Professional Documents

Culture Documents

HEAT EXCHANGER INSPECTION GUIDE

Uploaded by

senthilkumar subramanian0 ratings0% found this document useful (0 votes)

133 views3 pagescc

Original Title

number1

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcc

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

133 views3 pagesHEAT EXCHANGER INSPECTION GUIDE

Uploaded by

senthilkumar subramaniancc

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

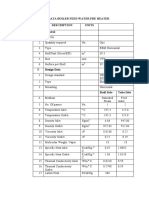

EXCHANGER INSPECTION:

Working principle: It is used to transfer heat between two or more fluid streams

TYPE OF EXCHANGER : 1) TUBLAR TYPE A) DOUBLE PIPE FIXED TUBE

B) SHELL & TUBE FLOATING HEAD

C) SPIRAL TUBE U TUBE

2) PLATE TPYE A) GASKETED

B) WELDED

3) FIN FAN COOLER

PARTS OF EXCHANGER :

1.Channel head 19. Split Shear Ring

4. Channel Cover 20. Slip-On Backing Flang

5. Stationary Head Nozzle 21. Floating Head Cover

6. Tubesheet 22. Floating Tubesheet Skirt

7. Tubes 27. Tierods and Spacers

8. Shell 28. baffles or Support Plates

9. Shell Cover 29. Impingement Plate

12. Shell Nozzle 15. Floating Tubesheet

14. Expansion Joint 16. Floating Head Cover

Shell SA516Gr60/70 SA387GR5CL2 SA240Gr316

Shell cover barrel SA516Gr60/70 SA387GR5CL2 SA240Gr316

Channel SA516Gr60/70 SA387GR5CL2 SA240Gr316

Channel cover SA105 SA182GrF5 SA182Gr316

Tubes SA179 SA213GrT5 SA213Gr316

Tubes sheet SA266Gr.2 SA336GrF5 SA240Gr316

Baffles SA516Gr60/70 SA387 Gr5CL2 SA240Gr316

Floating Head Dish SA266Gr.2 SA336GrF5 SA336Gr316

Nozzles Neck SA106GrB SA335GrP5 SA312Gr316

Nozzles Flanges SA105 SA182GrF5 SA182Gr316

PAD SA516Gr60/70 SA387GR5CL2 SA240Gr316

Tie Rods SA516Gr60/70 SA387GR5CL2 SA240Gr316

Partition Plate SA516Gr60/70 SA387GR5CL2 SA240Gr316

Impingement plate SA516Gr60/70 SA387GR5CL2 SA240Gr316

Spacers SA179 SA213GrT5 SA213Gr316

Type of Nozzels : Heat exchaner cleaning :

1) nozzel with reinforcement pad A) Chemical cleaning :

2) nozzel with out reinforcement pad 1.salphamic acid

2.ArmoniB-31

NDT Methods used : 3.Soda ash

Ultrasonic thickness gauge B) Mechanical cleaning :

Dye penetrant test. 1.Flat

boroscope. 2.Nylon brush

IRIS - internal rotating inspection system. 3.rod

Eddy current testing. 4.wire brush

RFET -Remote Field Electromagnetic testing C) High pressure jetting cleaning:

MFL - magnetic flux leakage. Pressure range 8000PSI to 12000PSI

Stage of inspection in exchanger :

1) Intial inspction ( as on open condition )

2) Intermediate inspection

3) Final inspection

Intial inspection ( as on open condition )

ᴥ To check the condition of shell , dish end and tube bundle and observed what type of detertation o

ᴥ To check the condition of the flange and nozzle gasket surface and check any unusual profiles such

as out of skew flanges or out-of-round pipes.

ᴥ clear for the hydrojet cleaning and offer intermediate inspction.

Intermediate inspection

SHELL: Note the :( After

condition of thehydrojet cleaning

flange gasket )

surface. Look for any unusual profiles such as out of

skew flanges or out-of-round pipes.

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Ingersoll Rand-Vibratory Pump AssemblyDocument8 pagesIngersoll Rand-Vibratory Pump AssemblyMohamed ZakiNo ratings yet

- Installation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersDocument5 pagesInstallation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersCLIFFORDPANo ratings yet

- Inspection and Test Plan For Shell and Tube Heat ExchangerDocument6 pagesInspection and Test Plan For Shell and Tube Heat ExchangertomychalilNo ratings yet

- Know Your ItemsDocument132 pagesKnow Your ItemsSyed ShabbirNo ratings yet

- Feed Water Preheater Data SheetDocument4 pagesFeed Water Preheater Data SheetPrabhakarNo ratings yet

- CO Storage: 20 ASCO ISO Tank ContainersDocument5 pagesCO Storage: 20 ASCO ISO Tank ContainersMB ManyauNo ratings yet

- Contractor's Responsibilities for Construction Site OrganizationDocument65 pagesContractor's Responsibilities for Construction Site OrganizationJosh Allen Gojo CruzNo ratings yet

- Final HE IndustrialSeminar DeshbandhuRawatDocument22 pagesFinal HE IndustrialSeminar DeshbandhuRawatdeshbandhu_rawat_me12100% (1)

- CO2 Storage Solutions in 20' ISO Tank ContainersDocument5 pagesCO2 Storage Solutions in 20' ISO Tank ContainersSmart LauNo ratings yet

- 01 Surface Spooled (Stack-Up) WellheadsDocument111 pages01 Surface Spooled (Stack-Up) WellheadsYoucef LiasNo ratings yet

- WTS Sample PrintoutDocument21 pagesWTS Sample Printoutsaka dewaNo ratings yet

- Tube Pitch HEDocument29 pagesTube Pitch HEDitha TiyaraNo ratings yet

- Specification For Fire Pump - Part 10Document5 pagesSpecification For Fire Pump - Part 10Melisa MackNo ratings yet

- ASCO 20 ISO Tank ContainersDocument5 pagesASCO 20 ISO Tank ContainersJay McKearnNo ratings yet

- 40SS Series: High Pressure Stainless Steel FilterDocument8 pages40SS Series: High Pressure Stainless Steel FilterYair Alexis Muñoz RojasNo ratings yet

- Urea StripperDocument15 pagesUrea Strippermujahidali500100% (1)

- GROHE Specification Sheet 33183002Document3 pagesGROHE Specification Sheet 33183002Pierre-olivier FournandNo ratings yet

- Resultado Do Cálculo e Seleção - TERREO-R5Document12 pagesResultado Do Cálculo e Seleção - TERREO-R5RICELLES SILVEIRA MARTINSNo ratings yet

- Spec He Urea P-4Document144 pagesSpec He Urea P-4M Aditya Regisyah PNo ratings yet

- Standard Operating Procedures for Drilling OperationsDocument456 pagesStandard Operating Procedures for Drilling OperationsSiddhartha ChakradharNo ratings yet

- ENQUIRY NO.: E-Mail Dated 28.03.2019 CLIENT: M/s.M.K.Roy & Bros Projects Limited. Our Offer Ref.: LI/101/QTN/ 5237 / 3742 /2018 - 2019 Date. 28.03.2019Document3 pagesENQUIRY NO.: E-Mail Dated 28.03.2019 CLIENT: M/s.M.K.Roy & Bros Projects Limited. Our Offer Ref.: LI/101/QTN/ 5237 / 3742 /2018 - 2019 Date. 28.03.2019Vetsa VivekNo ratings yet

- Ficha Tecnica Cisterna L&S Nassi - 10 000galDocument5 pagesFicha Tecnica Cisterna L&S Nassi - 10 000galOverhaul Mining EirlNo ratings yet

- AQ70 CylindersDocument8 pagesAQ70 CylinderslayetajNo ratings yet

- Design Basis Memorandum1Document3 pagesDesign Basis Memorandum1chikaofiliNo ratings yet

- OVSOL Evacuated-Tube CollectorDocument7 pagesOVSOL Evacuated-Tube CollectorTanveer ShaikhNo ratings yet

- Jacketed PipingDocument59 pagesJacketed Pipingvedadon75% (4)

- HydrantDocument10 pagesHydrantjdsa123No ratings yet

- Specification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byDocument13 pagesSpecification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreNo ratings yet

- TUV India HEAT EXCHANGER InspectionDocument43 pagesTUV India HEAT EXCHANGER InspectionParthiban NCNo ratings yet

- Filtro HaywardDocument4 pagesFiltro HaywardalmacidNo ratings yet

- Presentation of CIPL - CompressedDocument30 pagesPresentation of CIPL - CompressedNikhil VermaNo ratings yet

- Specification for Steam Jacketed PipingDocument14 pagesSpecification for Steam Jacketed Pipingvishal bhamreNo ratings yet

- Material Specification SheetDocument2 pagesMaterial Specification Sheetcalvin.bloodaxe4478No ratings yet

- Tri 21 DMP 002Document3 pagesTri 21 DMP 002adi sihombingNo ratings yet

- SF6 CB by HKRDocument87 pagesSF6 CB by HKRRajeevAgrawalNo ratings yet

- 11"-5000psi Double Ram BOP ManualDocument64 pages11"-5000psi Double Ram BOP ManualDavid EskarousNo ratings yet

- Scaffold FundamentalDocument28 pagesScaffold Fundamentaljay b100% (1)

- General: Crude Oil - 219 1.117 4.6 Crude Oil - 219Document1 pageGeneral: Crude Oil - 219 1.117 4.6 Crude Oil - 219amirNo ratings yet

- API 5L Line Pipe 24 Inch SCH 40 ERW PipeDocument14 pagesAPI 5L Line Pipe 24 Inch SCH 40 ERW PipeJuan CilloNo ratings yet

- Standard Rates for Water ProjectsDocument303 pagesStandard Rates for Water Projectsnimm196250% (2)

- ROV Actuator DatasheetDocument5 pagesROV Actuator DatasheetNawfel ArafathNo ratings yet

- Equipment and PipingDocument49 pagesEquipment and Pipingnuruddin2409No ratings yet

- Model 3201 Liquid Level Controller: FeaturesDocument8 pagesModel 3201 Liquid Level Controller: Featuresio1_roNo ratings yet

- 8931 PDFDocument27 pages8931 PDFPawan Kumar100% (1)

- Trencor Electric (25k)Document72 pagesTrencor Electric (25k)Adades Safede EfdNo ratings yet

- Operating Manual for 5/8”-5000psi Double (Single) Ram BOPDocument32 pagesOperating Manual for 5/8”-5000psi Double (Single) Ram BOPKurniadi WibowoNo ratings yet

- International Standard: First Edition MB-0745Document9 pagesInternational Standard: First Edition MB-0745INGAUTIN ProyectosNo ratings yet

- Pages FromThakore, Shuchen B. - Bhatt Introduction To Process Engineering and DesignDocument191 pagesPages FromThakore, Shuchen B. - Bhatt Introduction To Process Engineering and DesignAhmed HassanNo ratings yet

- Detail DesignDocument67 pagesDetail DesignBHAVISHA GOHILNo ratings yet

- StarterDocument16 pagesStarterswap2gzNo ratings yet

- BB. Docking Indent (Repair) Pioneer. 13th Feb.20Document11 pagesBB. Docking Indent (Repair) Pioneer. 13th Feb.20Thiet PhamNo ratings yet

- Asco Series 043 Gas Shutoff CatalogDocument4 pagesAsco Series 043 Gas Shutoff CatalogHomer SilvaNo ratings yet

- GROHE Specification Sheet 38661000Document2 pagesGROHE Specification Sheet 38661000Musataf GhotawalaNo ratings yet

- Piping Layout and Modelling EssentialsDocument7 pagesPiping Layout and Modelling EssentialsHarishKumarNo ratings yet

- VT-BAYARD-Automatic Control Valves-FloatDocument8 pagesVT-BAYARD-Automatic Control Valves-Floatsiva ramakrishnanNo ratings yet

- Instrumxx - Valves Catalogue PDFDocument42 pagesInstrumxx - Valves Catalogue PDFinternational dbalajiNo ratings yet

- Electrical Distribution in Papermills: Monographs on Paper and Board MakingFrom EverandElectrical Distribution in Papermills: Monographs on Paper and Board MakingRating: 2 out of 5 stars2/5 (1)

- Ans DRG ADocument10 pagesAns DRG Asenthilkumar subramanianNo ratings yet

- Eddy Current TheoryDocument5 pagesEddy Current TheorypondpakkaNo ratings yet

- Damage Mechanisum ChartDocument4 pagesDamage Mechanisum Chartsenthilkumar subramanianNo ratings yet

- Check List For AFCDocument4 pagesCheck List For AFCsenthilkumar subramanianNo ratings yet

- QSK60 Mounting SystemDocument24 pagesQSK60 Mounting SystemagvassNo ratings yet

- 2 and 3 Force Member ExampleDocument11 pages2 and 3 Force Member ExampleNIYASNo ratings yet

- DOCUMENT HYDRANT SYSTEM LOG SHEETDocument1 pageDOCUMENT HYDRANT SYSTEM LOG SHEETBAIDARUSEDONo ratings yet

- 76-71-006 Avkcms enDocument2 pages76-71-006 Avkcms enbre brilianNo ratings yet

- Basis of Design - Pipeline System TrunklineDocument10 pagesBasis of Design - Pipeline System TrunklineAndreas SchlagerNo ratings yet

- HSS AVAILABILITY CHARTSDocument4 pagesHSS AVAILABILITY CHARTSZHY HUNo ratings yet

- Electrical Commissioning ChecklistDocument2 pagesElectrical Commissioning Checklistalban ramabajaNo ratings yet

- Lifting Study by Various Crane+octo19 PDFDocument5 pagesLifting Study by Various Crane+octo19 PDFsky7No ratings yet

- NH35 Part ListDocument1 pageNH35 Part Listlivina D1778XGVNo ratings yet

- Condensate Estimation TemplateDocument2 pagesCondensate Estimation TemplateTee Chee KeongNo ratings yet

- Hydraulic JacksDocument8 pagesHydraulic JacksSharon ShineNo ratings yet

- Thermostatic Mixing Valve 4Document1 pageThermostatic Mixing Valve 4member1000No ratings yet

- Expansion-Joint-Catalog BellowsDocument142 pagesExpansion-Joint-Catalog BellowsRoberth AlejosNo ratings yet

- RD Alpha D21LiB5Document2 pagesRD Alpha D21LiB5Oscar AgmNo ratings yet

- Lifting Plan for Generator Set at CB SPL MahakamDocument10 pagesLifting Plan for Generator Set at CB SPL MahakamAditya Permana PutraNo ratings yet

- Milling Drilling Machine TM20VDocument3 pagesMilling Drilling Machine TM20Vpeter smithNo ratings yet

- International Standard: Fans - Vocabulary and Definitions of CategoriesDocument11 pagesInternational Standard: Fans - Vocabulary and Definitions of CategoriesprasannaNo ratings yet

- Zagreb Airport's 50th anniversaryDocument370 pagesZagreb Airport's 50th anniversaryDado ČokoladoNo ratings yet

- 60 KL KOTHRI OHT DesignDocument39 pages60 KL KOTHRI OHT Designsanju middyaNo ratings yet

- Murrplastik DragChain MP41.2Document12 pagesMurrplastik DragChain MP41.2topendwarriorNo ratings yet

- Six KipsDocument10 pagesSix Kipsyoshdog@gmail.comNo ratings yet

- Design of SlabDocument14 pagesDesign of Slabابراهيم المبيضينNo ratings yet

- 142 PDFDocument38 pages142 PDFsoklongsrengNo ratings yet

- Dumy Rack RXP501 PDFDocument1 pageDumy Rack RXP501 PDFTuyenNo ratings yet

- 10 Fan DrycoolerDocument36 pages10 Fan DrycoolersamersibaniNo ratings yet

- University of Hail: Gears - GeneralDocument51 pagesUniversity of Hail: Gears - GeneralROBINNo ratings yet

- Inline check sieve removes foreign matterDocument2 pagesInline check sieve removes foreign matterGreere Oana-NicoletaNo ratings yet

- Machine Design and Shop Practice Pre BoardDocument7 pagesMachine Design and Shop Practice Pre BoardFrankie NovelaNo ratings yet

- Series dc125Document2 pagesSeries dc125Daniel FigueroaNo ratings yet