Professional Documents

Culture Documents

3d Systems Accura 25 Datasheet Usen 2018 07 11 Web - 0

Uploaded by

Pankaj ShahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3d Systems Accura 25 Datasheet Usen 2018 07 11 Web - 0

Uploaded by

Pankaj ShahCopyright:

Available Formats

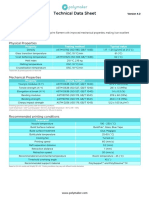

Accura® 25

PP Class

Flexible plastic to simulate and replace CNC-machined white polypropylene articles.

Post-Cured Material Features

MEASUREMENT CONDITION METRIC U.S. • Flexible

• Snap fit assemblies

Tensile Strength

(MPa | PSI) ASTM D 638 38 5540-5570 • Master patterns for vacuum casting

• Durable functional prototypes

Tensile Modulus

ASTM D 638 1590-1660 230-240

(MPa | KSI)

Elongation at Break (%) ASTM D 638 13-20 13-20

Flexural Strength

ASTM D 790 55-58 7960-8410

(MPa | PSI)

Flexural Modulus

ASTM D 790 1380-1660 200-240

(MPa | KSI)

Impact Strength

(J/m | Ft-lbs/in) ASTM D 256 19-24 0.4

Heat Deflection ASTM D 648

Temperature @ 66 PSI 58-63 °C 136-145 °F

@ 264 PSI 51-55 °C 124-131 °F

Coefficient of Thermal ASTM E 831-93

Expansion (CTE) TMA (T<Tg, 0-20 °C) 107 x 10¯6 59.4

TMA (T<Tg, 75-140 °C) 151 x 10¯6 83.9

Glass Transition (Tg) DMA, E” 72-74 162-165

Hardness, Shore D 80 80

Liquid Material

MEASUREMENT CONDITION VALUE

Viscosity @ 30 °C (86 °F) 250 cps www.3dsystems.com

Penetration Depth (Dp) 4.2 mils

Critical Exposure (Ec) 10.5 mJ/cm2

Color White Warranty/Disclaimer: The performance characteristics of these products may

vary according to product application, operating conditions, or with end use.

Solid Density @ 25 °C (77 °F) 1.19 g/cm3 at 25 °C 3D Systems makes no warranties of any type, express or implied, including, but

not limited to, the warranties of merchantability or fitness for a particular use.

Liquid Density @ 25 °C (77 °F) 1.13 g/cm3 at 25 °C

© 2017 by 3D Systems, Inc. All rights reserved. Specifications subject to change

without notice. 3D Systems and Accura are registered trademarks and the 3D

Systems logo is a trademark of 3D Systems, Inc.

07-18

You might also like

- Environmental Science in Building PDFDocument350 pagesEnvironmental Science in Building PDFmaxmanfren100% (4)

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Duraform Pa Plastic: General Properties FeaturesDocument2 pagesDuraform Pa Plastic: General Properties FeaturesMarouane MbarkiNo ratings yet

- PolyCast TDS V3Document2 pagesPolyCast TDS V3jerome.luganNo ratings yet

- 3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBDocument1 page3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBsdhgwdNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- Material Data Sheet: ABS+: Mechanical Properties Test Method High Grade-ABS Stratasys Abs M30Document1 pageMaterial Data Sheet: ABS+: Mechanical Properties Test Method High Grade-ABS Stratasys Abs M30Suryas SivaNo ratings yet

- Accura Clearvue US PDFDocument2 pagesAccura Clearvue US PDFqualityfreekNo ratings yet

- Onyx - MarkforgedDocument2 pagesOnyx - MarkforgedalkhalidibaiderNo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- Armadillo TDSDocument1 pageArmadillo TDSPIETRO DAVID DE LUCANo ratings yet

- PolyMax PLA TDS V4Document2 pagesPolyMax PLA TDS V4fNo ratings yet

- Sabic M80064SDocument2 pagesSabic M80064STungdinh NguyenNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- LS PEKK CF HT23 Material Datasheet 201705Document1 pageLS PEKK CF HT23 Material Datasheet 201705Angel LagrañaNo ratings yet

- Microstructure Evolution in Metal Forming Processes (2012)Document2 pagesMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNo ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- TECAPEEK Natural Polyetheretherketone 14Document2 pagesTECAPEEK Natural Polyetheretherketone 14kgrier8966No ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Polyester: Data SheetDocument1 pagePolyester: Data SheetñeNo ratings yet

- Polymax PC Tds v4Document2 pagesPolymax PC Tds v4Hector GarciaNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Rain Sheds Rightangle Boots Straight BootsDocument2 pagesRain Sheds Rightangle Boots Straight BootsEhab Abd-allaNo ratings yet

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Document2 pagesEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNo ratings yet

- HexTool M61 DataSheet GlobalDocument4 pagesHexTool M61 DataSheet GlobalMcFlyNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Golden Power ATF DEX III TDSDocument1 pageGolden Power ATF DEX III TDSsimon.clove034No ratings yet

- SPECSPEADM5370Document1 pageSPECSPEADM5370nicolas yoris marcoglieseNo ratings yet

- TECAPEEK Natural Polyetheretherketone 14Document2 pagesTECAPEEK Natural Polyetheretherketone 14e.montgomeryNo ratings yet

- PORON 4701-50 Firm - Supported MaterialsDocument2 pagesPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedNo ratings yet

- Sikadur®-42 MP Slow - PDSDocument7 pagesSikadur®-42 MP Slow - PDSkamran abbasiNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- ULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersDocument3 pagesULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersRui MatiasNo ratings yet

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 pageRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiNo ratings yet

- Polygomma EPDM Roofing Membrane CatalogueDocument4 pagesPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- SH8900-H (White) EngDocument4 pagesSH8900-H (White) EngKollinNo ratings yet

- Thermacool TC2007G Gap Filler TDS 1280Document2 pagesThermacool TC2007G Gap Filler TDS 1280xingdrewNo ratings yet

- Kopla Pa6 KNG1015Document3 pagesKopla Pa6 KNG1015agungNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- Sabic - Sabic® Hdpe CC453 PDFDocument4 pagesSabic - Sabic® Hdpe CC453 PDFquangga10091986No ratings yet

- Filament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinDocument4 pagesFilament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinRoberto Gonzalo PelazNo ratings yet

- Dimensional and Surface Texture Characterization in Fused Deposition Modelling (FDM) With ABS PlusDocument8 pagesDimensional and Surface Texture Characterization in Fused Deposition Modelling (FDM) With ABS PlusChris BurgerNo ratings yet

- Tritan TX1001Document2 pagesTritan TX1001qiongyao cuiNo ratings yet

- Somos DMX SL 100 Leaflet v2 PDFDocument2 pagesSomos DMX SL 100 Leaflet v2 PDFBenjamin NGNo ratings yet

- ABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Magnum 3416 SC: Product InformationDocument2 pagesMagnum 3416 SC: Product InformationDridi BadredineNo ratings yet

- DS-DuraForm Flex Plastic USDocument2 pagesDS-DuraForm Flex Plastic USBahadır UysalNo ratings yet

- Teslin: Quick OverviewDocument3 pagesTeslin: Quick OverviewDewiNo ratings yet

- Selective Laser SinteringDocument12 pagesSelective Laser SinteringMihai CitcauanNo ratings yet

- Adhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Document4 pagesAdhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Reza AbdolahiNo ratings yet

- Akulon F130-C1: Property DataDocument2 pagesAkulon F130-C1: Property DataJackNo ratings yet

- Technical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Document1 pageTechnical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Paulo RicardoNo ratings yet

- Sikadur®-42 MP Slow HC: Product Data SheetDocument4 pagesSikadur®-42 MP Slow HC: Product Data SheetCbeztNo ratings yet

- Poron 4701-30 Very SoftDocument2 pagesPoron 4701-30 Very SoftItzelMalagonVeraNo ratings yet

- Design and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesFrom EverandDesign and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Thermal Expansion of Polytetrafluoroethylene (Teflon)Document4 pagesThermal Expansion of Polytetrafluoroethylene (Teflon)Josafat Cruz-PrietoNo ratings yet

- Composite Layer TheoryDocument45 pagesComposite Layer Theorychiru the greatNo ratings yet

- Installation Guide For PVC PipeDocument43 pagesInstallation Guide For PVC Pipeb1gm3nNo ratings yet

- Chapterwise Super Thirty FinalDocument158 pagesChapterwise Super Thirty FinalAnil KumarNo ratings yet

- Catalog e PDFDocument253 pagesCatalog e PDFNguyễn Quí ThànhNo ratings yet

- Metal Matrix CompositesDocument29 pagesMetal Matrix CompositesBelinda Kely Chavez CruzNo ratings yet

- Mechanics of Materials Chap 2-II 2Document68 pagesMechanics of Materials Chap 2-II 2彭莉棋No ratings yet

- BestPracticesGuide EDocument108 pagesBestPracticesGuide EShandy PrimadaniNo ratings yet

- Expansion Loop DesignDocument11 pagesExpansion Loop DesignsabahiraqNo ratings yet

- Reducing The Cost To Process Molten AluminumDocument54 pagesReducing The Cost To Process Molten AluminumKen McgownNo ratings yet

- Lab Report 4Document3 pagesLab Report 4Rose Anne MalabananNo ratings yet

- 9 TemperatureDocument6 pages9 TemperatureMelania RJNo ratings yet

- Week 18 WW2 CompilationDocument52 pagesWeek 18 WW2 CompilationKenberly DingleNo ratings yet

- Lecture 5, Week 3 (Thermal Expansion)Document18 pagesLecture 5, Week 3 (Thermal Expansion)Umer MajeedNo ratings yet

- ACI 207.2 (R2002) EffectofRestraint VolumeChange &reinf Cracking MassConcreteDocument26 pagesACI 207.2 (R2002) EffectofRestraint VolumeChange &reinf Cracking MassConcretephilipyapNo ratings yet

- RT Duroid 6002 Laminate Data SheetDocument2 pagesRT Duroid 6002 Laminate Data SheetPratikNo ratings yet

- Polyisocyanurate vs. Cellular Glass in Low Temperature Mechanical InsulationDocument7 pagesPolyisocyanurate vs. Cellular Glass in Low Temperature Mechanical InsulationmacNo ratings yet

- Thermal Properties of MatterDocument18 pagesThermal Properties of MatterkunalsrichaitanyaNo ratings yet

- Tigris Gas Manual en FinalDocument14 pagesTigris Gas Manual en FinalLuis13956353No ratings yet

- B - Press Inox Technical BrochureDocument32 pagesB - Press Inox Technical BrochureAnonymous zyJRklNo ratings yet

- Heat & Thermodynamics (ADV)Document99 pagesHeat & Thermodynamics (ADV)xibojof446No ratings yet

- Gilsulate 500 XRManualDocument24 pagesGilsulate 500 XRManualadoptvnNo ratings yet

- Thermal Stress Composite Bars: Bibin ChidambaranathanDocument30 pagesThermal Stress Composite Bars: Bibin ChidambaranathanDr. BIBIN CHIDAMBARANATHAN100% (1)

- S355JRDocument2 pagesS355JRThanh NguyenNo ratings yet

- Mejia, John Christian G.: Questions: Answer The Following QuestionsDocument3 pagesMejia, John Christian G.: Questions: Answer The Following QuestionsJohn Christian MejiaNo ratings yet

- Chapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018Document40 pagesChapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018aomareltayebNo ratings yet

- Cálculo y Catálogo de Conexiones de PVC+GF+Document108 pagesCálculo y Catálogo de Conexiones de PVC+GF+Jesus ANo ratings yet

- D 3309 - 96a R02 RDMZMDKDocument11 pagesD 3309 - 96a R02 RDMZMDKHumberto GutierrezNo ratings yet

- Mathematical Approach For The Yarn Pressure in Bobbin Winding PDFDocument4 pagesMathematical Approach For The Yarn Pressure in Bobbin Winding PDFEduardoNo ratings yet