Professional Documents

Culture Documents

Construction Engineering Tutorial Work 1 9

Uploaded by

MatthewOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction Engineering Tutorial Work 1 9

Uploaded by

MatthewCopyright:

Available Formats

lOMoARcPSD|4172617

Construction Engineering - Tutorial work - 1 - 9

Construction Engineering (Griffith University)

StuDocu is not sponsored or endorsed by any college or university

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 1 (Week 3) – Engineering Economics

Q1 A contractor wishes to set aside enough money today in an interest-bearing account in

order to have $100,000 five years from now. Based on an interest rate of 8%, how much

should be set aside now?

Q2 How much must be deposited at the end of each year into a fund earning 10% interest

(compounded annually) in order to accumulate $200,000 for equipment replacement at the

end of 5 years?

Q3 An organisation invests $10,000 in the purchase of equipment, which will be used over

15 years and for which it will receive no salvage amount at the end of that time. Find the

annual cost of this investment, which should be included in the ownership costs, if

organisation’s MARR is 12%.

Q4 A crawler tractor costs $250,000, has an estimated salvage value of $50,000, and a 5 year

life. Using the double-declining-balance (DDB) method of depreciation, find the tractor’s

yearly depreciation and book value at the end of each year.

Q5 Find the annual depreciation and book value at the end of each year for the tractor from

the previous question using the sum-of-the-year’s-digits (SOY) method of depreciation.

Q6 A piece of equipment is available for purchase for $12,000. It has an estimated useful life

of 5 years, and has an estimated salvage value of $2,000. Determine the depreciation and the

book value for each of the 5 years using:

The SL method

The SOY method

The DDB method

Draw a graph showing the distribution of equipment’s book value using the three different

methods. Comment on the graph and the accuracy of each method.

Q7 A piece of equipment is estimated to cost $67,000 new and to have a useful life of 7 years

with a salvage value of $7,000. The company believes a realistic return on investment would

be 12%. Tax, insurance and storage should amount to an additional 8%; find the equivalent

uniform annual ownership cost.

END OF TUTORIAL

2104ENG Construction Engineering Tutorial Questions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 1 (Week 3) – Engineering Economics – Solutions

Q1 Cash flow diagram:

Where: i = 8% (0.08)

n=5

>

Q2 Cash flow diagram:

Where: i = 10% (0.1)

n=5

Q3 Cash flow diagram

Where: i = 12% (0.12)

n = 15

2104ENG Construction Engineering Tutorial Solutions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q4 DDB Method

, where N = 5

Year Depreciation Book Value (End of year)

0 0 $250,000

1 $100,000 $150,000

2 $60,000 $90,000

3 $36,000 $54,000

4 $4,000 (NOT $21,600) $50,000 (NOT $32,400)

5 $0 (NOT $12,960) $50,000 (NOT $19,440)

*Book value CANNOT go below salvage value, thus once salvage value has been reached,

no further depreciation takes place using this method.

Q5 SOY Method

where: P = $250,000; S = $50,000; N = 5; m = current year; SOY = 1+2+3+4+5 = 15

Year Depreciation Book Value (End of year)

0 0 $250,000

1 $66,667 $183,333

2 $53,333 $130,000

3 $40,000 $90,000

4 $26,667 $63,333

5 $13,333 $50,000

2104ENG Construction Engineering Tutorial Solutions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q6

SL Method

Year Depreciation Book Value (End of year)

0 $0 $12,000

1 $2,000 $10,000

2 $2,000 $8,000

3 $2,000 $6,000

4 $2,000 $4,000

5 $2,000 $2,000

SOY Method

where: P = $12,000; S = $2,000; N = 5; m = current year; SOY = 1+2+3+4+5 = 15

Year Depreciation Book Value (End of year)

0 $0 $12,000

1 $3,333.33 $8,667.67

2 $2,666.67 $6,000

3 $2,000 $4,000

4 $1,333.33 $2,666.67

5 $666.67 $2,000

DDB Method

, where N = 5

2104ENG Construction Engineering Tutorial Solutions 3

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Year Depreciation Book Value (End of year)

0 0 $12,000

1 $4,800 $7,200

2 $2,880 $4,320

3 $1,728 $2,592

4 $592 (NOT $1,036.80) $2,000 (NOT $1,555.20)

5 $0 (NOT $622.08) $2,000 (NOT $933.12)

*Book value CANNOT go below salvage value, thus once salvage value has been reached,

no further depreciation takes place using this method.

$14,000

$12,000

$10,000

Cost ($)

$8,000

$6,000

$4,000

$2,000

$0

0 1 2 3 4 5

Time (Yr.)

Comments:

SL Method is the most inaccurate method because it shows equal depreciation each year

when reality the greatest depreciation occurs in the first couple of years, particularly the first.

SoY Method seems to be the most appropriate of the presented method but it does not

indicate the true level of depreciation in the first year.

The main problem of DDB Method is that it can depreciate below the salvage value before its

service life.

2104ENG Construction Engineering Tutorial Solutions 4

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q7 Cash flow diagram

Where: i = 12% + 8% = 20% (0.2)

n=7

Determine present value of salvage:

Therefore the new present value = $67,000 - $1,953.57 = $65,046.43

Determine annual cost:

END OF SOLUTIONS

2104ENG Construction Engineering Tutorial Solutions 5

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 2 (Week 4) – Engineering Economics 2

Q1 A construction company has to decide between two options; to purchase or to lease an

asphalt plant based on the net present value comparison method. Detailed cost estimates are

shown below. Determine which option is the most cost effective and by how much. The bank

interest rate is 12%.

Purchase option:

Initial cost is $150,000. Salvage value at the end of 5 years is $30,000. Annual maintenance

cost is estimated at $5,000 at year end.

Leasing option:

Annual lease is $30,000 increasing by 15% each year (payable at the start of year). The plant

will be maintained by the lessor.

Q2

a) A construction company borrowed $10,000,000 from the bank. It was agreed that the

loan must be settled in 8 years, and the interest rate was fixed at 9%. Calculate the

year-end repayment amount if the company wished to settle the loan in 8 equal year-

end payments.

b) If the company made big profits at the end of the 3 rd year and increased the year-end

repayment to $3,000,000 for that particular year, what will be the new instalment

amount for the remaining 5 years?

Q3 A crawler tractor costs $180,000 has an estimated salvage value of $30,000 and has a 6

year life. Find the annual depreciation and book value at the end of each year using:

a) straight-line method

b) sum-of-the-years’ digits method

c) double-declining-balance method

END OF TUTORIAL

2104ENG Construction Engineering Tutorial Questions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 2 (Week 4) – Engineering Economics 2 – Solutions

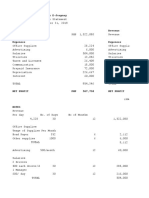

Q1

Purchase option:

Leasing option:

Difference:

Leasing – purchasing = $158,254.85 – $151,001.08 = $7,253.78

Therefore the purchasing option is the most cost effective by $7,253.78

2104ENG Construction Engineering Tutorial Solutions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q2

a)

b)

Convert first three payments to present value (including $3m 3rd year payment):

Determine present value for remaining 5 years:

Transfer new present value into 3rd year:

Determine annual payments for last five years:

2104ENG Construction Engineering Tutorial Solutions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q3

SL Method

Year Depreciation Book Value (End of year)

0 $0 $180,000

1 $25,000 $155,000

2 $25,000 $130,000

3 $25,000 $105,000

4 $25,000 $80,000

5 $25,000 $55,000

6 $25,000 $30,000

SOY Method

where: P = $180,000; S = $30,000; N = 6; m = current year; SOY = 1+2+3+4+5+6 = 21

Year Depreciation Book Value (End of year)

0 $0 $180,000

1 $42,857 $137,143

2 $35,714 $101,429

3 $28,571 $72,858

4 $21,429 $51,429

5 $14,286 $37,143

6 $7,143 $30,000

2104ENG Construction Engineering Tutorial Solutions 3

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

DDB Method

, where N = 6

Year Depreciation Book Value (End of year)

0 0 $180,000

1 $60,000 $120,000

2 $40,000 $80,000

3 $26,667 $53,333

4 $17,778 $35,555

5 $5,555 (NOT $11,852) $30,000 (NOT $23,703)

5 $0 (NOT $7,901) $30,000 (NOT $15,802)

*Book value CANNOT go below salvage value, thus once salvage value has been reached,

no further depreciation takes place using this method.

END OF SOLUTIONS

2104ENG Construction Engineering Tutorial Solutions 4

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 3 (Week 5) – Earthmoving

Summary

Production = (volume/cycle)x(cycle/hour)

Cost/unit production = (equipment cost/hr)/(equipment production/hr.)

Bank vol. [Bm3]: Material in its natural state before disturbance

Loose vol. [Lm3]: Material has been excavated or loaded

Compacted vol. [Cm3]: Material after compaction

Swell is a soils increase in volume when it is excavated and is due to air fill and void

space increase (Bm3→Lm3)

Swell (%) = ((γB/ γL)-1)x100

Shrinkage is a soils volume decrease when its compacted

Shrinkage (%) = (1-(γB/ γc))x100

Load Factor (LF) = ((γL/ γB) or 1/(1+swell)

Shrinkage Factor (SF) = ((γB/ γC) or 1-shrinkage

2104ENG Construction Engineering Tutorial Questions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q1 Observations indicate that an excavator carries an average bucket load of 2.3 Lm3 per

cycle. The soil’s load factor is 0.80. Cycle time averages 0.35 min. Job conditions are rated as

fair, and management conditions are rated as good. Estimate the hourly production in Bm3 for

the excavator. You will need to use Table 2-1 provided in the summary.

Q2 The hourly cost of a hydraulic shovel is $65 and of a truck is $35. If an equipment fleet

consisting of one shovel and six trucks achieves a production of 229 Bm3/hr, what is the unit

cost of loading and hauling?

Q3 A soil weighs 1089 kg loose, 1383 kg in-place and 1633kg compacted. Find the swell and

shrinkage of this soil.

Q4 A soil weighs 1471 kg loose, 1839 kg in-place and 2047kg compacted. How many bank

cubic meters of this material can a 7.6 m3 (heaped load) truck haul assuming no weight

limitation?

Q5 A contract requires 50,000m3 of compacted fill. The imported fill has load and shrinkage

factors of 0.725 and 0.8, respectively. This soil is to be hauled in trucks having rated heaped

capacity of 10m3. How many truck-loads are required for this contract?

Q6 A soil weighs 1483 kg loose, 1839 kg in its natural state, and 2166 kg compacted. Find:

a) The soil’s load factor and shrinkage factor.

b) How many truck loads of truck hauling an average volume of 4.6 LCM would be

required to haul 764,600 CCM of the soil to a dam site?

Q7 Calculate the volume excavation in bank measure required for the basement shown

below. Excavation depths are in (m).

END OF TUTORIAL

2104ENG Construction Engineering Tutorial Questions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 3 (Week 5) – Earthmoving – Solutions

Q1

Excavator = 2.3m3/cycle

Cycle Time = 1cycle/0.35min.

LF = 0.80

Job eff. Factor = 0.69 (Table 2.1)

Need to apply job efficiency factor and load factor to convert to Bm3.

( )

Q2

Hydraulic shovel cost = $65/hour

Trucks cost = $35/hour x 6 trucks = $210/hour

Production (one shovel + 6 trucks) = 229Bm3/hour

*The unit for hours is applied to each item in the equation, however is completely cancelled

out

Q3

Loose = 1089kg

Bank = 1383kg

Compacted = 1633kg

*Assumed same volume and thus density is not required

( ) ( ) ( )

( ) ( ) ( )

Q4

Loose (Lm3) = 1471kg/m3

Bank (Bm3) = 1839kg/m3

Compacted (Cm3) = 2047kg/m3

Truck capacity = 7.6Lm3

( ) ( )

2104ENG Construction Engineering Tutorial Solutions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q5

LF = 0.725

SF = 0.8

Volume (Cm3) = 50,000Cm3

( )

( )

( )

( )

( )

*Trucks can only haul loose material and round up to the nearest load

Q6

Loose (Lm3) = 1483kg/m3

Bank (Bm3) = 1839kg/m3

Compacted (Cm3) = 2166kg/m3

a)

b)

Volume (Cm3) = 764,600Cm3

*Exact values should be used throughout calculations and rounded at the end.

( )

( )

( )

( )

( )

Q7

( ) ( ) ( )

( )

( )

END OF SOLUTIONS

2104ENG Construction Engineering Tutorial Solutions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 4 (Week 6) – Excavation

Summary

Actual Volume = Heaped vol. × Bucket Fill Factor (Table 3.2)

Production Estimating for hydraulic shovel and backhoe

Production (P) = C × S × V × B × E [Lm3/hr]

Cycle/h

Job efficiency

Swing factor

Bucket fill factor

Heaped bucket volume

Reference tables from text book:

2104ENG Construction Engineering Tutorial Questions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q1 Estimate the actual volume of common earth in bank measure carried by a hydraulic

excavator bucket whose heaped capacity is 1.91 Lm3.

Q2 Estimate the actual bucket load in bank measure for a hydraulic backhoe whose heaped

capacity is 1.6 Lm3. The machine is excavating sand and gravel.

Q3 Estimate the hourly production in bank measures of a hydraulic shovel loading sand and

gravel into trucks. The machine is equipped with a front dump bucket having a heaped bucket

capacity of 2.3 Lm3. Average swing angle is 75 degrees, job conditions are good, and

management conditions are excellent.

Q4 A hydraulic shovel with a bottom dump bucket and a 2.68Lm3 heaped capacity is

excavating tough clay. The swing angle is 120 degrees, and job efficiency is 75%. Estimate

the shovel’s hourly production in bank measure.

END OF TUTORIAL

2104ENG Construction Engineering Tutorial Questions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 4 (Week 6) – Excavation – Solutions

Q1

Heaped volume = 1.91Lm3

Bucket Fill Factor (Common earth) = 0.95 (from table 3.2)

Convert to bank volume: LF = 0.8 (from table 2.5)

Q2

Heaped volume = 1.6Lm3

Bucket Fill Factor (Sand and gravel) = 0.95 (from table 3.2)

Convert to bank volume: LF = 0.89 (from table 2.5)

Q3

Hourly Production (P) = C S V B E

C = 170 cycles/hr (Table 3.3)

S = 1.05 (Table 3.3)

V = 2.3Lm3

B = 0.95 (Table 3.2)

E = 0.78 (Table 2.1)

Convert to bank volume: LF = 0.89 (from table 2.5)

Q4

Hourly Production (P) = C S V B E

C = 150 cycles/hr (Table 3.3)

S = 0.94 (Table 3.3)

V = 2.68Lm3

B = 0.80 (Table 3.2)

E = 0.75 (Provided in question)

Convert to bank volume: LF = 0.77 (from table 2.5)

END OF SOLUTIONS

2104ENG Construction Engineering Tutorial Solutions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 5 (Week 7) ± Mid Semester Exam Revision

Summary

Refer to previous weeks summaries for formulas and tables

Q1 The expected return on an investment opportunity is considered as 15%. Additionally, tax

is 5% and insurance cost is 5%. Find the MARR.

Using the MARR, how much must be deposited at the end of each year into a bank in order to

accumulate $100,000 after 15 years?

Q2 A crawler tractor costs $25,000 has an estimated salvage value of $5,000 and a 5-year

life. Using the double-declining-balance method of depreciation, find the tractor’s yearly

depreciation and book value at the end of each year.

Q3 The average load of an excavator is 4.0 Lm3 per cycle. The soil’s load factor is 0.80,

cycle time average is 1.5 minutes and the job efficiency factor is 0.9.

a) What is the hourly production in Bm3 for the excavator?

b) If the hourly cost of the excavator is $75 and one truck is $55. If one excavator and

eight trucks are required to achieve the production, find the unit cost of production.

Q4 A soil weighs 1089 kg/m3 loose, 1839 kg/m3 in its natural state, and 2166 kg/m3

compacted. Find the following:

a) Load factor and shrinkage factor of soil.

b) Swell and shrinkage of soil

c) How many truckloads are required for hauling 500,000 BCM of the soil to a

construction site if the capacity of truck is 5m3 ?

Q5 Estimate the time required to load 306 m3 of loose gravel into trucks using a clamshell

having a heaped bucket capacity of 0.75m3 with an estimated cycle time of 25 seconds.

Q6 A small hydraulic shovel is excavating hard clay. Heaped capacity of the front dump

bucket is 1.25m3. The bucket fill factor is 0.90, job efficiency is estimated to be 40 min/hr

and the average swing angle is 180°. Estimate the hourly production in bank measure.

END OF TUTORIAL

2104ENG Construction Engineering Tutorial Questions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 5 (Week 7) – Mid Semester Exam Revision – Solutions

Q1

MARR = 15% + 5% + 5% = 25%

Cash flow diagram:

where: i = 25% (0.25)

n = 15 years

Determine annual payments required:

Q2 DDB Method

, where N = 5

Year Depreciation Book Value (End of year)

0 0 $25,000

1 $10,000 $15,000

2 $6,000 $9,000

3 $3,600 $5,400

4 $400 (NOT $2,160) $5,000 (NOT $3,240)

5 $0 (NOT $1,296) $5,000 (NOT $1,944)

*Book value CANNOT go below salvage value, thus once salvage value has been reached,

no further depreciation takes place using this method.

2104ENG Construction Engineering Tutorial Solutions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q3

a)

Excavator = 4.0Lm3/cycle

Cycle Time = 1cycle/1.5min.

LF = 0.80

Job eff. Factor = 0.9

Need to apply job efficiency factor and load factor to convert to Bm3.

b)

Excavator cost = $75/hour

Trucks cost = $55/hour x 8 trucks = $440/hour

Production (one excavator + 8 trucks) = 115.2Bm3/hour

Q4

Loose (Lm3) = 1089kg/m3

Bank (Bm3) = 1839kg/m3

Compacted (Cm3) = 2166kg/m3

a)

b)

c)

Volume (Bm3) = 500,000Bm3

*Exact values should be used throughout calculations and rounded at the end.

2104ENG Construction Engineering Tutorial Solutions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q5

Heaped volume = 0.75Lm3

Bucket Fill Factor (Gravel) = 0.95 (from table 3.2)

Q6

Hourly Production (P) = C S V B E

C = 135 cycles/hr (Table 3.3)

S = 0.83 (Table 3.3)

V = 1.25 Lm3

B = 0.90 (Table 3.2)

E = 40/60 = 0.67 (Provided in question)

Convert to bank volume: LF = 0.77 (from table 2.5)

END OF SOLUTIONS

2104ENG Construction Engineering Tutorial Solutions 3

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 6 (Week 9) – Loading and Hauling

Summary

Total Cycle Time = Fixed time + Variable time

- Fixed time (Loading & dumping): Components of cycle time other than travel

time.

- Variable time (Haul, return & turning): The travel time required for a unit to haul

material to the unloading site and return.

Hauling

Time

Loading Dumping

Return

Time

To determine maximum speed of vehicle, total resistance to movement of vehicle is

required.

Total Resistance [kg] = Grade Resistance (G.R.) + Rolling Resistance (R.R.)

Rolling Resistance (R.R.) is primary due to tyre flexing and penetration of the travel

surface and is determined by:

- R.R. [kg] = Rolling Resistance Factor (R.R.F.) [kg/t] × Weight [t]

- R.R.F. [kg/t] = 20 + (6 × cm Penetration)

Grade Resistance (G.R.) represents that component of vehicle weight which acts

parallel to inclined surface.

- G.R. [kg] = Grade Resistance Factor (G.R.F.) (kg/t) × Vehicle weight (t), or

- G.R. [Kg] = Vehicle (kg) × Grade

- G.R.F. [kg/t] = 10 × Grade (%)

Total resistance to movement of vehicle can be expressed in [Kg]. However, simpler

method for expressing as grade is as a percentage (%). This method of expressing is

referred to as effective grade, equivalent grade or percentage total resistance:

- Effective Grade (%) = Grade(%) + R.R.F. [Kg/t] / 10

Maximum usable pull (traction force) = Coefficient of traction × weight on driving

wheels

Compactor Production (CCM/hr) = (10 × W × S × L × E)/P

- P = number of passes required

- W = width compacted per pass (m)

- S = compactor speed (km/hr)

- L = compacted lift thickness (cm)

- E = job efficiency

2104ENG Construction Engineering Tutorial Questions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Reference tables:

2104ENG Construction Engineering Tutorial Questions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q1 The haul road from the borrow pit to the fill has an adverse grade of 4%. Wheel–type

hauling units will be used on the job and it is expected that the haul road rolling resistance

will be 50 kg/t.

a) What will be the effective grade for the haul?

b) Will the hauling units experience the same effective grade for the return trip?

Q2 An off-highway truck weighs 18,144 kg empty and carries a payload of 29,030 kg. The

loaded truck travels up a 5% grade over a road having a rolling resistance factor of 50 kg/t.

a) What is the total resistance (kg)

b) What is the effective grade?

Q3 A wheel tractor-scraper whose weight on the driving wheels is 16,330 kg has a gross

weight of 29,030 kg. If the road surface is wet earth having a rolling resistance of 60 kg/t,

what is the maximum grade the scraper could ascend?

Q4 A rubber-tired tractor has a total weight of 18,000 kg and the maximum rimpull is

9000kg. If the tractor is operating on wet sand with a coefficient of traction of 0.30:

a) What would be the traction force? Would you expect the wheels to slip?

b) If the tractor is operating on dry clay, would the full power of the engine be used?

Q5 A power-shift crawler tractor is excavating tough clay and pushing it a distance of 29m.

Maximum reverse speed are; first range 4.8 km/hr, second range 8.1 km/hr, and third range

12.9 km/hr. Rated blade capacity is 7.65 Lm3. Estimate dozer production if the job efficiency

factor is 0.83.

Q6 Why might the laboratory and field optimum moisture contents vary for a particular soil?

Q7 Estimate the production in compacted cubic meters per hour of a self-propelled tamping

foot roller under the following conditions:

Average speed = 8.0 km/hr

Compacted lift thickness = 15.2 cm

Effective roller width = 3.05m

Job efficiency = 0.75

Number of passes = 8

Q8 32km of gravel road require reshaping and leveling. You estimate that a motor grader will

require 2 passes at 4.8 km/hr, 2 passes at 6.4 km/hr, and 2 passes at 8.9 km/hr to accomplish

the work. How many grader hours will be required for this work if the job efficiency factor is

0.75?

END OF TUTORIAL

2104ENG Construction Engineering Tutorial Questions 3

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 6 (Week 9) – Loading and Hauling – Solutions

Q1

Grade = 4%

RRF = 50 kg/t

a)

b)

*Grade for return trip is negative as it is going downhill

There is not the same effective grade for the two cases.

Q2

Truck mass = 18,144kg

Payload = 29,030kg

Grade = 5%

RRF = 50kg/t

a)

b)

2104ENG Construction Engineering Tutorial Solutions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q3

Total mass = 29,030kg

Mass on driving wheels = 16,330kg

RRF = 60kg/t

Coefficient of traction (wet earth, driving wheels) = 0.45 (table 4.2)

Traction force = coefficient of traction × weight on driving wheels

= 0.45 × 16,330kg = 7348.5kg

Q4

a)

Traction force = coefficient of traction × weight on driving wheels

= 0.3 × 18,000kg = 5,400kg

Maximum rimpull = 9000kg > 5400kg

The power of the engine is greater than the traction force, so the wheels will slip on this

surface.

b)

Coefficient of traction (dry clay) = 0.6

Traction force = coefficient of traction × weight on driving wheels

= 0.6 × 18,000kg = 10,800kg

Maximum rimpull = 9000kg < 10,800kg

The power of the engine is smaller than the traction force, so the wheels will not slip on this

surface and the full power of the engine can be used.

2104ENG Construction Engineering Tutorial Solutions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q5

Distance = 29m

Capacity = 7.65Lm3

Job efficiency = 0.83

Fixed time = 0.05min (table 4.4)

Speed (haul) = 2.4km/h (table 4.5 – hard materials 30m or less)

Speed (return) = 8.1km/h (table 4.5 – 30m or less, max 2nd range speed)

Q6

The compactive effort delivered by a piece of compaction equipment is seldom exactly the

same as that of either the standard or modified laboratory compaction test. Therefore the

field optimum moisture content for a particular soil/compactor combination rarely exactly

matches the laboratory optimum moisture content for the soil.

Q7

W = 3.05m

S = 8.0km/hr

L = 15.2cm

E = 0.75

P=8

Q8

Apply efficiency factor:

END OF SOLUTIONS

2104ENG Construction Engineering Tutorial Solutions 3

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 7 (Week 10) – Rock Excavation

Summary

Rock investigation:

Where:

- H = thickness of layer (m)

- D = distance from sound source to first intersection of line of graph (critical distance)

- V1 = velocity of upper layer (∆d/∆t)

- V2 = Velocity of second layer (∆d/∆t)

Drilling pattern and rock yield:

- where H = effective depth (90% of original hole depth)

Rock ripping production:

Where:

- D = average penetration (m)

- W = average width loosened (m)

- L = length of pass (m)

- E = job efficiency

- T = time for one ripper pass (minutes)

2104ENG Construction Engineering Tutorial Questions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q1 Given the refraction seismograph test data in the table below; calculate the seismic wave

velocity in each soil layer. Find the depth of upper layer.

Time 2.5 5.0 7.5 8.8 10.0 11.3 12.5

(ms)

Dist. 3.05 6.10 9.15 12.20 15.25 18.30 21.35

(m)

Q2 Trial operation indicate that a rectangular pattern with holes 6.1m deep spaced on 2.44m

centers will yield a satisfactory rock break with an effective depth of 5.8m. Determine the

rock volume produced per meter of drilling

Q3 A tractor mounted ripper will be used for excavating a limestone having a seismic

velocity of 1830m/sec. Field tests indicate that the ripper can obtain satisfactory rock

fracturing to a depth of 0.61m with one pass of a single shank at 0.91m intervals. Average

ripping speed for each 122m pass is 2.4km/h. Maneuver and turn time for each pass averages

0.3min. Job efficiency is estimated at 0.70. Machine cost including the operator is $130/h.

Estimate the hourly production and unit cost of excavation.

Q4 A site is 91.4m by 121.9m and must be excavated an average depth of 3.658m. The

drilling equipment to be used will consist of an air-powered track drill and air compressor.

The average drilling rate is estimated at 30.5m/h. Trial blasting indicates that holes drilled in

a 3.658m rectangular pattern will provide adequate fracturing. A hole depth of 4.115m must

be drilled to yield a 3.658m effective depth. The blasting agent to be used is ANFO with a

powder factor of 0.297 kg/Bm3. Primer with an electric blasting cap will be used in each hole.

A labour force of one drill operator and one compressor operator will be used for drilling.

One blaster and one helper will be employed for the blasting.

Cost information for the excavation is shown below:

Labour: Blaster $18/h

Helper $15/h

Drill Operator $17.50/h

Compressor Operator $18/h

Equipment: Track drill and compressor $63/h

Materials: ANFO $0.705/kg

Primer, cap and stemming $3/hole

a) Estimate the hourly production (Bm3/h)

b) Determine:

i) The unit cost of drilling ($/Bm3)

ii) The unit cost of blasting ($/Bm3)

iii) The total unit cost for the excavation ($/Bm3)

END OF TUTORIAL

2104ENG Construction Engineering Tutorial Questions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 7 (Week 10) – Rock Excavation – Solutions

Q1

Graph the data:

Determine the velocities:

Determine the depth of the upper layer:

2104ENG Construction Engineering Tutorial Solutions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q2

Diagram for visualisation:

Hole depth = 6.1m

Effective depth = 5.8m

*If effective depth is not given, use 90% of hole depth

*Note the units are not m2 for the second part

Q3

D = 0.61m

W = 0.91m

L = 122m

E = 0.70

Machine and operator cost = $130/h

Determine time taken for each pass:

Determine production:

Determine unit cost:

2104ENG Construction Engineering Tutorial Solutions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q4

a) Determine production values:

b) Costs

i) Determine drilling cost:

Labour cost = one drill operator ($17.50/h) + one compressor operator ($18.00/h) = $35.50/h

Equipment = $63.00/hour

ii) Determine blasting cost:

Material cost

Primer, cap and stemming = $3/hole

Labour cost = one blaster ($18/h) + one helper ($15/h) = $33/h

iii) Determine total cost:

END OF SOLUTIONS

2104ENG Construction Engineering Tutorial Solutions 3

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 8 (Week 11) – Concrete Formwork

Summary

Calculate pressures

- Hydrostatic Pmax = γh (kN/m2)

- Stiffening Pmax = γR + 5 (kN/m2)

- Arching (width < 500mm) Pmax = 3R + 0.1d + 15 (kN/m2)

- γ = unit weight of concrete (typically 24kN/m3)

- h = height of wall

- R = rate of pouring (m/hr)

- d = wall thickness (mm)

- take the smallest value of the three calculated pressures as design pressure

Checking bending

- f = allowable flexural stress

- b = load checking distance (typically 1000mm)

- h = thickness of formwork

- w = design pressure

Checking shear

- = allowable shear stress

max

- Adopt smaller value of L(span) and L(shear) when checking deflection

Checking deflection

- L = span determined from bending and shear checking

- E = elastic modulus of formwork material

- I = second moment of inertia

- For deflection to be okay, it must satisfy either:

- ∆ < 0.003L if L ≤ 1m

- ∆ < 3mm if L > 1m

2104ENG Construction Engineering Tutorial Questions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q1 A 250mm thick basement wall has a total length of 50m and height of 3.5m. Calculate the

rate of pour based on a concrete pump capacity of 15 cubic meters per hour.

Q2 A 300mm thick wall, 15m in length and 4m high, is poured at the rate of 1.20 m/hr.

Assume concrete unit weight 24 kN/m3. Calculate the maximum pressure developed in the

concrete to be used in formwork design.

Q3 A concrete column 450x450mm square and 8m high is poured in 15 minutes. Calculate

the resulting pressure design for the formwork.

Q4 Form are being designed for a 2.4m high concrete wall to be poured at a rate of 1.20m/hr.

Sheathing will be 1.2x2.4m sheets of 16mm thick plyform. Determine stud spacing if

allowable flexural and shear stresses are 10.0 and 1.20 N/mm2, respectively. Assume elastic

modulus value of 7.0 kN/mm2 and ignore the arching effect.

Q5 Calculate the rate of pore for a section of an elevator shaft in the central core on the tenth

floor of a high-rise building. Assume the distance from the ground to the top of the wall form

is 40 m. A tower crane, using the two buckets, each with a capacity of 1.1 cubic meters, has a

rate of travel of 30m/min up and 45m/min down. Assume pick-up time is 20 seconds and

dump time is 3 minutes. Pour conditions are: wall height = 4.0 m, wall thickness = 250 mm,

and wall length = 30 m.

END OF TUTORIAL

2104ENG Construction Engineering Tutorial Questions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 8 (Week 11) – Concrete Formwork – Solutions

Q1

d = 250mm

l = 50m

h = 3.5m

Pump capacity = 15m3/hr

Q2

d = 300mm

l = 15m

h = 4m

R = 1.2m/h

γ= 24kN/m3

Hydrostatic

Pmax = γ

h = 24kN/m3 x 4m = 96kN/m2

Stiffening

Pmax = γR + 5 = 24kN/m3 x 1.2m/h + 5 = 33.8kN/m2

Arching (width < 500mm)

Pmax = 3R + 0.1d + 15 = 3 x 1.2m/h + 0.1 x 300 + 15 = 48.6kN/m2

Therefore the maximum pressure to be used in the formwork design is 33.8kN/m2

2104ENG Construction Engineering Tutorial Solutions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q3

d = 450mm

l = 450m

h = 8m

t = 15minutes = 0.25hrs

γ= 24kN/m3

Determine rate of pour:

Determine pressures:

Hydrostatic

Pmax = γ

h = 24kN/m3 x 8m = 192kN/m2

Stiffening

Pmax = γR + 5 = 24kN/m3 x 32m/h + 5 = 773kN/m2

Arching (width < 500mm)

Pmax = 3R + 0.1d + 15 = 3 x 32 m/h + 0.1 x 450 + 15 = 156kN/m2

Therefore the maximum pressure to be used in the formwork design is 156kN/m2

Q4

h = 2.4m

R = 1.2m/h

γ= 24kN/m3

Determine pressures:

Hydrostatic

Pmax = γ

h = 24kN/m3 x 2.4m = 57.6kN/m2

Stiffening

Pmax = γR + 5 = 24kN/m3 x 1.2m/h + 5 = 33.8kN/m2

Arching (width < 500mm)

No information is given on thickness so this method cannot be used

Therefore the maximum pressure to be used in the formwork design is 33.8kN/m2

2104ENG Construction Engineering Tutorial Solutions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Check bending:

f = 10N/mm2

b = 1000mm (checking for loading on 1m of plywood)

h = 16mm

w = 33.8

2

max = 1.2N/mm

2

E = 7kN/mm

Use a span (L) of 350mm

Check shear:

350mm < 630mm so adopt L = 350mm

Check deflection:

As allowable deflection is lower than actual deflection, a smaller span should be used, try

300mm

The stud spacing should be 300mm

2104ENG Construction Engineering Tutorial Solutions 3

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q5

Cycle times:

Total cycle time = 5.56min

*Filling time does not need to be considered as two buckets are being used (one bucket is

filled while the other is emptied).

END OF SOLUTIONS

2104ENG Construction Engineering Tutorial Solutions 4

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 9 (Week 13) – Final Exam Review

Summary

See summaries from previous tutorials

Q1 A construction company has to decide between two options; to purchase or to lease an

asphalt plant based on the net present value comparison method. Detailed cost estimates are

shown below. Determine which option is the most cost effective and by how much. The bank

interest rate is 12%.

Purchase option:

Initial cost is $150,000. Salvage value at the end of 5 years is $30,000. Annual maintenance

cost is estimated at $5,000 at year end.

Leasing option:

Annual lease is $30,000 increasing by 15% each year (payable at the start of year). The plant

will be maintained by the lessor.

Q2 A construction company has to decide between buying a new asphalt paver and a second

hand one. The income and expenditure estimates for these are presented below. The interest

rate is 9%. Compare the two options on the basis of (a) present worth and (b) annual cost

methods. Which option is best on economic grounds?

New paver Second-hand paver

Purchase price 400,000 150,000

Annual operating cost 50,000 60,000

Period of operation (years) 6 4

Salvage value 80,000 30,000

Annual income 180,000 160,000

Q3 The plot of area shown below will have to be excavated for the construction of a

basement. The figures within brackets are the depth of cut required at those locations in

metres. Calculate the amount of total excavation. Find loose and compacted volume of total

excavation. Use shrinkage factor and load factor as 0.7 and 0.5, respectively.

2104ENG Construction Engineering Tutorial Questions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q4 An off-highway truck weights 20,000 kg empty and carries a payload of 30,000 kg. The

loaded truck travels over a flat road having a rolling resistance factor of 50 kg/t. Find:

a) total resistance (kg)

b) effective grade

Q5 Three different types of graders will be used for leveling three different sections of a 45.0

km gravel road. Using information given in the following table, estimate grader hours. Job

efficiency factor is 0.80.

Q6 A 600.0 mm thick concrete wall, 40.0 m in length and 5.0 m in height is poured at the rate

of 12.0 m3/hr. Assume concrete density is 24 kN/m3. Calculate resulting design pressure for

the formwork.

Q7 Trial blasting indicates that 15.0 cm holes; each of 10.0 m length, drilled in a 3 m by 2 m

rectangular pattern will provide adequate fracturing. The average drilling rate is 20.0 m/hr.

Estimate the yield, drilling yield and hourly production. Considering only blasting operation,

estimate unit cost of rock excavation by using following information:

The blasting agent is ANFO; powder factor is 0.30 kg/Bm3. One blaster and two helpers will

be employed for blasting. Use following cost table:

Labour: Blaster $20/hour

Helper $15/hour

Material: ANFO $0.9/kg

END OF TUTORIAL

2104ENG Construction Engineering Tutorial Questions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Tutorial 9 (Week 13) – Final Exam Review – Solutions

Q1

Purchase option:

Leasing option:

Difference:

Leasing – purchasing = $158,254.85 – $151,001.08 = $7,253.78

Therefore the purchasing option is the most cost effective by $7,253.78

2104ENG Construction Engineering Tutorial Solutions 1

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q2

a) Present worth method

New paver:

Second hand paver:

Therefore the new paver is worth more in today’s money so is more economical using this

method.

2104ENG Construction Engineering Tutorial Solutions 2

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

b) Annual cost method

New paver:

Second hand paver:

Therefore the second hand paver is worth more per year so is more economical using this

method.

Q3

2104ENG Construction Engineering Tutorial Solutions 3

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q4

a) Total resistance

b) Effective grade

Q5

Q6

d = 600mm

l = 40m

h = 5m

Pouring rate = 12m3/h

γ = 24kN/m3

Determine rate of pour:

Determine pressures:

Hydrostatic

Pmax = γh = 24kN/m3 x 5m = 120kN/m2

Stiffening

Pmax = γR + 5 = 24kN/m3 x 0.5 m/h + 5 = 17kN/m2

Arching (width < 500mm)

Arching cannot be considered as the thickness is over 500mm

Therefore the maximum pressure to be used in the formwork design is 17.0kN/m2

2104ENG Construction Engineering Tutorial Solutions 4

Downloaded by Matthew .Raison (matthewraison@gmail.com)

lOMoARcPSD|4172617

Q7

Effective depth (h) = 10m x 0.9 = 9m

Yield:

Drilling yield:

Hourly production:

Unit cost of production:

Labour cost = one blaster ($20/h) + two helpers ($15/h) = $50/h

*This unit cost is for blasting only

END OF SOLUTIONS

2104ENG Construction Engineering Tutorial Solutions 5

Downloaded by Matthew .Raison (matthewraison@gmail.com)

You might also like

- Septic Tank SizingDocument9 pagesSeptic Tank SizingKitchen KnifeNo ratings yet

- Construction PDFDocument18 pagesConstruction PDFMohamedRaahim100% (2)

- Issue Date: Week 1 Submission Date: 18 November 2020 Feedback Date: Week 6Document8 pagesIssue Date: Week 1 Submission Date: 18 November 2020 Feedback Date: Week 6teck yuNo ratings yet

- 10 CH 17 SchedulingDocument48 pages10 CH 17 SchedulingDarsh MenonNo ratings yet

- SRT259 Construction Projects - Assignment 1 Guide Individual Report On Regulatory RequirementsDocument4 pagesSRT259 Construction Projects - Assignment 1 Guide Individual Report On Regulatory Requirementssikandar abbasNo ratings yet

- Application Packaging Course ContentsDocument6 pagesApplication Packaging Course ContentsrajasekharNo ratings yet

- Applied Physics Lab Report 6 (Group A4) PDFDocument6 pagesApplied Physics Lab Report 6 (Group A4) PDFT RexNo ratings yet

- Heinemann Maths Year 9 VELS AnswersDocument48 pagesHeinemann Maths Year 9 VELS AnswersNihal RaoNo ratings yet

- PROBLEM 17.137: SolutionDocument7 pagesPROBLEM 17.137: SolutiontaNo ratings yet

- Week 3 SolutionDocument5 pagesWeek 3 SolutionI190006 Taimoor JanNo ratings yet

- Mini Project On Design of Shallow FoundationsDocument2 pagesMini Project On Design of Shallow Foundationsdaryhero42100% (1)

- Chapter 1 - MFRS 116Document60 pagesChapter 1 - MFRS 116Muhammad HazlamiNo ratings yet

- BCS Company ProfileDocument42 pagesBCS Company ProfileAnnie MagdaleneNo ratings yet

- Halifax County School Board Aug. 25 MeetingDocument50 pagesHalifax County School Board Aug. 25 MeetingDavid CrossNo ratings yet

- 11 SolutionsDocument10 pages11 Solutionsttufan1No ratings yet

- New England Root Beer DC LocationDocument4 pagesNew England Root Beer DC LocationFazal Shaikh0% (1)

- MS Brothers Super Rice MillDocument9 pagesMS Brothers Super Rice MillMasud Ahmed khan100% (1)

- Load Bearing Structure Quantity EstimateDocument9 pagesLoad Bearing Structure Quantity EstimateNabin KalauniNo ratings yet

- Precon Company ProfileDocument81 pagesPrecon Company Profileanon_889047815No ratings yet

- Tsurumi's RSR-KS Rotary Air Blowers with 3-lobe Spur RotorDocument7 pagesTsurumi's RSR-KS Rotary Air Blowers with 3-lobe Spur RotorEef Enterpises ValenzuelaNo ratings yet

- ACCT 5001 Final ExamDocument18 pagesACCT 5001 Final Examaditya dashNo ratings yet

- Kent's E-Jeepney Kent's E-Jeepney: TotalDocument20 pagesKent's E-Jeepney Kent's E-Jeepney: TotalKentNo ratings yet

- Sample Acca Study Question Bank Paper f9 Financial Management December 2014 June 2015 EditionDocument64 pagesSample Acca Study Question Bank Paper f9 Financial Management December 2014 June 2015 EditionNiharika LuthraNo ratings yet

- Aero-Engine Speed Reducer Gearbox: Mechanical Design BDocument14 pagesAero-Engine Speed Reducer Gearbox: Mechanical Design BanuNo ratings yet

- Car Rental AgreementDocument3 pagesCar Rental Agreementron haddrick100% (1)

- Programme 6 10Document17 pagesProgramme 6 10Pragadesh Hari. SNo ratings yet

- Source: Company DataDocument9 pagesSource: Company DataPhang Yu ShangNo ratings yet

- Exercise 14Document11 pagesExercise 14dwitaNo ratings yet

- Assignment DFA6127Document3 pagesAssignment DFA6127parwez_0505No ratings yet

- Intermediate Track II: September 2000 Minneapolis, MinnesotaDocument60 pagesIntermediate Track II: September 2000 Minneapolis, MinnesotaFayDulNo ratings yet

- Pricol Limited - Broker Research - 2017 PDFDocument25 pagesPricol Limited - Broker Research - 2017 PDFnishthaNo ratings yet

- Orange County Comptroller Audit On BridgesDocument44 pagesOrange County Comptroller Audit On BridgesDaniel R. DahmNo ratings yet

- Taking-Off Sheet, BQ Sheet and Concrete Mix Design FormDocument7 pagesTaking-Off Sheet, BQ Sheet and Concrete Mix Design FormiskandarNo ratings yet

- Robbins, Coulter, Sidani, Jamali: Management: Second Arab World EditionDocument45 pagesRobbins, Coulter, Sidani, Jamali: Management: Second Arab World EditionHassan ElbayyaNo ratings yet

- Project Charter Project Name: Start Date: End Date: Project Description: Project ScopeDocument1 pageProject Charter Project Name: Start Date: End Date: Project Description: Project ScopeMuhammad Musa100% (1)

- Report - 2022 09 16 - 11 31 32Document1 pageReport - 2022 09 16 - 11 31 32Ricky Yadav100% (1)

- Interest & Equivalence: Reporter: Dinah Fe T. OlitanDocument24 pagesInterest & Equivalence: Reporter: Dinah Fe T. OlitanDinah Fe Tabaranza-OlitanNo ratings yet

- Sample-B O QDocument39 pagesSample-B O QKeyur Gajjar50% (2)

- Linear Programming Graphical MethodDocument45 pagesLinear Programming Graphical Methodprasobh911No ratings yet

- CB510 Project Cash Flow AnalysisDocument3 pagesCB510 Project Cash Flow AnalysisShroukAdelMohamedGaribNo ratings yet

- Proposal Chaity Composite of Gulshan BranchDocument25 pagesProposal Chaity Composite of Gulshan BranchMD Meftahul Alam50% (2)

- Sewerage Project of Barmer TownDocument1 pageSewerage Project of Barmer TownsombansNo ratings yet

- WR Assignment OneDocument12 pagesWR Assignment Oneashe zinab100% (1)

- Amirul Bin Abd Rashid: Faculty of Mechanical Engineering, University Teknologi MARADocument85 pagesAmirul Bin Abd Rashid: Faculty of Mechanical Engineering, University Teknologi MARAimran hafizNo ratings yet

- List of Structure Drawing To Be Taken From HO As On Date 16.01.2023Document1 pageList of Structure Drawing To Be Taken From HO As On Date 16.01.2023SRK QSNo ratings yet

- 7 Final Accounts of CompaniesDocument15 pages7 Final Accounts of CompaniesAakshi SharmaNo ratings yet

- CH 10 Incomplete RecordsDocument27 pagesCH 10 Incomplete RecordsPawan Poynauth0% (1)

- Presentable Industrial Training Experience GabrielDocument15 pagesPresentable Industrial Training Experience GabrielOkortnne AyibaNo ratings yet

- 4-Quantity CalculationsDocument18 pages4-Quantity CalculationsAhmad SalihNo ratings yet

- BoQ - Structure Steel Request CostingDocument12 pagesBoQ - Structure Steel Request CostingRanu JanuarNo ratings yet

- Cashbook SampleDocument17 pagesCashbook SampleSubramaniam NathanNo ratings yet

- Materials Management Manual 22042017Document148 pagesMaterials Management Manual 22042017shishirgupta20070% (1)

- AUSMAT Student Guide 2011Document16 pagesAUSMAT Student Guide 2011Sunway UniversityNo ratings yet

- Importance of Site Surveys for Quantity SurveyingDocument6 pagesImportance of Site Surveys for Quantity SurveyingyhNo ratings yet

- Rugby Club Income Statement & Balance SheetDocument3 pagesRugby Club Income Statement & Balance SheetAdorf JamesNo ratings yet

- DepreciationDocument4 pagesDepreciationMùhammad TàhaNo ratings yet

- Tutorial Solution DepreciationDocument2 pagesTutorial Solution DepreciationbillNo ratings yet

- BAP Corporation Investment Proposal ReviewDocument4 pagesBAP Corporation Investment Proposal Reviewmohitgaba19No ratings yet

- DEPRESIASIDocument7 pagesDEPRESIASISaffira Annisa BeningNo ratings yet

- Calculating NPV, IRR, PBP and DPBP for an Investment ProjectDocument7 pagesCalculating NPV, IRR, PBP and DPBP for an Investment ProjectNgân NguyễnNo ratings yet

- Assignment 1Document1 pageAssignment 1MatthewNo ratings yet

- Action:: 2105ENG Tri 2 2020 Students Number Used in AssignmentsDocument4 pagesAction:: 2105ENG Tri 2 2020 Students Number Used in AssignmentsMatthewNo ratings yet

- Assignment 3Document2 pagesAssignment 3MatthewNo ratings yet

- Soil mechanics notes and formulasDocument132 pagesSoil mechanics notes and formulasMatthewNo ratings yet

- 2020-2101ENG Tutorial 1Document22 pages2020-2101ENG Tutorial 1MatthewNo ratings yet

- Week 5b - Revision ExercicesDocument2 pagesWeek 5b - Revision ExercicesMatthewNo ratings yet

- 2002ENG Final-Exam 2010 NathanDocument9 pages2002ENG Final-Exam 2010 NathanMatthewNo ratings yet

- Fluid Mechanics ExamDocument6 pagesFluid Mechanics ExamMatthewNo ratings yet

- 1501ENG Supplementary Material & Workbook For Statics 2019 (T3) - Pages-DeletedDocument14 pages1501ENG Supplementary Material & Workbook For Statics 2019 (T3) - Pages-DeletedMatthewNo ratings yet

- Eng Ec Example Question SolutionDocument3 pagesEng Ec Example Question SolutionMatthewNo ratings yet

- 1501ENG Supplementary Material & Workbook For Statics 2019 (T3) - Pages-DeletedDocument6 pages1501ENG Supplementary Material & Workbook For Statics 2019 (T3) - Pages-DeletedMatthewNo ratings yet

- Calculus II Exam Buster Answers PDFDocument3 pagesCalculus II Exam Buster Answers PDFMatthewNo ratings yet

- Questions - Site InvestigationDocument2 pagesQuestions - Site InvestigationMatthewNo ratings yet

- Exam 2014 Answers Quiz Week 4Document3 pagesExam 2014 Answers Quiz Week 4MatthewNo ratings yet

- Exam 2011 Questions and AnswersDocument13 pagesExam 2011 Questions and AnswersMatthewNo ratings yet

- Exam 2012 Questions and Answers Final ExamDocument11 pagesExam 2012 Questions and Answers Final ExamMatthewNo ratings yet

- Exam 2013 Questions and Answers Final ExamDocument9 pagesExam 2013 Questions and Answers Final ExamMatthewNo ratings yet

- SoE Report of TamilnaduDocument97 pagesSoE Report of TamilnaduAditya SharmaNo ratings yet

- A Smart Solution For Plant Disease Detection Based On Iot: November 2020Document4 pagesA Smart Solution For Plant Disease Detection Based On Iot: November 2020Mangala NageshwariNo ratings yet

- Minor Irrigation Drip Irrigation GuideDocument44 pagesMinor Irrigation Drip Irrigation GuideSrinivasan SakthivelNo ratings yet

- In Situ Stresses - CH 9Document36 pagesIn Situ Stresses - CH 9waleed khalidNo ratings yet

- SG 2 CE 411 Properties of SoilDocument9 pagesSG 2 CE 411 Properties of SoilkennsindayenNo ratings yet

- Class 8 Crop Production CH 1 (Lesson Plan)Document5 pagesClass 8 Crop Production CH 1 (Lesson Plan)sunita mishra100% (3)

- Landscape and Architecture SpecificationsDocument30 pagesLandscape and Architecture SpecificationsNouman Mohsin100% (1)

- Indian Standard: Method of Determination of Modulus of Sw3Grade Reaction (K-VALUE) of Soils in FieldDocument23 pagesIndian Standard: Method of Determination of Modulus of Sw3Grade Reaction (K-VALUE) of Soils in Fieldrahulgehlot2008No ratings yet

- Japanese Organic Agriculture Standard for PlantsDocument12 pagesJapanese Organic Agriculture Standard for PlantsNereyda SanchezNo ratings yet

- ToolingDocument30 pagesToolingKarym GomezNo ratings yet

- Activity 2 Report SheetDocument10 pagesActivity 2 Report SheetPatrick Anthony Calica JeminezNo ratings yet

- SoilTest Report (Baneswor)Document30 pagesSoilTest Report (Baneswor)Surendra MaharjanNo ratings yet

- Em Brewing Guide and ApplicationsDocument12 pagesEm Brewing Guide and ApplicationsDavidNo ratings yet

- Compaction Test Sand Cone MethodDocument27 pagesCompaction Test Sand Cone MethodAlex PandiazNo ratings yet

- Soil Moisture Estimation Using Remote Sensing and Data AssimilationDocument9 pagesSoil Moisture Estimation Using Remote Sensing and Data AssimilationJean_LucPicardNo ratings yet

- Syntropic FarmingDocument9 pagesSyntropic FarmingMou DASNo ratings yet

- SPTDocument43 pagesSPTAnonymous bUtSDElMTMNo ratings yet

- Shone Organic Farming IIDocument15 pagesShone Organic Farming IIShone Philips ThomasNo ratings yet

- Important Environment Notes From Wikipedia Ecosystem ServicesDocument24 pagesImportant Environment Notes From Wikipedia Ecosystem ServicesyaazelNo ratings yet

- EntisolsDocument25 pagesEntisolsSagar BasnetNo ratings yet

- Boulanger, Idriss - Soil Liquefaction During Earthquakes - 2008Document263 pagesBoulanger, Idriss - Soil Liquefaction During Earthquakes - 2008Roberto MonettaNo ratings yet

- Urton Takes A Breath With Yoga: Elphos EraldDocument10 pagesUrton Takes A Breath With Yoga: Elphos EraldThe Delphos HeraldNo ratings yet

- Guide To Specification of Geotextiles - Newzealand PDFDocument0 pagesGuide To Specification of Geotextiles - Newzealand PDFthadikkaranNo ratings yet

- Anti Termite Treatment Is.6313.2.2001 PDFDocument16 pagesAnti Termite Treatment Is.6313.2.2001 PDFGokulNathNo ratings yet

- Simple Present and Present Contiuous ExerciseDocument5 pagesSimple Present and Present Contiuous ExerciseIylia NatasyaNo ratings yet

- Rate AnalysisDocument15 pagesRate AnalysisBhagirath Bishnoi100% (1)

- Unit4 Lab PorosityPermeabilityDocument7 pagesUnit4 Lab PorosityPermeabilitynick5252No ratings yet

- Towards Sustainable Agriculture in CubaDocument24 pagesTowards Sustainable Agriculture in CubaTsamara KhansaNo ratings yet

- Ongole Data Sheet-18-19Document204 pagesOngole Data Sheet-18-19brahmamNo ratings yet

- Diesel Storage - Above Ground TankDocument16 pagesDiesel Storage - Above Ground TankBasil Oguaka100% (1)