Professional Documents

Culture Documents

OPRP PLAN Updated & Final

Uploaded by

sajid waqas100%(1)100% found this document useful (1 vote)

863 views2 pagesOriginal Title

OPRP PLAN Updated & final

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

863 views2 pagesOPRP PLAN Updated & Final

Uploaded by

sajid waqasCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

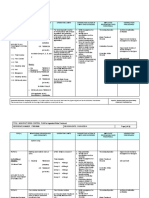

Doc No:QS-4-022

Issue No : 02

Issue Date : 12-08-2020

HACCP (OPRP ) PLAN

Critical limits Monitoring

Ingredient/ Control

Significant for each

S. No Processing Measure(s) Corrective action(s) Records Ver

Hazard(s) preventive

step

measure

Sieving

Oversize What How Frequency Who Dai

Hold the production,

OPRP Stone, dust, HACCP-06-OPRP of

Initial Sifter ≤ 1 mm check Sieve, Clean

# 01 fiber, thread, Every Two # 01 Monitoring b

Foreign Physical Sieve

husk Hours Process Operator O

Particles Inspection

Series of Every Two

Magnets Hours Dai

Hold the production,

OPRP ( Before rice ≥ 10000 Magnet Magnet Pull HACCP-06-OPRP of

Metal Magnet Bars Shift Engineer check Magnetic

# 02 storage and Gauss Strength Test # 02 Monitoring b

strength ( Gauze),

after 1st O

sifting )

Every Two Dai

Hold the production,

OPRP Final Sifter / Small size Sieving Foreign Physical Hours HACCP-06-OPRP of

≤ 0.4 mm Process Operator check Sieve, Clean

# 03 Classifier Stone Particles Inspection # 03 Monitoring b

Sieve

O

Coliforms, Every Two

E.Coli, Hours

Hold the production, Dai

Faeceal

OPRP UV Light at Visual QC Officer / check UV Lamp, Clean HACCP-06-OPRP of

Enterococci/ ≥ 65 % UV Light UV Intensity

# 04 R.O Outlet Inspection Analyst Lamp Sleeve or change # 04 Monitoring b

Streptococci,

sleeve / lamp O

Pseudomona

s Aeruginos

Jet Cooking Every Two Hold the production, HACCP-06-OPRP Dai

Temperature

OPRP Slurry Pesticides Hours Maintain the # 05 Monitoring of

95◦c - 105◦c Temperature gauge Process Operator

# 05 Preparation Residue Temperature with in b

Monitoring

operating Limits O

Doc No:QS-4-022

Issue No : 02

Issue Date : 12-08-2020

HACCP (OPRP ) PLAN

Total Jet Cooking Every Two HACCP-06-OPRP Dai

Hold the production,

Aflatoxin Temperature Hours # 06 Monitoring of

OPRP Slurry Maintain the

(AFB1+AFB2 95◦c - 105◦c Temperature gauge Process Operator b

# 06 Preparation Temperature with in

+AFG1 Monitoring O

operating Limits

+AFG2)

Jet Cooking Every Two HACCP-06-OPRP Dai

Hold the production,

Temperature Hours # 07 Monitoring of

OPRP Slurry Maintain the

Aflatoxin 95◦c - 105◦c Temperature gauge Process Operator b

# 07 Preparation Temperature with in

Monitoring O

operating Limits

Moisture Every Two Hold the production, HACCP-06-CCP # Dai

Moisture Hours Maintain the 03 Monitoring of

Drying

OPRP ≤10 % Moisture analyzing Temperature with in b

( Rice Protein Aflatoxin Process Operator

# 08 Content Test operating Limits to O

Concentrate )

achieve targeted

moisture.

Filtration via Filter Press Every Two HACCP-06-OPRP Dai

Filter aid Pressure Hours Hold the production, # 08 Monitoring of

OPRP Chemical Pressure

( Diatomaceou < 5 Bar Gauge Process Operator Maintain the Pressure b

# 09 impurities Gauge

s Earth) & Monitoring with in operating Limits O

Filter Press

You might also like

- Yum Packaging Score CardDocument5 pagesYum Packaging Score Cardshani31No ratings yet

- 09 - Validation of CCP & OPRPDocument57 pages09 - Validation of CCP & OPRPAnilZapate100% (6)

- HACCP Manual Revised EditionDocument210 pagesHACCP Manual Revised EditionTanzila SiddiquiNo ratings yet

- BRCGS Food Safety Culture Excellence - Action Plan TemplateDocument2 pagesBRCGS Food Safety Culture Excellence - Action Plan TemplateLuis Gutiérrez100% (1)

- Ehaccp - Allergen Control SOPDocument2 pagesEhaccp - Allergen Control SOPAlfred Rangel100% (1)

- Materi Training ISO 22000 - 2018Document50 pagesMateri Training ISO 22000 - 2018Dedeq AiiyaNo ratings yet

- Who? What? How? (Examples) : Strong LeadershipDocument1 pageWho? What? How? (Examples) : Strong LeadershipYann100% (2)

- CCP and OprpDocument5 pagesCCP and OprpGorack ShirsathNo ratings yet

- Public Training Implementing FSSC 22000 Ver 5.1Document104 pagesPublic Training Implementing FSSC 22000 Ver 5.1Intan Pandini100% (1)

- FSSC Terbaru Feb 2018Document106 pagesFSSC Terbaru Feb 2018yudhNo ratings yet

- Case Food Fraud PreventionDocument17 pagesCase Food Fraud PreventionAulia AnnaNo ratings yet

- Procedure For Preliminary Analysis of Production ProcessDocument14 pagesProcedure For Preliminary Analysis of Production ProcessNurulsakinah SailinNo ratings yet

- FSSC 22000 Training: Food Safety System RequirementsDocument7 pagesFSSC 22000 Training: Food Safety System RequirementsRizqi Ahsan NashrullahNo ratings yet

- ISO 22000 FSMS Compliance Summary - IsO TS 22002Document4 pagesISO 22000 FSMS Compliance Summary - IsO TS 22002Departed Moon100% (1)

- Food Safety Manual Valley Sport-FS (00000003)Document30 pagesFood Safety Manual Valley Sport-FS (00000003)Balaji Rajaraman100% (1)

- PRM020 Food Defence PlanDocument4 pagesPRM020 Food Defence PlanTASTETECH100% (4)

- Procedure Manual: Function: Haccp Support Programs Title: Allergen ManagementDocument3 pagesProcedure Manual: Function: Haccp Support Programs Title: Allergen Managementajan76100% (1)

- Procurment in Emergency SituationsDocument2 pagesProcurment in Emergency Situationspalani velanNo ratings yet

- An Overview of FSSC 22000 V 5Document26 pagesAn Overview of FSSC 22000 V 5miz baigNo ratings yet

- Contoh Dokumen OPRPDocument11 pagesContoh Dokumen OPRPAnna FrederikaNo ratings yet

- Allergen Information ManualDocument39 pagesAllergen Information ManualAhmedAmer1100% (1)

- Food Traceability Template for Production and Dispatch RecordsDocument4 pagesFood Traceability Template for Production and Dispatch RecordsCharles J KunjumonNo ratings yet

- 2012rap BRC PDFDocument185 pages2012rap BRC PDFFarikhNo ratings yet

- QM 6.9.3c Glass & Brittle Material Breakage ProcedureDocument2 pagesQM 6.9.3c Glass & Brittle Material Breakage ProcedureDaniel Modica100% (2)

- 1.3 Food Safety Policy Statement WebDocument1 page1.3 Food Safety Policy Statement Webジョンナ メイ ハイミNo ratings yet

- SOP Food DefenceDocument5 pagesSOP Food DefenceIsna Andrianto100% (6)

- Food Defense Program Security MeasuresDocument5 pagesFood Defense Program Security MeasuresgmbyNo ratings yet

- Glass Policy & Hard Plastic PolicyDocument2 pagesGlass Policy & Hard Plastic PolicySRI VYJAYANTHI QANo ratings yet

- BRCGS Issue 9 Templates Toolkit IndexDocument14 pagesBRCGS Issue 9 Templates Toolkit IndexJayashri chitte0% (1)

- FSSC 22000 V5.1 For Food Manufacturing ChecklistDocument40 pagesFSSC 22000 V5.1 For Food Manufacturing ChecklistAbdul Rhman100% (1)

- Complete Prerequisite Program v2Document78 pagesComplete Prerequisite Program v2Ramasubramanian Sankaranarayanan100% (1)

- VERIFICATION PLAN HaccpDocument4 pagesVERIFICATION PLAN HaccpnasuhaNo ratings yet

- DJ Brothers ISO 22000-2018 ManualDocument40 pagesDJ Brothers ISO 22000-2018 ManualSunith Desai100% (1)

- Allergen Control PDFDocument22 pagesAllergen Control PDFTracyBate0% (1)

- Mock Call Record Sample SheetDocument1 pageMock Call Record Sample SheetSiddharth soniNo ratings yet

- TACCP - VACCP Assessment - GlucoseDocument6 pagesTACCP - VACCP Assessment - Glucosesajid waqas100% (1)

- BRC 3.9.2 Trace Exercise SampleDocument10 pagesBRC 3.9.2 Trace Exercise SampleAmine Simo Jackson100% (1)

- Glass and Plastic Breakage PolicyDocument1 pageGlass and Plastic Breakage PolicyKriston EdwardNo ratings yet

- O-G1 Glass Brittle Plastic PolicyDocument2 pagesO-G1 Glass Brittle Plastic PolicySantiago Giraldo100% (8)

- AIB HACCP Checklist2007Document9 pagesAIB HACCP Checklist2007m125esteban2003No ratings yet

- PRO 8.2 Validation Procedure TemplatDocument6 pagesPRO 8.2 Validation Procedure TemplatSuresh SubbuNo ratings yet

- Food DefenceDocument46 pagesFood DefenceNitesh Kumar67% (3)

- TACCP Risk Assessment Template Sample ReportDocument4 pagesTACCP Risk Assessment Template Sample Reportadhavanannathurai80% (5)

- BRC Food Safety Culture QuestionnaireDocument3 pagesBRC Food Safety Culture QuestionnaireKamonrat Pangarean100% (1)

- Monthly Glass and Brittle Plastics Risk AuditDocument3 pagesMonthly Glass and Brittle Plastics Risk AuditAdnan Meghani100% (3)

- PRP ISTS 22002-1 2009 - Updated 2019 Shared PDFDocument77 pagesPRP ISTS 22002-1 2009 - Updated 2019 Shared PDFJill DagreatNo ratings yet

- Risk Assessment AllergensDocument5 pagesRisk Assessment AllergensDutch Charming90% (10)

- ISO 22000 guidance decision treeDocument2 pagesISO 22000 guidance decision treeSartika Mutiarasani100% (1)

- FSMS ManualDocument14 pagesFSMS ManualSusheel Talreja100% (2)

- Power Outage: Food Safety Emergency Preparedness PlanDocument1 pagePower Outage: Food Safety Emergency Preparedness PlanAmrut Bhalerao100% (1)

- 38-SOP-Layout of Work Place and PremisesDocument4 pages38-SOP-Layout of Work Place and Premisesarun100% (1)

- Moving from HACCP to HARPC: A Guide to FSMA ComplianceDocument33 pagesMoving from HACCP to HARPC: A Guide to FSMA ComplianceElvira100% (1)

- Allergen Control Checklist Manufacturer 0908Document4 pagesAllergen Control Checklist Manufacturer 0908shakeyken100% (1)

- HACCP Audit Check ListDocument28 pagesHACCP Audit Check List23906157100% (4)

- FSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFDocument80 pagesFSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFSyahrizal MuhammadNo ratings yet

- Sample HACCP PlanDocument1 pageSample HACCP PlanBRIGHT DZAHNo ratings yet

- Haccp ManualDocument51 pagesHaccp ManualJack Mata100% (2)

- Daily Progress Report: Mtr. 4690 Mtr. Mtr. 4690Document3 pagesDaily Progress Report: Mtr. 4690 Mtr. Mtr. 4690Manoranjan sharmaNo ratings yet

- Daily Progress ReportDocument3 pagesDaily Progress ReportManoranjan sharmaNo ratings yet

- QAP (ITP) FOR STRUCTURAL FAB & ERECTION CommentsDocument4 pagesQAP (ITP) FOR STRUCTURAL FAB & ERECTION CommentsEr Mangesh MohiteNo ratings yet

- HACCP CCP Monitoring ProceduresDocument5 pagesHACCP CCP Monitoring Proceduressajid waqasNo ratings yet

- Raw Material, 005Document1 pageRaw Material, 005sajid waqasNo ratings yet

- 07-Hazard Analysis, 007Document4 pages07-Hazard Analysis, 007sajid waqasNo ratings yet

- Product SpecificationsDocument1 pageProduct Specificationssajid waqasNo ratings yet

- CCP Determination Tree, 008Document1 pageCCP Determination Tree, 008sajid waqasNo ratings yet

- United Kingdom Regulatory Requirements For Product IngredientsDocument6 pagesUnited Kingdom Regulatory Requirements For Product Ingredientssajid waqasNo ratings yet

- CCP Determination, 009Document10 pagesCCP Determination, 009sajid waqasNo ratings yet

- HACCP System Manual Food SafetyDocument34 pagesHACCP System Manual Food Safetysajid waqas100% (1)

- Chiller and Carcass Temp. Record Sheet, 013Document2 pagesChiller and Carcass Temp. Record Sheet, 013sajid waqasNo ratings yet

- 17000.0606 Manufacturing Control Plan For Ingredient Water TreatmentDocument10 pages17000.0606 Manufacturing Control Plan For Ingredient Water Treatmentsajid waqasNo ratings yet

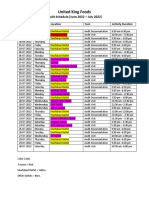

- Internal Audit Schedule June - July 2022Document2 pagesInternal Audit Schedule June - July 2022sajid waqasNo ratings yet

- Express Fumigation Services PVT (LTD)Document2 pagesExpress Fumigation Services PVT (LTD)sajid waqasNo ratings yet

- Training Plan 2021 (United King Korangi Factory)Document2 pagesTraining Plan 2021 (United King Korangi Factory)sajid waqasNo ratings yet

- Proposition 65 Declaration GLUCORPDocument1 pageProposition 65 Declaration GLUCORPsajid waqasNo ratings yet

- Problem Solving WorksheetDocument7 pagesProblem Solving WorksheetJSH100No ratings yet

- ADMN-2-002, Issue 01, Procedure For Personal Hygiene, Employee Facility and HousekeepingDocument4 pagesADMN-2-002, Issue 01, Procedure For Personal Hygiene, Employee Facility and Housekeepingsajid waqasNo ratings yet

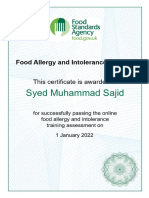

- Syed Muhammad Sajid: 1 January 2022Document1 pageSyed Muhammad Sajid: 1 January 2022sajid waqasNo ratings yet

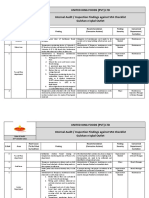

- Internal Audit Findings for Nimco FactoryDocument28 pagesInternal Audit Findings for Nimco Factorysajid waqasNo ratings yet

- Global 3D Quality Scorecard: Karachi - Yassir (5109)Document1 pageGlobal 3D Quality Scorecard: Karachi - Yassir (5109)sajid waqasNo ratings yet

- Course Outline ISO 22000 LEAD IMPLEMENTATION DIPLOMADocument4 pagesCourse Outline ISO 22000 LEAD IMPLEMENTATION DIPLOMAsajid waqasNo ratings yet

- United King Foods (PVT) LTD Internal Audit / Inspection Findings Against SFA Checklist Sharfabad OutletDocument7 pagesUnited King Foods (PVT) LTD Internal Audit / Inspection Findings Against SFA Checklist Sharfabad Outletsajid waqasNo ratings yet

- UNITED KING FOODS AUDIT FINDS COLD STORE, PACKAGING ISSUESDocument6 pagesUNITED KING FOODS AUDIT FINDS COLD STORE, PACKAGING ISSUESsajid waqasNo ratings yet

- Audit Report Nimko Factory (Shafiq Mor 29th May 2021)Document17 pagesAudit Report Nimko Factory (Shafiq Mor 29th May 2021)sajid waqas100% (1)

- Audit Report Gulshan Outlet 7 October 2021Document9 pagesAudit Report Gulshan Outlet 7 October 2021sajid waqasNo ratings yet

- Audit Report DHA Outlet 3rd Aug 2021Document13 pagesAudit Report DHA Outlet 3rd Aug 2021sajid waqasNo ratings yet

- Audit Report Sweets Factory (6th July2021) Unannounced - FinalDocument25 pagesAudit Report Sweets Factory (6th July2021) Unannounced - Finalsajid waqasNo ratings yet

- Internal Audit Findings for Nimco FactoryDocument28 pagesInternal Audit Findings for Nimco Factorysajid waqasNo ratings yet

- H&H Audit Factory GMP Audit ReportDocument2 pagesH&H Audit Factory GMP Audit Reportsajid waqasNo ratings yet

- Audit Report Korangi Factory (12th June 2021) AnnouncedDocument35 pagesAudit Report Korangi Factory (12th June 2021) Announcedsajid waqasNo ratings yet

- Audit Report Gulshan E Iqbal Outlet 4th Aug 2021Document13 pagesAudit Report Gulshan E Iqbal Outlet 4th Aug 2021sajid waqasNo ratings yet

- General Biology 2-Week 2-Module 4-Evidence of EvolutionDocument16 pagesGeneral Biology 2-Week 2-Module 4-Evidence of EvolutionFEMALE Dawal LaizaNo ratings yet

- College of Physical Therapy Produces Skilled ProfessionalsDocument6 pagesCollege of Physical Therapy Produces Skilled ProfessionalsRia Mae Abellar SalvadorNo ratings yet

- Lineapelle: Leather & Non-LeatherDocument16 pagesLineapelle: Leather & Non-LeatherShikha BhartiNo ratings yet

- United Airlines Case Study: Using Marketing to Address External ChallengesDocument4 pagesUnited Airlines Case Study: Using Marketing to Address External ChallengesSakshiGuptaNo ratings yet

- Project Report On Evaporative CoolerDocument12 pagesProject Report On Evaporative Coolersourabh singh tomerNo ratings yet

- Environmental Threats Differentiated Reading Comprehension Ver 1Document20 pagesEnvironmental Threats Differentiated Reading Comprehension Ver 1Camila DiasNo ratings yet

- Hanwha Engineering & Construction - Brochure - enDocument48 pagesHanwha Engineering & Construction - Brochure - enAnthony GeorgeNo ratings yet

- Quick Reference - HVAC (Part-1) : DECEMBER 1, 2019Document18 pagesQuick Reference - HVAC (Part-1) : DECEMBER 1, 2019shrawan kumarNo ratings yet

- Political Engineering and Party Politics in Conflict-Prone SocietiesDocument18 pagesPolitical Engineering and Party Politics in Conflict-Prone SocietiesNashiba Dida-AgunNo ratings yet

- L Williams ResumeDocument2 pagesL Williams Resumeapi-555629186No ratings yet

- Galambos 1986Document18 pagesGalambos 1986gcoNo ratings yet

- Continuous Sampling PlanDocument2 pagesContinuous Sampling PlanAnonymous wA6NGuyklDNo ratings yet

- Chronological OrderDocument5 pagesChronological OrderDharWin d'Wing-Wing d'AriestBoyzNo ratings yet

- The Unbounded MindDocument190 pagesThe Unbounded MindXtof ErNo ratings yet

- Chirag STDocument18 pagesChirag STchiragNo ratings yet

- Eole Press KitDocument15 pagesEole Press KitBob AndrepontNo ratings yet

- Complete Guide To E-Commerce TechnologyDocument420 pagesComplete Guide To E-Commerce Technologypilatus100% (4)

- Request For Proposal Construction & Phase 1 OperationDocument116 pagesRequest For Proposal Construction & Phase 1 Operationsobhi100% (2)

- Pharma TestDocument2 pagesPharma TestMuhammad AdilNo ratings yet

- Manual Handling Risk Assessment ProcedureDocument6 pagesManual Handling Risk Assessment ProcedureSarfraz RandhawaNo ratings yet

- Presepsi Khalayak Terhadap Program Acara Televise Reality Show "Jika Aku Menjadi" Di Trans TVDocument128 pagesPresepsi Khalayak Terhadap Program Acara Televise Reality Show "Jika Aku Menjadi" Di Trans TVAngga DianNo ratings yet

- Ketchikan Shipyard Improvements Plan CompleteDocument230 pagesKetchikan Shipyard Improvements Plan CompleteOpó Ishak Bawias Adare100% (1)

- Reversing a String in 8086 Micro Project ReportDocument4 pagesReversing a String in 8086 Micro Project ReportOm IngleNo ratings yet

- Year 10 Maths PlaneDocument62 pagesYear 10 Maths Planehal wangNo ratings yet

- DNA Affirmative - MSDI 2015Document146 pagesDNA Affirmative - MSDI 2015Michael TangNo ratings yet

- Emilio Aguinaldo CollegeDocument1 pageEmilio Aguinaldo CollegeRakeshKumar1987No ratings yet

- Strategic Flexibility: The Evolving Paradigm of Strategic ManagementDocument3 pagesStrategic Flexibility: The Evolving Paradigm of Strategic Managementnanthini kanasanNo ratings yet

- Ek Pardesi Mera Dil Le Gaya Lyrics English Translation - Lyrics GemDocument1 pageEk Pardesi Mera Dil Le Gaya Lyrics English Translation - Lyrics Gemmahsa.molaiepanahNo ratings yet

- Lesson Plan 2 Revised - Morgan LegrandDocument19 pagesLesson Plan 2 Revised - Morgan Legrandapi-540805523No ratings yet

- BOQ - Hearts & Arrows Office 04sep2023Document15 pagesBOQ - Hearts & Arrows Office 04sep2023ChristianNo ratings yet