Professional Documents

Culture Documents

Check List For Works

Uploaded by

SM ConsultantsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check List For Works

Uploaded by

SM ConsultantsCopyright:

Available Formats

SMC . .

5 M CONSULTANTS

. .

Site Ofncc: At Rekula. Po. Kjmakha\ n Nagar Dist. Dhenkanal Pin- 5901S

Hnrjeci management Consultancy for "Execution of road bed and minor bridges between kin 0/00 lu km 19/00 &

17/00 km to 96/00 km for 76 Route km and laying of hlankeh fur entire length of 104 k.ni. including 28 Nos of bridges

between Budhapunka to Baghuapal under Angul to Sukinda Mrn D.C Rail line in Odisha India .

CHECK LIST FOR WORKS

I Follow RVNL, IS and other specifications as applicable. Follow and refer codes & manuals,

.

RVNL' circular, and RVNL' Quality Assurance Manual etc. For doing works of high quality &

standard. And record & maintain all registers and records for works as per RVNL guide lines.

Some of the points to follow are mentioned below for information.

2 EARTHWORK

.

(i) . Clearing & Grubbing(C&G) of ground.

(ii) . OGL should be recorded in level books.

(iii) . Suitability of natural ground for embankment. If required ground

improvement should be done.

(iv) . Selection of borrow areas for suitable earth for embankment.

(v) . Lab testing of borrow area earth.

(vi) . Earthwork in layers not exceeding 300mm in loose state and compaction to ensure 98% MDD.

(vii) . Maintenance of side slopes & berms.

(viii) . In LAB

-

Classification of soil.

-

Free soil index.

-

Modified proctor compaction test to find MDD & OMC.

-

CBR test.

(ix) . In filling minimum width of formation 6.85m in straight and in curve 7.15m

(x) . In cuttings formation with 6.60m excluding drains (considering OHE foundation provision).

(xi) . Suitability of soil at FL in cuttings as per specifications.

(xii) . Finished formation should have 1:30 cross slope.

(xiii) . Turfing of side slopes in embankments and in cuttings if required.

(xiv) . Toe wall and Pitching of slopes in water logged areas.

(xv) . Back filling of bridges by approve granular material (GW.GP&SW) and ensuring proper

compaction with 150mm layers.

(xvi) . Drain in cutting with proper longitudinal slopes & outlets.

(xvii) . Sub-bank to bank and in cuttings height> 6m.

(xviii) .Trolley refuges at 100 m interval in cutting & in high banks and 200m interval in filling

alternatively.

(xix). Safety fencing during execution of works and if required permanent fencing

Page-01

lAS-AW

CENTRAL OFFICE : S.M. TOWER PLOT N0.-130, KANCHESWAfi INDUSTRIAL ESTATE. RASULGARH. BHUfiANESWAR-751010, ODISHA

Or ,

PH.: (0674) 2580682 85 . TELEFAX: 2580686 . Web :

. http://www.smcindia.cofn. e-mail: supportesnKindia.com

SMC

. .

5 M CONSULTANTS

. .

Site Office: At-Rekula. Po.-Kamakhava Na°ar Dist. -Dhenkaual Pin ~5001S

Project managemeni Cunsultancy for "Execution of rood bed and minor bridges between km 0/00 to kni 19/00 A

17/00 kni tu 96/00 km for 76 Route km and luying of blankets far enure lengih uf 10-4 k-in. including 28 Nus of bridges

between Budkupunko to Baghuapai under Angul to Suhnda New B C Rati line in Odisha India

. .

3 . Bridges _

(i) . Ensuring SBC at formation level.

(ii) . verifying drawing as per site conditions.

(iii) . Temporary TBM & Reference pillar for every' bridge.

(iv) . Layout marking as per co-ordinates by TS & verifying by tapes.

(v) . Design mix - lab test to verify design mix.

(vi) . Sturdy & good finish shutters to have good surface of concrete.

(vii) . No leakage of joints - to avoid honeycombing. (Foam sheet and putty used in gaps).

(viii) . Use of good quality and tested vibrators with standby- for better vibration/compaction of

concrete. (6Qmm needle with electric and diesel vibrator).

(ix) . Slump tests at site and casting of concrete cubes as per IS 456:2000, pg-29

(x) . Proper slope of weep holes (1 in 30 as mentioned in all approved GAD).

(xi) . Quality pitching & flooring (Dry stone pitching & flooring).

(xii) . Attention to concrete surface to ensure proper surface without honeycombing.

(xiii) . Moisture correction in batching plant. "

(xiv) . Initial slump tests in batching plant.

(xv) . Ensuring proper proportioning of aggregate, sand, cement, water, admixture & to verify batch

report time to time as per mix design.

(xvi) . Compressive strength test of cubes. .

(xvii) . Permeability test.

(xviii) . Cement test - consistency of cement, fineness, initial (30minutes) & final (600minutes)

setting time.

(xix) . Cement mortar compressive test.

(xx) . Steel- 3rd party test -chemical & physical.

(xxi) . Proper bars bending

Placement of reinforcement bars. Spacing, Lapping, Chairs

-

Ensure concrete cover all-round (50mm).

-

(xxii) . Slump test.

(xxiii) . Ensuring proper sound shuttering & supporting.

(xxiv) . clean surface before concreting.

(xxv) . Keys & roughing of surface in next layer of concreting in walls etc.

(xxvi) . Concreting in layers (max 450mm).

(xxvii) . Casting of slabs and rafts in one go.

(xxix). Casting of test cubes and achieving strength at least fck + 4

Copy to: REs/Experts & Supervisors- for information and necessary action please.

PM/PM Kamakhyanagar

Page-02

CENTRAL OFFICE : 5.M. TOWER, PLOT H0.-130, MAWCHESWAR INDUSTRIAL ESTATE, RASULCARH BHU6ANE5WAR-751010. OOISHA

Gr m ,

. MSyH PH-: (0674, 25<l0682 . 85 ' TELEFAX: 2580686 . Web . ; http://www.smdmHa.cofn, e-mail: soppon smcindia.com

You might also like

- Result Sheet 107Document30 pagesResult Sheet 107SM ConsultantsNo ratings yet

- Behavior and Design of Buried Concrete Pipes: A Review and EvaluationDocument50 pagesBehavior and Design of Buried Concrete Pipes: A Review and EvaluationHeba S. Al-saudiNo ratings yet

- The Use of BS 5400: Part 3: 1982: The Highways Agency Ba 19/85Document26 pagesThe Use of BS 5400: Part 3: 1982: The Highways Agency Ba 19/85SM ConsultantsNo ratings yet

- Letter FormatDocument1 pageLetter FormatSM ConsultantsNo ratings yet

- Silt Factor 107Document12 pagesSilt Factor 107SM ConsultantsNo ratings yet

- HPC Template Revised Final 310518Document31 pagesHPC Template Revised Final 310518SM ConsultantsNo ratings yet

- Geotech Report SummaryDocument13 pagesGeotech Report SummarySM ConsultantsNo ratings yet

- Second Order Analysis of Hollow Tapered Circular Bridge PierDocument8 pagesSecond Order Analysis of Hollow Tapered Circular Bridge PierSM ConsultantsNo ratings yet

- Des Gnation: Carriage (30MPUTER Wing Covering LetterDocument20 pagesDes Gnation: Carriage (30MPUTER Wing Covering LetterSM ConsultantsNo ratings yet

- Letter FormatDocument1 pageLetter FormatSM ConsultantsNo ratings yet

- Carriage Director@ Computerwing Covering Lelter: Different Directorates of RdsoDocument32 pagesCarriage Director@ Computerwing Covering Lelter: Different Directorates of RdsoSM ConsultantsNo ratings yet

- Is 4 DC 688 400 C038Document10 pagesIs 4 DC 688 400 C038SM ConsultantsNo ratings yet

- Carriage: Director Computer WingDocument20 pagesCarriage: Director Computer WingSM ConsultantsNo ratings yet

- Second Order Analysis of Hollow Tapered Circular Bridge PierDocument8 pagesSecond Order Analysis of Hollow Tapered Circular Bridge PierSM ConsultantsNo ratings yet

- The Use of BS 5400: Part 3: 1982: The Highways Agency Ba 19/85Document26 pagesThe Use of BS 5400: Part 3: 1982: The Highways Agency Ba 19/85SM ConsultantsNo ratings yet

- Designationof: Carriage Directorxe WingDocument17 pagesDesignationof: Carriage Directorxe WingSM ConsultantsNo ratings yet

- RBF 5Document19 pagesRBF 5SM ConsultantsNo ratings yet

- Dwarf Mast Foundation Design - 11.05.20Document8 pagesDwarf Mast Foundation Design - 11.05.20SM ConsultantsNo ratings yet

- Girder MIDocument11 pagesGirder MISM ConsultantsNo ratings yet

- Paradip Port Connectivity Project Temperature Gradient CalculationsDocument79 pagesParadip Port Connectivity Project Temperature Gradient CalculationsSM ConsultantsNo ratings yet

- Vba Programming GuideDocument472 pagesVba Programming Guideravindra a deshpandeNo ratings yet

- 3Document1 page3SM ConsultantsNo ratings yet

- Pier Cap Corbel 30m SGDocument3 pagesPier Cap Corbel 30m SGSM ConsultantsNo ratings yet

- VermaDocument12 pagesVermaSM ConsultantsNo ratings yet

- ABUTMENT 17 - SM With PilesDocument513 pagesABUTMENT 17 - SM With PilesSM Consultants100% (1)

- SFHirakudDocument3 pagesSFHirakudSM ConsultantsNo ratings yet

- Erection SchemeDocument1 pageErection SchemeSM ConsultantsNo ratings yet

- Particle size analysis of soil samplesDocument24 pagesParticle size analysis of soil samplesSM ConsultantsNo ratings yet

- PHP NotesDocument70 pagesPHP NotesPablo AhmedNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Coir Pith ProjectDocument24 pagesCoir Pith ProjectMohan Raj67% (6)

- Characters Distribution and Types of BrassicaseaeDocument11 pagesCharacters Distribution and Types of Brassicaseaesamuel mainaNo ratings yet

- Sdre14-12 PNR 1-2-1dec17Document3 pagesSdre14-12 PNR 1-2-1dec17lwin_oo2435No ratings yet

- Foundations: Understanding the Base of any StructureDocument5 pagesFoundations: Understanding the Base of any StructureForbes KambaNo ratings yet

- The Natural Home - Tips, Ideas & Recipes For A Sustainable Life PDFDocument170 pagesThe Natural Home - Tips, Ideas & Recipes For A Sustainable Life PDFGiulia VanauNo ratings yet

- Herbal Bonsai Practicing The Art With Fast Growing HerbsDocument141 pagesHerbal Bonsai Practicing The Art With Fast Growing HerbsVlad PopaNo ratings yet

- Table A1.6.3.1 - Recommended Slumps For Various Types of Construction (SI) Slump, MM Types of ConstructionDocument6 pagesTable A1.6.3.1 - Recommended Slumps For Various Types of Construction (SI) Slump, MM Types of Constructiongreat_triskelionNo ratings yet

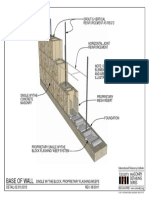

- 02.010.0313 Base of Wall Single Wythe Block Proprietary Flashing and WeepsDocument1 page02.010.0313 Base of Wall Single Wythe Block Proprietary Flashing and WeepsYolanda Leah UrbanoNo ratings yet

- Tree Removal Burwood Council Regulations - SummaryDocument6 pagesTree Removal Burwood Council Regulations - SummaryBenNo ratings yet

- Literature Cited Apa FormatDocument5 pagesLiterature Cited Apa FormatKai de LeonNo ratings yet

- Effect of Nitrogen and Phosphorus on Dry Weight, N and P Content of Tropical LegumesDocument50 pagesEffect of Nitrogen and Phosphorus on Dry Weight, N and P Content of Tropical LegumesYanti Nya IkbalNo ratings yet

- Vsim 030106 GuideDocument5 pagesVsim 030106 Guide2009modestoNo ratings yet

- Landscape Assessment of Gangtok SikkimDocument133 pagesLandscape Assessment of Gangtok SikkimSelvaPunitha100% (2)

- GR6 Tle Q1 W5 D1-D5Document10 pagesGR6 Tle Q1 W5 D1-D5Erdell BaronNo ratings yet

- Spring Fall Vegetable Planting Revised 2012Document2 pagesSpring Fall Vegetable Planting Revised 2012usama zedanNo ratings yet

- BILL NO 04 Drainage WorkDocument19 pagesBILL NO 04 Drainage Workaz90% (1)

- Lower Higher Plants TaxonomyDocument36 pagesLower Higher Plants TaxonomyIvka Zemiakova100% (2)

- TileDocument2 pagesTileRICPL - Quality Management Department- HONo ratings yet

- L-2 - Principles of Gardening, Garden Style and TypeDocument14 pagesL-2 - Principles of Gardening, Garden Style and TypeSrijeet Bhakta100% (1)

- Traditional Aquapoinics SystemDocument3 pagesTraditional Aquapoinics SystemAfaq AhmedNo ratings yet

- Proposed Construction of One-Storey Masjid Cotabato City Bill of MaterialsDocument3 pagesProposed Construction of One-Storey Masjid Cotabato City Bill of MaterialsNasroden PagayaoNo ratings yet

- Lesson Plan in Science Iv I. Lesson ObjectivesDocument4 pagesLesson Plan in Science Iv I. Lesson ObjectivesKim Rose BorresNo ratings yet

- Ereca T. Navarro: Item Description Qty. Unit Unit Cost Material Cost Labor Cost Total Cost ADocument9 pagesEreca T. Navarro: Item Description Qty. Unit Unit Cost Material Cost Labor Cost Total Cost AEreca NavarroNo ratings yet

- Foundation Layout and Reinforcement Details: 16D@10" CC 16D@10" CC 16D@10" CCDocument3 pagesFoundation Layout and Reinforcement Details: 16D@10" CC 16D@10" CC 16D@10" CCkiranNo ratings yet

- Drip Irrigation Design GuideDocument11 pagesDrip Irrigation Design GuideSiva KumaravelNo ratings yet

- Seed SavingDocument21 pagesSeed SavingElectroPig Von FökkenGrüüven100% (2)

- Evaluation of Growth, Development and Yield of Strawberry under Different Mulching MaterialsDocument12 pagesEvaluation of Growth, Development and Yield of Strawberry under Different Mulching MaterialsJoydeb GomastaNo ratings yet

- Contextualized Exercises 1-5Document13 pagesContextualized Exercises 1-5Roline JulatonNo ratings yet

- BILL No 8 - AtriumDocument86 pagesBILL No 8 - AtriumTigistuNo ratings yet

- UmehOjiako CucumberDocument8 pagesUmehOjiako CucumberPasha PascaNo ratings yet