Professional Documents

Culture Documents

Handout Us PDF

Uploaded by

pngchanhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Handout Us PDF

Uploaded by

pngchanhCopyright:

Available Formats

Why Use Solid State Switching Technology?

DEC Long Life Solid state relays and contactors have no moving parts.

Therefore, there is no mechanical wear and tear on the output contacts.

The typical life expectancy of a solid state relay may be more than 50 times

that of an electromechanical relay. Ideal for repetitive applications.

What is a Solid State

Quiet Operation Solid state switching solutions make no Relay / Contactor?

acoustical noise when the output contacts change states. This is highly

desirable in many commercial and medical applications.

Minimum Electrical Noise Zero voltage turn-on and zero

current turn-off allows for minimum electrical disturbances generated by

SSRs.

Low Power Consumption Solid state relays and contactors

require very little input power "coil current" to switch large loads. Crydom

solid state relays can switch up to 150 A load current with less than 15 mA

current draw from the control input.

Shock & Vibration Resistant Solid state switching solutions

are not susceptible to erratic or unreliable operation when operating under

tough environments. A Solid State Relay or Contactor (SSR or SSC)

is an electronic component that switches

Ideal for Harsh Environments SSRs & SSCs do not Power (AC or DC current) to a load circuit and

generate sparks or electric arcs, do not bounce either electrically or provides electrical isolation between an

mechanically. Designed as pollution degree 2 devices per IEC 60664-1. application's control circuit and load circuit. It is

Isolation levels up to 4k V. Magnetic fields have little effect on SSR. a competitive technology to Electromechanical

Relays (EMRs) and other switching technologies

High Compatibility with Control Systems DC such as Mercury Displacement Relays (MDRs).

controlled SSRs can be switched ON and OFF by digital systems such as

PLC and µC based systems. AC controlled SSRs can be driven by limit

switches, thermal switches and sensors carrying AC control signals.

ol

Contr

0

Fast Switching Random turn-on solid state relays and contactors

Triircui

C

gg t

er

respond to a control signal in less than 100 µs. Phase control and Burst

control can be easily achieved to provide accurate AC power control.

Position Insensitive Suitable for mounting in either vertical or

horizontal position, "dead bug" position and adjacent mounting.

AMERICA EMEA ASIA PACIFIC

Sales Support Sales Support Sales Support

Tel.: +1 (877) 502 5500 Tel.: +44 (0) 1202 606030 Tel.: +86 (0) 21 6065 7725

sales@crydom.com sales-europe@crydom.com sales-cn@crydom.com

Technical Support Tech Support Tech Support

Tel.: +1 (877) 702 7700 support-europe@crydom.com support-cn@crydom.com

support@crydom.com

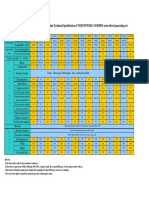

Ratings by Type of Package *

* Crydom's maximum ratings

Solid State Relay & Contactor Applications

Although there are literally thousands of individual uses for Solid State Relays and Contactors, most can be categorized into the

following applications:

Heating Control

This encompasses the largest segment of solid state relay users. Applications include, but are not limited

to: professional food equipment, plastic molding/extrusion machinery, HVAC&R and soldering

equipment.

Benefits: Long life, no maintenance, safe product, easy to interface, as well as enabling temperature

accuracy. Suitable for heater, fan, blower and valve control.

Lighting Control

These applications are usually broken down into three categories: theatrical, warehouse and commercial.

Many of the products used in this segment are custom designed.

Benefits: Dimming, silent operation, fast switching, long life, no maintenance, safe product, easy to

interface, reduced parts count.

Motion Control

Includes elevators, lifts, hoists, exercise equipment, conveyor systems, solar trackers, fans, solenoid and

valve control.

Benefits: Endurance, shock & vibration resistance, Soft Start, reversing, no arcing, fast switching, long

life, no maintenance, easy to interface, reduced parts count.

HO/CR/RC/EN/US

Rev.110311

www.crydom.com

You might also like

- News and Media VGM 1 2016 SalesDocument52 pagesNews and Media VGM 1 2016 SalespngchanhNo ratings yet

- Ut Ma6mk1Document2 pagesUt Ma6mk1pngchanhNo ratings yet

- E17047 TUF GAMING Z490-PLUS WI-FI UM v3 WEBDocument68 pagesE17047 TUF GAMING Z490-PLUS WI-FI UM v3 WEBpngchanhNo ratings yet

- Anti-Splash Tape: To Purchase Call - 732-247-2300Document2 pagesAnti-Splash Tape: To Purchase Call - 732-247-2300pngchanhNo ratings yet

- Volvo Standard Time Guide (VSTG), Foreword and Introduction: Volvo Car Corporation / Dealership DevelopmentDocument27 pagesVolvo Standard Time Guide (VSTG), Foreword and Introduction: Volvo Car Corporation / Dealership DevelopmentpngchanhNo ratings yet

- Horizon 200Document140 pagesHorizon 200pngchanhNo ratings yet

- 278 VistaDocument259 pages278 VistapngchanhNo ratings yet

- Daily Daily: Cyber SecurityDocument24 pagesDaily Daily: Cyber SecuritypngchanhNo ratings yet

- Ga-X150M-Plus WS: User's ManualDocument40 pagesGa-X150M-Plus WS: User's ManualpngchanhNo ratings yet

- High Pressure Control Valve: Model 4418FDocument7 pagesHigh Pressure Control Valve: Model 4418FpngchanhNo ratings yet

- Price List 2009: Genset Range - Indiviual ApplicationsDocument23 pagesPrice List 2009: Genset Range - Indiviual ApplicationspngchanhNo ratings yet

- WT Micro Temperature Controller CatalogueDocument7 pagesWT Micro Temperature Controller CataloguepngchanhNo ratings yet

- 05V H ValvesDocument9 pages05V H ValvespngchanhNo ratings yet

- Pumps Aeration Steering Controls.122212108 PDFDocument149 pagesPumps Aeration Steering Controls.122212108 PDFpngchanhNo ratings yet

- WT Operation ManualDocument51 pagesWT Operation ManualpngchanhNo ratings yet

- Pumps Aeration Steering Controls.122212108 PDFDocument149 pagesPumps Aeration Steering Controls.122212108 PDFpngchanhNo ratings yet

- Catalogo Lombardini EngDocument20 pagesCatalogo Lombardini EngpngchanhNo ratings yet

- Trillion Gasifier 0710Document1 pageTrillion Gasifier 0710pngchanhNo ratings yet

- Bega ENGELS 2019 07Document156 pagesBega ENGELS 2019 07pngchanhNo ratings yet

- Powertech ™ 6135Sfm85 Diesel Engine: Marine Propulsion Engine SpecificationsDocument2 pagesPowertech ™ 6135Sfm85 Diesel Engine: Marine Propulsion Engine SpecificationspngchanhNo ratings yet

- Parker Fluid Power Seals Catálogo EN1016PPDocument101 pagesParker Fluid Power Seals Catálogo EN1016PPpngchanhNo ratings yet

- VPC Chongqing CumminsDocument1 pageVPC Chongqing CumminspngchanhNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- INVENTARISDocument4 pagesINVENTARISMora SyahroniNo ratings yet

- EDC - Lecture PlanDocument4 pagesEDC - Lecture PlanMahendra BabuNo ratings yet

- LP Series: Service ManualDocument38 pagesLP Series: Service ManualPedro GuilarteNo ratings yet

- En SensorsDocument16 pagesEn SensorsBojan BjelajacNo ratings yet

- Cat Ic-10-Ch04 2017 enDocument84 pagesCat Ic-10-Ch04 2017 enDebye101No ratings yet

- LPBP HPSU Document PDFDocument131 pagesLPBP HPSU Document PDFGanga PrasadNo ratings yet

- HL7807ADocument6 pagesHL7807AluismdmjNo ratings yet

- What Is A Fluid Coupling PDFDocument3 pagesWhat Is A Fluid Coupling PDFYogesh TheCyaNo ratings yet

- Spare Parts HCS5515Document61 pagesSpare Parts HCS5515SergeyNo ratings yet

- Flash Memory: Secure Your BusinessDocument3 pagesFlash Memory: Secure Your BusinessNaod ZerihunNo ratings yet

- stm32f103c8 956229 PDFDocument118 pagesstm32f103c8 956229 PDFMuhammad Sultan NaufalNo ratings yet

- Resume Kondisi Dan Problem Unit PT HIP List Write OffDocument134 pagesResume Kondisi Dan Problem Unit PT HIP List Write OfffajardiniantNo ratings yet

- CSS SopecificationDocument11 pagesCSS SopecificationBiswajit GuriaNo ratings yet

- Transformer Bushings PDFDocument28 pagesTransformer Bushings PDFSaravananSelvarajNo ratings yet

- 091-0226A MK2000A PowerSupplyDocument29 pages091-0226A MK2000A PowerSupplySneyder YepesNo ratings yet

- 32MD359B F7Document206 pages32MD359B F7pepperrooNo ratings yet

- Product Name Product Name: - Safer by Design - Safer by Design - Safer by DesignDocument8 pagesProduct Name Product Name: - Safer by Design - Safer by Design - Safer by DesignPriesilia PresleyNo ratings yet

- Second Quarter: Week 8Document31 pagesSecond Quarter: Week 8Mary Grace Lamarroza RosagaranNo ratings yet

- New Holland Cx7080 - Cx7090 - Cx8070 - Cx8080 - Cx8090 Elevation Cr8070 Cr8080 Cr9070 Cr9080 Cr9090 Combine SMDocument31 pagesNew Holland Cx7080 - Cx7090 - Cx8070 - Cx8080 - Cx8090 Elevation Cr8070 Cr8080 Cr9070 Cr9080 Cr9090 Combine SMggjjjjotones100% (1)

- .Auwp Contentuploads2022030525 055 Install Guide Commercial Package Ver. 9 PDFDocument56 pages.Auwp Contentuploads2022030525 055 Install Guide Commercial Package Ver. 9 PDF7tddprzxbbNo ratings yet

- Hotel Office: XX XXDocument1 pageHotel Office: XX XXthamizharasan11No ratings yet

- 20HP Riding MowerDocument60 pages20HP Riding MowerSTPNo ratings yet

- Testing & Adjusting Cat - Dcs.sis - Controller PDFDocument179 pagesTesting & Adjusting Cat - Dcs.sis - Controller PDFmnlar100% (7)

- Powershift TransmissionsDocument27 pagesPowershift TransmissionsJonathanDavidDeLosSantosAdornoNo ratings yet

- 5iseries Product ManualDocument76 pages5iseries Product ManualSithu Zaw100% (1)

- Open429I C UserManualDocument30 pagesOpen429I C UserManualivanlbragaNo ratings yet

- ECE5545 Lecture0 Spring24 2Document38 pagesECE5545 Lecture0 Spring24 2eshwar_worldNo ratings yet

- ITW GSE AXA 3400 PCA Brochure UK 130 210 2016Document4 pagesITW GSE AXA 3400 PCA Brochure UK 130 210 2016loadrpkNo ratings yet

- Maxi Driver ManualDocument50 pagesMaxi Driver Manualpp3665No ratings yet

- APC Smart-UPS SRT 5000VA RM 230V: Technical SpecificationsDocument3 pagesAPC Smart-UPS SRT 5000VA RM 230V: Technical SpecificationsVicthor CondorNo ratings yet