Professional Documents

Culture Documents

Contoh Dokumen OPRP

Uploaded by

Anna FrederikaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Contoh Dokumen OPRP

Uploaded by

Anna FrederikaCopyright:

Available Formats

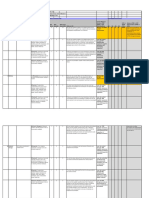

PT. SEKAR KATOKICHI Doc.

Number FSL-HACCP-OPRP-001

Revision 04

HACCP BREADED SHRIMP

Date March 10th , 2017

OPERATIONAL PRE REQUISITE PROGRAME (OPRP) Page 1of 11

Responsibili

Control Direct Corrective Document /

OPRP Hazard Inspection ty and Verification Validation

Measures Correction Action Record

Authority

Receiving Raw Pathogen Raw material What Raw material If the Supplier Responsibility: Form 4. Check Microbiology VCM-06

Material bacteria’ temperature temperature, personal temperature and training QC Raw Material at every raw

contamination checking and equipment at the cleanliness do Receiving material arrive

receiving cleanliness. not fulfill the Authority:

Personal and Where Receiving shrimp raw standard, Chief of QC Form 1.

equipment at the material returned the Microbiology Total

receiving cleanliness When Every supplier each material. Analysis

arrival

Who QC

How Shrimp temperature

checking, and personal

and equipment

cleanliness

Deheading Pathogen Hand and What Hand employee and If employees do employee Responsibility: Form 1. 1.Employee VCM-07

bacteria’ equipment equipment cleanliness not meet the training t QC Microbiology Total Hand Swab

contamination cleanliness Where Process room hygiene Analysis

When Every day requirements Authority: 2. Product

Microbiology

Who QC should not enter Chief of QC Form 13.

Testing

How Employee and the process room Daily Sanitation

equipment cleanliness Examination

OPRP/ Not CCP Breaded Process

Written by : Checked by : Acknowledge by :

Date :

PT. SEKAR KATOKICHI Doc. Number FSL-HACCP-OPRP-001

Revision 04

HACCP BREADED SHRIMP

Date March 10th , 2017

OPERATIONAL PRE REQUISITE PROGRAME (OPRP) Page 2of 11

Control Direct Corrective Responsibility Document /

OPRP Hazard Inspection Verification Validation

Measures Correction Action and Authority Record

Filth Check filth every What Filth By Filth taking Training and Responsibility: Form 7. Review of record VCM-08

hour sanction QC Deheading Deheading by

Where Deheading process Chief of QC

Authority:

When Every hour Production

Who QC

How By random sampling

Grading contamination Cleanliness of What Cleanliness of the machine The machine Employee Responsibility: Form. 01 1. Machine Swab VCM.- 09

of pathogenic the machine is before use training for QC Lab Analysis

bacteria maintained Where Process Room should be engine Results 2. Product

clean cleanliness Authority: Microbiology

Form 13 Testing

When Every day Chief of QC

Sanitation

Inspection

Who QC

How Check the machine

cleanliness

Control Direct Corrective Responsibility Document /

OPRP Hazard Inspection Verification Validation

Measures Correction Action and Authority Record

Peeling & contamination of Hand and What Hand employee and If employees employee Responsibility: Form 1. 1.Employee VCM-10

Deveining pathogenic equipment equipment cleanliness do not meet trainingt QC Microbiology Hand Swab

Written by : Checked by : Acknowledge by :

Date :

PT. SEKAR KATOKICHI Doc. Number FSL-HACCP-OPRP-001

Revision 04

HACCP BREADED SHRIMP

Date March 10th , 2017

OPERATIONAL PRE REQUISITE PROGRAME (OPRP) Page 3of 11

bacteria cleanliness the hygiene Total Analysis 2. Product

Where Process room requirements Authority: Microbiology

When Every day should not Chief of QC Form 13. Testing

Who QC enter the Daily

How Employee and equipment process room Sanitation

cleanliness Examination

Filth Checking Filth Filth checking What Filth By Filth taking Training and Responsibility: Form 7. Review of record VCM-11

every hour sanction QC Deheading Deheading by

Where Checking filth table Chief of QC

Authority:

When Every hour Production

Who QC

How By random sampling

Control Direct Corrective Responsibility Document /

OPRP Hazard Inspection Verification Validation

Measures Correction Action and Authority Record

Written by : Checked by : Acknowledge by :

Date :

PT. SEKAR KATOKICHI Doc. Number FSL-HACCP-OPRP-001

Revision 04

HACCP BREADED SHRIMP

Date March 10th , 2017

OPERATIONAL PRE REQUISITE PROGRAME (OPRP) Page 4of 11

Cutting contamination Hand and knife What Hand employee and knife before work training Responsibility: Form 1. 1.Employee VCM-12

of pathogenic cleanliness cleanliness hand and knife employees QC Microbiology Hand Swab

bacteria should be to hand Total Analysis

Where Process room clean condition hygiene and Authority: 2. Product

Microbiology

knife Chief of QC Form 13.

Testing

When Every day Daily

Sanitation

Who QC Examination

How Employee and knife

cleanliness

Stretching contamination Machine What Machine cleanliness the machine training of Responsibility: Form 1. 1 Machine Swab VCM-13

of pathogenic cleanliness before use employees QC Microbiology

bacteria Where Process room should be formachine Total Analysis 2. Product

clean condition cleanliness Authority: Microbiology

Testing

When Every day Chief of QC Form 13.

Daily

Who QC Sanitation

Examination

How Check machine cleanliness

OPRP/ Not CCP BREADED CRUMB PROCESS

Control Direct Corrective Responsibility Document /

OPRP Hazard Inspection Verification Validation

Measures Correction Action and Authority Record

Written by : Checked by : Acknowledge by :

Date :

PT. SEKAR KATOKICHI Doc. Number FSL-HACCP-OPRP-001

Revision 04

HACCP BREADED SHRIMP

Date March 10th , 2017

OPERATIONAL PRE REQUISITE PROGRAME (OPRP) Page 5of 11

Fermentasi I Pathogen Equipnent What cleanliness of material training of Responsibility: Form 1. VCM-14

bacteria’ cleanliness material storage storage should employees QC Microbiology Product

contamination be clean for the Total Analysis Microbiology

Where Process room cleanliness Authority: Testing

of storage Chief of QC Form 13.

When Every day Daily

Sanitation

Who QC Examination

How check material

hygiene

Rounding Filth Filth checking What Filth By Filth taking Training and Responsibility: Form 14. Review of record VCM-15

every hour sanction QC Filth Check at Filth Check at

Where Checking filth table Bread Crumb Bread Crumb by

Authority: Chief of QC

When Every hour Production

Who QC

How By random sampling

OPRP/ Not CCP BREADED CRUMB PROCESS

Control Direct Corrective Responsibility Document /

OPRP Hazard Inspection Verification Validation

Measures Correction Action and Authority Record

Written by : Checked by : Acknowledge by :

Date :

PT. SEKAR KATOKICHI Doc. Number FSL-HACCP-OPRP-001

Revision 04

HACCP BREADED SHRIMP

Date March 10th , 2017

OPERATIONAL PRE REQUISITE PROGRAME (OPRP) Page 6of 11

Proofing Filth Filth checking What Filth By Filth taking Training and Responsibility: Form 14. Review of record VCM-16

every hour sanction QC Filth Check at Filth Check at

Where Checking filth table Bread Crumb Bread Crumb by

Authority: Chief of QC

When Every hour Production

Who QC

How By random sampling

Fermentasi II Pathogen Equipnent What cleanliness of material training of Responsibility: Form 1. VCM-17

bacteria’ cleanliness material storage storage should employees QC Microbiology Product

contamination be clean for the Total Analysis Microbiology

Where Process room cleanliness Authority: Testing

of storage Chief of QC Form 13.

When Every day Daily

Sanitation

Who QC Examination

How check material

hygiene

OPRP/ Not CCP BREADED CRUMB PROCESS

Control Direct Corrective Responsibility Document /

OPRP Hazard Inspection Verification Validation

Measures Correction Action and Authority Record

Written by : Checked by : Acknowledge by :

Date :

PT. SEKAR KATOKICHI Doc. Number FSL-HACCP-OPRP-001

Revision 04

HACCP BREADED SHRIMP

Date March 10th , 2017

OPERATIONAL PRE REQUISITE PROGRAME (OPRP) Page 7of 11

Moulding Filth Filth checking What Filth By Filth taking Training and Responsibility: Form 14. Review of record VCM-18

every hour sanction QC Filth Check at Filth Check at

Where Checking filth table Bread Crumb Bread Crumb by

Authority: Chief of QC

When Every hour Production

Who QC

How By random sampling

Baking Pathogen Temperature What Temperature Product Training and Responsibility: Form 1. Microbiology VCM-19

bacteria’ control after rejected sanction QC Microbiology Checking

contamination baking Where Cooking Total Analysis

Authority:

When After cooking Chief of QC Form 32.

Bread Crumb

Who QC Process

How Temperature

calculate after baking

OPRP/ Not CCP BREADED CRUMB PROCESS

Control Direct Corrective Responsibility Document /

OPRP Hazard Inspection Verification Validation

Measures Correction Action and Authority Record

Written by : Checked by : Acknowledge by :

Date :

PT. SEKAR KATOKICHI Doc. Number FSL-HACCP-OPRP-001

Revision 04

HACCP BREADED SHRIMP

Date March 10th , 2017

OPERATIONAL PRE REQUISITE PROGRAME (OPRP) Page 8of 11

Crushing Filth Filth checking What Filth By Filth taking Training and Responsibility: Form 14. Review of record VCM-20

every hour sanction QC Filth Check at Filth Check at

Where Checking filth table Bread Crumb Bread Crumb by

Authority: Chief of QC

When Every hour Production

Who QC

How By random sampling

OPRP/ NOT CCP RAW MATERIAL

Control Direct Corrective Responsibility Document /

OPRP Hazard Inspection Verification Validation

Measures Correction Action and Authority Record

Written by : Checked by : Acknowledge by :

Date :

PT. SEKAR KATOKICHI Doc. Number FSL-HACCP-OPRP-001

Revision 04

HACCP BREADED SHRIMP

Date March 10th , 2017

OPERATIONAL PRE REQUISITE PROGRAME (OPRP) Page 9of 11

Shrimp Raw Pathogen Arrival Raw What Pathogen bacteria’ Product recall Supplier Responsibility: Form 4. Check VCM-21

Material bacteria Material contamination training QC Raw Material Microbiology at

temperature Where Receiving shrimp raw material Receiving every raw

checking and When Every supplier during Authority: material arrive

Laboratory receiving raw material Director / Plant Form 3.

Analysis Who QC Manager Microbiology

How Raw Material temperature Total Analysis

checking and Laboratory

Analysis

Smell Organoleptic What Smell (Ammoniac) The raw material Supplier Responsibility: Form 4. Review of VCM-22

(Ammoniac) Checking Where Receiving shrimp raw material returned to the training QC Raw Material record Raw

When During receive raw material supplier Receiving Material

Who QC Authority: Receiving

How By random sampling Director / Plant by Chief of

Manager QC

OPRP/ NOT CCP Proses Breaded Ebikatzu

Control Direct Corrective Responsibility Document /

OPRP Hazard Inspection Verification Validation

Measures Correction Action and Authority Record

Written by : Checked by : Acknowledge by :

Date :

PT. SEKAR KATOKICHI Doc. Number FSL-HACCP-OPRP-001

Revision 04

HACCP BREADED SHRIMP

Date March 10th , 2017

OPERATIONAL PRE REQUISITE PROGRAME (OPRP) Page 10of 11

Peeling And Pathogen Equipnent What Hand employee before work hand training Responsibility: Form 1. 1.Employee Hand VCM-23

Deveining (PND) bacteria’ cleanliness cleanliness should be clean employees to QC Microbiology Swab

contamination condition hand hygiene Total Analysis

Where Process room Authority: 2. Product

Microbiology

Chief of QC Form 13.

Testing

When Every day Daily

Sanitation

Who QC Examination

How Employee cleanliness

Cutting Pathogen Hand and knife What Hand employee and before work hand training Responsibility: Form 1. 1.Employee Hand VCM-24

bacteria’ cleanliness knife cleanliness and knife should be employees to QC Microbiology Swab

contamination clean condition hand hygiene Total Analysis

Where Process room and knife Authority: 2. Product

Microbiology

Chief of QC Form 13.

Testing

When Every day Daily

Sanitation

Who QC Examination

How Employee and knife

cleanliness

Control Direct Corrective Responsibility Document /

OPRP Hazard Inspection Verification Validation

Measures Correction Action and Authority Record

Written by : Checked by : Acknowledge by :

Date :

PT. SEKAR KATOKICHI Doc. Number FSL-HACCP-OPRP-001

Revision 04

HACCP BREADED SHRIMP

Date March 10th , 2017

OPERATIONAL PRE REQUISITE PROGRAME (OPRP) Page 11of 11

Blanching Pathogen Hand and What Hand employee and before work training Responsibility: Form 1. 1.Employee VCM-25

bacteria’ equipment equipment hand and employees QC Microbiology Hand Swab

contamination cleanliness cleanliness equipment to hand Total Analysis

Where Process room should be hygiene and Authority: 2. Product

Microbiology

clean condition equipment Chief of QC Form 13.

Testing

When Every day Daily

Sanitation

Who QC Examination

How Employee and

equipment

cleanliness

Moulding Pathogen Temperature What Hand employee and before work training Responsibility: Form 1. 1.Employee VCM-26

bacteria’ control after mould cleanliness hand and employees QC Microbiology Hand Swab

contamination baking Where Process room mouldt should to hand Total Analysis

be clean hygiene and Authority: 2. Product

Microbiology

When Every day condition mould Chief of QC Form 13.

Testing

Daily

Who QC Sanitation

Examination

How Employee and mould

cleanliness

Written by : Checked by : Acknowledge by :

Date :

You might also like

- Yum Packaging Score CardDocument5 pagesYum Packaging Score Cardshani31No ratings yet

- Materi Training ISO 22000 - 2018Document50 pagesMateri Training ISO 22000 - 2018Dedeq AiiyaNo ratings yet

- OPRP PLAN Updated & FinalDocument2 pagesOPRP PLAN Updated & Finalsajid waqas100% (1)

- CCP and OprpDocument5 pagesCCP and OprpGorack ShirsathNo ratings yet

- Form FSSC AuditDocument31 pagesForm FSSC AuditShofiNo ratings yet

- Proposal Iso 22000.2018 (PT XXXX) Rev 00Document9 pagesProposal Iso 22000.2018 (PT XXXX) Rev 00dc tanobelfoodNo ratings yet

- Audit Monitoring Internal FSSC 22000 v.5.1 PT. United CanDocument10 pagesAudit Monitoring Internal FSSC 22000 v.5.1 PT. United CanFahal Abdi WijayaNo ratings yet

- 09 - Validation of CCP & OPRPDocument57 pages09 - Validation of CCP & OPRPAnilZapate100% (6)

- ISO 22000 FSMS Compliance Summary - IsO TS 22002Document4 pagesISO 22000 FSMS Compliance Summary - IsO TS 22002Departed Moon100% (1)

- An Overview of FSSC 22000 V 5Document26 pagesAn Overview of FSSC 22000 V 5miz baigNo ratings yet

- ISO 22000 guidance decision treeDocument2 pagesISO 22000 guidance decision treeSartika Mutiarasani100% (1)

- Food Defense Program Security MeasuresDocument5 pagesFood Defense Program Security MeasuresgmbyNo ratings yet

- Understanding ISO 22000-2018 Training-Upgrading (Rev.00, Oct 2018)Document86 pagesUnderstanding ISO 22000-2018 Training-Upgrading (Rev.00, Oct 2018)Aku MumuNo ratings yet

- Form CCP MonitoringDocument1 pageForm CCP MonitoringAlfiNurfauziahNo ratings yet

- M. S. Asia Group Page 1 of 1 Document No.: SOP/ANA/PDP Effective Date: 21-6-2021 Rev. No.: 0 Document Title: Product Defense PlanDocument1 pageM. S. Asia Group Page 1 of 1 Document No.: SOP/ANA/PDP Effective Date: 21-6-2021 Rev. No.: 0 Document Title: Product Defense Plannurhafizah jabarNo ratings yet

- CCPDocument3 pagesCCP9876030206No ratings yet

- 1 QSA - Guide - 2013 FINALDocument52 pages1 QSA - Guide - 2013 FINALfrmgs100% (2)

- 31 Validation, Verification and Improvement of The FSMSDocument5 pages31 Validation, Verification and Improvement of The FSMSVeera Venkatesh MareeduNo ratings yet

- Ensure Flour Purity Through Magnet TestingDocument1 pageEnsure Flour Purity Through Magnet TestingMilan BankNo ratings yet

- BRC 3.9.2 Trace Exercise SampleDocument10 pagesBRC 3.9.2 Trace Exercise SampleAmine Simo Jackson100% (1)

- Annex 3B. Guidelines: Vulnerability Assessment and Critical Control Point Work Sheet 1: Guidelines and Definitions: The VACCP SystemDocument2 pagesAnnex 3B. Guidelines: Vulnerability Assessment and Critical Control Point Work Sheet 1: Guidelines and Definitions: The VACCP SystemcarlaNo ratings yet

- FSSC 22000 Version 5Document4 pagesFSSC 22000 Version 5victoria3go100% (2)

- Case Food Fraud PreventionDocument17 pagesCase Food Fraud PreventionAulia AnnaNo ratings yet

- Validation of control measures in a food chain using the FSO conceptDocument7 pagesValidation of control measures in a food chain using the FSO conceptcaraquena123No ratings yet

- HACCP Validation Checklist (Annual Reassement)Document2 pagesHACCP Validation Checklist (Annual Reassement)Dutch Charming100% (11)

- Food Safety/ Haccp/ Food Defense Team Selection CriteriaDocument14 pagesFood Safety/ Haccp/ Food Defense Team Selection CriteriaNarinder Pal Singh SokheyNo ratings yet

- Public Training Implementing FSSC 22000 Ver 5.1Document104 pagesPublic Training Implementing FSSC 22000 Ver 5.1Intan Pandini100% (1)

- Gap Analysis Iso 22000 2005 To 2018 v.3 - PublicDocument8 pagesGap Analysis Iso 22000 2005 To 2018 v.3 - PublicJorge Gallardo100% (2)

- Food Fraud Prevention PlanDocument4 pagesFood Fraud Prevention Plannurhafizah jabarNo ratings yet

- FSMS Stage 2 Audit of Cashew ProcessorDocument15 pagesFSMS Stage 2 Audit of Cashew ProcessorArpita TripathiNo ratings yet

- FSSC 22000 V5.1 For Food Manufacturing ChecklistDocument40 pagesFSSC 22000 V5.1 For Food Manufacturing ChecklistAbdul Rhman100% (1)

- VACCP - Food Fraud PreventionDocument28 pagesVACCP - Food Fraud Preventionnichecon1100% (4)

- ISO 22000 Audit ChecklistDocument19 pagesISO 22000 Audit ChecklistjessiquimiNo ratings yet

- Halalube SDS SummaryDocument10 pagesHalalube SDS Summarycit pbNo ratings yet

- Audit Findings Report FSSC 22000 Non-CompliancesDocument3 pagesAudit Findings Report FSSC 22000 Non-CompliancesMd Kamruzzaman MonirNo ratings yet

- Iso 22001 Efresh IndiaDocument13 pagesIso 22001 Efresh IndiaMahmoud KhalifaNo ratings yet

- ValidationDocument29 pagesValidationnilebhal100% (1)

- Procurment in Emergency SituationsDocument2 pagesProcurment in Emergency Situationspalani velanNo ratings yet

- FSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFDocument80 pagesFSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFSyahrizal MuhammadNo ratings yet

- Food Allergen Information SheetDocument7 pagesFood Allergen Information SheetJohn Henry WellsNo ratings yet

- TACCPDocument17 pagesTACCProbit SiddikiNo ratings yet

- Procedure For HACCP PlanDocument22 pagesProcedure For HACCP PlanKh'adîijàDh100% (1)

- Glass Plastic ControlDocument9 pagesGlass Plastic ControlSandra Ibañez GarayNo ratings yet

- Guideline For The Validation of Food Safety Control MeasuresDocument16 pagesGuideline For The Validation of Food Safety Control MeasuresKriston EdwardNo ratings yet

- Food Safety Manual Valley Sport-FS (00000003)Document30 pagesFood Safety Manual Valley Sport-FS (00000003)Balaji Rajaraman100% (1)

- FSSC Terbaru Feb 2018Document106 pagesFSSC Terbaru Feb 2018yudhNo ratings yet

- Perancangan Standar Prosedur Operasi Sistem Manajemen Alergen Dalam Industri Perisa Di Ptgivaudan Indonesia Ignatius Trijoko PrihantoroDocument104 pagesPerancangan Standar Prosedur Operasi Sistem Manajemen Alergen Dalam Industri Perisa Di Ptgivaudan Indonesia Ignatius Trijoko Prihantoroayu laksita0% (1)

- How To Set Up Sampling Zone For An Environmental Monitoring ProgramDocument46 pagesHow To Set Up Sampling Zone For An Environmental Monitoring ProgramAsep R100% (1)

- OPRP 4 Management of Cleaning ValidationDocument1 pageOPRP 4 Management of Cleaning ValidationJuan Pablo Azcuña C.No ratings yet

- PRP ISTS 22002-1 2009 - Updated 2019 Shared PDFDocument77 pagesPRP ISTS 22002-1 2009 - Updated 2019 Shared PDFJill DagreatNo ratings yet

- Taccp/Vaccp: Maltsters' Association of Great BritainDocument16 pagesTaccp/Vaccp: Maltsters' Association of Great BritainMohamedNo ratings yet

- ISO 22005.2007 TraceabilityDocument15 pagesISO 22005.2007 TraceabilitySunil Girdhar100% (2)

- 2012rap BRC PDFDocument185 pages2012rap BRC PDFFarikhNo ratings yet

- FSSC V5 2019Document30 pagesFSSC V5 2019danuNo ratings yet

- Introduction To Environmental Monitoring ProgramsDocument4 pagesIntroduction To Environmental Monitoring Programsmarmaduke32No ratings yet

- TACCP Risk Assessment Template Sample ReportDocument4 pagesTACCP Risk Assessment Template Sample Reportadhavanannathurai80% (5)

- Allergen Risk Assessment Analysis Report-StagewiseDocument8 pagesAllergen Risk Assessment Analysis Report-StagewiseSiva SuryaNo ratings yet

- NCC-IMS-FM-05-02 - OPRP Control Chart Is7.0Document9 pagesNCC-IMS-FM-05-02 - OPRP Control Chart Is7.0baseimNo ratings yet

- 05 Food Safety Plan Template and Sample For FSCODocument4 pages05 Food Safety Plan Template and Sample For FSCOTeacher JoanNo ratings yet

- PROCESS - Risk Assessment & HACCP Planning: Section 7.4.1Document4 pagesPROCESS - Risk Assessment & HACCP Planning: Section 7.4.1Wisnu samuel Atmaja triwarsitaNo ratings yet

- MSDS EMB AgarDocument7 pagesMSDS EMB AgarAnna FrederikaNo ratings yet

- Letter of GuaranteeDocument1 pageLetter of GuaranteeAnna FrederikaNo ratings yet

- Volta Application Album 2017 - Low - Res PDFDocument120 pagesVolta Application Album 2017 - Low - Res PDFAnna FrederikaNo ratings yet

- Hygiene en Ver D 2016 LowDocument6 pagesHygiene en Ver D 2016 LowAnna FrederikaNo ratings yet

- Survey of Modular Z Conveyor For RetrofittingDocument9 pagesSurvey of Modular Z Conveyor For RetrofittingAnna FrederikaNo ratings yet