Professional Documents

Culture Documents

Angrenaj Cilindric PDF

Uploaded by

Diana Maria CozmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Angrenaj Cilindric PDF

Uploaded by

Diana Maria CozmaCopyright:

Available Formats

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

With the following program based on the standard calculations DIN 3960, the geometry of spur gears can be calculated.

This module has different operations and possibilities for calculation profile shift.

These possibilities are the following:

Automatic calculation and distribution of the total profile shift coefficient according to DIN 3992 (DIN 3993)

Input of centre distance

Input of total profile shift

Input of profile shift

With the following program the strength examination (pitting load capacity, root load capacity, corrosion load capacity) of spur gears will be

calculated. Therefore the calculation base DIN 3990 and also the international ISO 6336 can chose by the user.

With this program standard gauges for spur gears will be calculated.

The application of the number of teeth thickness, spherical dim.-roll diameter DM, deviations of center distance and deviations of teeth thickness

are optional.

Groundwork calculations

Geometry of the spur gear pair and the gear

The standard calculations for this module are described by DIN 3960, edition March 1987.

The following DIN specifications will also be utilized:

DIN 780 Module sequence for spur gears

DIN 867 edition February 1986 (basic profile)

DIN 3960 edition March 1987 (concept and dimension determination for spur gear pairs with involute gearing)

DIN 3960 supplement 1, edition July 1980

DIN 3992 edition March 1964 (profile displacement for spur gears with outer gearing)

DIN 3993 edition August 1981, part 1 - 4 (geometric design of cylindrical inner gear pairs).

Strength examination of spur gears

The standard calculations for this module are described by the following DIN specifications:

DIN 3990 Part 1 edition December 1987 (general influence factors)

DIN 3990 Part 2 edition December 1987 (calculation of the pitting load capacity)

DIN 3990 Part 3 edition December 1987 (calculation of the root load capacity)

DIN 3990 Part 4 edition December 1987 (calculation of the corrosion load capacity)

DIN 3990 Part 5 edition December 1987 (fatigue stress values and material qualities)

DIN 3990 Part 6 edition December 1994 (operational stability)

DIN 3990 Part 11 edition February 1989 (application standards for industrial gears)

DIN 3961 edition August 1961 (ground tolerances)

DIN 3962 Part 1 edition August 1978 (tolerances for deviation of individual determined dimensions)

DIN 3962 Part 2 edition August 1978 (tolerances for flank line deviations)

DIN 50 150, edition December 1976 1976 (conversion table for Vickers - Rockwell- Brinell hardness and ultimate strength)

ISO 6336 Part 1 edition September 2006 (Basic principles, influence factors)

ISO 6336 Part 2 edition September 2006 (Calculation of surface durability (pitting))

ISO 6336 Part 3 edition September 2006 (Calculation of tooth bending strength)

ISO 6336 Part 6 edition September 2006 (Calculation of service life under variable load)

ISO 6336-1 Technical Corrigendum 1

ISO 6336-2 Technical Corrigendum 1

ISO 6336-3 Technical Corrigendum 1

ISO 1328 Part 1 edition August 2005 (Definitions and allowable values of deviations)

Gauge Design for Spur Gears

The standard calculations for this program are described by DIN 3960, edition March 1987.

The following DIN specifications will also be utilized:

DIN 3961 edition August 1978 (tolerances for spur gearing)

DIN 3962 supplement 1 edition August 1978 (tolerances for deviation of individual determined dimensions)

DIN 3964 edition November 1980 (axis position and Axis position tolerances of housing for spur gears)

DIN 3967 edition August 1978 (flank play, tooth thickness dimension, tooth thickness tolerances)

DIN 3977 edition February 1981 (dimension diameter for the radial or diametric standard gauge of the tooth thickness of spur gears

(cylinder gears))

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 1/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

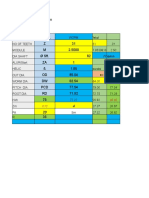

Input data:

Spur Gear, Gear Rack

Calculation method Spur gear

Calculation variants Spur gear calculation,

strength

Calculation standard DIN 3990

Type of toothing External toothing

Spur gear geometry

Basic data

Normal modulus mn = 6 mm

Helical angle : 16 °

Centre distance a: 0 mm

Driving element Pinion

Input of geometry z1, z2

Number of teeth (pinion) z1 = 24

Number of teeth (wheel) z2 = 72

Translation ratio i= 3

Pinion Wheel

Tooth width b = 112 110 mm

Input method for tooth-tip height modification No input

Addendum modification according to DIN 3992/3993

Input methode profile shift coefficients No input

Optimization for profile shift coefficient Special case (very high

strength capacity)

Basic gear rack Pinion Wheel

Tip clearance factor cP* = 0,2 0,2

Root fillet radius factor f P* = 0,4 0,4

Pressure angle p = 20 °

Tooth-tip thickness factor san* = 0,4

Pinion Wheel

Tooth-tip height factor haP* = 1 1

Residual fillet undercut spr : 0 0 mm

Cutter data Pinion Wheel

Number of cutter teeth z0 : 0 0

Basic gear rack profile shift coefficient x0 : 0 0

Spur Gear Calculation - Strength

Drive data

Load case Nominal load

Pinion Wheel

Number of meshed teeth nZE = 1 1

Application factor KA = 1,25

Dynamic factor Kv : 0

Performance P= 20,6 kW

Rotation speed (pinion) n1 = 27,3 1/min

Required lifetime Lh = 10000 h

Lubrication

Viscosity class for 40° oil = 220 cSt

Viscosity class for 100° oil = 4 cSt

Density for 15°C oil = 800 kg/m³

Oil temperature oil = 40 °C

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 2/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Force level (according to FZG-test) 3

Type of oil distribution Splash lubrication

Material selection

Pinion - materials (strength values) according to MDESIGN database

International materials no

Material designation 18CrNiMo7-6

Material number 1.6587

Material group Casehardening steel

Heat treatment / State trial hardened

Standard dimension dNm = 16 mm

Standard dimension dNp = 16 mm

Ultimate strength for dNm RmN = 1200 N/mm²

Yield point for dNp RpN = 850 N/mm²

Tooth root strength Flim = 430 N/mm²

Surface durability (pitting) Hlim = 1500 N/mm²

Type of Material 7

Modulus of elasticity E = 210000 N/mm²

Poisson's ratio = 0,3

Hardness scale HB

Hardness =0

Density = 7850 kg/m³

Linear expansion factor = 12 10^-6/K

Temperature T= 0 °C

Enable pitting ? no

Wheel - materials (strength values) according to MDESIGN database

International materials no

Material designation 18CrNiMo7-6

Material number 1.6587

Material group Casehardening steel

Heat treatment / State trial hardened

Standard dimension dNm = 16 mm

Standard dimension dNp = 16 mm

Ultimate strength for dNm RmN = 1200 N/mm²

Yield point for dNp RpN = 850 N/mm²

Tooth root strength Flim = 430 N/mm²

Surface durability (pitting) Hlim = 1500 N/mm²

Type of Material 7

Modulus of elasticity E = 210000 N/mm²

Poisson's ratio = 0,3

Hardness scale HB

Hardness =0

Density = 7850 kg/m³

Linear expansion factor = 12 10^-6/K

Temperature T= 0 °C

Enable pitting ? yes

Spur gear calculation material Pinion Wheel

Structure factor XW = 1 1

Thermal conductivity = 50 50 N/(s*K)

Heat capacity cM = 485 485 N*m/(k

g*K)

Root roughness Rz = 3,2 3,2 µm

Tooth flank roughness Rz = 1,6 1,6 µm

Data width load factor

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 3/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Tooth modification No

Face load factor (root stress) KF : 0

Face load factor (contact stress) KH : 0

Face load factor (scuffing load) KB : 0

Bearing span l = 120 mm

Eccentricity (pinion) s: 0 mm

Shaft diameter at pinion dsh = 50 mm

Factor K' = 1.33

Type of helical toothing Simple

Transverse load factors

Transverse load factor (root stress) KF : 0

Transverse load factor (contact stress) KH : 0

Transverse load factor (scuffing load) KB : 0

General input Pinion Wheel

Gearing quality 1 1

Design Disk Disk

Inner diameter of rim di : 0 0 mm

Tooth modification, base relief Ca : 0 0 µm

Loading type Pulsating Pulsating

Stress ratio = 0 0

Minimal root safety SFmin = 1,3

Minimal flank safety SHmin = 1,3

Minimal scuffing load safety SBmin = 1

Standard gauge spur gear

General data Pinion Wheel

Deviation of teeth thickness (DIN 3967) f f

Tolerances of teeth thickness (DIN 3967) 25 25

Free input deviations Pinion Wheel

Upper deviation of teeth thickness Asne : 0 0 µm

Lower deviation of teeth thickness Asni : 0 0 µm

Machining allowance q: 0 mm

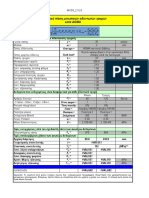

Results:

General data

Effective number of teeth ratio u = 3

Effective translation ratio i = 3

Transverse pressure angle t = 20,739 °

Pressure angle at pitch cylinder wt = 23,912 °

Ground lead b = 15,012 °

Zero centre distance ad = 299,606 mm

Centre distance a = 306,5 mm

Profile shift coefficient (pinion) x1 = 0,5849

Profile shift coefficient (wheel) x2 = 0,65

Sum profile shift coefficient xs = 1,2349

Length of path of contact g = 20,074 mm

Length of recess path ga = 12,882 mm

Length of approach path gf = 7,192 mm

Transverse contact ratio = 1,095

Overlap ratio = 1,609

Total contact ratio = 2,703

Number of teeth z = 24 72

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 4/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Virtual number of teeth of helical gear zn = 26,763 80,288

Geometrical data

Reference diameter d = 149,803 449,409 mm

Base diameter db = 140,097 420,29 mm

Pitch diameter dw = 153,25 459,75 mm

Root diameter df = 142,422 442,809 mm

V-circle diameter dv = 156,822 457,209 mm

Tip diameter da = 165,378 465,766 mm

Theoretical tip diameter da th = 168,822 469,209 mm

Root form circle diameter dFf = 145,896 445,892 mm

Root form diameter dNf = 148,005 449,924 mm

Specific sliding at point A A = -0,402 0,287

Specific sliding at point E E = 0,391 -0,642

Tooth thickness on the tip cylinder san = 5,176 5,82 mm

Tooth depth h = 11,478 11,478 mm

Addendum ha = 7,788 8,178 mm

Dedendum hf = 3,691 3,3 mm

Theoretical bottom clearance c = 1,2 1,2 mm

Actual topland play ctat = 2,496 2,476 mm

Tooth – tip height modification k = -1,7217 -1,7217 mm

Normal base pitch pen = 17,713 mm

Transverse base pitch pet = 18,339 mm

Normal pitch on base cylinder pbn = 17,713 mm

Transverse pitch on base cylinder pbt = 18,339 mm

Cutter data of gear rack

Cutter data pinion type cutter

Number of teeth z0 = 0 0

Profile shift coefficient x0 = 0 0

Topland height factor haP0* = 1,2 1,2

Root height factor hfP0* = 1 1

Reference diameter d0 = 0 0 mm

Base diameter db0 = 0 0 mm

Tip diameter da0 = 14,4 14,4 mm

Deddendum diameter (generation) dfE = 142,281 442,631 mm

Centre distance a0 = 77,955 228,322 mm

Zere centre distance ad0 = 74,902 224,705 mm

Pressure angle at pitch cylinder wt0 = 26,029 23,017 °

Results of calculation strength

Forces, moment, speed

Transverse tangential load Ft = 96202,22 N

at reference cylinder

Transverse tangential load Ftw = 94038,451 N

at pitch cylinder

Radial load at pitch cylinder Frw = 41695,05 N

Axial load at pitch cylinder Faw = 27585,543 N

Tooth load at pitch cylinder Fw = 106501,97 N

Moment (pinion) T1 = 7205,696 N*m

Moment (wheel) T2 = 21617,089 N*m

Line load = 1093,207 N/mm

Peripheral speed at reference cylinder v = 0,214 m/s

Peripheral speed at pitch cylinder vw = 0,219 m/s

Rotation speed (pinion) n1 = 27,3 1/min

Rotation speed (wheel) n2 = 9,1 1/min

Number of loading cycle (pinion) NL1 = 16380000

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 5/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Number of loading cycle (wheel) NL2 = 5460000

General factors

Hekix slope deviation fH = 3 3 µm

Transverse pitch deviation fpe = 1,5 2 µm

Profile form deviation ff = 2 2 µm

Effective meshing slope deviation fpe eff = 1,519 µm

Effective profile form deviation ff eff = 1,45 µm

Flank line deviation fx = 21,04 µm

Manufacturing - flank line deviation fma = 3 µm

Flank line deviation through pinion def. fsh = 13,564 µm

Reduced mass / tooth width mred = 0,079 kg/mm

Individual spring rigidity c' = 15,58 N/(mm*µm)

Meshing spring rigidity c = 15,017 N/(mm*µm)

Resonance velocity (pinion) nE1 = 5475,442 1/min

Resonance velocity (gear) nE2 = 1825,147 1/min

Basic velocity NR = 0,005

Dynamic factor Kv = 1

Face load factor (root stress) KF = 1,058

Face load factor (contact stress) KH = 1,065

Face load factor (scuffing load) KB = 1,065

Transverse load factor (root stress) KF = 1

Transverse load factor (contact stress) KH = 1

Transverse load factor (scuffing load) KB = 1

Helix angle factor KB = 1,254

Pitting load capacity

Zone factor ZH = 2,232

Elasticity factor ZE = 191,646

Contact ratio factor Z = 0,956

Helix angle factor Z = 0,98

Work hardening factor ZW = 1

Lubricant factor ZL = 1,016 -

Velocity factor Zv = 0,952 -

Roughness factor ZR = 1,068 -

Life factor for contact stress ZNT = 1,088 1,354

Size factor ZX = 1 1

Single pair tooth contact factor ZB = 1 ZD = 1,000

Pitting stress limit HG = 1685,976 2059,616 N/mm²

Allowable flank pressure HP = 1296,904 1584,32 N/mm²

Contact stress H = 1290,648 1290,648 N/mm²

Safety factor for pitting SH = 1,306 1,596

Attainable lifetime Lh = fat. strength fat. strength

Root load capacity

Overlapping factor (root stress) Y = 0,914

Helix angle factor Y = 0,867

Deep tooth factor YDT = -

Rim thickness factor YB = - -

Tooth form factor YF = 1,385 1,42

Stress correction factor YS = 2,153 2,183

Relativ notch sensitivity factor YrelT = 1,007 1,011

Relativ survace factor YRrelT = 1,042 1,042

Size factor YX = 0,994 0,994

Life factor for tooth root stress YNT = 1 1

Mean stress influence factor YM = 1 1

Tooth root stress limit FG = 896,777 900,365 N/mm²

Allowable root stress FP = 689,828 692,588 N/mm²

Tooth root stress F = 498,51 518,204 N/mm²

Safety factor for tooth breakage SF = 1,799 1,737

Attainable lifetime Lh = fat. strength fat. strength

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 6/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Scuffing load capacity

Angle factor X = 1,026

Lubricant factor XS = 1

Flash temperature calculation way

Load distribution factor X = 0,667

Flash factor XM = 50,235

Geometry factor XB = 0,169

Tangential line force at weigth wBt = 1460,877 N/mm

Scuffing temperature = 95,857 °C

Corrosion safety factor SB = 2,178

Integral calculation way

Flash factor XM = 50,235

Geometry factor (pinion tip) XBE = 0,193

Pitch factor XQ = 1

Tip relief factor XCa = 1

Contact ratio factor X = 0,369

Mass temperature M = 46,679 °C

Integral temperature int = 60,99 °C

Scuffing integral temperature intS = 95,857 °C

Corrosion safety factor SintS = 1,572

Scuffing load safety factor SSL = 2,661

Ultimate strength for pinion Rm = 1200 N/mm² (for deff = 140,1 mm )

Ultimate strength for gear Rm = 1200 N/mm² (for deff = 420,29 mm )

Yielding point for pinion Re = 850 N/mm² (for deff = 140,1 mm )

Yielding point for gear Re = 850 N/mm² (for deff = 420,29 mm )

Specific sliding accord. to DIN 3960

Kg External toothing

x1 = 0,585

x2 = 0,650

4,3 xs = 1,235

1,621

3,2 ga = 12,882

gf = 7,192

Kg1

2,1 g = 20,074

A E Kga1 = 0,224

0,540 1,1 Kga2 = 0,125

C

0,224 Kgf1 = 0,125

0,125

0 Kgf2 = 0,224

-0,125

-0,224

spec. sliding: pinion

-1,1

-0,540

A = -0,402

1 E = 0,391

-2,1

2 Kg2

spec. sliding: gear

-3,2

-1,621 A = 0,287

-4,3 E = -0,642

0 12,423 37,270 62,117 86,963 111,810 [mm]

Meshing Line

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 7/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Tooth profile (evolvent) pinion

da1

dw 1

d1

df1

Tooth profile (evolvent) gear

da2

dw 2

d2

df2

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 8/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Gap of tooth (envelope curv e, ev olv ent) pinion

da1

dw 1

d1

df1

Gap of tooth (envelope curv e, evolvent) gear

da2

dw 2

d2

df2

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 9/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Side view pinion

df1 d1 da1

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 10/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Side view gear

df2 d2 da2

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 11/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Front view pinion

df1 d1da1

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 12/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Front view gear

df2 d2 da2

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 13/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Gear wheel (evolvent) pinion

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 14/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Gear wheel (evolvent) gear

Pinion, Pitting Bearing Capacity Diagram

HG material : 18CrNiMo7-6 load cycle [-] lifetime [h]

[N /mm²]

2

10 0,06

3000 3

10 0,61

4

10 6,11

static

5

10 61,05

2400 6

10 610,50

7

10 6105,01

time strength

8

10 61050,06

1800

fatigue strength

1200

600

0

2 3 4 5 6 7 8

10 10 10 10 10 10 10 load cy cle

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 15/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Gear, Pitting Bearing Capacity Diagram

HG material : 18CrNiMo7-6 load cycle [-] lifetime [h]

[N /mm²]

2

10 0,18

3000 3

10 1,83

4

10 18,32

static

5

10 183,15

2400 6

10 1831,50

7

10 18315,02

time strength

8

10 183150,18

1800

9

10 1831501,83

10

fatigue strength 10 18315018,32

1200

600

0

2 3 4 5 6 7 8 9 10

10 10 10 10 10 10 10 10 10 load cy cle

Pinion, Root Bearing Capacity Diagram

FG material : 18CrNiMo7-6 load cycle [-] lifetime [h]

[N /mm²]

2

10 0,06

3000 3

10 0,61

4

10 6,11

5

10 61,05

2400 static

6

10 610,50

7

10 6105,01

8

10 61050,06

1800

time strength

1200

fatigue strength

600

0

2 3 4 5 6 7 8

10 10 10 10 10 10 10 load cy cle

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 16/17

Transilvania University of Brasov

Program : MDESIGN User : TEDATA Customer: Test

Module version: 15.0 Date : 21.06.2019 Project: 11

Spur Gear, Gear Rack

Gear, Root Bearing Capacity Diagram

FG material : 18CrNiMo7-6 load cycle [-] lifetime [h]

[N /mm²]

2

10 0,18

3000 3

10 1,83

4

10 18,32

5

10 183,15

2400 static

6

10 1831,50

7

10 18315,02

8

10 183150,18

1800

time strength

1200

fatigue strength

600

0

2 3 4 5 6 7 8

10 10 10 10 10 10 10 load cy cle

ANGRENAJ CILINDRIC.mdp 11/03/2019 07:57:33 Page 17/17

You might also like

- Content PDF 1Document15 pagesContent PDF 1jesbmnNo ratings yet

- Helical Gear Basic PDFDocument13 pagesHelical Gear Basic PDFCarlosQuelartNo ratings yet

- Mdesign 2016 Gears Verzahnungen en PDFDocument86 pagesMdesign 2016 Gears Verzahnungen en PDFmgualdiNo ratings yet

- Various Hardening Processes of GearsDocument32 pagesVarious Hardening Processes of GearsYash VermaNo ratings yet

- Agma Grade 5 Smpe Grade 10Document25 pagesAgma Grade 5 Smpe Grade 10er_winwibowoNo ratings yet

- A Procedure To Determine The Unknown Geometry of External Cylindrical Gears - Gear Solutions Magazine Your Resource To The Gear IndustryDocument11 pagesA Procedure To Determine The Unknown Geometry of External Cylindrical Gears - Gear Solutions Magazine Your Resource To The Gear IndustryChetan PrajapatiNo ratings yet

- The Importance of Profile Shift, Root Angle Correction and Cutter Head TiltDocument4 pagesThe Importance of Profile Shift, Root Angle Correction and Cutter Head TiltvijaykumarnNo ratings yet

- 02 Mechanical BasicsDocument29 pages02 Mechanical BasicsVLADIMIR YOLVIS CHOQUEHUANCA GALINDONo ratings yet

- Axisymmetric Shrink Fit Analysis and DesignDocument10 pagesAxisymmetric Shrink Fit Analysis and DesignParag NaikNo ratings yet

- Pressing Force Calculator UpdatedDocument25 pagesPressing Force Calculator Updatedanush_swaminathanNo ratings yet

- Spur SizingDocument126 pagesSpur SizingjccforeverNo ratings yet

- Shaft Calculation Base PDFDocument27 pagesShaft Calculation Base PDFBarsanu AlexNo ratings yet

- Worm Gear PairDocument585 pagesWorm Gear Pairer_winwibowoNo ratings yet

- Mod10 1ToothBendingDocument4 pagesMod10 1ToothBendingMario AndradeNo ratings yet

- CALCULATIONS CONVENTIONAL SUCKER ROD PUMPING SYSTEMDocument20 pagesCALCULATIONS CONVENTIONAL SUCKER ROD PUMPING SYSTEMErick DavidNo ratings yet

- Gear 1Document9 pagesGear 1Ariyant CreativeNo ratings yet

- Worm Gea Pairs ReferenceDocument6 pagesWorm Gea Pairs Referenceer_winwibowoNo ratings yet

- 0611 GearSolutionsDocument72 pages0611 GearSolutionspoorianaNo ratings yet

- Spiral Bevel Gear Arcoid System ZFTKK 250-1Document2 pagesSpiral Bevel Gear Arcoid System ZFTKK 250-1er_winwibowoNo ratings yet

- Equations For The Design of Standard Sprocket TeethDocument4 pagesEquations For The Design of Standard Sprocket TeethvanjaurkeNo ratings yet

- Tooth ThicknessDocument9 pagesTooth ThicknessPraveen VundrajavarapuNo ratings yet

- Crane Girder Design FinalDocument11 pagesCrane Girder Design FinalRakesh SharmaNo ratings yet

- MidasNFX Quick Start GuideDocument14 pagesMidasNFX Quick Start GuideHipow87No ratings yet

- GEAR CALCULATION CORRECTIONDocument9 pagesGEAR CALCULATION CORRECTIONmahendravsNo ratings yet

- Spur Gear, Helical Gear Design Step Final1Document2 pagesSpur Gear, Helical Gear Design Step Final1Venkadesh ShanmugamNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- Measuring Helix Angle of GearsDocument6 pagesMeasuring Helix Angle of Gearsdarshan.hegdebNo ratings yet

- Ball - Screw - Calculations - As Per THK and PmiDocument5 pagesBall - Screw - Calculations - As Per THK and PmiDharmeshPatelNo ratings yet

- Choice Choice Normal ModuleDocument5 pagesChoice Choice Normal Module149933No ratings yet

- Σχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMADocument1 pageΣχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMAkstayroskNo ratings yet

- Flange CouplingDocument17 pagesFlange CouplingROCKY DUBEYNo ratings yet

- Gear DesignDocument83 pagesGear DesignmuhammadaminjamalmutNo ratings yet

- A Method to Optimize Brass Synchronizer RingDocument6 pagesA Method to Optimize Brass Synchronizer RingaravindhNo ratings yet

- Technical Card Ck45 Mechanical PropertiesDocument3 pagesTechnical Card Ck45 Mechanical PropertiesNuno Miguel TorcatoNo ratings yet

- Involute Spline Strength CalculationsDocument1 pageInvolute Spline Strength CalculationsRjgandhi65No ratings yet

- Shaft Design - Overheads PDFDocument20 pagesShaft Design - Overheads PDFRyan BaleNo ratings yet

- Kisssoft Tut 003 E KeyDocument11 pagesKisssoft Tut 003 E KeyJorge Ronald Cabrera ÑaupaNo ratings yet

- Machine Design Lec3Document75 pagesMachine Design Lec3sam0415No ratings yet

- TechnicalData KGSTOCKGEARS PDFDocument171 pagesTechnicalData KGSTOCKGEARS PDFChetan PrajapatiNo ratings yet

- Design of Bevel and Worm Gear: Machine Element IIDocument60 pagesDesign of Bevel and Worm Gear: Machine Element IIkibromgidey12No ratings yet

- Spiral Springs PDFDocument18 pagesSpiral Springs PDFEngr Eze Chuklet ChukwumaNo ratings yet

- CMAA 70 2000 Structure DesignDocument19 pagesCMAA 70 2000 Structure DesignmishikhanNo ratings yet

- Fea Analysis of A Caliper Bracket For Disk BrakeDocument5 pagesFea Analysis of A Caliper Bracket For Disk Brakesuraj dhulannavar100% (1)

- Loads Acting On Crane Structure During TravelDocument11 pagesLoads Acting On Crane Structure During Travelaiyubi2No ratings yet

- ISO Gear Standards GuideDocument6 pagesISO Gear Standards GuideEslam YehiaNo ratings yet

- Renold Conveyor Chain Catalogue Designer GuideDocument41 pagesRenold Conveyor Chain Catalogue Designer Guidedeep200No ratings yet

- Gear Table Format: Confidential 2016 Page 1 of 3Document3 pagesGear Table Format: Confidential 2016 Page 1 of 3Sanjay ShelarNo ratings yet

- Small Commercial Vehicles India 2022Document26 pagesSmall Commercial Vehicles India 2022tussi_91100% (1)

- Involute Spur Gear Geometry Calculations: Input DataDocument11 pagesInvolute Spur Gear Geometry Calculations: Input DataNILESH YADAVNo ratings yet

- Integral Analysis of Conveyor Pulley Using ®nite Element MethodDocument30 pagesIntegral Analysis of Conveyor Pulley Using ®nite Element MethodEsteban CorderoNo ratings yet

- Addendum Modified Gear For An All-Terrain Vehicle GearboxDocument6 pagesAddendum Modified Gear For An All-Terrain Vehicle GearboxIJRASETPublicationsNo ratings yet

- RP11LDocument18 pagesRP11Lمحمد جوادNo ratings yet

- Brugg Catalog enDocument28 pagesBrugg Catalog enSinoj V AntonyNo ratings yet

- Spur GearsDocument8 pagesSpur GearstopjobNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- Din 3990 Mdesign 2016 Esempio Spur Gear Gear RackDocument17 pagesDin 3990 Mdesign 2016 Esempio Spur Gear Gear RackSunil AundhekarNo ratings yet

- DIN 3990 MDesign 2016 Esempio Spur Gear, Gear RackDocument17 pagesDIN 3990 MDesign 2016 Esempio Spur Gear, Gear RackmgualdiNo ratings yet

- Data 1Document11 pagesData 1ARUNNo ratings yet

- Cylindrical worm gear pairs strength and load calculationsDocument4 pagesCylindrical worm gear pairs strength and load calculationsDiana Maria CozmaNo ratings yet

- Transilvania University Bevel Gear CalculationDocument6 pagesTransilvania University Bevel Gear CalculationDiana Maria CozmaNo ratings yet

- Transilvania University Designs Narrow V-BeltsDocument2 pagesTransilvania University Designs Narrow V-BeltsDiana Maria CozmaNo ratings yet

- Angrenaj Cilindric PDFDocument17 pagesAngrenaj Cilindric PDFDiana Maria CozmaNo ratings yet

- Transilvania University Bevel Gear CalculationDocument6 pagesTransilvania University Bevel Gear CalculationDiana Maria CozmaNo ratings yet

- Transilvania University Bevel Gear CalculationDocument6 pagesTransilvania University Bevel Gear CalculationDiana Maria CozmaNo ratings yet

- Cylindrical worm gear pairs strength and load calculationsDocument4 pagesCylindrical worm gear pairs strength and load calculationsDiana Maria CozmaNo ratings yet

- Transilvania University Bevel Gear CalculationDocument6 pagesTransilvania University Bevel Gear CalculationDiana Maria CozmaNo ratings yet

- Cylindrical worm gear pairs strength and load calculationsDocument4 pagesCylindrical worm gear pairs strength and load calculationsDiana Maria CozmaNo ratings yet

- Calcul LantDocument2 pagesCalcul LantDiana Maria CozmaNo ratings yet

- Lini ACCSMDocument86 pagesLini ACCSMDiana Maria CozmaNo ratings yet

- Calcul LantDocument2 pagesCalcul LantDiana Maria CozmaNo ratings yet

- Lini ACCSMDocument86 pagesLini ACCSMDiana Maria CozmaNo ratings yet

- Einstein's Theory of Gravity - General RelativityDocument5 pagesEinstein's Theory of Gravity - General RelativityBob StumanNo ratings yet

- Mass vs Period of OscillationDocument2 pagesMass vs Period of OscillationKAH HUINo ratings yet

- Fleet Strategy - ACS Power TransformersDocument96 pagesFleet Strategy - ACS Power TransformersManojNo ratings yet

- FluentDocument13 pagesFluentMilan Krishna Singha SarkarNo ratings yet

- Physics Astronomy PDFDocument22 pagesPhysics Astronomy PDFAbhik SarkarNo ratings yet

- Strength-Durability Correlation of OsteosynthesisDocument17 pagesStrength-Durability Correlation of OsteosynthesisdeniNo ratings yet

- Aquinas' Commentary on Aristotle's PhysicsDocument498 pagesAquinas' Commentary on Aristotle's PhysicsishmailpwquodNo ratings yet

- Chemical Equilibrium and Acids-Bases SummaryDocument7 pagesChemical Equilibrium and Acids-Bases SummaryGagan NdNo ratings yet

- (STATISTICS & PROBABILITY) Unit II - Lesson 1 Understanding The Normal Curve DistributionDocument14 pages(STATISTICS & PROBABILITY) Unit II - Lesson 1 Understanding The Normal Curve DistributionVany SpadesNo ratings yet

- Odd Even Signals ExplainedDocument11 pagesOdd Even Signals ExplainedNathaniel BaldevinoNo ratings yet

- Ilnas-En Iso 12048:2000Document13 pagesIlnas-En Iso 12048:2000Jimmy HuynhNo ratings yet

- Preparing for Typhoons - Emergency Tips Before, During and After Natural DisastersDocument5 pagesPreparing for Typhoons - Emergency Tips Before, During and After Natural Disasterstrishia matasNo ratings yet

- Nepal Aviation Authority 8Document5 pagesNepal Aviation Authority 8Janup PokharelNo ratings yet

- Static Analysis of Transmission Tower BeDocument9 pagesStatic Analysis of Transmission Tower BecivildepartmentmycemNo ratings yet

- MAM100 User ManualDocument23 pagesMAM100 User Manualsteve@air-innovations.co.za100% (5)

- 8934 - Tests For A Level Year 2 SM Expert Set A PDFDocument6 pages8934 - Tests For A Level Year 2 SM Expert Set A PDFCherie ChowNo ratings yet

- 1x5x5 Design ReportDocument47 pages1x5x5 Design ReportGajendra BishtNo ratings yet

- Matrix Algebra 1.Document4 pagesMatrix Algebra 1.Snaya SharmaNo ratings yet

- Uta BarthDocument12 pagesUta Barthapi-381291798No ratings yet

- 1 Production Section 11Document44 pages1 Production Section 11Kunal RanaNo ratings yet

- LeHTN PDFDocument220 pagesLeHTN PDFjasimabdNo ratings yet

- YL2B-Unit-test-10 - (101, 102) OkDocument6 pagesYL2B-Unit-test-10 - (101, 102) OkrobiNo ratings yet

- Physics Trial ExamDocument27 pagesPhysics Trial ExamaNo ratings yet

- August Sept 2014 PDFDocument105 pagesAugust Sept 2014 PDFGeta BercaruNo ratings yet

- Class Xii Physics SQPDocument125 pagesClass Xii Physics SQPbrutalrx3310No ratings yet

- Is 1828 1 2005Document19 pagesIs 1828 1 2005Rajesh KumarNo ratings yet

- M5 AMT Ktunotes - inDocument16 pagesM5 AMT Ktunotes - invivekNo ratings yet

- Sensory PhysiologyDocument34 pagesSensory PhysiologyRaissaNo ratings yet

- XRD TheoryDocument78 pagesXRD TheoryThilaga KaviNo ratings yet

- Data Modulus ElastisitasDocument5 pagesData Modulus ElastisitasYohan S.No ratings yet