Professional Documents

Culture Documents

Line Pipe Dimensional Tolerence

Uploaded by

sudeep dsouzaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Line Pipe Dimensional Tolerence

Uploaded by

sudeep dsouzaCopyright:

Available Formats

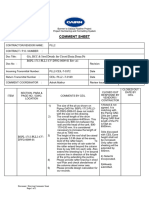

Tolerance Captured in Tolerance mentioned in API 5L Section 9, TABLE 10 &

Tolerances Mentioned in MR Tolerance mentioned in 01-SAMSS-35 Tolerance mentioned in API 5L Annex J

MR 11

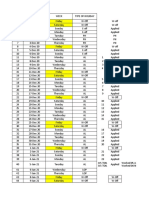

-0% / +0.1% of the length in meters for Pipeline ‘Line

SUPPLY TOLERANCES Pipe items; The total length of pipe supplied per item on an order shall not

(Tolerances applicable to -0% of the length in meters / +1 joint for Risers/Spools’ be less than the amount ordered and shall not exceed the

whole Pipe Lot supplied) Line pipe items; amount ordered by more than three lengths, except by

agreement.

07-02-20 Confirmed

a) Unless otherwise agreed, random lengths shall be

delivered within the tolerances given in Table 12.

b) Approximate lengths shall be delivered within a tolerance J.6.3 Unless otherwise agreed, the minimum average length of

of ± 500 mm (20 in.). pipe shall be 12.1 m (39.7 ft). If

requested by the purchaser, the pipe manufacturer shall confirm

Pipe joint Length average: 12.2m, Max: 12.4m, Min: No pipe lengths less than 32.8 ft (9.99 m) will be accepted. the maximum average length of pipe to be supplied per order

12.0m, 98% Pipe supply shall be: within 12.1 - 12.3m Pipe lengths less than 38.1 ft (11.61 m) shall not exceed 2% of item. Unless otherwise agreed, the actual length of each pipe

Remaining: 2%. Shortest individual length allowed is the total line item quantity. Pipe intended for subsequent (end face to end face) shall lie within the range 11.70 m (38.4 ft)

Pipe joint Length 11.9m: 2% short pipe needs to be colour coded at Mill, internal coating shall have a maximum length of 42.0 ft (12.80) to 12.70 m (41.7 ft).

preferably for operations ease. for any individual length.

07-02-20 Confirmed Note:- it is, therefore, the responsibility of the purchaser to agree

with both the

manufacturer and the pipe-lay contractor on the length range to

be supplied.

9.12.6.3 The out-of-squareness, as shown in Figure 3, shall

be ≤ 1.6 mm (0.063 in.). The out-ofsquareness is measured

as the gap between the end of the pipe and the pipe end leg.

Max 1.6mm from true 90°.

Pipe End Squareness

07-02-20 Confirmed

1) The total deviation from a straight line, over the entire

pipe length, shall be ≤ 0.2 % of the pipe length, as shown in

Figure 1.

2)The local deviation from a straight line in the 1.5 m (5.0 ft)

portion at each pipe end shall be ≤ 3.2 mm (0.125 in.), as

Max 0.15% of pipe length shown in Figure 2. J.6.4 The total deviation from a straight line over the entire pipe

Pipe straightness 07-02-20 Confirmed length shall be ≤ 0.15 % of the pipe length.

Nominal OD ≤ 16” = ±0.5%ID but maximum ±1.0mm

(ID) Inside Diameter at

Pipe Ends

07-02-21- To proceed as of now.

Nominal OD ≤ 16” = 1.0% ID, but max. 2.0 mm

OOR Pipe Ends (ID)

07-02-21- To proceed as of now.

Tolerances for Wall Thickness (SMLS) Table 11

Tolerances for Wall Thickness (SMLS) Table J.4

t > 4.0 mm (0.157) to < 25.0 mm (0.984) = +0.150t –0.125t tickness - 10.0mm (0.394) to < 25.0mm (0.984) = +0.125t

10 ≤ WT ≤ 25.4 mm = -10%, + 12.5% −0.125t

Note-If the purchase order specifies a minus tolerance for

Wall Thickness wall thickness smaller than the applicable value given in this Note -If the purchase order specifies a minus tolerance for wall

07-02-21- To proceed as of now. table, the plus tolerance for wall thickness shall be increased thickness smaller than the applicable value given in this table, the

by an amount sufficient to maintain the applicable tolerance plus tolerance for wall thickness shall be increased by an amount

range. sufficient to maintain the applicable tolerance range.

Nominal OD ≤16” = ± 0,75% OD Diameter Tolerances -Pipe Except the End (SMLS) (Table 10) Diameter Tolerances-Pipe Except the End (SMLS) (Table J.3)

OD Tolerances at Pipe

Body 07-02-21- Below note to be added in MR OD > 168.3 (6.625) to 610 (24.000) = ±0.0075D OD ≥ 60.3 mm (2.375) to 610 mm (24.000) = ± 0.5 (0.020) or ±

"To be measured through out the body of the pipe" 0.0075D, whichever is the greater

Nominal OD ≤16” = ± 1.5% OD Out-of-roundness Tolerances- Pipe Except the End (Table 10) Out-of-roundness Tolerances-Pipe Except the End (Table J.3)

OOR at Pipe Body (OD) 07-02-21- Below note to be added in MR

"To be measured through out the body of the pipe" OD> 168.3 (6.625) to 610 (24.000) = 0.020D OD ≥ 60.3mm (2.375) to 610mm (24.000) = 0.015D for D/t ≤ 75

07-02-21- This toleance not mentioned in MR.

"As per Annexure J" to be added in MR (Need to re Diameter Tolerances -Pipe End (SMLS) (Table 10) Diameter Tolerances-Pipe End (SMLS) (Table J.3)

OD Tolerances at confirm)

Pipe Ends 07-02-21- Below to be added in MR. OD> 168.3 (6.625) to 610 (24.000) = ±0.005D, but maximum OD ≥ 60.3 mm (2.375) to 610 mm (24.000) = ± 0.5 (0.020) or ±

"OD Tolerances at Pipe Ends shall as per Annexure J" of ±1.6 (0.063) 0.005D, whichever is the greater, but max of ± 1.6 (0.063)

07-02-21- This toleance not mentioned in MR. Out-of-Roundness at the ends shall not exceed 1.0% of

" Nominal OD ≤16” = ± 0,75% OD " to be added in MR specified (nominal) O.D. For pipe with D/t < 75, the difference Out-of-roundness Tolerances-Pipe End (Table 10) Out-of-roundness Tolerances-Pipe End (Table J.3)

(Need to re confirm) between maximum diameter and minimum diameter shall

OOR at Pipe Ends (OD) OD ≥ 60.3 mm (2.375) to 610 mm (24.000) = 0.01D for D/t ≤ 75

meet the requirement of paragraph 9.11.3.1 [Table 10] of API OD> 168.3 (6.625) to 610 (24.000) = 0.015D

07-02-21- Below to be added in MR

" Nominal OD ≤16” = ± 0.75% OD " SPEC 5L subject to a maximum of 0.24 inch.

07-02-21- below SAMSS note to be added in MR

Pipe that is to be joined The difference in outside or inside diameter, at the ends,

using pipeline field "The difference in outside or inside diameter, at the between any two lengths of the same Line Item shall not

mechanized welding ends, between any two lengths of the same Line Item exceed 0.063 inch for 75% of the pipes produced.

systems: shall not exceed 0.063 inch for 75% of the pipes

produced"

You might also like

- E-Book SSC GS (Eng)Document291 pagesE-Book SSC GS (Eng)Shivam SwarnimNo ratings yet

- Design of Rectangular Reinforced Concrete BeamDocument13 pagesDesign of Rectangular Reinforced Concrete BeamChie SierraNo ratings yet

- Earthing System Design Tool For Low Voltage InstallationsDocument36 pagesEarthing System Design Tool For Low Voltage InstallationsLim BoraNo ratings yet

- Ansi FlangeDocument23 pagesAnsi FlangeVenkatesh GangadharNo ratings yet

- CW Pipe Thickness Calculation - 80% Vacuum - With RCCDocument39 pagesCW Pipe Thickness Calculation - 80% Vacuum - With RCCAshitava Sen0% (1)

- Astm B2Document4 pagesAstm B2Bryan Mesala Rhodas GarciaNo ratings yet

- Installation & Commissioning of 11 KV Cables - 400 KmsDocument8 pagesInstallation & Commissioning of 11 KV Cables - 400 KmsUsman ArifNo ratings yet

- My - Spreadsheet - SlabDocument26 pagesMy - Spreadsheet - SlabBilal Ahmed Barbhuiya50% (2)

- Eurocode: 1.0 Column DesignDocument5 pagesEurocode: 1.0 Column DesignsopnanairNo ratings yet

- STATCOMDocument17 pagesSTATCOMAbdel-Rahman Saifedin ArandasNo ratings yet

- Technical ClarificationDocument2 pagesTechnical Clarificationsudeep dsouzaNo ratings yet

- Deck Slab LSD (12.9m) - 14mDocument17 pagesDeck Slab LSD (12.9m) - 14mGaurav SinghNo ratings yet

- Science 8 1st Quarter Exam 2021-2022Document4 pagesScience 8 1st Quarter Exam 2021-2022JingjingAloComendador100% (3)

- Tubular TYK Fabrication and Inspection: It Is Important To Plan Ahead For These Complex WeldsDocument5 pagesTubular TYK Fabrication and Inspection: It Is Important To Plan Ahead For These Complex Weldsluz82No ratings yet

- Fabrication Tolerances 51G14r1Document7 pagesFabrication Tolerances 51G14r1Selvakpm06100% (1)

- AC Duct Design PDFDocument6 pagesAC Duct Design PDFkumar123rajuNo ratings yet

- Astm A1064Document10 pagesAstm A1064mikollimNo ratings yet

- 02 - Modul A+ Fizik Tg5Document36 pages02 - Modul A+ Fizik Tg5Bee Dz81% (16)

- PP3-PP9-PP10 Quality-Plan 10-10-2013 WP1.3 01 Version1 1Document73 pagesPP3-PP9-PP10 Quality-Plan 10-10-2013 WP1.3 01 Version1 1Roni EnjelaniNo ratings yet

- PP3-PP9-PP10 Quality-Plan 10-10-2013 WP1.3 01 Version1 1Document73 pagesPP3-PP9-PP10 Quality-Plan 10-10-2013 WP1.3 01 Version1 1Roni EnjelaniNo ratings yet

- Calculating Ground ResistanceDocument5 pagesCalculating Ground Resistancebouncerhawk67% (3)

- Tcst11105r0 - Limitation Tel CablesDocument10 pagesTcst11105r0 - Limitation Tel CablesengrandyNo ratings yet

- Dokumen - Tips - Simplified Reinforced Concrete Design 2010 NSCPDocument200 pagesDokumen - Tips - Simplified Reinforced Concrete Design 2010 NSCPmedel araoNo ratings yet

- Misalignment ToleranceDocument1 pageMisalignment TolerancemrmerajNo ratings yet

- Akatherm HDPE 4 Product RangeDocument2 pagesAkatherm HDPE 4 Product RangeMon BoualNo ratings yet

- Basic CalculationDocument2 pagesBasic CalculationArindam SamantaNo ratings yet

- Earthing System Design Tool For Low Voltage InstallationsDocument36 pagesEarthing System Design Tool For Low Voltage InstallationsSilvio MarianoNo ratings yet

- Technical Specification AL-59 Conductor 893Document18 pagesTechnical Specification AL-59 Conductor 893pramjitNo ratings yet

- B415Document4 pagesB415rohit kumarNo ratings yet

- Composite ConductorsDocument6 pagesComposite ConductorsAmresh KumarNo ratings yet

- Deflection RC BeamDocument13 pagesDeflection RC BeamhusnasyahidahNo ratings yet

- Gas Pipeline CalculationDocument17 pagesGas Pipeline CalculationsiavashNo ratings yet

- Soft or Annealed Copper Wire: Standard Specification ForDocument5 pagesSoft or Annealed Copper Wire: Standard Specification Fororlando acevedoNo ratings yet

- Seamless Precision Steel Tubes: 1 Scope and Field of ApplicationDocument6 pagesSeamless Precision Steel Tubes: 1 Scope and Field of ApplicationVignesh fireflyNo ratings yet

- 2023-06-01 Reinstatement Slope X1 at T07 SiteDocument29 pages2023-06-01 Reinstatement Slope X1 at T07 SiterihongkeeNo ratings yet

- Shall Conform To Those Specified inDocument1 pageShall Conform To Those Specified inAkshat JainNo ratings yet

- 1 ACSR380/50mm2 (NA)Document3 pages1 ACSR380/50mm2 (NA)bassamwael6689No ratings yet

- Design Calculation of Tower T1&T2&T3Document111 pagesDesign Calculation of Tower T1&T2&T3Allan MwesigwaNo ratings yet

- Ceil-Pll2-Com-0622 - A1-0149 - BSPL-1712-PLL2-CV-DWG-0009Document2 pagesCeil-Pll2-Com-0622 - A1-0149 - BSPL-1712-PLL2-CV-DWG-0009krishnaNo ratings yet

- 3 - AAAC-Tech. SpecDocument7 pages3 - AAAC-Tech. SpecSumit TyagiNo ratings yet

- Fixação JurisDocument6 pagesFixação JurisAna LuaNo ratings yet

- Eht Earthing ThesisDocument28 pagesEht Earthing ThesisAnonymous 2l8XJIVNo ratings yet

- General Abstract Estimate For Providing Augmentation To Pws Scheme at Degoan (V) of Armoor (M)Document6 pagesGeneral Abstract Estimate For Providing Augmentation To Pws Scheme at Degoan (V) of Armoor (M)dee balkondaNo ratings yet

- Detailed Composite Beam Design AISCDocument20 pagesDetailed Composite Beam Design AISCRaveendra Babu CherukuriNo ratings yet

- Acsr Panther Conductor 10 PDFDocument14 pagesAcsr Panther Conductor 10 PDFSenthil ThanappanNo ratings yet

- 2009-02-27 Full Specification For Anti-Bacteria 3-Layer Polymer PipeDocument14 pages2009-02-27 Full Specification For Anti-Bacteria 3-Layer Polymer Pipewong lingNo ratings yet

- RCD NSCP 1929 - 1950 by Laureen FloranteDocument14 pagesRCD NSCP 1929 - 1950 by Laureen FlorantesallyNo ratings yet

- Conduct Preliminary Layout Design of Earthing Electrode Configuration & Size & Earthing Conductor SizeDocument35 pagesConduct Preliminary Layout Design of Earthing Electrode Configuration & Size & Earthing Conductor SizeAshwin NarayanNo ratings yet

- HSDD AppxCDocument31 pagesHSDD AppxCSharifNo ratings yet

- Technical Specification For Acsr Conductors: WbsedclDocument9 pagesTechnical Specification For Acsr Conductors: Wbsedclraja kumarNo ratings yet

- Hard-Drawn Copper Wire: Standard Specification ForDocument5 pagesHard-Drawn Copper Wire: Standard Specification ForAhmed BilalNo ratings yet

- GL II-1-2 e Rule Change Notice Ur w13 2011-12 enDocument2 pagesGL II-1-2 e Rule Change Notice Ur w13 2011-12 entaddeoNo ratings yet

- B869-07 (2013) Standard Specification For Copper-Clad Steel Electrical Conductor For CATV Drop WireDocument3 pagesB869-07 (2013) Standard Specification For Copper-Clad Steel Electrical Conductor For CATV Drop WireislamakthamNo ratings yet

- CE Board Nov 2020 - Hydraulics - Set 12Document2 pagesCE Board Nov 2020 - Hydraulics - Set 12Justine Ejay MoscosaNo ratings yet

- TDS Jumbo Gabion P8+2.2 PVC - PubDocument2 pagesTDS Jumbo Gabion P8+2.2 PVC - PubszemianNo ratings yet

- Development of Conductors With Reduced Wind Drag and Wind Noise For Overhead Power Transmission LinesDocument6 pagesDevelopment of Conductors With Reduced Wind Drag and Wind Noise For Overhead Power Transmission LinesKy TaNo ratings yet

- HDD Calculation For Gas PipelineDocument3 pagesHDD Calculation For Gas Pipelinesamotavijaypal26No ratings yet

- Hard-Drawn Copper Wire: Standard Specification ForDocument5 pagesHard-Drawn Copper Wire: Standard Specification ForPetrotrim ServicesNo ratings yet

- Appendix E PDFDocument20 pagesAppendix E PDFIranthaMuthuNo ratings yet

- Development Length & Splices of ReinforcementDocument19 pagesDevelopment Length & Splices of ReinforcementAshraf ZayedNo ratings yet

- Karmasingh Phant Lift ISP BOQ PDFDocument4 pagesKarmasingh Phant Lift ISP BOQ PDFatit shresthaNo ratings yet

- Report For EarthingDocument6 pagesReport For EarthingRatheesh R NairNo ratings yet

- NBR-15417-2007 - Vasos de Pressão - Inspecao de Segurança em ServiçoDocument3 pagesNBR-15417-2007 - Vasos de Pressão - Inspecao de Segurança em ServiçoRodrigo PagnossinNo ratings yet

- Bronze Trolley Wire: Standard Specification ForDocument6 pagesBronze Trolley Wire: Standard Specification ForYayan RnsNo ratings yet

- P.S AssignDocument9 pagesP.S AssignYomifi AberaNo ratings yet

- Colreg ManagerialDocument4 pagesColreg ManagerialIonutGalaniNo ratings yet

- Aluminum Conductors Carbon Fiber Core Reinforced-LAPWINGDocument6 pagesAluminum Conductors Carbon Fiber Core Reinforced-LAPWINGgabriel yair sanchez henandezNo ratings yet

- List of Documents For Plates & TubularsDocument6 pagesList of Documents For Plates & Tubularssudeep dsouzaNo ratings yet

- NDT Technician ChecklistDocument1 pageNDT Technician Checklistsudeep dsouzaNo ratings yet

- Leave PlanDocument3 pagesLeave Plansudeep dsouzaNo ratings yet

- Leave PlanDocument3 pagesLeave Plansudeep dsouzaNo ratings yet

- Charpy Test - ShapesDocument1 pageCharpy Test - Shapessudeep dsouzaNo ratings yet

- Chemical Elements - DNVGL-B101 Vs EN 10025-2Document3 pagesChemical Elements - DNVGL-B101 Vs EN 10025-2Sudeep DsouzaNo ratings yet

- Charpy TestDocument1 pageCharpy Testsudeep dsouzaNo ratings yet

- Charpy TestDocument1 pageCharpy Testsudeep dsouzaNo ratings yet

- Chemical Elements - DNVGL-B101 Vs EN 10210-1Document3 pagesChemical Elements - DNVGL-B101 Vs EN 10210-1sudeep dsouzaNo ratings yet

- GAP Analysis DNVGL-B101 Vs EN 10025-4Document2 pagesGAP Analysis DNVGL-B101 Vs EN 10025-4sudeep dsouzaNo ratings yet

- GAP Analysis DNVGL-B101 Vs EN 10025-4Document2 pagesGAP Analysis DNVGL-B101 Vs EN 10025-4sudeep dsouzaNo ratings yet

- Pmi Cost For J-Tube Scope: Machine Type Item 100% 25% Per HeatDocument2 pagesPmi Cost For J-Tube Scope: Machine Type Item 100% 25% Per Heatsudeep dsouzaNo ratings yet

- Hardness SymbolsDocument3 pagesHardness Symbolssudeep dsouzaNo ratings yet

- Dimension Report - Mono Rail Beam PDFDocument2 pagesDimension Report - Mono Rail Beam PDFsudeep dsouzaNo ratings yet

- QC SlidesDocument1 pageQC Slidessudeep dsouzaNo ratings yet

- SF-467 13Document10 pagesSF-467 13sudeep dsouzaNo ratings yet

- Rolled - Clad - Plates Voestalpine PDFDocument26 pagesRolled - Clad - Plates Voestalpine PDFakhileshNo ratings yet

- Specification For Wrought Austenitic Stainless Steel Piping FittingsDocument11 pagesSpecification For Wrought Austenitic Stainless Steel Piping Fittingssudeep dsouzaNo ratings yet

- PS195 QLab 6Document6 pagesPS195 QLab 6John Vissel F. ParaisoNo ratings yet

- O22934v83 HAMM Compaction Meter en PDFDocument2 pagesO22934v83 HAMM Compaction Meter en PDFHewa PCNo ratings yet

- HydraulicsDocument234 pagesHydraulicsChristine CastroNo ratings yet

- Fluid Mechanics Lab Report Name Muhammad Fawad Naeem Roll NO. 2021-ME-527 Submit To Sir Shahid Department MechanicalDocument15 pagesFluid Mechanics Lab Report Name Muhammad Fawad Naeem Roll NO. 2021-ME-527 Submit To Sir Shahid Department Mechanicalfawad naeemNo ratings yet

- Biased Data: Student Worksheet: Three Dart Players Were Aiming For The TargetDocument3 pagesBiased Data: Student Worksheet: Three Dart Players Were Aiming For The TargetAlanahNo ratings yet

- Course No. 309 Experiment No.: 2 Name of The Experiment:: Determination of Absolute Capacitance of A CondenserDocument16 pagesCourse No. 309 Experiment No.: 2 Name of The Experiment:: Determination of Absolute Capacitance of A Condenserafm kollolNo ratings yet

- 1 Electric Charges and Fields: SolutionsDocument36 pages1 Electric Charges and Fields: SolutionsArdh0072100% (1)

- Summative Assessment: Using The Radar GunDocument3 pagesSummative Assessment: Using The Radar GunMark MwashaNo ratings yet

- Chapter 2. Limits, Tolerance and Fits - RevisedDocument44 pagesChapter 2. Limits, Tolerance and Fits - RevisedNguyễn Sĩ CườngNo ratings yet

- Spectrophotometric Determination of IronDocument12 pagesSpectrophotometric Determination of Ironnazrin shahNo ratings yet

- Hand Out Precision EnggDocument5 pagesHand Out Precision EnggkrishnanNo ratings yet

- Chapter 2Document50 pagesChapter 2Shalin IlyaniNo ratings yet

- Ac CircuitsDocument1 pageAc Circuitsjoevicpaster5No ratings yet

- Vernier CalipersDocument22 pagesVernier CalipersMohammad Rashik ZamanNo ratings yet

- SLP Konstanter 320W - Technical Data SheetDocument8 pagesSLP Konstanter 320W - Technical Data SheetMihai CherechesNo ratings yet

- WL-WC4400, WL4405 Basic MFMDocument6 pagesWL-WC4400, WL4405 Basic MFMRohit KumarNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityYankit VasavaNo ratings yet

- Gas Control Turbine Meters: Low Pressure DropDocument1 pageGas Control Turbine Meters: Low Pressure DropSinggih KurniawanNo ratings yet

- Cblephpl 03Document9 pagesCblephpl 03Akshpreet SinghNo ratings yet

- Electric Charges and Fields - Practice Sheet - VIJETA SERIES CLASS-12THDocument7 pagesElectric Charges and Fields - Practice Sheet - VIJETA SERIES CLASS-12THAshutosh SinghNo ratings yet

- Model Answer Winter 2014Document21 pagesModel Answer Winter 2014Prashant KasarNo ratings yet

- Omega HH509R Thermocouple Meter ManualDocument20 pagesOmega HH509R Thermocouple Meter Manualtestbase6yNo ratings yet

- 7601 ClassSheet TSD1Document13 pages7601 ClassSheet TSD1yamansinghrajput1234No ratings yet

- Noisefilter eDocument46 pagesNoisefilter eLam quocNo ratings yet

- DPP 01 Gravitation + Geometrical Optics + Electrostatics PhysicsDocument17 pagesDPP 01 Gravitation + Geometrical Optics + Electrostatics PhysicsAditya TripathyNo ratings yet