Professional Documents

Culture Documents

82 Uses For 9901 Almasol Syntemp Grease

Uploaded by

Deltalube TangerangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

82 Uses For 9901 Almasol Syntemp Grease

Uploaded by

Deltalube TangerangCopyright:

Available Formats

TeCHNI/TIPS

A Publicat:ion of t:he Lubricat:ion Engineers Technical Depart:ment:

LEADERS IN LUBRICANTS g 1-. NUMBER 1

USES FOR 9901 ALMASOL SYNTEMP LUBRICANT

9901 ALMASOL SYNTEMP Lubricant, a synthetic lubricant specifically designed for high

temperature application is one of LE'S most unique specialty lubricants. While the ap

plications for which it should be used may be more limited than some of the LE brand

multi-ftmctionallubricants, its use for those special applications generally means the

difference between operating without difficulity and not operating at all.

9901 ALMASOL SYNTEMP is a heavy molecular weight synthetic fluid, compounded with

other synthesized additives and an inorganic base component. All of which give it its ''no

drop" characteristic, which is essential for most high temperature applications. Because

9901 ALMASOL SYNTEMP is produced chemically, it gives exceptional protection at tem

peratures at which a petroleum oil lubricant or a petroleum derived grease would oxidize

or carbonize. This extremely tacky lubricant will not sling off or melt off in service in

such applications as large, high speed open gears exposed to very high temperature en

vironments. It will not melt and run off of cams, slides, or similar hot running applications.

9901 ALMASOL SYNTEMP gives exceptional service when used in such heavily-loaded bearings

as kiln car wheels, operating in very high temperature environments. It carriers a mjnimum

Timken OK load of 45 pounds. In kilns, driers, and other temperature environments, 9901

ALMASOL SYNTEMP will dissipate slowly, produce no noxious or harmful vapors, and leave

no harmful deposits. No residue remains when the fluid vaporizes (or volatilizes) in service,

since the vapors are soluble with the material. This allows the product to remain "plastic"

in work, protecting the application against wear while it ensures constant lubrication and

protection against metal-to-metal contact. Because of the consistency of 9901 ALMASOL

SYNTEMP, it is not normally recommended for use in fas~moving, anti-friction bearings

which generally are lightly loaded.

The principal applications for 9901 ALMASOL SYNTEMP include:

(1) the girth gearing on large driers or mills

(2) the expansion tires or carriers which on the trunnions supporting the equipment

(3) kiln car wheels

(4) high temperature oven chains and sliding surfaces

(5) large slow moving friction and/or roller bearings in heavily loaded applications

(6) open gears and pinions In high temperature envioromnents such as those found in the

"cabs" (or on the machinery decks) of large cranes, shovels anddraglines

(7) slides, cams and rollers on pipe handling and laying equipment, either on land or

offshore

(8) sliding rod and ejector block applications on casting or molding machines and other

high temperature sliding mechanisms.

Finally, 9901 ALMASOL SYNTEMP is completely water resistant, resisting sea water as well

as boiling water or high temperature steam, and remains plastic down to OOF. It has excellent

mechanical stability and excellent adhesive and cohesive qualities which allow it to stick to the

metal and to protect against rust and corrosion.

TT-994

© 1984 LUBAIC",TION ENGINEER., INC, REV. 2-84

You might also like

- Mobil Mobilux EP DatasheetDocument3 pagesMobil Mobilux EP Datasheetphankhoa83-1No ratings yet

- MobiluxeDocument3 pagesMobiluxesharin79No ratings yet

- Molykote Anti-Seize CompoundsDocument1 pageMolykote Anti-Seize CompoundsProject Sales CorpNo ratings yet

- Complex GreaseDocument1 pageComplex Greasecarlos samilaNo ratings yet

- 118 Worm Gear LubesDocument4 pages118 Worm Gear LubesWajahat RasoolNo ratings yet

- Zeon Productguide 20150717Document16 pagesZeon Productguide 20150717khushboo.mamtani2932No ratings yet

- Fuchs Cement BrochureDocument8 pagesFuchs Cement Brochureshani5573No ratings yet

- Mobilux Ep SeriesDocument3 pagesMobilux Ep Seriesyurik119281No ratings yet

- Characteristics (Typical Figures) Eni OTE 32 46 68 80 100Document2 pagesCharacteristics (Typical Figures) Eni OTE 32 46 68 80 100ranjanguptNo ratings yet

- Mobilux™ EP 0, 1, 2, 3, 004 and 023: GreaseDocument2 pagesMobilux™ EP 0, 1, 2, 3, 004 and 023: GreaseyierbNo ratings yet

- Packing Brochure SADocument20 pagesPacking Brochure SAfrederick alayonNo ratings yet

- Viton VS NBRDocument13 pagesViton VS NBRKathiravan PalanisamyNo ratings yet

- Titan Atf 5500 TdsDocument2 pagesTitan Atf 5500 TdsluayhabibbNo ratings yet

- SHELL Product Data Guide Industry 2013Document78 pagesSHELL Product Data Guide Industry 2013Edgar Real ViúlaNo ratings yet

- Product Guide 2012Document16 pagesProduct Guide 2012Daniele BoscoNo ratings yet

- Shell Tellus T BrochureDocument8 pagesShell Tellus T BrochureJiang XuNo ratings yet

- Tranself NFJ 75w-80Document1 pageTranself NFJ 75w-80Ionita RalucaNo ratings yet

- Uniurex NDocument2 pagesUniurex NPradeep SinghNo ratings yet

- Choicest Anti-Seize Compounds From MolykoteDocument1 pageChoicest Anti-Seize Compounds From MolykoteProject Sales CorpNo ratings yet

- Renolin Unisyn OLDocument5 pagesRenolin Unisyn OLOliver CelestialNo ratings yet

- Shell Omala S2 GX 1000 - TDSDocument2 pagesShell Omala S2 GX 1000 - TDSbiron rumangunNo ratings yet

- Orkot Hydro Bearings enDocument8 pagesOrkot Hydro Bearings enLakeNo ratings yet

- Trunk piston oil for medium speed enginesDocument2 pagesTrunk piston oil for medium speed enginesnoar anwarNo ratings yet

- Renolin CLPDocument6 pagesRenolin CLPjacl88No ratings yet

- Omniguard QLT GreaseDocument2 pagesOmniguard QLT GreaseCarlosNo ratings yet

- Shell Omala S4 WE 220 Technical Data SheetDocument3 pagesShell Omala S4 WE 220 Technical Data SheetPro.MechanicNo ratings yet

- Gpcdoc Local Tds Qatar Shelml Omala s4 We 320 (Ar-Qa) TdsDocument3 pagesGpcdoc Local Tds Qatar Shelml Omala s4 We 320 (Ar-Qa) TdsEhsanNo ratings yet

- Mobilux EP 3Document3 pagesMobilux EP 3Sachin JawaleNo ratings yet

- Shell Omala S4 WE 220Document3 pagesShell Omala S4 WE 220Muhammad SaputraNo ratings yet

- Shell Omala S4 WE 320Document3 pagesShell Omala S4 WE 320Muhammad SaputraNo ratings yet

- RENOLIN UNISYN OL PI41107e_Document5 pagesRENOLIN UNISYN OL PI41107e_barcaza_13No ratings yet

- Wind Turbine Brochure PDFDocument4 pagesWind Turbine Brochure PDFfherreraenesaNo ratings yet

- Shell Omala S2 GX 680 TDSDocument2 pagesShell Omala S2 GX 680 TDSEdgar Leonel CortésNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Shell Omala S2 G 680 (Ar-BH) TDSDocument4 pagesShell Omala S2 G 680 (Ar-BH) TDSJavier GonzalezNo ratings yet

- GPCDOC Local TDS Bahrain Shell Omala S2 G 680 (Ar-BH) TDSDocument4 pagesGPCDOC Local TDS Bahrain Shell Omala S2 G 680 (Ar-BH) TDSAditomo PutrantoNo ratings yet

- Crater 5Document2 pagesCrater 5gersonmoraisNo ratings yet

- Engen TQH 10 SeriesDocument1 pageEngen TQH 10 SeriesCristina LimaNo ratings yet

- Omala s4 GXDocument2 pagesOmala s4 GXjeffturboNo ratings yet

- Mobil Unirex N Data SheetDocument3 pagesMobil Unirex N Data SheetCeliocp PinheiroNo ratings yet

- FUCHS_RENOLIN_UNISYN_OL_PDSDocument7 pagesFUCHS_RENOLIN_UNISYN_OL_PDSVictor ZhicayNo ratings yet

- Choose Mobil Industrial Greases As Your Lubrication SolutionDocument2 pagesChoose Mobil Industrial Greases As Your Lubrication SolutionGustavo Henrique MachucaNo ratings yet

- Shell Omala S2 G 100 Gear Oil TDSDocument3 pagesShell Omala S2 G 100 Gear Oil TDSWawanDarmawanNo ratings yet

- Wear Parts Brochure 2019 PDFDocument24 pagesWear Parts Brochure 2019 PDFBorza DorinNo ratings yet

- Omala S2 GX 68Document2 pagesOmala S2 GX 68Kieran MañalacNo ratings yet

- Shell Omala S4 WE 460Document3 pagesShell Omala S4 WE 460Muhammad SaputraNo ratings yet

- Shell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsAliNo ratings yet

- Shell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsRaden ArdyNo ratings yet

- Mobil SHC™ Gear SeriesDocument4 pagesMobil SHC™ Gear SeriesJeefNo ratings yet

- Operational Safety in Power Stations With New Molykote P37 500g Brush Top TinsDocument3 pagesOperational Safety in Power Stations With New Molykote P37 500g Brush Top TinsProject Sales CorpNo ratings yet

- Shell Omala S2 G 220 DatasheetDocument5 pagesShell Omala S2 G 220 DatasheetSergio OrdoviniNo ratings yet

- Eni OSO D 46 PDFDocument2 pagesEni OSO D 46 PDFbfygNo ratings yet

- Shell Tellus S2 M 100 Technical Data SheetDocument3 pagesShell Tellus S2 M 100 Technical Data SheetMuhtiar DarjaNo ratings yet

- Mobilgrease XHP 222 & Special PDSDocument3 pagesMobilgrease XHP 222 & Special PDScatoeraleifNo ratings yet

- Shell Tivela S 220: Advanced Synthetic Gear OilsDocument2 pagesShell Tivela S 220: Advanced Synthetic Gear OilsViruzfhmNo ratings yet

- Operational Safety in Power StationsDocument2 pagesOperational Safety in Power StationsProject Sales CorpNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Product Information: Full Torque™ Diesel Fuel ImproverDocument4 pagesProduct Information: Full Torque™ Diesel Fuel ImproverDeltalube TangerangNo ratings yet

- RTN 950A V100R011C00 User Guide For North America 02 PDFDocument107 pagesRTN 950A V100R011C00 User Guide For North America 02 PDFDeltalube TangerangNo ratings yet

- Hydraulic 6105Document8 pagesHydraulic 6105Deltalube TangerangNo ratings yet

- Product Information: Monolec Ultra® Engine OilDocument2 pagesProduct Information: Monolec Ultra® Engine OilDeltalube TangerangNo ratings yet

- 1136 TDB FlyerDocument2 pages1136 TDB FlyerDeltalube TangerangNo ratings yet

- 6722 TDB Flyer PDFDocument1 page6722 TDB Flyer PDFDeltalube TangerangNo ratings yet

- 6414 Low ToxDocument8 pages6414 Low ToxDeltalube TangerangNo ratings yet

- Le 2799Document2 pagesLe 2799Widhi NugrohoNo ratings yet

- Product Information: Wirelife™ Almasol® Coating LubricantDocument2 pagesProduct Information: Wirelife™ Almasol® Coating LubricantDeltalube TangerangNo ratings yet

- 6477 TDB PDFDocument2 pages6477 TDB PDFDeltalube TangerangNo ratings yet

- 99454032&4046 QuinplexDocument4 pages99454032&4046 QuinplexDeltalube TangerangNo ratings yet

- 6601 6603 TDB PVDocument1 page6601 6603 TDB PVDeltalube TangerangNo ratings yet

- Monolec PDFDocument6 pagesMonolec PDFDeltalube TangerangNo ratings yet

- 7567451-453 WirelifeDocument14 pages7567451-453 WirelifeDeltalube TangerangNo ratings yet

- 93234700-4702 Monolec PDFDocument6 pages93234700-4702 Monolec PDFDeltalube TangerangNo ratings yet

- 086 Screening of Influent StreamsDocument4 pages086 Screening of Influent StreamsDeltalube TangerangNo ratings yet

- 1150 TDB Flyer PDFDocument2 pages1150 TDB Flyer PDFDeltalube TangerangNo ratings yet

- 6190 Monolec PDFDocument5 pages6190 Monolec PDFDeltalube TangerangNo ratings yet

- 074 Hydro Static TransmissionsDocument4 pages074 Hydro Static TransmissionsPrakash Chandrasekaran100% (1)

- 076 All Le ExclusiveDocument1 page076 All Le ExclusiveDeltalube TangerangNo ratings yet

- 4204 White Utility Oil PDFDocument7 pages4204 White Utility Oil PDFDeltalube TangerangNo ratings yet

- 1601 1610 1302 TDB FlyerDocument2 pages1601 1610 1302 TDB FlyerDeltalube TangerangNo ratings yet

- 072 Piston Ring Cylinder PDFDocument8 pages072 Piston Ring Cylinder PDFDeltalube TangerangNo ratings yet

- 0401 TDB FlyerDocument2 pages0401 TDB FlyerDeltalube TangerangNo ratings yet

- 1150 TDB Flyer PDFDocument2 pages1150 TDB Flyer PDFDeltalube TangerangNo ratings yet

- 1250 1251 Product InfoDocument2 pages1250 1251 Product InfoDeltalube TangerangNo ratings yet

- 071 Equipment Food IndustryDocument4 pages071 Equipment Food IndustryDeltalube TangerangNo ratings yet

- 1232 TDB FlyerDocument2 pages1232 TDB FlyerDeltalube TangerangNo ratings yet

- 1136 TDB FlyerDocument2 pages1136 TDB FlyerDeltalube TangerangNo ratings yet

- 382 All PDFDocument72 pages382 All PDFthanh nguyenNo ratings yet

- BA 301 Final Exam QuestionsDocument14 pagesBA 301 Final Exam QuestionsJakeSimmonsNo ratings yet

- Cisco ASR 5000 System Administration GuideDocument380 pagesCisco ASR 5000 System Administration Guiderohitkamahi100% (1)

- HSE Manager CV PDFDocument4 pagesHSE Manager CV PDFSayeed MalikNo ratings yet

- Tata Steel IdeationDocument13 pagesTata Steel IdeationAnu SinghNo ratings yet

- Flutter Introduction and Dummy App WorkshopDocument27 pagesFlutter Introduction and Dummy App WorkshopubdNo ratings yet

- Nagavara Ramarao Narayana MurthyDocument6 pagesNagavara Ramarao Narayana MurthyDave DanielNo ratings yet

- Tutorial-9 PDocument1 pageTutorial-9 Ppriyanshu gangwarNo ratings yet

- E-Commerce 2018: Business. Technology. Society: Fourteenth EditionDocument54 pagesE-Commerce 2018: Business. Technology. Society: Fourteenth EditionCarlo WidjajaNo ratings yet

- DH Ipc Hdbw5541e Z5e Datasheet 20190620Document3 pagesDH Ipc Hdbw5541e Z5e Datasheet 20190620Ali KılıçkayaNo ratings yet

- TM 11398Document592 pagesTM 11398krill.copco50% (2)

- Cestas en TanquesDocument2 pagesCestas en Tanquesjose gregorioNo ratings yet

- Donna Gawlik 2 PG Resume 2014Document2 pagesDonna Gawlik 2 PG Resume 2014api-244892096No ratings yet

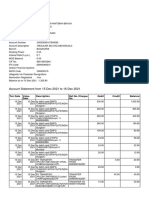

- Mr. RONAK J BHUVA's SBI account statement from 15-16 Dec 2021Document2 pagesMr. RONAK J BHUVA's SBI account statement from 15-16 Dec 2021Ronak BhuvaNo ratings yet

- Important Concepts and Formulas - ProbabilityDocument2 pagesImportant Concepts and Formulas - ProbabilityhareshtankNo ratings yet

- All Matrix OperationsDocument4 pagesAll Matrix OperationsCeleste Allysa Cullen Williams100% (1)

- AIRBAGS! Technical ManualDocument13 pagesAIRBAGS! Technical Manualhagar18No ratings yet

- UML notations and symbols summaryDocument6 pagesUML notations and symbols summaryHabibul HaqNo ratings yet

- Original Line Cylinders: BIMBA BIM-PFL-0119 Catalog 2019 - For Technical Assistance: 800-442-4622Document124 pagesOriginal Line Cylinders: BIMBA BIM-PFL-0119 Catalog 2019 - For Technical Assistance: 800-442-4622iqbal chaerulNo ratings yet

- Prestressed ConcreteDocument66 pagesPrestressed ConcreteTech BisuNo ratings yet

- Viking: Product ManualDocument26 pagesViking: Product ManualCristian RobiconNo ratings yet

- Example 1Document13 pagesExample 1LeswNo ratings yet

- AIA'sDocument3 pagesAIA'sVictorNo ratings yet

- Database Management System Lab Assignment - 6Document6 pagesDatabase Management System Lab Assignment - 6Niroop ReddyNo ratings yet

- Wordvice - EDITOR SAMPLE TEST - 20200526 (Edited Samples)Document6 pagesWordvice - EDITOR SAMPLE TEST - 20200526 (Edited Samples)wenelyn pinoNo ratings yet

- Revision MemoDocument2 pagesRevision Memoapi-309860565No ratings yet

- What Is UtautDocument2 pagesWhat Is UtautBunaya Mngwale HamisiNo ratings yet

- The Innovators DNADocument5 pagesThe Innovators DNAzia.ulhaq100% (2)

- PL 660 ManualDocument27 pagesPL 660 ManualSpeedyGonsalesNo ratings yet

- EIT062 Software TestingDocument190 pagesEIT062 Software TestingMayank SharmaNo ratings yet