Professional Documents

Culture Documents

DS-DuraForm Flex Plastic US

Uploaded by

Bahadır UysalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DS-DuraForm Flex Plastic US

Uploaded by

Bahadır UysalCopyright:

Available Formats

PRELIMINARY

DuraForm ® Flex plastic

Flexible plastic material for use with all SLS® systems

An elastomeric plastic with outstanding rubber-

like performance characteristics used to produce

functional prototypes or end-use parts where

flexible characteristics is a key requirement.

Above: Radiator hose prototype withstands bending without permanent

damage or deformation (shown with neutral infiltrant).

Left: Primary infiltrant colors of red, yellow and blue can be mixed to

create custom colors (black infiltrant also available).

BENEFITS

Rubber-like flexibility and functionality

• Use in place of urethane, silicone, or rubber parts

Durability and stability

APPLICATIONS • Accomodates harsh environmental conditions such as heat and

• Functional rubber-like prototypes and parts chemicals

without tooling Superior surface finish and fine feature detail

• Gaskets, hoses, seals, and other rubber-like • Minimizes finishing and renders even fine details

parts • Builds thin 0.004 in (0.1 mm) layer thickness for improved

• Watertight parts surface finish*

• Athletic shoes and equipment Superior tear resistance compared to competitive materials

• Rapid pre-production testing and optimization • Resilient material withstands bends and deformation

• Demonstration models Wide processing latitude

• Excellent output yield

• Low-volume manufacturing

Fluid-tight, even under pressure

• Easy-to-apply infiltration fluid seals parts for functional

applications

Array of color options

• Simulate end-use coloration with colored infiltrants —

red, yellow, blue or black. Neutral infiltrant sealer also available.

• Easily mix custom colors

* See back side for details.

3D SYSTEMS CORPORATION TRANSFORM YOUR PRODUCTS

DuraForm Flex plastic

For use with all Sinterstation SLS systems

"DuraForm Flex is a significant leap forward in material development," said Fabio Ciciani, CEM's partner.

"With DuraForm Flex, producing flexible parts is simple -- there are no special requirements. The possibility

to infiltrate and color parts easily, make this material very interesting for our automotive, appliance and

shoe-sole markets."

— Fabio Ciciani, CEM

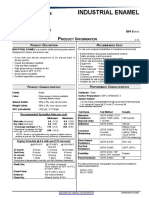

TECHNICAL DATA (PRELIMINARY)

Powder Properties

MEASUREMENT CONDITION VALUE:

Appearance visual opaque white

Density (tap) ASTM D4164 0.44 g/cm3

Particle Size Ave. d50 Laser Diffraction 85 µm

Particle Size Range 90% Laser Diffraction 21 - 138 µm

Melting Point: Tm DSC 192 °C (378 °F)

Sintered Properties

MEASUREMENT METHOD/CONDITION VALUE (AS PRODUCED) VALUE (INFILTRATED)

Tensile Strength ASTM D638 1.6 MPa (228 PSI) 20 MPa (293 PSI)

Tensile Modulus ASTM D638 6.4 MPa (926 PSI) 9.9 MPa (1440 PSI)

Elongation at Break (%) ASTM D638 104 % 117%

Flexural Modulus

at 23 °C (73 °F) ASTM D790 5.9 MPa (860 PSI) 9.4 MPa (1360 PSI)

Initial Tear Resistance

Die C at 23 °C (73 °F) ASTM D624 15.1 kN/m (86 lb/lin) 16.8 kN/m (96 lb/lin)

Abrasion Resistance (per 1000 cycles)

Taber, CS-17 wheel, 1 kg (2.2 lb) load ASTM D4060 83.5 mg

Bursting Strength (Straight) @23 °C 25 mm ID x 2 mm thick x 300 mm long hose 0 PSI 11 PSI (with Flex-Seal infiltration)

>30 PSI (with two-part polyurethane infiltration)

Shore A Hardness at 23 °C ASTM D2240 60 67

Chemical Resistance - Material doesn’t dissolve in hydrocarbons, ketones, ethers and alcohols. May swell in some solvents or solvent mixtures.

Detailed test conditions are available upon request. Performance characteristics may vary according to product application and/or operating conditions.

* Owners of Sinterstation 2000, 2500 and 2500ci SLS systems are limited to 0.005 in build layer thickness rather than the 0.004 in layer thickness used by Sinterstation 2500plus or later SLS systems.

3D Systems Corporation 661.295.5600, ext. 2882 moreinfo@3dsystems.com

26081 Avenue Hall Toll-free: 888.337.9786 www.3dsystems.com

Valencia, CA 91355 U.S.A. Fax: 661.294.8406 Nasdaq: TDSC

Warranty/Disclaimer: The performance characteristics of these products may vary according to product application, operating conditions, material combined with, or with end

use. 3D Systems makes no warranties of any type, express or implied, including, but not limited to, the warranties of merchantability or fitness for a particular use.

© 2005 by 3D Systems, Inc. All rights reserved. Specifications subject to change without notice. The 3D logo is a trademark, and DuraForm, SLS and Sinterstation are registered

trademarks of 3D Systems, Inc.

Transform Your Products

PN 70618 Issue Date - 25 Mar 05

You might also like

- Ficha Tecnica Um180821 Tds Tough Pla RB v11Document3 pagesFicha Tecnica Um180821 Tds Tough Pla RB v11Servirol CiaNo ratings yet

- Duraform Pa Plastic: General Properties FeaturesDocument2 pagesDuraform Pa Plastic: General Properties FeaturesMarouane MbarkiNo ratings yet

- ABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- 3D-Systems DuraForm HST DATASHEET 03.27.17 USEN WEB 0Document2 pages3D-Systems DuraForm HST DATASHEET 03.27.17 USEN WEB 0sdhgwdNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- ABS-M30: Real Production-Grade ThermoplasticDocument2 pagesABS-M30: Real Production-Grade ThermoplasticqualityfreekNo ratings yet

- Product PDF 244478Document3 pagesProduct PDF 244478lorejaz84071127No ratings yet

- FDM Nylon FamilyDocument6 pagesFDM Nylon FamilykaledioskoppNo ratings yet

- Microstructure Evolution in Metal Forming Processes (2012)Document2 pagesMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNo ratings yet

- Hoja Tecnica Material Pa 12 GBDocument2 pagesHoja Tecnica Material Pa 12 GBCarlosNo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- ULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersDocument3 pagesULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersRui MatiasNo ratings yet

- SikaWrap PS 103C PdsDocument4 pagesSikaWrap PS 103C PdsPedro OscarNo ratings yet

- 3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBDocument1 page3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBsdhgwdNo ratings yet

- Pmma Plexigals Hfi7-101Document4 pagesPmma Plexigals Hfi7-101countzeroaslNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- Lldpe - LL7410D PDSDocument1 pageLldpe - LL7410D PDSchinchotarngNo ratings yet

- Onyx - MarkforgedDocument2 pagesOnyx - MarkforgedalkhalidibaiderNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Polygomma EPDM Roofing Membrane CatalogueDocument4 pagesPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdNo ratings yet

- TDS - Acrylic V825 - From PolyOneDocument2 pagesTDS - Acrylic V825 - From PolyOneVio Amariei0% (1)

- Technical Data Sheet PLA: Filament Specifications Value MethodDocument5 pagesTechnical Data Sheet PLA: Filament Specifications Value MethodHany EdwardNo ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- TDS CPE V3.010-EnDocument3 pagesTDS CPE V3.010-EnspicefooNo ratings yet

- TDS Nylon v3.011-enDocument3 pagesTDS Nylon v3.011-enmartinf090574No ratings yet

- Sabic - Sabic® Hdpe CC453 PDFDocument4 pagesSabic - Sabic® Hdpe CC453 PDFquangga10091986No ratings yet

- TPU 95A Technical Data SheetDocument3 pagesTPU 95A Technical Data SheetSteven DonosoNo ratings yet

- 1120192 Technical Data SheetDocument1 page1120192 Technical Data SheetSilversnape00No ratings yet

- Dural Fast Epoxy Gel EuclidDocument3 pagesDural Fast Epoxy Gel Euclidpayaso1973No ratings yet

- Tds Infinam RG 7100 LDocument2 pagesTds Infinam RG 7100 LKacperNo ratings yet

- Sikaflex 252 TDSDocument3 pagesSikaflex 252 TDSxingobuilderNo ratings yet

- Ess-Tool: Composite Syntactic Tool BoardDocument6 pagesEss-Tool: Composite Syntactic Tool Boardray9699No ratings yet

- Ube Nylon 5034bDocument1 pageUbe Nylon 5034bDiegoTierradentroNo ratings yet

- Somos DMX SL 100 Leaflet v2 PDFDocument2 pagesSomos DMX SL 100 Leaflet v2 PDFBenjamin NGNo ratings yet

- Lustran® 433: INEOS StyrolutionDocument3 pagesLustran® 433: INEOS StyrolutionJames FaunceNo ratings yet

- 128en PDFDocument2 pages128en PDFspicajamesNo ratings yet

- 14IAF001A Spark Cooler Brochure WebDocument4 pages14IAF001A Spark Cooler Brochure Weberikmaxramos72No ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- Ficha Tecnica Cinta de Juntas 930 35 50 PDFDocument3 pagesFicha Tecnica Cinta de Juntas 930 35 50 PDFfernando100% (1)

- Ultimaker ABS (TDS)Document3 pagesUltimaker ABS (TDS)reinaldolubeNo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- Polygomma EPDM Pond Liner BrochureDocument4 pagesPolygomma EPDM Pond Liner Brochurepolygomma Industries Pvt. LtdNo ratings yet

- pds-cpd-SikaWrap Hex100G-us PDFDocument2 pagespds-cpd-SikaWrap Hex100G-us PDFjohanes b mudaNo ratings yet

- Pultruded Composites Material Property ComparisonDocument5 pagesPultruded Composites Material Property ComparisonJohn WycliffeNo ratings yet

- Conductive "MC" Nylon/ ESD "MC" Nylon: Nippon PolypencoDocument1 pageConductive "MC" Nylon/ ESD "MC" Nylon: Nippon PolypencoVC KannanNo ratings yet

- TDS Penguard WF Euk GBDocument5 pagesTDS Penguard WF Euk GBfranky leo fernandezNo ratings yet

- SF SeriesDocument1 pageSF SeriesDannys PradanaNo ratings yet

- DATA SHEET Industrial Enamel BlancoDocument4 pagesDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNo ratings yet

- LS PEKK CF HT23 Material Datasheet 201705Document1 pageLS PEKK CF HT23 Material Datasheet 201705Angel LagrañaNo ratings yet

- LS Nylon 11 DatasheetDocument1 pageLS Nylon 11 DatasheetkeeblerkhanNo ratings yet

- DPF 390 FlexDocument3 pagesDPF 390 FlexCESAR GUERRERONo ratings yet

- PDS - H2Ri - tcm29-17001 PDFDocument2 pagesPDS - H2Ri - tcm29-17001 PDFJean Paul Et La PetiteNo ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Tech Rep 4-2011 Copper Zirkonium AlloysDocument14 pagesTech Rep 4-2011 Copper Zirkonium AlloysBahadır UysalNo ratings yet

- Technical Rep El Conductivity of Metals, 2011-2Document11 pagesTechnical Rep El Conductivity of Metals, 2011-2Bahadır UysalNo ratings yet

- Some Aspects of Stress Peening of Coil Springs For Vehicle SuspensionsDocument8 pagesSome Aspects of Stress Peening of Coil Springs For Vehicle SuspensionsBahadır UysalNo ratings yet

- Cut Wire Shots 1949004 PDFDocument11 pagesCut Wire Shots 1949004 PDFBahadır UysalNo ratings yet

- TC227 Shot Peening WD26910-1 060901Document13 pagesTC227 Shot Peening WD26910-1 060901Bahadır Uysal100% (1)

- Galvanic SeriesDocument4 pagesGalvanic SeriesBahadır UysalNo ratings yet

- Ae0301 095 102Document8 pagesAe0301 095 102Eswara ReddyNo ratings yet

- Creo2 SheetmetalDocument77 pagesCreo2 SheetmetalBahadır UysalNo ratings yet

- Relax at High Temp Project 4Document4 pagesRelax at High Temp Project 4Bahadır UysalNo ratings yet

- Creo2 HW NotesDocument7 pagesCreo2 HW NotesBahadır UysalNo ratings yet

- PTC Creo - Analyzing 3D StructuresDocument20 pagesPTC Creo - Analyzing 3D StructuresTommaso LeatiNo ratings yet

- Volvo 850 Instrument Panel WiringDocument22 pagesVolvo 850 Instrument Panel Wiringfbr4No ratings yet

- Relax at High Temp Project 4Document4 pagesRelax at High Temp Project 4Bahadır UysalNo ratings yet

- Creo2 Top-Down OHDocument10 pagesCreo2 Top-Down OHBahadır UysalNo ratings yet

- Produktblad 2Document1 pageProduktblad 2Bahadır UysalNo ratings yet

- ML2202 - CAD-delen - UtvarderingDocument13 pagesML2202 - CAD-delen - UtvarderingBahadır UysalNo ratings yet

- Thermal-Mechanical Coupled Analysis of A Brake Disc RotorDocument7 pagesThermal-Mechanical Coupled Analysis of A Brake Disc RotortsegayNo ratings yet

- Zr-Cu Alloy Material Replaces Be-Cu AlloyDocument2 pagesZr-Cu Alloy Material Replaces Be-Cu AlloyBahadır UysalNo ratings yet

- Compression Spring (30x16x2)Document1 pageCompression Spring (30x16x2)Bahadır UysalNo ratings yet

- X Ray Residual Stress Maesurement 1969021Document3 pagesX Ray Residual Stress Maesurement 1969021Bahadır UysalNo ratings yet

- Creo Config OptionsDocument128 pagesCreo Config OptionsBahadır UysalNo ratings yet

- SW 2017 Keyboard ShortcutsDocument1 pageSW 2017 Keyboard ShortcutsBahadır UysalNo ratings yet

- Tolerances for Leaf SpringsDocument1 pageTolerances for Leaf SpringsBahadır UysalNo ratings yet

- Adapter PlateDocument1 pageAdapter PlateShubham GuptaNo ratings yet

- Knowledge Transfer Brass MaterialDocument1 pageKnowledge Transfer Brass MaterialBahadır UysalNo ratings yet

- Adapter PlateDocument1 pageAdapter PlateShubham GuptaNo ratings yet

- Adapter PlateDocument1 pageAdapter PlateShubham GuptaNo ratings yet

- Adapter PlateDocument1 pageAdapter PlateShubham GuptaNo ratings yet

- Webquest Lesson PlanDocument5 pagesWebquest Lesson Planapi-271682763No ratings yet

- ZW-5A series wheel loader delivers 10% fuel savings and enhanced controllabilityDocument9 pagesZW-5A series wheel loader delivers 10% fuel savings and enhanced controllabilityallnainggolanNo ratings yet

- SPT10000Document4 pagesSPT10000Ha QuyenNo ratings yet

- Project With Header Spring 2015 PDFDocument111 pagesProject With Header Spring 2015 PDFPavan Sandeep V VNo ratings yet

- Generic 6-Panel Brochure TemplateDocument4 pagesGeneric 6-Panel Brochure Templateapi-459387854No ratings yet

- Ways in Responding To An Unplanned Events or Condition in Accordance With Established ProceduresDocument8 pagesWays in Responding To An Unplanned Events or Condition in Accordance With Established Proceduresapi-196541959100% (1)

- SMC2012 CFPDocument1 pageSMC2012 CFP馮介川No ratings yet

- Chapter10 Test BankDocument8 pagesChapter10 Test Bankapi-250771617No ratings yet

- UmppDocument6 pagesUmppVIBHAVNo ratings yet

- TOFD - Study Material, Rev.1, 24.05.2019Document125 pagesTOFD - Study Material, Rev.1, 24.05.2019Agung Prastyo Wibowo100% (2)

- International Marketing StrategiesDocument37 pagesInternational Marketing StrategiesAkanksha SonkerNo ratings yet

- Caregiving For Grades 7 To 10Document26 pagesCaregiving For Grades 7 To 10Yeshua YeshaNo ratings yet

- Roadmap Slides For Powerpoint: This Is A Sample Text. Insert Your Desired Text HereDocument5 pagesRoadmap Slides For Powerpoint: This Is A Sample Text. Insert Your Desired Text HereSai ChaitanyaNo ratings yet

- Steps To Generate AWR Report: 1. Log in To DatabaseDocument8 pagesSteps To Generate AWR Report: 1. Log in To DatabaseAnonymous 8RhRm6Eo7hNo ratings yet

- NETS International Company ProfileDocument10 pagesNETS International Company ProfileHuma KhanNo ratings yet

- Denis Wick PDFDocument2 pagesDenis Wick PDFvicentikooNo ratings yet

- DatumDocument237 pagesDatumMohammad Budi RifaNo ratings yet

- Overview of IFIC Bank Limited's Products and ServicesDocument54 pagesOverview of IFIC Bank Limited's Products and ServicesTanvir Nayim0% (1)

- Insulation Thickness CalculationDocument2 pagesInsulation Thickness CalculationLepanto SakyodNo ratings yet

- Serpentine Pavilion Press PackDocument21 pagesSerpentine Pavilion Press PackAlvaro RosaDayerNo ratings yet

- Profibus - DP Master Simulator: ... The Measurable DifferenceDocument13 pagesProfibus - DP Master Simulator: ... The Measurable DifferencenarciscondomNo ratings yet

- DrillDocument18 pagesDrillvivekNo ratings yet

- Ccna NotesDocument127 pagesCcna NotesRajumallepoola93% (14)

- Extreme Weather Concreting and Chemical Admixtures in ConcreteDocument8 pagesExtreme Weather Concreting and Chemical Admixtures in ConcretetyashraniNo ratings yet

- Base OilsDocument2 pagesBase Oilsingbarragan87No ratings yet

- F-443 VENDOR HSEQ MS QUESTIONNAIRE Rev 4 PDFDocument4 pagesF-443 VENDOR HSEQ MS QUESTIONNAIRE Rev 4 PDFAhmed Imtiaz RaoNo ratings yet

- Common Records FieldsDocument50 pagesCommon Records FieldsPriyaNo ratings yet

- Vacuum Breadth First SearchDocument3 pagesVacuum Breadth First SearchNguyen HuyenNo ratings yet

- Birth Certificate AkanshDocument1 pageBirth Certificate AkanshSUDHANSU MOHARANANo ratings yet

- Ves Masina User ManualDocument16 pagesVes Masina User ManualL10Sh1No ratings yet