Professional Documents

Culture Documents

7721 - 920 Tee Mecánica

Uploaded by

miturraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7721 - 920 Tee Mecánica

Uploaded by

miturraCopyright:

Available Formats

7721

7721 F-01

MODEL 7721 MECHANICAL TEE,

FEMALE THREADED OUTLET

The Model 7721 Mechanical Tee when mounted on hole cut pipe provides

a fast and easy mid-pipe threaded branch outlet. By utilizing the Model

7721 you eliminate the need for welding or the use of multiple fittings. The

Mechanical Tee is comprised of upper and lower ductile iron housing

segments, a grade “E” EPDM rubber molded gasket and plated track bolts

and nuts. The Model 7721 Mechanical Tee is rated to 20 bar (300 psi)

working pressure. Mechanical tees are supplied with our standard painted

finishes, i.e. orange or RAL3000 red. Optional finishes such as hot dipped

zinc galvanized and custom epoxy coatings are also available.

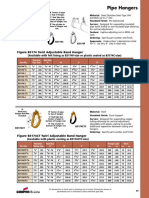

MODEL 7721 MECHANICAL TEE, FEMALE THREADED OUTLET

Model 7721 Mechanical Tee, Female Threaded Outlet

Nominal Size Hole Dia. Dimensions Bolt

Run x Branch +3.2, -0 / +0.13, -0 T* A B C D Size Weight

mm mm mm mm mm mm mm in Kgs

in in in in in in in Lbs

50 x 15 38 50 64 40 128 73 3/8 x 2-1/8 1.1

2 x 0.5 1.50 1.97 2.50 1.57 5.04 2.87 2.4

50 x 20 38 50 64 40 128 73 3/8 x 2-1/8 1.1

2 x 0.75 1.50 1.97 2.50 1.57 5.04 2.87 2.4

50 x 25 38 51 68 40 128 73 3/8 x 2-1/8 1.2

2x1 1.50 2.00 2.68 1.57 5.04 2.87 2.6

50 x 32 [45] 53 71 40 128 82 3/8 x 2-1/8 1.3

2 x 1.25 [1.75] 2.08 2.80 1.57 5.04 3.22 2.9

50 x 40 [45] 53 71 40 128 82 3/8 x 2-1/8 1.3

2 x 1.5 [1.75] 2.08 2.80 1.57 5.04 3.22 2.9

65 x 15 38 57 71 48 146 73 1/2 x 3 1.4

2.5 x 0.5 1.50 2.25 2.80 1.89 5.75 2.87 3.1

65 x 20 38 59 73 48 146 73 1/2 x 3 1.4

2.5 x 0.75 1.50 2.32 2.88 1.89 5.75 2.87 3.1

65 x 25 38 58 75 48 146 73 1/2 x 3 1.5

2.5 x 1 1.50 2.28 2.95 1.89 5.75 2.87 3.3

65 x 32 51 61 79 48 146 82 1/2 x 3 1.6

2.5 x 1.25 2.00 2.40 3.11 1.89 5.75 3.22 3.5

65 x 40 51 61 79 48 146 82 1/2 x 3 1.6

2.5 x 1.5 2.00 2.40 3.11 1.89 5.75 3.22 3.5

80 x 15 38 63 81 56 160 67 1/2 x 3 1.6

3 x 0.5 1.50 2.47 3.19 2.20 6.39 2.63 3.5

80 x 20 38 62 81 56 160 67 1/2 x 3 1.6

3 x 0.75 1.50 2.44 3.19 2.20 6.39 2.63 3.5

80 x 25 38 64 81 56 160 67 1/2 x 3 1.7

3x1 1.50 2.50 3.19 2.20 6.39 2.63 3.7

80 x 32 51 71 89 56 160 88 1/2 x 3 1.9

3 x 1.25 2.00 2.80 3.50 2.20 6.39 3.46 4.2

80 x 40 51 71 89 56 160 88 1/2 x 3 2.0

3 x 1.5 2.00 2.80 3.50 2.20 6.39 3.46 4.4

80 x 50 64 72 91 56 160 101 1/2 x 3 2.3

3x2 2.50 2.83 3.58 2.20 6.39 3.98 5.1

100 x 15 38 76 94 72 190 67 1/2 x 3 1.9

4 x 0.5 1.50 3.00 3.70 2.83 7.48 2.63 4.2

100 x 20 38 75 94 72 190 67 1/2 x 3 1.9

4 x 0.75 1.50 2.95 3.70 2.83 7.48 2.63 4.2

100 x 25 38 77 94 72 190 67 1/2 x 3 2.0

4x1 1.50 3.03 3.70 2.83 7.48 2.63 4.4

100 x 32 51 81 99 72 190 85 1/2 x 3 2.2

4 x 1.25 2.00 3.19 3.89 2.83 7.48 3.35 4.8

100 x 40 51 81 99 72 190 85 1/2 x 3 2.3

4 x 1.5 2.00 3.19 3.89 2.83 7.48 3.35 5.1

F-01-1 Rev. A 112305

7721

7721 F-01

Model 7721 Mechanical Tee, Female Threaded Outlet

Nominal Size Hole Dia. Dimensions Bolt

Run x Branch +3.2, -0 / +0.13, -0 T* A B C D Size Weight

mm mm mm mm mm mm mm in Kgs

in in in in in in in Lbs

100 x 50 64 86 105 72 190 101 1/2 x 3 2.7

4x2 2.50 3.38 4.13 2.83 7.48 3.98 5.9

100 x 65 70 82 111 72 190 112 1/2 x 3 3.3

4 x 2.5 2.75 3.23 4.37 2.83 7.48 4.40 7.3

100 x 80 89 82 112 72 190 136 5/8 x 3-1/2 5.6

4x3 3.50 3.23 4.40 2.83 7.48 5.35 12.3

125 x 50 64 105 124 86 236 102 5/8 x 3-1/2 4.2

5x2 2.50 4.13 4.88 3.39 9.29 4.00 9.2

125 x 65 70 99 127 86 236 118 5/8 x 3-1/2 4.5

5 x 2.5 2.75 3.89 5.00 3.39 9.29 4.65 9.9

150 x 32 51 109 127 98 256 93 5/8 x 5-5/16 4.4

6 x 1.25 2.00 4.29 5.00 3.86 10.07 3.66 9.7

150 x 40 51 109 127 98 256 93 5/8 x 5-5/16 4.4

6 x 1.5 2.00 4.29 5.00 3.86 10.07 3.66 9.7

150 x 50 64 113 132 98 256 101 5/8 x 5-5/16 4.8

6x2 2.50 4.45 5.29 3.86 10.07 3.98 10.6

150 x 65 70 111 140 98 256 118 5/8 x 5-5/16 5.4

6 x 2.5 2.75 4.37 5.50 3.86 10.07 4.65 11.9

150 x 80 89 110 140 98 256 137 5/8 x 5-5/16 6.0

6x3 3.50 4.33 5.50 3.86 10.07 5.39 13.2

150 x 100 114 107 140 98 256 164 3/4 x 4-3/4 6.6

6x4 4.50 4.21 5.50 3.86 10.07 6.46 14.5

200 x 50 [70] 135 166 120 327 101 3/4 x 4-3/4 6.2

8x2 [2.75] 5.31 6.54 4.72 12.87 3.98 13.6

200 x 65 70 137 166 120 327 104 3/4 x 4-3/4 6.3

8 x 2.5 2.75 5.39 6.54 4.72 12.87 4.09 13.9

200 x 80 89 136 166 120 327 128 3/4 x 4-3/4 7.1

8x3 3.50 5.35 6.54 4.72 12.87 5.04 15.6

200 x 100 114 133 166 120 327 164 3/4 x 4-3/4 8.0

8x4 4.50 5.24 6.54 4.72 12.87 6.46 17.6

Hole diameters listed are suggested hole diameters. T*: Take-Out (Center of run to end of pipe to be engaged.)

Special caution is required to some exceptional hole sizes shown in [ ].

MODEL 7721 – MATERIAL SPECIFICATIONS

• Housing:

Ductile Iron to ASTM A536, Gr. 65-45-12, Min. tensile strength Grade “T” Nitrile (Color code: Orange stripe) (Option)

448 MPa (65,000 psi). Recommended for petroleum products, vegetable oils,

mineral oils and air with oil vapors. Temperature range:

-29 oC to +82 oC (-20 oF to +180 oF). Also good for water

• Surface Finish: services under +66 oC (+150 oF).

Orange color painted or red RAL3000 color painted. Do not use for HOT WATER above +66 oC (+150 oF) or

Hot dip galvanized (Option). HOT DRY AIR above +60 oC (+140 oF)

Epoxy coated in red RAL3000 or other colors (Option)

Other options: Grade “O” Fluoro-Elastomer, Grade “L”

Silicone.

• Rubber Gasket:

Grade E EPDM (Color code: Green stripe) Recommended for

cold and hot water within the specified temperature range, dilute • Bolts & Nuts:

acids, alkalis, salts, oil-free air and many chemical services not Heat treated carbon manganese steel track bolts to ASTM

involving hydrocarbons, oils or gases. A449-83a (or A183 Gr. 2), minimum tensile strength 758 MPa

Do not use for HYDROCARBONS and PETROLEUM service. (110,000psi), Zinc electroplated, with heavy-duty hexagonal nuts to

Temperature range: -34 oC to +110 oC (-30 oF to +230 oF). For water ASTM A563.

services of constant high temperature higher than +85 oC (+150 oF),

however, please contact Shurjoint for recommendation.

General Notes:

z Pressure ratings listed are CWP (cold water pressure) or maximum working pressure within the service temperature range of the gasket

used in the coupling. This rating may occasionally differ from maximum working pressures listed and/or approved by UL, ULC, and/or FM

as testing conditions and test pipes differ. For additional information contact Shurjoint..

z Maximum working pressures and end loads listed are total of internal and external pressures and loads based on Sch. 40 steel pipe with

roll grooves to ANSI/AWWA C606-97 specifications. For information on other pipe schedules contact Shurjoint..

z For one time field test only the maximum joint working pressure may be increased 1-1/2 times the figures shown.

z Warning: Piping systems must always be depressurized and drained before attempting disassembly and or removal of any components.

z Shurjoint reserves the right to change specifications, designs and or standard equipment without notice and without incurring any

obligations.

F-01-2 Rev. A 112305

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- How To Make Black PowderDocument7 pagesHow To Make Black PowderMax100% (7)

- Engineer's Guide To Level Measurement For Power and Steam MeasurementDocument262 pagesEngineer's Guide To Level Measurement For Power and Steam Measurementvlcmstne04100% (1)

- Welding Processes ModuleDocument27 pagesWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- Cambridge Primary Science 2 Learner 39 S Book PDFDocument80 pagesCambridge Primary Science 2 Learner 39 S Book PDFpablo100% (4)

- 0100 1042 PDFDocument112 pages0100 1042 PDFmiturraNo ratings yet

- MODEL 5128/29: Installation ManualDocument38 pagesMODEL 5128/29: Installation Manualmiturra100% (1)

- Group 4 - Lab Assignment Size Exclusion ChromatographyDocument14 pagesGroup 4 - Lab Assignment Size Exclusion ChromatographyHasni Abdul RahimNo ratings yet

- Engineer Guide Tank Gauging PDFDocument104 pagesEngineer Guide Tank Gauging PDFnknicoNo ratings yet

- Pipe Hangers: Figure B3174 Twirl Adjustable Band HangerDocument7 pagesPipe Hangers: Figure B3174 Twirl Adjustable Band HangermiturraNo ratings yet

- vlf250 Upgrade Tech Tip11115Document6 pagesvlf250 Upgrade Tech Tip11115jairofgfNo ratings yet

- Transmisor de Nivel Tipo Radar EmersonDocument192 pagesTransmisor de Nivel Tipo Radar EmersonVRIMSANo ratings yet

- vlf250 Upgrade Tech Tip11115Document6 pagesvlf250 Upgrade Tech Tip11115jairofgfNo ratings yet

- 5128spec PDFDocument2 pages5128spec PDFmiturraNo ratings yet

- A05 0177 PDFDocument2 pagesA05 0177 PDFArgile-assholeNo ratings yet

- Scientemp - MODEL AD-2000 Automatic Voice/Pager Dialer System With Verification Manual, BrochureDocument18 pagesScientemp - MODEL AD-2000 Automatic Voice/Pager Dialer System With Verification Manual, BrochurescientempNo ratings yet

- Alarm Pressure Switch PDFDocument2 pagesAlarm Pressure Switch PDFmiturraNo ratings yet

- Troubleshooting: Accu-Zone Troubleshooting (Mode 25)Document3 pagesTroubleshooting: Accu-Zone Troubleshooting (Mode 25)miturraNo ratings yet

- My FM Globel SprinklerDocument119 pagesMy FM Globel SprinklerVaibhav SharmaNo ratings yet

- Soporte Antisísmico Fig1CBSDocument1 pageSoporte Antisísmico Fig1CBSmiturraNo ratings yet

- Alarm Pressure Switch PDFDocument2 pagesAlarm Pressure Switch PDFmiturraNo ratings yet

- A05 0177 PDFDocument2 pagesA05 0177 PDFArgile-assholeNo ratings yet

- 2 Conductor 16 AWG Fire Alarm CableDocument1 page2 Conductor 16 AWG Fire Alarm CablemiturraNo ratings yet

- Commercial Fireequipment: Silent KnightDocument2 pagesCommercial Fireequipment: Silent KnightmiturraNo ratings yet

- 2 Conductor 16 AWG Fire Alarm CableDocument1 page2 Conductor 16 AWG Fire Alarm CablemiturraNo ratings yet

- Scientemp - MODEL AD-2000 Automatic Voice/Pager Dialer System With Verification Manual, BrochureDocument18 pagesScientemp - MODEL AD-2000 Automatic Voice/Pager Dialer System With Verification Manual, BrochurescientempNo ratings yet

- RPT E3Document1 pageRPT E3miturraNo ratings yet

- 7771 - 07Document2 pages7771 - 07miturraNo ratings yet

- 7721 - 920 Tee MecánicaDocument2 pages7721 - 920 Tee MecánicamiturraNo ratings yet

- Grooved Fittings GuideDocument2 pagesGrooved Fittings GuidemiturraNo ratings yet

- Model 723 "Saddle-Let" Small Mechanical TeeDocument2 pagesModel 723 "Saddle-Let" Small Mechanical TeemiturraNo ratings yet

- Technical Data: 2-1/2" & 3" (Dn65 & Dn80) Model F Deluge Valve Vertical Conventional Trim ChartDocument4 pagesTechnical Data: 2-1/2" & 3" (Dn65 & Dn80) Model F Deluge Valve Vertical Conventional Trim ChartmiturraNo ratings yet

- 7771 - 07Document2 pages7771 - 07miturraNo ratings yet

- Grooved Fittings GuideDocument2 pagesGrooved Fittings GuidemiturraNo ratings yet

- Biomedicine & Pharmacotherapy: Osasenaga Macdonald Ighodaro TDocument7 pagesBiomedicine & Pharmacotherapy: Osasenaga Macdonald Ighodaro TMohammed RickyNo ratings yet

- Module 8 RationaleDocument3 pagesModule 8 RationaleG INo ratings yet

- Question Bank Nitric Acid and NitratesDocument19 pagesQuestion Bank Nitric Acid and NitratesGanesh sargarNo ratings yet

- Mil PRF 46194aDocument10 pagesMil PRF 46194aliuyx866No ratings yet

- Full Download Biology A Guide To The Natural World 5th Edition Krogh Test BankDocument35 pagesFull Download Biology A Guide To The Natural World 5th Edition Krogh Test Bankgaryramella1375100% (18)

- Carbonyl Compounds 1654147338445Document33 pagesCarbonyl Compounds 1654147338445Harsh VardhanNo ratings yet

- Slot 1 - Chapter 2-5 (Edit)Document51 pagesSlot 1 - Chapter 2-5 (Edit)Rabbi 08No ratings yet

- Additivity of Heats of Reaction: Hess's LawDocument5 pagesAdditivity of Heats of Reaction: Hess's Lawnipuna920% (1)

- Bending ProtocolDocument9 pagesBending ProtocolvikramchowdaryNo ratings yet

- New Release Agent Free From Wax and Siloxane: Wax-Free Water Dispersion With Water-Repellent EffectDocument1 pageNew Release Agent Free From Wax and Siloxane: Wax-Free Water Dispersion With Water-Repellent EffectFadhli KusumaNo ratings yet

- Water-in-Oil-in Water (W/O/W) Double Emulsion Formulations Using Variation Concentration of Carboxymethyl Cellulose SodiumDocument10 pagesWater-in-Oil-in Water (W/O/W) Double Emulsion Formulations Using Variation Concentration of Carboxymethyl Cellulose SodiumRinaldi Dwi CahyoNo ratings yet

- PML and RNF4 Remove Misfolded Proteins in Mammalian CellsDocument16 pagesPML and RNF4 Remove Misfolded Proteins in Mammalian CellsAndonis AngelovNo ratings yet

- A7793a A7797aDocument1 pageA7793a A7797aCarlos Rafael Rondon AbreuNo ratings yet

- Beckosol 12-035 Short Oil Non-Drying Alkyd: Product Code: 12035-00Document2 pagesBeckosol 12-035 Short Oil Non-Drying Alkyd: Product Code: 12035-00Manoj Lalita GoswamiNo ratings yet

- CoolMaster - Installation Manual 3.9.8Document38 pagesCoolMaster - Installation Manual 3.9.8alejandro pimientaNo ratings yet

- CH CH 1 PDFDocument36 pagesCH CH 1 PDFZahra HassanNo ratings yet

- National Standard of The People's Republic of China PDFDocument16 pagesNational Standard of The People's Republic of China PDFJCuchapin100% (1)

- 1 Digit Numeric Displays: DimensionDocument1 page1 Digit Numeric Displays: DimensionhenriquezrsNo ratings yet

- FIITJEE ALL INDIA TEST SERIES CONCEPT RECAPITULATION TEST – III JEE (Advanced)-2019 PAPER – 2 ANSWERS, HINTS & SOLUTIONSDocument15 pagesFIITJEE ALL INDIA TEST SERIES CONCEPT RECAPITULATION TEST – III JEE (Advanced)-2019 PAPER – 2 ANSWERS, HINTS & SOLUTIONSAtulNo ratings yet

- Ieep 104Document7 pagesIeep 104Praveen KumarpillaiNo ratings yet

- Seminar On Gypsum ProductsDocument17 pagesSeminar On Gypsum ProductsHarish Khundrakpam0% (1)

- SANDVIK 23.12.2.LR Covered Electrodes: DatasheetDocument3 pagesSANDVIK 23.12.2.LR Covered Electrodes: DatasheetFilipe CordeiroNo ratings yet

- Rising Damp - FactsheetDocument2 pagesRising Damp - FactsheetAdam ClutterbuckNo ratings yet

- 7697A AdvOperationDocument92 pages7697A AdvOperationEdgar Ordoñez OrjuelaNo ratings yet

- An Advanced Laboratory Manual of Organic Chemistry 1923 - Heidelberger PDFDocument103 pagesAn Advanced Laboratory Manual of Organic Chemistry 1923 - Heidelberger PDFRodrigo Negrelli GuzzoNo ratings yet

- Catalytic Application of NanomaterialsDocument23 pagesCatalytic Application of NanomaterialsViji VijithaNo ratings yet