserviceDocument8 pagesThe Mud Logging Process - GeoservicevanthodcNo ratings yet

- UNU - Geothermal Well TestingDocument30 pagesUNU - Geothermal Well TestingZakariyaNo ratings yet

- Artificial Island: SDM College of Engineering and Technology, Dhavalagiri, DharwadDocument17 pagesArtificial Island: SDM College of Engineering and Technology, Dhavalagiri, DharwadYogesh KhanapurNo ratings yet

- Ground Support in Karstified ConditionsDocument14 pagesGround Support in Karstified ConditionswjzabalaNo ratings yet

- (1996 Vick) 1995 Omai Tailings Dam Failure PDFDocument7 pages(1996 Vick) 1995 Omai Tailings Dam Failure PDFsanpaz75100% (1)

- Submarine Tailings Disposal ToolkitDocument16 pagesSubmarine Tailings Disposal Toolkit2012nibiruNo ratings yet

- No Longer Just A Hole in The Ground: The Adaptive Re-Use of Resource Depleted QuarriesDocument19 pagesNo Longer Just A Hole in The Ground: The Adaptive Re-Use of Resource Depleted QuarriesBiju SebastianNo ratings yet

- Kwong2019 Article ComparisonOfEnvironmentalImpacDocument10 pagesKwong2019 Article ComparisonOfEnvironmentalImpacRizka Hari RakhmahNo ratings yet

- Bastian2005 - Assessment and Development of The Dry Horseshoe Canyon CBM Play in CanadaDocument13 pagesBastian2005 - Assessment and Development of The Dry Horseshoe Canyon CBM Play in CanadamakhaNo ratings yet

- Assessment of Critical State Shear Strength Properties of Copper TailingsDocument7 pagesAssessment of Critical State Shear Strength Properties of Copper TailingsBrahian Roman CabreraNo ratings yet

- T8 Sudbury2003 - Jakubick - McKenna - AMRDocument9 pagesT8 Sudbury2003 - Jakubick - McKenna - AMRCarlos Sebastian RetamalNo ratings yet

- Thickened Tailings Disposal at Musselwhite MineDocument12 pagesThickened Tailings Disposal at Musselwhite MineΙωάννης ΖαφειράτοςNo ratings yet

- Mining Dams Grow To Colossal Heights, and So Do The Risks - WSJDocument8 pagesMining Dams Grow To Colossal Heights, and So Do The Risks - WSJFernando GomesNo ratings yet

- SPE Estimating Fracture Gradient in Gulf of Mexico Deepwater, Shallow, Massive Salt SectionsDocument9 pagesSPE Estimating Fracture Gradient in Gulf of Mexico Deepwater, Shallow, Massive Salt SectionsTHiago LOpesNo ratings yet

- Cayman Islands National Biodiversity Action Plan 2009 2.T.5 Terrestrial Habitats CavesDocument6 pagesCayman Islands National Biodiversity Action Plan 2009 2.T.5 Terrestrial Habitats Cavessnaip1370No ratings yet

- The Challenger Gold MineDocument10 pagesThe Challenger Gold MinegeolukeNo ratings yet

- RTR Canada OptionDocument16 pagesRTR Canada OptionPeteNo ratings yet

- SPE 78701 Medina Stimulation: Is Bigger Really Better?Document11 pagesSPE 78701 Medina Stimulation: Is Bigger Really Better?godix57127No ratings yet

- A Review of Exploration, Development, and Production Cost Offshore NewfoundlandDocument38 pagesA Review of Exploration, Development, and Production Cost Offshore NewfoundlandYakubu WagajaNo ratings yet

- 1 s2.0 S2095268617303518 MainDocument5 pages1 s2.0 S2095268617303518 MainSaudah PlkNo ratings yet

- Ekati - 2021 EA and WL Annual Report Plain Language Summary - May 19 - 22Document38 pagesEkati - 2021 EA and WL Annual Report Plain Language Summary - May 19 - 22Moisés CacamaNo ratings yet

- d5742-2076 Mains Approach-Answer e 2023Document22 pagesd5742-2076 Mains Approach-Answer e 2023Atul Kumar ChaubeyNo ratings yet

- Settlement Behaviour of A Major Dam: November 2006Document11 pagesSettlement Behaviour of A Major Dam: November 2006Isabela BalanNo ratings yet

- Protecting Bristol Bay:: Saving America's Last Wild PlacesDocument2 pagesProtecting Bristol Bay:: Saving America's Last Wild PlacesPanos PanosNo ratings yet

- Historic Mine Sites in British Columbia PDFDocument150 pagesHistoric Mine Sites in British Columbia PDFDaniel PachecoNo ratings yet

- 01 Integrated Wellbore Cleanout PDFDocument10 pages01 Integrated Wellbore Cleanout PDFLarry ShultzNo ratings yet

- 21 Purvasanjaypatil Laii DypcoaDocument7 pages21 Purvasanjaypatil Laii DypcoaTejashree GuptaNo ratings yet

- Pnas 0913721107Document6 pagesPnas 0913721107Divya ShahNo ratings yet

- Copper-Nickel Controversy MinnesotaDocument10 pagesCopper-Nickel Controversy MinnesotaNenadZRadovićNo ratings yet

- Nature MarginsDocument10 pagesNature MarginsRUDRADEB BHATTACHARYYANo ratings yet

- Atkinson 2006Document22 pagesAtkinson 2006Ryan PermanaNo ratings yet

- 41 Keith PDFDocument14 pages41 Keith PDFLucas ModNo ratings yet

- Stream Diversion and Reinstatement On A Mine Backfill in Tropical BorneoDocument14 pagesStream Diversion and Reinstatement On A Mine Backfill in Tropical BorneoBakang MolefeNo ratings yet

- L13 WBK424 CoastDefencePart2BreakwatersDocument64 pagesL13 WBK424 CoastDefencePart2BreakwaterskgosiNo ratings yet

- Carbonate ReservoirDocument22 pagesCarbonate ReservoirIbrahim MohamedNo ratings yet

- Structural Failures of Earth Dams in Nigera A Case Study - Umaru 2010Document7 pagesStructural Failures of Earth Dams in Nigera A Case Study - Umaru 2010Sushma AnanthNo ratings yet

- Section 2 The Natural EnvironmentDocument13 pagesSection 2 The Natural EnvironmentGivemore MuromboNo ratings yet

- Natural Kind of DefenceDocument2 pagesNatural Kind of DefenceCoastNetNo ratings yet

- Integrated Reservoir InterpretationDocument15 pagesIntegrated Reservoir InterpretationDr-Adel SalemNo ratings yet

- Blackpool Tanks (Wharmby Et Al BGS-BTS 2001)Document12 pagesBlackpool Tanks (Wharmby Et Al BGS-BTS 2001)Nick WharmbyNo ratings yet

- Gnangara Park 1Document12 pagesGnangara Park 1Emma YoungNo ratings yet

- CBM Article in The GleanerDocument1 pageCBM Article in The GleanermoonbugNo ratings yet

- 9 - Student - Coastal Processes and LandformsDocument53 pages9 - Student - Coastal Processes and LandformsZander RobertNo ratings yet

- SB 7 YearsofmonitoringDocument14 pagesSB 7 YearsofmonitoringWycleaf Geffin GalulaNo ratings yet

- IMWA2013 Paul 395Document8 pagesIMWA2013 Paul 395Glenn NyirendaNo ratings yet

- Leetaru 2014Document16 pagesLeetaru 2014Katherin Herrera HernandezNo ratings yet

- Northwest News & Updates: Restored Springs Dazzle GuestsDocument8 pagesNorthwest News & Updates: Restored Springs Dazzle GuestsMichael AllenNo ratings yet

- 02 Sweet SpotDocument14 pages02 Sweet SpotGhassen LaouiniNo ratings yet

- Rock Seawall Design and Construction With Deeper Toes For Climate ChangeDocument6 pagesRock Seawall Design and Construction With Deeper Toes For Climate ChangepradeepNo ratings yet

- Literature Review Coastal ErosionDocument8 pagesLiterature Review Coastal Erosiongw10ka6s100% (1)

- 01 09ever Picayune FinalDocument2 pages01 09ever Picayune FinalzgibbsNo ratings yet

- Coastal Erosion Research PaperDocument6 pagesCoastal Erosion Research Paperafeawjjwp100% (1)

- Coastal ProcessesDocument23 pagesCoastal ProcessesrpaulicansNo ratings yet

- Rock Mechanics Challenges in Underground Construction and Mining - Peter Kaiser - 2008Document28 pagesRock Mechanics Challenges in Underground Construction and Mining - Peter Kaiser - 2008Darkie LeeNo ratings yet

- Case Studies - ScoriaDocument15 pagesCase Studies - ScoriaPabloNo ratings yet

- Underground Mining With Backfills: Soils and Rocks May 2007Document10 pagesUnderground Mining With Backfills: Soils and Rocks May 2007Morgana RibeiroNo ratings yet

- International Journal of Greenhouse Gas Control: Jared T. Freiburg, Robert W. Ritzi, Kelsey S. KehoeDocument13 pagesInternational Journal of Greenhouse Gas Control: Jared T. Freiburg, Robert W. Ritzi, Kelsey S. KehoeGuillaume LepêcheurNo ratings yet

- RT WeirsDocument16 pagesRT WeirsFITSUM BerheNo ratings yet

- Grade 6 Science Paper 2 Term 2Document5 pagesGrade 6 Science Paper 2 Term 2Chamika TNo ratings yet

- Plates On The Move OLogy Web SiteDocument3 pagesPlates On The Move OLogy Web SitechabriesNo ratings yet

- 11 - Chapter 4Document40 pages11 - Chapter 4anbuselvarajNo ratings yet

- Notes - Eng Geol of MelbourneDocument6 pagesNotes - Eng Geol of MelbourneRagha VendraNo ratings yet

- Reservoir Design and OperationDocument36 pagesReservoir Design and OperationUssamaLatifNo ratings yet

- Hemeda2018 Article EngineeringFailureAnalysisAndD PDFDocument24 pagesHemeda2018 Article EngineeringFailureAnalysisAndD PDFDudley DeuxWriteNo ratings yet

- Black Obsidian - Everything You Need To Know - by Minded SpiritDocument17 pagesBlack Obsidian - Everything You Need To Know - by Minded SpiritKelsie BrownNo ratings yet

- A Novel Approach To The Geometallurgical Modelling of The Collahuasi Grinding CircuitDocument10 pagesA Novel Approach To The Geometallurgical Modelling of The Collahuasi Grinding CircuitPablo Agüero MezaNo ratings yet

- 4MC - UOI - ScienceDocument228 pages4MC - UOI - ScienceHardik NagdaNo ratings yet

- Earthquakes and FaultsDocument14 pagesEarthquakes and FaultsBEALYN OLANNo ratings yet

- 04.mapping of Fractures and Its Implication On Exploration Potential of Oligo-Miocene Carbonate Interval, North Madura PlatformDocument16 pages04.mapping of Fractures and Its Implication On Exploration Potential of Oligo-Miocene Carbonate Interval, North Madura PlatformHerry SuhartomoNo ratings yet

- I3C Symposium ProgrammeDocument4 pagesI3C Symposium Programmemoe9kaNo ratings yet

- Speciation of The Most Soluble Phases in A SequentialDocument14 pagesSpeciation of The Most Soluble Phases in A Sequentialjose amezquitaNo ratings yet

- Class Viii Science Chap 14 NotesDocument2 pagesClass Viii Science Chap 14 NotesAbhaygyan SinghNo ratings yet

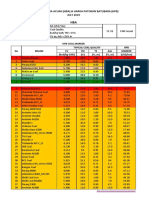

- Harga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) JULY 2019Document8 pagesHarga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) JULY 2019Adnan NstNo ratings yet

- Disaster Management - Case StudyDocument7 pagesDisaster Management - Case StudypecmbaNo ratings yet

- Draft Environmental Assessment For Hanakapiai Stream BridgeDocument69 pagesDraft Environmental Assessment For Hanakapiai Stream BridgeHonolulu Star-AdvertiserNo ratings yet

- MArch Geol Class I 2017Document31 pagesMArch Geol Class I 2017palaniNo ratings yet

- Flow Units and Rock Type For Reservoir Characterization in Carbonate Reservoir: Case Study, South of IraqDocument20 pagesFlow Units and Rock Type For Reservoir Characterization in Carbonate Reservoir: Case Study, South of IraqSaber daboussiNo ratings yet

- How Do The Different Soil Horizons Develop?Document2 pagesHow Do The Different Soil Horizons Develop?leilagreeyyyNo ratings yet

- Lesson 7 Unit Operations in MiningDocument5 pagesLesson 7 Unit Operations in MiningrosarionaritNo ratings yet