Professional Documents

Culture Documents

Agfa - cp1000 v1

Uploaded by

Suwandra I Gede PutuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agfa - cp1000 v1

Uploaded by

Suwandra I Gede PutuCopyright:

Available Formats

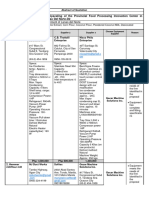

PAGE 4 PAGE 1

for Information Sharing

CP 1000 Tabletop

Processor

Specifications

A Self-Contained Darkroom

Dimensions: Warm-up Time: 5-Liter Replenishment Processor That Sets Up Anywhere

39" W × 25.5" D × 17" H 7 minutes Bottles:

(without Light Cover) A set of three bottles with and Requires No Plumbing

Clearance Dimensions: regular caps

Automatic

41" W × 27" D × 28" H Standby Mode:

Minimum Counter Manual replenishment key 2.5-Liter Replenishment

Required: Bottles:

26" × 26" A set of three bottles with

Infrared Dryer: regular caps

Heat generated during

Weight: continuous operation at

119 lb (empty) dryer setting of #4 is Processor Stand: The CP 1000 is designed to provide

154 lb (with chemistry 1990 BTU/hr Sturdy and easy-to-clean

and water) FormicaTM covered wood optimal image quality when combined

construction with RADIOMAT films as well as Agfa

Noise Level:

Film Sizes: 60 ±1dB (A) branded films.

Maximum Width: 14" Dimensions:

Minimum Size: 4" × 4" 26" W × 28" H × 32" D

Power Requirements:

120 VAC, 60 Hz,

Tank Capacity: 1100 W max Options:

Developer: 5-Gallon Waste Bottle

Standby Mode:

0.24 gal (0.9 liter) 100 W Feed Tray/Light Cover

Fixer: Average Power Plug it in, insert

0.24 gal (0.9 liter) Consumption:

Wash-Water: 400 W/hr

CP 1000 Chemistry: Agfa Reliability, Tabletop Convenience filled chemical and

0.24 gal (0.9 liter) Agfa G153 Developer wash-water bottles,

Concentrate: Totally Self-Contained

Standard Equipment: 2.5 liter mixes

then start working

Replenisher Bottles:

1.3 gal (5 liter) CP 1000 Processor with (Part A and B) Designed and built with the same

drain hoses 12 mixes per case

3 Replenisher Bottles Agfa G353 Fixer reliability as our large, high-volume

Film Transport Speed: Valves and Caps

11 in/min (28.5 cm/min) Concentrate: processors, the CP 1000 Processor is ideal Fast, quiet, infrared

Adapter Hose 2.5 liter mixes

Accessory (drain) (Part A and B) Premeasured concentrate makes accurate for diagnostic offices, military field clinics, dryer lowers energy

Processing Time: Accessory Operator’s 18 mixes per case chemical mixing simple. costs

125 sec (leading edge Manual remote departments, and chiropractic and

to leading edge) Specifications are subject veterinary offices. It is also an excellent

Fixed Water Supply to change without notice.

backup for your regular processor. The

Output: Connection:

60 films/hr (10" × 12") Type 9424/100 for CP 1000 provides consistent, high-quality processing of film sizes

continuous water supply ranging from 4" × 4" up to 14" × 36" for applications with moderate Automatic

replenishment

patient/film volume.

For the latest information on product specifications Fast Processing

and features, visit our website at:

www.agfa.com/healthcare With its 125-second cycle time (leading edge into developer to leading

edge at dryer), the CP 1000 provides quick access to finished radiographs. Fast start-up time

(7 minutes from

cold start)

Energy Efficient

Agfa-Gevaert has been approved by Lloyd’s Register Quality Assurance limited to the following Quality Management Agfa Corporation The CP 1000 operates on only 400 watts of power. Economical stand-by

System Standards: ISO 9001:1994; EN ISO 9001:1994, and ANSI/ASQC Q9001-1994. Imaging Headquarters

The Quality Management System is applicable to the development, production and distribution of Agfa Medical Films.

10 South Academy Street, Greenville, SC 29601 mode reduces power to 100 watts when the processor is idle. To further

Tel: 1-864-421-1600 • Fax: 864-421-1622

Agfa-Gevaert has been awarded the Approval of Conformity certificate by Lloyd’s Register Quality Assurance. Canada reduce power consumption, the processor may be turned off when not in

It certifies that the Quality Management System for our X-ray films conforms to the requirements of Annex V of the EEC Directive Agfa, Inc.

93/42 and Medical Devices Regulation 1994:3017. 77 Belfield Road, Etobicoke, Ont., M9W 1G6 active use, then, because of its fast warm-up time, quickly restarted.

Tel: 416-240-7315 • Fax: 416-241-5409

Agfa Medical Imaging has been approved by Lloyd’s Register Quality Assurance limited to the following Quality Management

Mexico

System Standards: ISO 9001:1994; EN ISO 9001:1994, and ANSI/ASQC Q9001-1994.

Agfa de México, S.A. de C.V.

The Quality Management System is applicable to: Selling, Servicing, Distribution, and Design of Marketing of Agfa‘s Product Via Morelos 330 E, Sta. Clara Ecatepec, 55540 Edo. de México

Assortment of Equipment and Sensitive Materials Used in Medical Diagnostic Imaging, Non-Destructive Testing, Microfilm and Tel: +52 (55) 5699 1414 • Telefax: +52 (55) 5699 1403

Motion Picture Applications.

Agfa-Gevaert has been awarded the ISO 9001 certificate by TÜV Zertifizierungsgemeinschaft e.V.

This is applicable to Agfa’s Quality Management System for design, production and servicing of Agfa Medical Equipment.

Agfa, the Agfa-Rhombus, Point of Knowledge, see more do more and CP 1000 are trademarks of Agfa Corporation or its affiliates.

©Copyright 2002, Agfa. All rights reserved.

MI-00077 Rev 8/02

PAGE 2

CP 1000 Tabletop

Processor

Advantages Over Typical Low-Volume Processors Easy Film Processing

• The CP 1000 uses a simple, accessible film transport system with Simply open the optional Feed Tray/Light Cover, feed the film into

fewer rollers instead of conventional heavy roller racks. Clean-up is

the processor, and close the Light Cover as soon as the film has

much easier

cleared the feed tray. You’re free to leave the darkroom without risk

• The CP 1000 uses an infrared dryer instead of the typical hot-air of fogging the film. Film is deposited into the receiver tray, ready for

dryer. It’s fast-drying, quiet and energy efficient viewing in about two minutes. The CP 1000 may also be operated

• The CP 1000 uses only 400 watts of power, compared with the without using the Feed Tray/Light Cover.

typical 1500 watts for other processors. In standby mode it uses

only 100 watts Feed Tray/Light Cover shortens time in

Unique features for better performance, Simple Film Path

• The rapid start-up time allows the CP 1000 to be shut off when the darkroom.

higher productivity and value. When film enters the processor, it passes the film scanner which

not in use and restarted only when needed. It can be ready for

processing from a cold start in only seven minutes regulates the replenishment system. A series of rollers transports

the film through the developer, the fixer and wash-water tanks and

the dryer section. The film exits the dryer and is deposited into the

Easy Cleaning receiver tray.

With the cover removed, the tanks are easily drained. Rollers, guide

plates and chemical tanks lift out, and are easily rinsed. The

Easy Chemical Mixing

processor can be properly cleaned in only minutes.

1. Fill developer and fixer dispenser bottles to 2.5 L mark with

clean water.

Easy Operation

2. Pierce seals of two bottles of Agfa developer concentrate, Part A,

There are only three controls: Simplifying the film path improves reliability

and pour into dispenser bottle. Agitate slowly to mix solution.

• Power ON/OFF switch – Turns processor and tank heaters on Faster clean-up equals cost savings and and ease of cleaning.

operational efficiency. 3. Perform the same step with concentrate Part B, and fill dispenser

• Manual Replenishment Key/Film Feed Light – Used to manually

bottle to “FULL” mark with water. Replace valve and shake

start the replenishment cycle when the processor has been idle

for more than a day. The Film Feed Light is illuminated during thoroughly to mix solution.

the replenishment cycle and when film is passing through the 4. Follow similar procedure as in steps 2 and 3 for mixing Agfa

processor. When the light turns off, a new film may be fed into

fixer concentrate.

the processor

• Dryer temperature step-switch – adjusts the temperature of the 5. Fill wash-water bottle with clean water to “FULL” mark and

infrared dryer as required replace valve.

6. Insert each bottle into the processor.

Easy Set Up

Mixing chemicals for the CP 1000 Processor

The CP 1000 does not require professional installation or plumbing.

is as simple as 1-2-3.

Setting up and installing it takes less than one hour and requires Three simple controls provide easy-to-use,

only simple tools. hassle-free results.

PAGE 2

CP 1000 Tabletop

Processor

Advantages Over Typical Low-Volume Processors Easy Film Processing

• The CP 1000 uses a simple, accessible film transport system with Simply open the optional Feed Tray/Light Cover, feed the film into

fewer rollers instead of conventional heavy roller racks. Clean-up is

the processor, and close the Light Cover as soon as the film has

much easier

cleared the feed tray. You’re free to leave the darkroom without risk

• The CP 1000 uses an infrared dryer instead of the typical hot-air of fogging the film. Film is deposited into the receiver tray, ready for

dryer. It’s fast-drying, quiet and energy efficient viewing in about two minutes. The CP 1000 may also be operated

• The CP 1000 uses only 400 watts of power, compared with the without using the Feed Tray/Light Cover.

typical 1500 watts for other processors. In standby mode it uses

only 100 watts Feed Tray/Light Cover shortens time in

Unique features for better performance, Simple Film Path

• The rapid start-up time allows the CP 1000 to be shut off when the darkroom.

higher productivity and value. When film enters the processor, it passes the film scanner which

not in use and restarted only when needed. It can be ready for

processing from a cold start in only seven minutes regulates the replenishment system. A series of rollers transports

the film through the developer, the fixer and wash-water tanks and

the dryer section. The film exits the dryer and is deposited into the

Easy Cleaning receiver tray.

With the cover removed, the tanks are easily drained. Rollers, guide

plates and chemical tanks lift out, and are easily rinsed. The

Easy Chemical Mixing

processor can be properly cleaned in only minutes.

1. Fill developer and fixer dispenser bottles to 2.5 L mark with

clean water.

Easy Operation

2. Pierce seals of two bottles of Agfa developer concentrate, Part A,

There are only three controls: Simplifying the film path improves reliability

and pour into dispenser bottle. Agitate slowly to mix solution.

• Power ON/OFF switch – Turns processor and tank heaters on Faster clean-up equals cost savings and and ease of cleaning.

operational efficiency. 3. Perform the same step with concentrate Part B, and fill dispenser

• Manual Replenishment Key/Film Feed Light – Used to manually

bottle to “FULL” mark with water. Replace valve and shake

start the replenishment cycle when the processor has been idle

for more than a day. The Film Feed Light is illuminated during thoroughly to mix solution.

the replenishment cycle and when film is passing through the 4. Follow similar procedure as in steps 2 and 3 for mixing Agfa

processor. When the light turns off, a new film may be fed into

fixer concentrate.

the processor

• Dryer temperature step-switch – adjusts the temperature of the 5. Fill wash-water bottle with clean water to “FULL” mark and

infrared dryer as required replace valve.

6. Insert each bottle into the processor.

Easy Set Up

Mixing chemicals for the CP 1000 Processor

The CP 1000 does not require professional installation or plumbing.

is as simple as 1-2-3.

Setting up and installing it takes less than one hour and requires Three simple controls provide easy-to-use,

only simple tools. hassle-free results.

PAGE 4 PAGE 1

for Information Sharing

CP 1000 Tabletop

Processor

Specifications

A Self-Contained Darkroom

Dimensions: Warm-up Time: 5-Liter Replenishment Processor That Sets Up Anywhere

39" W × 25.5" D × 17" H 7 minutes Bottles:

(without Light Cover) A set of three bottles with and Requires No Plumbing

Clearance Dimensions: regular caps

Automatic

41" W × 27" D × 28" H Standby Mode:

Minimum Counter Manual replenishment key 2.5-Liter Replenishment

Required: Bottles:

26" × 26" A set of three bottles with

Infrared Dryer: regular caps

Heat generated during

Weight: continuous operation at

119 lb (empty) dryer setting of #4 is Processor Stand: The CP 1000 is designed to provide

154 lb (with chemistry 1990 BTU/hr Sturdy and easy-to-clean

and water) FormicaTM covered wood optimal image quality when combined

construction with RADIOMAT films as well as Agfa

Noise Level:

Film Sizes: 60 ±1dB (A) branded films.

Maximum Width: 14" Dimensions:

Minimum Size: 4" × 4" 26" W × 28" H × 32" D

Power Requirements:

120 VAC, 60 Hz,

Tank Capacity: 1100 W max Options:

Developer: 5-Gallon Waste Bottle

Standby Mode:

0.24 gal (0.9 liter) 100 W Feed Tray/Light Cover

Fixer: Average Power Plug it in, insert

0.24 gal (0.9 liter) Consumption:

Wash-Water: 400 W/hr

CP 1000 Chemistry: Agfa Reliability, Tabletop Convenience filled chemical and

0.24 gal (0.9 liter) Agfa G153 Developer wash-water bottles,

Concentrate: Totally Self-Contained

Standard Equipment: 2.5 liter mixes

then start working

Replenisher Bottles:

1.3 gal (5 liter) CP 1000 Processor with (Part A and B) Designed and built with the same

drain hoses 12 mixes per case

3 Replenisher Bottles Agfa G353 Fixer reliability as our large, high-volume

Film Transport Speed: Valves and Caps

11 in/min (28.5 cm/min) Concentrate: processors, the CP 1000 Processor is ideal Fast, quiet, infrared

Adapter Hose 2.5 liter mixes

Accessory (drain) (Part A and B) Premeasured concentrate makes accurate for diagnostic offices, military field clinics, dryer lowers energy

Processing Time: Accessory Operator’s 18 mixes per case chemical mixing simple. costs

125 sec (leading edge Manual remote departments, and chiropractic and

to leading edge) Specifications are subject veterinary offices. It is also an excellent

Fixed Water Supply to change without notice.

backup for your regular processor. The

Output: Connection:

60 films/hr (10" × 12") Type 9424/100 for CP 1000 provides consistent, high-quality processing of film sizes

continuous water supply ranging from 4" × 4" up to 14" × 36" for applications with moderate Automatic

replenishment

patient/film volume.

For the latest information on product specifications Fast Processing

and features, visit our website at:

www.agfa.com/healthcare With its 125-second cycle time (leading edge into developer to leading

edge at dryer), the CP 1000 provides quick access to finished radiographs. Fast start-up time

(7 minutes from

cold start)

Energy Efficient

Agfa-Gevaert has been approved by Lloyd’s Register Quality Assurance limited to the following Quality Management Agfa Corporation The CP 1000 operates on only 400 watts of power. Economical stand-by

System Standards: ISO 9001:1994; EN ISO 9001:1994, and ANSI/ASQC Q9001-1994. Imaging Headquarters

The Quality Management System is applicable to the development, production and distribution of Agfa Medical Films.

10 South Academy Street, Greenville, SC 29601 mode reduces power to 100 watts when the processor is idle. To further

Tel: 1-864-421-1600 • Fax: 864-421-1622

Agfa-Gevaert has been awarded the Approval of Conformity certificate by Lloyd’s Register Quality Assurance. Canada reduce power consumption, the processor may be turned off when not in

It certifies that the Quality Management System for our X-ray films conforms to the requirements of Annex V of the EEC Directive Agfa, Inc.

93/42 and Medical Devices Regulation 1994:3017. 77 Belfield Road, Etobicoke, Ont., M9W 1G6 active use, then, because of its fast warm-up time, quickly restarted.

Tel: 416-240-7315 • Fax: 416-241-5409

Agfa Medical Imaging has been approved by Lloyd’s Register Quality Assurance limited to the following Quality Management

Mexico

System Standards: ISO 9001:1994; EN ISO 9001:1994, and ANSI/ASQC Q9001-1994.

Agfa de México, S.A. de C.V.

The Quality Management System is applicable to: Selling, Servicing, Distribution, and Design of Marketing of Agfa‘s Product Via Morelos 330 E, Sta. Clara Ecatepec, 55540 Edo. de México

Assortment of Equipment and Sensitive Materials Used in Medical Diagnostic Imaging, Non-Destructive Testing, Microfilm and Tel: +52 (55) 5699 1414 • Telefax: +52 (55) 5699 1403

Motion Picture Applications.

Agfa-Gevaert has been awarded the ISO 9001 certificate by TÜV Zertifizierungsgemeinschaft e.V.

This is applicable to Agfa’s Quality Management System for design, production and servicing of Agfa Medical Equipment.

Agfa, the Agfa-Rhombus, Point of Knowledge, see more do more and CP 1000 are trademarks of Agfa Corporation or its affiliates.

©Copyright 2002, Agfa. All rights reserved.

MI-00077 Rev 8/02

You might also like

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Ecomax Front Loading DishwashersDocument4 pagesEcomax Front Loading Dishwashersrichard9982No ratings yet

- Homogenizer Technical Sheet enDocument2 pagesHomogenizer Technical Sheet enPS VANo ratings yet

- 60 KVA PowerlineDocument4 pages60 KVA Powerlineroby saputraNo ratings yet

- 2022 Cirrus 620 Spec Sheet Min PDFDocument2 pages2022 Cirrus 620 Spec Sheet Min PDFErnesto Alejandro Farias CespedNo ratings yet

- Ultra Aire 70H Spec SheetDocument2 pagesUltra Aire 70H Spec SheetErik BellNo ratings yet

- Lavazza Blue ClassyCustomMilk ENG LowDocument2 pagesLavazza Blue ClassyCustomMilk ENG LowninaNo ratings yet

- Urix Rocessor: High-Quality Images With Table-Top ProcessorDocument2 pagesUrix Rocessor: High-Quality Images With Table-Top ProcessorsamsonNo ratings yet

- APL PP30 Information EnglishDocument2 pagesAPL PP30 Information EnglishAndres Martin RNo ratings yet

- Lit 117248 Versa-Portion En-Us Rev-A HRDocument2 pagesLit 117248 Versa-Portion En-Us Rev-A HREusebio Caballero OlivellaNo ratings yet

- Honor Machine 800bph-1.5L Drinking Water Filling LineDocument19 pagesHonor Machine 800bph-1.5L Drinking Water Filling Linerob changNo ratings yet

- 10litre Home DehumidifierDocument8 pages10litre Home Dehumidifiernfaa1986No ratings yet

- Brochure en LRDocument24 pagesBrochure en LRMohit TyagiNo ratings yet

- Old2023 - LDNFIC - AQSDocument6 pagesOld2023 - LDNFIC - AQSSameeha Ali (Sam)No ratings yet

- 60 PowerlineDocument4 pages60 PowerlineSame FirdausNo ratings yet

- NucleoBond Xtra Plasmid DNA Purification User Manual - Rev - 15Document46 pagesNucleoBond Xtra Plasmid DNA Purification User Manual - Rev - 15AbsjeyNo ratings yet

- Fair Cap PresentationDocument8 pagesFair Cap Presentationinstrumed_globalNo ratings yet

- Haier Washing MachineDocument19 pagesHaier Washing MachineJin HeeNo ratings yet

- C Spec Sheet RANCILIO C5 USB TALL 1G v1Document2 pagesC Spec Sheet RANCILIO C5 USB TALL 1G v1joey divinoNo ratings yet

- imagePROGRAF PRO 4100 DatasheetDocument2 pagesimagePROGRAF PRO 4100 Datasheetlucas.purssNo ratings yet

- Service Manual: Drum Washing MachineDocument74 pagesService Manual: Drum Washing MachineAlioverBetancourtNo ratings yet

- 100 KVA PowerlineDocument4 pages100 KVA Powerlineroby saputraNo ratings yet

- GhjujDocument18 pagesGhjujLuh SuciantariNo ratings yet

- 800-1000BPH Pure Water LineDocument11 pages800-1000BPH Pure Water LineDárcio CarvalhoNo ratings yet

- Katalog ALLEGRA Update 20122021-cmprssdDocument8 pagesKatalog ALLEGRA Update 20122021-cmprssdBrother In Arms ShopNo ratings yet

- Brosur PRIMUS RX 350 520 TMIDocument2 pagesBrosur PRIMUS RX 350 520 TMIWahyudi SihiteNo ratings yet

- M 1 Milk PSDocument1 pageM 1 Milk PSstephane.robert.1995No ratings yet

- Plasma Thawing DH4 DH8Document2 pagesPlasma Thawing DH4 DH8lab rsutebetNo ratings yet

- Whirlpool Service Manual Dishwasher ADP9411WHDocument19 pagesWhirlpool Service Manual Dishwasher ADP9411WHasafhoxlNo ratings yet

- Balancing Syphon Silver: SpesifikasiDocument5 pagesBalancing Syphon Silver: SpesifikasiSmk Negeri 2 TegalsariNo ratings yet

- PS 438919566en W4600H enDocument4 pagesPS 438919566en W4600H enTiến NguyễnNo ratings yet

- 2018 KKF470 enDocument1 page2018 KKF470 enImad MhannaNo ratings yet

- X Ray - AGFA CURIX 60 BrochureDocument2 pagesX Ray - AGFA CURIX 60 BrochureWisal AhdabNo ratings yet

- Dust Collection Vacuums 6-16rDocument2 pagesDust Collection Vacuums 6-16rEric CastilloNo ratings yet

- Asset CapabilityDocument1 pageAsset CapabilityBambang PermanaNo ratings yet

- Pourover Thermal Carafe Coffee Brewer: FeaturesDocument2 pagesPourover Thermal Carafe Coffee Brewer: Featuresalaska120No ratings yet

- Specification of Reverse Osmosis PlantsDocument8 pagesSpecification of Reverse Osmosis PlantsMuraliKrishna Naidu100% (1)

- S D V S C: SpecificationsDocument2 pagesS D V S C: Specificationsjude tallyNo ratings yet

- Combimat 4 DatasheetDocument2 pagesCombimat 4 DatasheetyossefamghariNo ratings yet

- 818 Series 0Document2 pages818 Series 0Jorge Luis VazquezNo ratings yet

- Bosch CTL636ES1 Coffee Machine Specifications SheetDocument2 pagesBosch CTL636ES1 Coffee Machine Specifications Sheetmaimonides76No ratings yet

- 24 Head 3 in 1 Water Filling Machine - NEW CROWNDocument19 pages24 Head 3 in 1 Water Filling Machine - NEW CROWNTedi SNo ratings yet

- Dental XDocument16 pagesDental XindraNo ratings yet

- PDF File 29909Document2 pagesPDF File 29909Eb SeventhNo ratings yet

- C Spec Sheet RANCILIO CLASSE 9 USB v9Document2 pagesC Spec Sheet RANCILIO CLASSE 9 USB v9joey divinoNo ratings yet

- Brosur DDL6Document6 pagesBrosur DDL6andi takwaNo ratings yet

- Accumulator Volume Capacity Calculation (API RP53 and IRP 1)Document2 pagesAccumulator Volume Capacity Calculation (API RP53 and IRP 1)aqawaqawNo ratings yet

- Tanvo 45LDocument4 pagesTanvo 45LTom AvidNo ratings yet

- Cimbali s39 Docevita2 Cap+cafDocument2 pagesCimbali s39 Docevita2 Cap+cafSturla SighvatssonNo ratings yet

- Catalogo WakaDocument10 pagesCatalogo Wakahernandezmarcoo2121No ratings yet

- Wm3360hvca Spec SheetDocument2 pagesWm3360hvca Spec SheetMalisa MaganaNo ratings yet

- Mode NG I 111116Document68 pagesMode NG I 111116Ahmed AzadNo ratings yet

- TAEHWA Encapsulation SystemsDocument8 pagesTAEHWA Encapsulation SystemsAdrian NovelNo ratings yet

- Manual Amana NFW5800DWDocument80 pagesManual Amana NFW5800DWAnonymous CqddyPpbNo ratings yet

- Anzir Zero DischargeDocument7 pagesAnzir Zero DischargeMohammad MahediNo ratings yet

- Environmental Profile Sheet: Canon. The Natural Partner For BusinessDocument2 pagesEnvironmental Profile Sheet: Canon. The Natural Partner For BusinessFuadAna'eJendraleNo ratings yet

- Hydrolysis Options: By: Jonatan LaraDocument5 pagesHydrolysis Options: By: Jonatan LaraJonatan LaraNo ratings yet

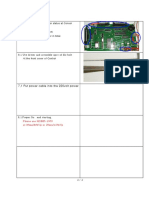

- Instalation Manual Mobix1000Document1 pageInstalation Manual Mobix1000Suwandra I Gede PutuNo ratings yet

- User S - Manual D PDFDocument46 pagesUser S - Manual D PDFISlam Mohamed HassaanNo ratings yet

- Instalation Manual Mobix1000 Part 4Document1 pageInstalation Manual Mobix1000 Part 4Suwandra I Gede PutuNo ratings yet

- Instalation Manual Mobix1000 Part 3Document1 pageInstalation Manual Mobix1000 Part 3Suwandra I Gede PutuNo ratings yet

- Instalation Manual Mobix1000 Part 2Document1 pageInstalation Manual Mobix1000 Part 2Suwandra I Gede PutuNo ratings yet

- Ian R. McClelland X-Ray Equipment Maintenance and Repairs Workbook For Radiographers and Radiological TechnologistsDocument272 pagesIan R. McClelland X-Ray Equipment Maintenance and Repairs Workbook For Radiographers and Radiological Technologistssavannah78No ratings yet

- DC30-022 Rev F Generator Installation Planning GuideDocument30 pagesDC30-022 Rev F Generator Installation Planning GuideLuis Fernando Garcia S100% (1)

- LM2576/LM2576HV Series SIMPLE SWITCHER 3A Step-Down Voltage RegulatorDocument37 pagesLM2576/LM2576HV Series SIMPLE SWITCHER 3A Step-Down Voltage RegulatorSuwandra I Gede PutuNo ratings yet

- DC30-022 Rev F Generator Installation Planning GuideDocument30 pagesDC30-022 Rev F Generator Installation Planning GuideLuis Fernando Garcia S100% (1)

- DC30-022 Rev F Generator Installation Planning GuideDocument30 pagesDC30-022 Rev F Generator Installation Planning GuideLuis Fernando Garcia S100% (1)

- Tip 41 DatasheetDocument4 pagesTip 41 DatasheetelectrodruidaNo ratings yet

- Pc817 DatasheetDocument5 pagesPc817 DatasheetprincebahariNo ratings yet

- Alsa Excell 200 MCDS - Manual de ServicioDocument17 pagesAlsa Excell 200 MCDS - Manual de ServicioAlberto0% (1)

- HOT D1877 Datasheet PDFDocument1 pageHOT D1877 Datasheet PDFlaurentina52No ratings yet

- ABB SoftstarterDocument108 pagesABB SoftstarterBen ChanNo ratings yet

- NCP1397A, NCP1397B High Performance Resonant Mode Controller With Integrated High-Voltage DriversDocument27 pagesNCP1397A, NCP1397B High Performance Resonant Mode Controller With Integrated High-Voltage DriversSuwandra I Gede PutuNo ratings yet

- LM2576/LM2576HV Series SIMPLE SWITCHER 3A Step-Down Voltage RegulatorDocument37 pagesLM2576/LM2576HV Series SIMPLE SWITCHER 3A Step-Down Voltage RegulatorSuwandra I Gede PutuNo ratings yet

- Sedecal sm0510R4Document90 pagesSedecal sm0510R4PatriciaAraujo100% (2)

- CNY17., CNY17G Optocoupler, Phototransistor Output, With Base ConnectionDocument8 pagesCNY17., CNY17G Optocoupler, Phototransistor Output, With Base ConnectionAjish joNo ratings yet

- A115x DatasheetDocument14 pagesA115x DatasheetkhoaNo ratings yet

- DSE60xx MKII Operators ManualDocument100 pagesDSE60xx MKII Operators ManualJan AhmedNo ratings yet

- Semiconductor Technical Data: L SuffixDocument12 pagesSemiconductor Technical Data: L SuffixSuwandra I Gede PutuNo ratings yet

- Polymobil10 FunctionDescriptionDocument14 pagesPolymobil10 FunctionDescriptionSuwandra I Gede Putu100% (2)

- Repair Instructions: © 2003 A. Hettich, D-78532 Tuttlingen Order No. AR1004ENDocument38 pagesRepair Instructions: © 2003 A. Hettich, D-78532 Tuttlingen Order No. AR1004ENbalya mulkanNo ratings yet

- Repair Instructions: © 2003 A. Hettich, D-78532 Tuttlingen Order No. AR1004ENDocument38 pagesRepair Instructions: © 2003 A. Hettich, D-78532 Tuttlingen Order No. AR1004ENbalya mulkanNo ratings yet

- Agfa - cp1000 v1Document4 pagesAgfa - cp1000 v1Suwandra I Gede PutuNo ratings yet

- Repair Instructions: © 2003 A. Hettich, D-78532 Tuttlingen Order No. AR1004ENDocument38 pagesRepair Instructions: © 2003 A. Hettich, D-78532 Tuttlingen Order No. AR1004ENbalya mulkanNo ratings yet

- Erbe Icc 50 80 SMDocument56 pagesErbe Icc 50 80 SMMiguel De Los Santos PavisicNo ratings yet

- Technical Data: Rotanode E7239X E7239FX E7239GXDocument16 pagesTechnical Data: Rotanode E7239X E7239FX E7239GXSuwandra I Gede PutuNo ratings yet

- User Manual-Heated DryerDocument65 pagesUser Manual-Heated Dryersasa hhNo ratings yet

- Seal of BushingDocument6 pagesSeal of BushingB.k. BirtiaNo ratings yet

- Ee6211 - Electric Circuit LabDocument101 pagesEe6211 - Electric Circuit Labsujith100% (1)

- 03 Item 220 (Salwico NS-AOHS) Incl 221 and 222Document3 pages03 Item 220 (Salwico NS-AOHS) Incl 221 and 222AlexDorNo ratings yet

- Rotary ActuatorsDocument34 pagesRotary Actuatorsmr3478No ratings yet

- Gk247a T-014 PDFDocument1 pageGk247a T-014 PDFsujit5584No ratings yet

- Air Ventilation & Housing.Document25 pagesAir Ventilation & Housing.Mrs RehanNo ratings yet

- Solid Waste Management Tech - Tracxn Feed Report - 09 Dec 2021Document70 pagesSolid Waste Management Tech - Tracxn Feed Report - 09 Dec 2021ElephantNo ratings yet

- 80010046v01 15 7 2013 10 19 5 331Document2 pages80010046v01 15 7 2013 10 19 5 331Ricardo LoureiroNo ratings yet

- Masterplan + Fence Plan + Fence Detail DrawingDocument14 pagesMasterplan + Fence Plan + Fence Detail DrawingarifNo ratings yet

- Revolution Wind (Deepwater Wind LLC) Public BidDocument130 pagesRevolution Wind (Deepwater Wind LLC) Public BidAndy TomolonisNo ratings yet

- Seminar Report Electronic SensorsDocument19 pagesSeminar Report Electronic SensorsRohan dwivedi100% (1)

- Aa5tb Magnetic Loop v1Document9 pagesAa5tb Magnetic Loop v1api-3839541No ratings yet

- Rotel RMB-1075 Service - ManualDocument8 pagesRotel RMB-1075 Service - Manualpeter11No ratings yet

- Pressure Loss AwwaDocument1 pagePressure Loss AwwaSashiNo ratings yet

- Reporte HOMER WIND 5kW-PV 6.36kWDocument10 pagesReporte HOMER WIND 5kW-PV 6.36kWlandoa junNo ratings yet

- Radiography Procedure RNDTDocument27 pagesRadiography Procedure RNDTrashmibetuNo ratings yet

- Quick Start Guide XR (H, V) S 336-506 CD APP 2954 6440 01 ENDocument2 pagesQuick Start Guide XR (H, V) S 336-506 CD APP 2954 6440 01 ENahmedNo ratings yet

- Radiation Production and Characteristics Lecture2021 22Document188 pagesRadiation Production and Characteristics Lecture2021 22Lei ClamorNo ratings yet

- Furnace Oil ProjectDocument16 pagesFurnace Oil ProjectRohit PNo ratings yet

- EIR 221 Prac 3 Guide 2017Document5 pagesEIR 221 Prac 3 Guide 2017mpaka felliNo ratings yet

- Lab Report On Climate ChangeDocument3 pagesLab Report On Climate ChangecmsbballNo ratings yet

- PIA B2 - Module 2 (PHYSICS) SubModule 2.5 (Wave Motion and Sound) FinalDocument17 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.5 (Wave Motion and Sound) Finalsamarrana1234679No ratings yet

- Article Review CSR 7Document2 pagesArticle Review CSR 7Gwendoline BoucherNo ratings yet

- Catalogue: Zeeta Electrical Engineering Pvt. LTDDocument37 pagesCatalogue: Zeeta Electrical Engineering Pvt. LTDKamitkumar PatelNo ratings yet

- 1 AQA Energy Tests 1HDocument21 pages1 AQA Energy Tests 1HAsik PogosyanNo ratings yet

- BY127, BY133, EM513, EM516: General Purpose Plastic Rectifier Reverse Voltage - Forward CurrentDocument3 pagesBY127, BY133, EM513, EM516: General Purpose Plastic Rectifier Reverse Voltage - Forward CurrentJose Fernandez LopezNo ratings yet

- GLA100Document2 pagesGLA100Al De LeonNo ratings yet

- ValProbe ManualDocument91 pagesValProbe ManualRicardo AugustoNo ratings yet

- 6055-31 VR Breaker 1200-2000A - May 2008Document42 pages6055-31 VR Breaker 1200-2000A - May 2008Rahil TasawarNo ratings yet