Professional Documents

Culture Documents

Hardness Symbols

Uploaded by

sudeep dsouza0 ratings0% found this document useful (0 votes)

65 views3 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

65 views3 pagesHardness Symbols

Uploaded by

sudeep dsouzaCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

BHN: An Abbreviation for Brinell Hardness Number.

Now

abbreviated HBW.

Brinell Hardness: Now abbreviated HBW. A designation of hardness,

usually of steel, performed by pressing a 10 mm

spherical tungsten carbide ball against a clean

prepared surface using a 3000 Kilogram force,

producing an impression, measured and given a

special numerical value. This numerical value

relates to steel tensile strength. API Spec

6A specifies minimum Brinell Hardness

requirements for different material

designations.NACE Standard MR0175

references maximum hardness in determining

steel’s suitability for use in H2S Service.

Hardness: A measured factor that reasonably predicts the

amount metal will resist abrasion and bending, as

well as indicating Ultimate Strength. Most

commonly expressed as Brinell

Hardness and Rockwell Hardness. ASTM E140

provides a guide for comparing hardness

determined by different methods and expressed on

different scales.

HBW: Abbreviation for Brinell Hardness, taken using a

carbide ball indenter.

HRB: (Sometimes RB) An abbreviation for Rockwell

Hardness measured on the B scale. The

abbreviation usually appears after a number, e.g.

83 HRB. See: Rockwell B Hardness.

HRC: (Sometimes RC) An abbreviation for Rockwell

Hardness measured on the C scale. The

abbreviation usually appears after a number, e.g.

22 HRC. See: Rockwell C Hardness.

HV: Abbreviation for Hardness Vickers. The Vickers

hardness testing method represents another

method of testing by indenting the test material

under a specified load and measuring the size of

the indention and comparing it to a number table.

This method has gained greater use in testing of

weld samples to meet NACE requirements.

Hydrogen Sulfide: The chemical commonly abbreviated H2S. This

deadly poison also has a destructive effect on high

strength low alloy steels when the hardness of

these steels exceeds a hardness of 22 Rockwell C.

Indenter: A hardened pointed or rounded contact object used

to impress an indentation into the surface of

steel (or other metal) parts in order to obtain

aHardness measurement of that

part. See HBW, HRC, and HRB.

Mechanical Properties: Measured aspects of Material used to describe its

elastic and inelastic reaction to applied force;

These may include Tensile Strength, Yield

Strength, Elongation, Reduction of Area, Impact

Strength and Hardness.

NACE MR 01 75: A document published by the National Association

of Corrosion Engineers defining the specific limits

of chemistry, hardness and microstructure

ofMaterials used to make equipment to contain or

control well production fluids that include hydrogen

sulfide.

Rockwell B Hardness: A designation of hardness of metallic

materialsmeasured by pressing a small

rounded indenter against a clean prepared surface

with a specific force. The machine making the

indention also measures the depth of the indention

and provides a numerical value for that depth. The

Rockwell B scale expresses more accuracy in the

hardness measurement of metallic materials softer

than HRC 20. To convert hardness numbers

between measuring methods and scales,

see Hardness Number Conversion Chart.

Rockwell C Hardness: A designation of hardness, usually of

steel orCorrosion Resistant Alloys, measured by

pressing a specially shaped indenter against a

clean prepared surface with a specific force. The

machine making the indention also measures the

depth of the indention and provides a numerical

value for that depth. This numerical value relates to

steel Tensile Strength and NACE Standard

MR0175 references hardness in determining steel’s

suitability for use in H2S Service. To convert

hardness numbers between measuring methods

and scales, see Hardness Number Conversion

Chart.

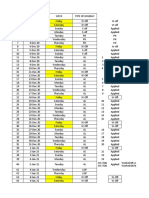

22 RC: 22 RC, 99 RB, 237 HBW (read 235 in table), and

248 HV represent the important upper hardness

limit for non austenitic steel for H2S service

specified in NACE MRO175 and referenced in API

Spec 6A. Some authorities may offer slightly

different equivalent hardness numbers.

HW - Webster Hardness Testing for

Aluminum and Aluminum Alloy. Refer below

link for manual.

http://www.txinstruments.com/uploads/file/w

ebster-users-manual.pdf

You might also like

- Determination of the Mechanical and Technological Properties of MetalsFrom EverandDetermination of the Mechanical and Technological Properties of MetalsNo ratings yet

- Dureza EnsayoDocument9 pagesDureza Ensayopriesblack12No ratings yet

- Rockwell hardness testDocument9 pagesRockwell hardness testMuhammad Zeeshaan JavedNo ratings yet

- Correlation of Hardness Values To Tensile Strength: Semih Genculu, P.EDocument9 pagesCorrelation of Hardness Values To Tensile Strength: Semih Genculu, P.ERakesh DasNo ratings yet

- HardnessTesting enDocument6 pagesHardnessTesting enhiren_mistry55No ratings yet

- EXPERIMENT 3 Hardness TestDocument7 pagesEXPERIMENT 3 Hardness TestHairi HangNo ratings yet

- Macro and Micro Hardness Testing: A.R.G Sreekar, M M 1 2 B 0 0 2Document6 pagesMacro and Micro Hardness Testing: A.R.G Sreekar, M M 1 2 B 0 0 2Arg SreekarNo ratings yet

- Rockwell Hardness Test.... 1Document2 pagesRockwell Hardness Test.... 1rafai167% (3)

- Hardness Testing Methods ExplainedDocument5 pagesHardness Testing Methods ExplainedMuthu GNo ratings yet

- Brinell Hardness Test (New)Document8 pagesBrinell Hardness Test (New)innocentsoul100% (2)

- Hardness TestingDocument10 pagesHardness TestingMekhmanNo ratings yet

- Vicker's Test For HardnessDocument5 pagesVicker's Test For HardnessManish TiwariNo ratings yet

- Section IIIDocument7 pagesSection IIIalaa12344.eslamNo ratings yet

- Hardness Experiment ReportDocument15 pagesHardness Experiment ReportsinabirecikNo ratings yet

- Procedure, Marking Vickers HV Brinell HB Rockwell HRC HRB: F 294 N/30 KPDocument1 pageProcedure, Marking Vickers HV Brinell HB Rockwell HRC HRB: F 294 N/30 KPRahul JadhavNo ratings yet

- MCE12L Activity No. 4 Hardness DeterminationDocument7 pagesMCE12L Activity No. 4 Hardness DeterminationAlex XanderNo ratings yet

- Hardness Testing.pptDocument11 pagesHardness Testing.pptJeyakumar JamesNo ratings yet

- HardnessDocument4 pagesHardnessMoazMohdTrawneh100% (1)

- Quantification of The Local Mechanical Behavior in Dissimilar Metal Welds Using Digital Image Correlation Instrumented Cross-Weld Tensile TestingDocument16 pagesQuantification of The Local Mechanical Behavior in Dissimilar Metal Welds Using Digital Image Correlation Instrumented Cross-Weld Tensile TestingengineeringNo ratings yet

- General Mechanical PropertiesDocument4 pagesGeneral Mechanical PropertiesRVRM1995No ratings yet

- Hardness Tests ExplainedDocument15 pagesHardness Tests ExplainedHossam SallamNo ratings yet

- HardnessDocument21 pagesHardnessJerry Man UtdNo ratings yet

- Military Institute of Science and Technology: Kaniza IslamDocument8 pagesMilitary Institute of Science and Technology: Kaniza IslamSakib RafeeNo ratings yet

- c1 Mechanical PropertiesDocument46 pagesc1 Mechanical PropertiesHusnal TaufiqNo ratings yet

- ASTM E18 (2019)_Part2Document1 pageASTM E18 (2019)_Part2david4231993No ratings yet

- Hardness TestDocument6 pagesHardness Testnigoxiy168No ratings yet

- Unit IIDocument23 pagesUnit IIvizhideepaNo ratings yet

- Hard EnessDocument1 pageHard EnessVictor Tmwble GerardoNo ratings yet

- Vickers Hardness TestDocument7 pagesVickers Hardness TestIhsan1991 YusoffNo ratings yet

- HTOMDocument8 pagesHTOMHalaaNo ratings yet

- TOM Unit 2 PDFDocument23 pagesTOM Unit 2 PDFNikhil NagarajanNo ratings yet

- What Is Hardness?: (Type Text)Document5 pagesWhat Is Hardness?: (Type Text)akif222999No ratings yet

- Open Ended Lab Project EmatDocument6 pagesOpen Ended Lab Project EmatAnas SattiNo ratings yet

- Hardness Testing NotesDocument2 pagesHardness Testing NotesJohnNo ratings yet

- HardnessDocument11 pagesHardnessglorialidwin.b dace mechNo ratings yet

- Rockwell Hardness Test MethodDocument5 pagesRockwell Hardness Test MethodAnonymous gFcnQ4goNo ratings yet

- CEB 2104 - Lecture - 5Document51 pagesCEB 2104 - Lecture - 5msigwadaniel1fbNo ratings yet

- 10080-1-SS-PP-016Document22 pages10080-1-SS-PP-016SURAJ PRSADNo ratings yet

- ME217 Material Lab Hardness TestsDocument12 pagesME217 Material Lab Hardness Testsyousef alhashelNo ratings yet

- Material Lab 10Document3 pagesMaterial Lab 1021pwind0685No ratings yet

- Hardness ScaleDocument26 pagesHardness ScaleMathu MohanNo ratings yet

- Mohs Hardness TestDocument3 pagesMohs Hardness TestSelva KumarNo ratings yet

- Assignment 3 - POMDocument8 pagesAssignment 3 - POMMcDhanesh JiNo ratings yet

- Bojo MmeDocument26 pagesBojo Mmepolymath thesolverNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument38 pagesRockwell Hardness of Metallic Materials: Standard Test Methods Foramit84indNo ratings yet

- Hardness Test: University of Jordan Mechanical Engineering Department Strength of Materials LabDocument14 pagesHardness Test: University of Jordan Mechanical Engineering Department Strength of Materials Labwaysh88% (8)

- ME 207 - Chapter 5 - P2Document9 pagesME 207 - Chapter 5 - P2rathanNo ratings yet

- Hardness ReportDocument11 pagesHardness Reportcheyaya100% (8)

- Lab ReportDocument21 pagesLab ReportMuhammad YasirNo ratings yet

- HARDNESS TEST METHODSDocument3 pagesHARDNESS TEST METHODSsachithNo ratings yet

- Surface Vehicle Standardsta Ndard: Rev. DEC83Document11 pagesSurface Vehicle Standardsta Ndard: Rev. DEC83san moedano100% (1)

- TGN-PE-01 Hardness Testing of Welds PDFDocument6 pagesTGN-PE-01 Hardness Testing of Welds PDFTeoTyJayNo ratings yet

- MQA Technical Report on Material Hardness TestingDocument8 pagesMQA Technical Report on Material Hardness TestingShaffan AbbasiNo ratings yet

- ASTM E18 (2019)_Part4Document1 pageASTM E18 (2019)_Part4david4231993No ratings yet

- Mechanical Properties and Hardness TestsDocument15 pagesMechanical Properties and Hardness TestsMitzySolòrzanoNo ratings yet

- Zinc Coated NutsDocument18 pagesZinc Coated NutsFaiz Uddin SiddiquiNo ratings yet

- Wear Resistance of Tool Steels Bulletin - 116Document2 pagesWear Resistance of Tool Steels Bulletin - 116Jai BhandariNo ratings yet

- Hardness Measurement LabDocument4 pagesHardness Measurement Labgodfree joyNo ratings yet

- Hardness Test of WeldsDocument4 pagesHardness Test of Weldsjose_sebastian_2No ratings yet

- Charpy TestDocument1 pageCharpy Testsudeep dsouzaNo ratings yet

- Leave PlanDocument3 pagesLeave Plansudeep dsouzaNo ratings yet

- List of Documents For Plates & TubularsDocument6 pagesList of Documents For Plates & Tubularssudeep dsouzaNo ratings yet

- Line Pipe Dimensional TolerenceDocument1 pageLine Pipe Dimensional Tolerencesudeep dsouzaNo ratings yet

- Leave PlanDocument3 pagesLeave Plansudeep dsouzaNo ratings yet

- NDT Technician ChecklistDocument1 pageNDT Technician Checklistsudeep dsouzaNo ratings yet

- GAP Analysis DNVGL-B101 Vs EN 10025-4Document2 pagesGAP Analysis DNVGL-B101 Vs EN 10025-4sudeep dsouzaNo ratings yet

- GAP Analysis DNVGL-B101 Vs EN 10025-4Document2 pagesGAP Analysis DNVGL-B101 Vs EN 10025-4sudeep dsouzaNo ratings yet

- Chemical Elements - DNVGL-B101 Vs EN 10025-2Document3 pagesChemical Elements - DNVGL-B101 Vs EN 10025-2Sudeep DsouzaNo ratings yet

- Charpy TestDocument1 pageCharpy Testsudeep dsouzaNo ratings yet

- Chemical Elements - DNVGL-B101 Vs EN 10210-1Document3 pagesChemical Elements - DNVGL-B101 Vs EN 10210-1sudeep dsouzaNo ratings yet

- Charpy Test - ShapesDocument1 pageCharpy Test - Shapessudeep dsouzaNo ratings yet

- PP3-PP9-PP10 Quality-Plan 10-10-2013 WP1.3 01 Version1 1Document73 pagesPP3-PP9-PP10 Quality-Plan 10-10-2013 WP1.3 01 Version1 1Roni EnjelaniNo ratings yet

- PMI Cost Breakdown for J-Tube and Cone Inspection by LIBS and XRFDocument2 pagesPMI Cost Breakdown for J-Tube and Cone Inspection by LIBS and XRFsudeep dsouzaNo ratings yet

- Technical ClarificationDocument2 pagesTechnical Clarificationsudeep dsouzaNo ratings yet

- Tubular TYK Fabrication and Inspection: It Is Important To Plan Ahead For These Complex WeldsDocument5 pagesTubular TYK Fabrication and Inspection: It Is Important To Plan Ahead For These Complex Weldsluz82No ratings yet

- Rolled - Clad - Plates Voestalpine PDFDocument26 pagesRolled - Clad - Plates Voestalpine PDFakhileshNo ratings yet

- QC SlidesDocument1 pageQC Slidessudeep dsouzaNo ratings yet

- PP3-PP9-PP10 Quality-Plan 10-10-2013 WP1.3 01 Version1 1Document73 pagesPP3-PP9-PP10 Quality-Plan 10-10-2013 WP1.3 01 Version1 1Roni EnjelaniNo ratings yet

- SF-467 13Document10 pagesSF-467 13sudeep dsouzaNo ratings yet

- Dimension Report - Mono Rail Beam PDFDocument2 pagesDimension Report - Mono Rail Beam PDFsudeep dsouzaNo ratings yet

- ANSI Flanges Dimensions Specs Grades ClassesDocument23 pagesANSI Flanges Dimensions Specs Grades ClassesVenkatesh GangadharNo ratings yet

- Specification For Wrought Austenitic Stainless Steel Piping FittingsDocument11 pagesSpecification For Wrought Austenitic Stainless Steel Piping Fittingssudeep dsouzaNo ratings yet

- Orac Charts - BuenisimoDocument92 pagesOrac Charts - BuenisimosanthigiNo ratings yet

- Fetal and Placental Development - FETAL Sac, Umbilical Cord .Abnormalities of PlacentaDocument150 pagesFetal and Placental Development - FETAL Sac, Umbilical Cord .Abnormalities of PlacentaKripa SusanNo ratings yet

- Waste Management in Vienna. MA 48Document12 pagesWaste Management in Vienna. MA 484rtttt4ttt44No ratings yet

- Surat Kecil Untuk TuhanDocument9 pagesSurat Kecil Untuk TuhanAsgarPurnamaNo ratings yet

- Logicroof V-RP enDocument1 pageLogicroof V-RP enCristina DogariNo ratings yet

- Interfacial Phenomena in Pharmaceutical FormulationDocument21 pagesInterfacial Phenomena in Pharmaceutical FormulationNickson DrabeNo ratings yet

- Concept of StateDocument10 pagesConcept of StateAryansh ShuklaNo ratings yet

- Drawing and Reading Structural FormulasDocument12 pagesDrawing and Reading Structural FormulasVy Nguyen100% (1)

- Quest The Last RemnantDocument67 pagesQuest The Last Remnantding suheNo ratings yet

- Guide 111: International Electrotechnical CommissionDocument7 pagesGuide 111: International Electrotechnical CommissionSayyid JifriNo ratings yet

- What Is A Supply ChainDocument20 pagesWhat Is A Supply ChainThanh Binh Tran NguyenNo ratings yet

- Determine PH by PH Indicator and Universal IndicatorDocument3 pagesDetermine PH by PH Indicator and Universal IndicatorhaleelNo ratings yet

- Rental Range Powered by YANMAR Diesel GeneratorDocument6 pagesRental Range Powered by YANMAR Diesel GeneratorJonathan CastilloNo ratings yet

- Entrepreneurship Macro Environment ForcesDocument26 pagesEntrepreneurship Macro Environment ForcesSivaNo ratings yet

- Practical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDocument3 pagesPractical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDitiro Maletsanake50% (2)

- CFD Answer KeyDocument12 pagesCFD Answer KeyRaahini IzanaNo ratings yet

- 2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFDocument9 pages2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFfawadintNo ratings yet

- Melese Hotel ST ReportDocument74 pagesMelese Hotel ST ReportKidist MollaNo ratings yet

- Science: Pure Substances Vs MixturesDocument33 pagesScience: Pure Substances Vs MixturesElle Ma Rie100% (1)

- Fire Crunch. M 08 Bushfire Attack Level BAL FZ TestedDocument3 pagesFire Crunch. M 08 Bushfire Attack Level BAL FZ TestedTimaiagNo ratings yet

- Final Seminar ReportDocument35 pagesFinal Seminar ReportHrutik BhandareNo ratings yet

- Pharmacy Preceptors Guild of The Philippines: ObjectiveDocument4 pagesPharmacy Preceptors Guild of The Philippines: ObjectiveCarline ScarletNo ratings yet

- Packaging Materials and Handling Technique: Dr. Ranjeet SinghDocument48 pagesPackaging Materials and Handling Technique: Dr. Ranjeet Singharon demagiba100% (1)

- GREEN AIR CONDITIONER Mechanical Presentation TopicsDocument9 pagesGREEN AIR CONDITIONER Mechanical Presentation TopicsCerin91No ratings yet

- Singaporean Notices To Mariners: Section ContentDocument35 pagesSingaporean Notices To Mariners: Section ContentGaurav SoodNo ratings yet

- November 2010 (v1) QP - Paper 3 CIE Biology A-Level PDFDocument12 pagesNovember 2010 (v1) QP - Paper 3 CIE Biology A-Level PDFWiji NingNo ratings yet

- MUSCULAR SYSTEM WORKSHEET Slides 1 To 4Document4 pagesMUSCULAR SYSTEM WORKSHEET Slides 1 To 4kwaiyuen ohnNo ratings yet

- Magellans of The Sky - Prologue - Summer 2010Document12 pagesMagellans of The Sky - Prologue - Summer 2010Prologue MagazineNo ratings yet

- Revision 2 Pages Grammar Drills 106078Document3 pagesRevision 2 Pages Grammar Drills 106078Ligia Dragomir100% (1)

- Catalog INSIZE - Instrumente de MasuraDocument32 pagesCatalog INSIZE - Instrumente de MasuraSculegero0% (1)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 4.5 out of 5 stars4.5/5 (2)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionFrom Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- General Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismFrom EverandGeneral Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismNo ratings yet

- Autophagy in Health and DiseaseFrom EverandAutophagy in Health and DiseaseBeverly RothermelNo ratings yet

- Exercise, Sport, and Bioanalytical Chemistry: Principles and PracticeFrom EverandExercise, Sport, and Bioanalytical Chemistry: Principles and PracticeNo ratings yet