Professional Documents

Culture Documents

Take UAN Corrosion Seriously

Uploaded by

maito22700 ratings0% found this document useful (0 votes)

57 views5 pagesWhen UAN fertilizer is stored without proper maintenance and corrosion prevention, it can corrode metal tanks and equipment, potentially resulting in leaks that contaminate the environment. However, with minimal effort and expense, dealers and growers can greatly reduce corrosion risks through actions like using tank liners, epoxy coatings, and stainless steel materials. The document discusses the causes of UAN corrosion and provides recommendations for ensuring quality product and minimizing corrosion.

Original Description:

Original Title

Take-UAN-Corrosion-Seriously

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWhen UAN fertilizer is stored without proper maintenance and corrosion prevention, it can corrode metal tanks and equipment, potentially resulting in leaks that contaminate the environment. However, with minimal effort and expense, dealers and growers can greatly reduce corrosion risks through actions like using tank liners, epoxy coatings, and stainless steel materials. The document discusses the causes of UAN corrosion and provides recommendations for ensuring quality product and minimizing corrosion.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

57 views5 pagesTake UAN Corrosion Seriously

Uploaded by

maito2270When UAN fertilizer is stored without proper maintenance and corrosion prevention, it can corrode metal tanks and equipment, potentially resulting in leaks that contaminate the environment. However, with minimal effort and expense, dealers and growers can greatly reduce corrosion risks through actions like using tank liners, epoxy coatings, and stainless steel materials. The document discusses the causes of UAN corrosion and provides recommendations for ensuring quality product and minimizing corrosion.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Fluid JOURNAL

Official Journal of the Fluid Fertilizer Foundation

Winter 2009

Vol. 17 No. 1, Issue #63

Phil Bureman and Dr. Craig Meyers

Take UAN Corrosion Seriously

If a tank leaks, you may be liable for water contamination in ground and surface water.

Summary: When there is

a lack of attention and little

effort on maintenance,

corrosion caused by fertilizers

(including UAN) can result in

financial losses, environmental

damage, and even loss of life.

However, these potential risks

can be greatly reduced with

only a small amount of effort

and minimal expense on the

part of the dealer or grower.

Figure 1. Collapsed storage tank. in UAN are usually detected

Managing corrosion be liable for environmental and through sampling and testing and

workplace safety violations, and are corrected prior to shipment to

UAN owes much of its popularity to

the entire business and/or business any customer. However, in some

its ability to mix easily with herbicides

reputation could be put at risk. facilities and terminals, no systems

and other fertilizers, thus enabling

or few systems are in place to detect

a one-pass application on the farm. Why care?

these corrosive properties. Since

It also allows for improved safety The majority of UAN suppliers strive the results of UAN corrosion events

versus anhydrous ammonia or to produce high quality UAN that may take some time to appear, the

dry ammonium nitrate. It is easy is only minimally corrosive. When supplier may not always be aware

to handle and apply accurately, manufactured and inhibited properly, that there is a problem. If corrosion

plus it is not so likely to be stolen UAN corrosivity can be minimized. in their facility can be minimized---

for illegal use. Nevertheless, it is However, when made improperly, for example by having tank liners,

important to remember UAN can UAN can corrode carbon steel very epoxy coatings, and stainless steel

be corrosive to most metal surfaces quickly. Fluid fertilizer dealers should or plastic pipe in place---there may

when stored. When not properly be aware that many UAN producers be less incentive for them to monitor

managed, UAN corrosion can cause and brokers have taken steps to corrosion quality

serious damage to pumps, pipelines, reduce their exposure to the risk

storage tanks, barges, rail cars, tank Fluid fertilizer dealers should seek

of UAN corrosion by installing tank

trucks, and agricultural equipment. out quality UAN producers and

liners, applying epoxy coatings, and

UAN corrosion can cost UAN brokers and ask what systems they

replacing carbon steel piping with

manufacturers, sellers and users in have in place to ensure UAN quality.

stainless steel.

many ways, including damage to Dealers should ask producers

In some cases, tank liners are and brokers about their sampling

equipment and the cost of cleaning,

applied simply to provide secondary procedures and ability to promptly

removing, and disposing of UAN

containment as required by some analyze those samples. Also, ask

corrosion sludge.

state regulations. In other plants, how these additional quality checks

For fluid fertilizer dealers, UAN UAN producers and brokers have can help minimize risk and make

corrosion can result in even more learned through experience that them more money in the long term.

severe problems. For example, if upsets can result in significant UAN from better quality suppliers

a UAN tank leaks, or worse yet if damage to storage systems in a very may cost a little more, but it is

it collapses (Figure 1), significant short time. Such upsets are rare but probably worth the higher price.

amounts of product and property they do happen. Corrosive properties Remember: If you never ask about

could be lost; the dealer might

anything except nitrogen content and

price, your supplier probably won’t

care about anything else either.

On the other hand, fluid fertilizer

dealers and UAN bulk tank owners

may not want to depend solely upon

their UAN supplier to manage the

corrosion that could occur in their

equipment. The potential for UAN

corrosivity can vary greatly from

producer to producer, plant-to-plant,

and even day-to-day in the same

plant or terminal.

Before we discuss more about

how to evaluate and minimize

the corrosive quality of UAN you

purchase, we must first understand

more about why UAN is corrosive

and the key corrosion mechanisms

that occur when UAN is stored.

Figure 2. Example of how “thin UAN film corrosion” can occur.

Excess ammonia

Of the components that make up stays in the UAN at adequate levels. into the UAN storage tank. For

UAN (urea, ammonium nitrate, water, The problem is there are many ways this reason, fluid fertilizer dealers

and a small amount of ammonia), in which ammonia can be reduced should ask about the typical

ammonium nitrate (AN) is the to levels that no longer provide the excess ammonia provided by their

more corrosive component. AN’s buffering required. UAN supplier. If there is a need to

corrosive affect is buffered by the For example, consider a rail car purchase a low ammonia product,

small amount of “excess” ammonia full of UAN, as depicted in Figure the dealer should be aware that

present; as little as 0.01 percent (100 2. When full, the ammonia quickly other steps may need to be taken to

ppm) to as much as 0.20 percent saturates the small vapor space help minimize the impact of this low

(2,000 ppm). Ammonia itself is not a above the liquid level in the car. Even ammonia level.

corrosion inhibitor. But without this when warm, no significant amount of The type of corrosion produced by

small amount of excess ammonia, ammonia is lost, so the UAN remains low ammonia levels is called “surface

UAN becomes extremely acidic fairly non-corrosive. However, upon corrosion.” The good news is that

and corrosion inhibitors cannot be arrival at a customer site, when surface corrosion initially is not very

applied cost effectively. One might the tanker is emptied, a thin film of damaging to the steel. However, it

wonder why extra ammonia is not UAN is left on the tank wall. At the does contribute to other problems.

always added to the UAN solution. same time, fresh air (that contains In a simple demonstration, that can

It generally is not an issue of cost. no ammonia at all) is sucked into be done in one’s own backyard,

Instead, excess ammonia content is the tank. When this happens, the a steel corrosion coupon was put

usually limited by plant design and ammonia levels in the vapor space inside a well-sealed glass jar along

customer preference. Some UAN must be reestablished. The only with just enough UAN 32 to barely

buyers prefer high ammonia levels in source of ammonia is the “thin film” cover most of the coupon. In this

the UAN they purchase because their left on the tank wall. If there is very example, an old coupon was used

customers prefer that the UAN have a little ammonia available, such as that happened to have a small

strong ammonia odor. Other buyers when excess ammonia levels in the corrosion spot on one side. The jar

worry about odor complaints from bulk UAN are less than 100 ppm was sealed and left in the sun for 7

neighbors if ammonia levels are too to begin with, the corrosivity of the days (Figure 3) and during that time

high during application. In addition, small amount of UAN remaining there was no sign of new corrosion.

very high ammonia levels could be a on the tank walls can increase The jar was then opened to the air for

safety hazard for personnel loading dramatically. about 3 hours and resealed and left

and unloading UAN. Furthermore, Surface corrosion overnight. The following morning, it

some herbicides and other tank mix was noted that severe corrosion had

As UAN levels in storage tanks

products are sensitive to having too developed on the coupon (Figure 4).

drop during the season, this same

much ammonia in the UAN. With However, this generalized surface

corrosive “thin film” is formed on

either preference, corrosion can be corrosion was not very damaging

the vertical wall as fresh air comes

controlled as long as the ammonia and was easily wiped off with a paper

towel. The amount of metal loss was

small enough that even the original

corrosion spot remained on the

coupon (Figure 5).

Sludge

It has been determined that opening

the jar resulted in the release of

the ammonia from the UAN, which

caused the corrosion that occurred

on the surface of the coupon. The

“Key Take Away” from this example

is that although surface corrosion

may not be very damaging, it does

generate a large amount of corrosion

sludge, and this sludge winds up

on the tank floor! The reason this is

important is that the generation of

surface corrosion sludge leads to

a major UAN corrosion mechanism

called “under deposit corrosion.”

Figure 4. Severe corrosion developed on coupon after loss of ammonia.

The chemistry that occurs with under

in steel piping. Blowing them

deposit corrosion is complicated

clear with air just flashes off

and a rigorous description is beyond

any remaining ammonia buffer,

the scope of this article. In brief,

leaving thin films of acidic

corrosion sludge prevents the normal

UAN on the pipe wall. Instead,

flow of ions in the UAN solution and

consider a flush with aqua

results in the formation of “pockets

ammonia or, where practical,

install corrosion- resistant pipe

such as plastic or stainless steel.

• Secure the dome covers on

all empty tanks or tankers that

Figure 5. Surface corrosion initially

hold or transport UAN. This is

results in minimal damage.

particularly important for trucks

UAN should assume a more active and rail cars because it helps

role managing UAN corrosion. There prevent the loss of excess

are mechanical, operational, and ammonia. Dealers who carelessly

chemical means to do so, and all leave this equipment open to

three areas should be considered at the atmosphere increase the

Figure 3. Sealed jar left in sun for 7 days. any UAN handling facility. cost that all dealers pay for UAN

Mechanical transport and storage.

of corrosive ions” under the sludge

• Drain and clean UAN storage • Install a recirculation header in

on the tank floor. The buildup of

tanks at least every two years. storage tanks. Corrosion sludge

corrosion sludge can also prevent

This will remove the surface is bad, but sludge that does

corrosion inhibitors from accessing

corrosion sludge that leads to the not move is even worse, as this

the steel under the sludge. The net

result is the deep pitting that usually more damaging “under deposit

occurs on UAN tank bottoms. It is not or pitting type corrosion.”

unusual to see UAN pits as deep as • Never leave small puddles or

a quarter inch develop in as little as “heels” of UAN in storage tanks

5 years when preventive measures for long periods of time. As in the

are not taken. Examples of UAN rail car example cited above, this

sludge buildup and the resulting UAN can easily be stripped of

pitting corrosion are shown below in the buffering ammonia and this

Figures 6, 7, 8 and 9. results in acidity in the UAN and

Managing UAN corrosion severe corrosion.

Fluid fertilizer dealers who handle • Avoid leaving puddles of UAN

Figure 6. UAN tank sludge.

allows for the buildup of “pockets tank sludge to keep moving • Consider installing a tank liner

of corrosive ions” under the across the tank bottom. This or applying a protective coating.

corrosion sludge. Many UAN helps to greatly reduce pitting Evaluate these options carefully,

producers now have adopted corrosion. as these components can also

a best practice of installing an • Some new tank builders are now fail, potentially resulting in an

inlet recirculation pipe across recommending installation of a even larger problem.

the entire diameter of their tank sloped tank bottom with a center Operational

bottom. This header pipe has outlet. This design is great for • Check the pH of incoming

several outlet spouts that point corrosion prevention, as sludge is UAN. Measurement of pH is a

toward the floor at a 45o angle. constantly removed from the tank good indication of how much

Recirculation of the UAN allows so buildup is always minimal. excess ammonia is contained

in the UAN. Most producers

ship product with a pH above

7.0. A pH as low as 6.5 is quite

acceptable, but much below

that there is a risk of stressing

all the corrosion management

systems. Discuss with your

supplier a desire to receive

product with a pH no lower than

6.5. UAN purchasers can check

the pH of incoming UAN with

something as inexpensive as pH

paper tape (less than $50), or

consider the purchase of a pH

meter (less than $500). This is

highly recommended if you are

purchasing imported product,

which has been known to lose

Figure 7. Pitting under UAN tank sludge.

Figure 9. Pitting under UAN rail car sludge.

excess ammonia during the long

transport time.

• If available, ask the supplier to

include excess ammonia levels

on the Certificate of Analysis

for each load. Excess ammonia

should be no less than 0.010

weight percent (100 ppm), and

preferably should be at least

0.020 to 0.050 weight percent

(200-500 ppm).

• Another important quality of

the UAN is known as the AN/

Urea Ratio. This is a simple

mathematical calculation of the

Figure 8. UAN rail car sludge.

weight percent of ammonium As detailed above, purchasers inhibitors actually combine with

nitrate divided by the weight should monitor the product they the corrosion products when

percent of urea. In UAN 32, this receive and ask questions about corrosion is initiated and stop

ratio is typically something like the quality of the UAN being corrosion by “sealing off” the

45%/35% = 1.28 AN/Urea Ratio. purchased. If suppliers can’t tell corrosion cell. Both types have

The AN/Urea Ratio is important buyers about the quality of the advantages and disadvantages

because it greatly affects the UAN being offered, they may not and when applied correctly

temperature at which UAN starts be monitoring it themselves. either type will greatly reduce

to salt out. UAN 32 typically Chemical UAN corrosion. Some inhibitor

has a salt-out temperature of formulations offer additional

• Fluid fertilizer dealers should

about 30o F. But this is only true features such as sludge

ask what type and how much

at the optimal AN/Urea ratio dispersants, metal chelants,

corrosion inhibitor is being used

range of about 1.20 to 1.40. At anti-foam additives and tracer

in the UAN they purchase. It

ratios above 1.6 or below 1.0, compounds. A sales engineer,

might be possible to request

UAN 32 could start to salt out educated in UAN corrosion

the treatment rate and brand of

at temperatures above 45o F or inhibitors, can help you decide

corrosion inhibitor be included on

higher. This is important because which type is best for your UAN.

the Certificate of Analysis.

salt-out means lost nitrogen

content. In addition, both AN and • If purchasing UAN from multiple Phil Bureman is Nalco’s

urea salts form very aggressive suppliers or sites, it is possible technical consultant for

corrosion cells, so they are not to end up with UAN containing Chemicals and Biofuels and

a good thing to have sitting at multiple inhibitors in your storage lives in Olathe, KS; pebureman@

the bottom of a tank (it’s like tanks. Although compatibility nalco.com and Dr. Craig Meyers

leaving rock salt on the driveway among different inhibitors is not is a research scientist at Nalco’s

at home). Lastly, both AN and an issue, these different inhibitors headquarters in Naperville, IL;

urea salts have a negative heat (now diluted) may not be as cmeyers1@nalco.com

of solution. This means that large effective together as they were by

amounts of heat are needed to themselves at full strength.

get these salts back into solution. • Fluid fertilizer dealers should

This may not be a problem when consider purchasing and

purchasing UAN in the spring, applying their own corrosion

when ambient temperatures are inhibitor programs. Corrosion

already well above 50o F, and the inhibitor chemicals are

UAN is to be applied right away. inexpensive, compared to the

But the AN/Urea Ratio should cost of UAN. Corrosion inhibitor

be considered if one plans to programs typically cost $0.60-

store UAN 32 during cold winter $0.70 per ton of treated UAN

months. There is no easy way for when purchasing in the small

UAN purchasers to measure this amounts likely to be needed by

parameter, but local suppliers fluid fertilizer dealers. This cost

should be able to give customers could be much less if the inhibitor

some typical values, or possibly choice is matched to the one

include this measurement on used by the UAN supplier. Most

the Certificate of Analysis, if UAN corrosion inhibitors are easy

requested. to apply and safe to use. There

• Try to store only UAN 32. are some products, however,

Contrary to what many believe, which themselves are quite acidic

UAN 28 is more corrosive than and are inherently hazardous

UAN 32. Consider purchasing to handle and store. Be sure

and storing only UAN 32, and to discuss this question with

then if needed, dilute it with water potential inhibitor vendors.

to 28% just prior to application. • There are two basic types of UAN

• Lastly, purchasing quality corrosion inhibitors. “Filmer”

UAN from a trusted source is type inhibitors form a protective

probably worth a higher price. film on steel. “Passivator” type

You might also like

- Cat Hose and Fitting GuideDocument390 pagesCat Hose and Fitting Guidegre29492% (24)

- 9-04-03 Contaminated Land IGNDocument6 pages9-04-03 Contaminated Land IGNChris KyriacouNo ratings yet

- Demineralization by Ion Exchange: In Water Treatment and Chemical Processing of Other LiquidsFrom EverandDemineralization by Ion Exchange: In Water Treatment and Chemical Processing of Other LiquidsRating: 4 out of 5 stars4/5 (2)

- Table-1 Scope of Work Supply (MR For ACHE)Document6 pagesTable-1 Scope of Work Supply (MR For ACHE)Avinash ShuklaNo ratings yet

- Pipeline: Contamination ControlDocument8 pagesPipeline: Contamination ControlMarcelo García FacalNo ratings yet

- Are Your Corrosion Control Practices Rusty?: Sponsored byDocument16 pagesAre Your Corrosion Control Practices Rusty?: Sponsored byJuan BustamanteNo ratings yet

- PAPTAC-FW Quality ExcursionsDocument5 pagesPAPTAC-FW Quality ExcursionsGarth110No ratings yet

- Water Staining GuidelinesDocument12 pagesWater Staining GuidelinesPradeep KumarNo ratings yet

- App Note 02 Amine UnitDocument2 pagesApp Note 02 Amine UnitJamesNo ratings yet

- Cleaning Spiral Wound MembranesDocument4 pagesCleaning Spiral Wound MembranesBhavik ZalaNo ratings yet

- Slurry Pooling and Transport Issues in SAG MillsDocument11 pagesSlurry Pooling and Transport Issues in SAG MillsJose Patricio VelardeNo ratings yet

- Cleaning Tech 4ppDocument4 pagesCleaning Tech 4ppeduardoNo ratings yet

- SPRAYING BITUMINOUS EMULSIONsDocument7 pagesSPRAYING BITUMINOUS EMULSIONsCharles LangatNo ratings yet

- Fertigation of Row-Crops Using Overhead Irrigation: Fertigation vs. Foliar-Feeding Advantages and LimitationsDocument5 pagesFertigation of Row-Crops Using Overhead Irrigation: Fertigation vs. Foliar-Feeding Advantages and LimitationsAngel_Scribd1No ratings yet

- MP Pumps Aticle Dec2017Document5 pagesMP Pumps Aticle Dec2017Eduardo Javier PerezNo ratings yet

- AAFDocument8 pagesAAFyamen-691904100% (1)

- Slurry Pooling and Transport Issues in SAG Mills PDFDocument10 pagesSlurry Pooling and Transport Issues in SAG Mills PDFMartin.c.figueroaNo ratings yet

- 2018 Baboo The Lessons Learned From The First 100 Safety Hazards in Urea Plants PDFDocument12 pages2018 Baboo The Lessons Learned From The First 100 Safety Hazards in Urea Plants PDFSatish SinghNo ratings yet

- Waste Minimisation Guide For The Textile Industry A Step TowardsDocument92 pagesWaste Minimisation Guide For The Textile Industry A Step TowardsKevin BundhunNo ratings yet

- Integrity and Disinfection: SWRO Pre-TreatmentDocument4 pagesIntegrity and Disinfection: SWRO Pre-Treatmentmona aminNo ratings yet

- Step by Step Maintenance Guide For Mast Hose: Used in Over-the-Sheave ApplicationsDocument6 pagesStep by Step Maintenance Guide For Mast Hose: Used in Over-the-Sheave ApplicationsYazad DoctorrNo ratings yet

- Norma SAE J1273Document10 pagesNorma SAE J1273mrioitaNo ratings yet

- Effects of Dust Suppression On Conveyor Belting: TechtipsDocument3 pagesEffects of Dust Suppression On Conveyor Belting: TechtipsAlbar BudimanNo ratings yet

- Aim of This Guide 4. References: Environmental Management When Spraying Bituminous MaterialsDocument8 pagesAim of This Guide 4. References: Environmental Management When Spraying Bituminous Materialsshalinie27No ratings yet

- Pig Sweep ClapperDocument10 pagesPig Sweep ClapperEuclides MezaNo ratings yet

- Dokumen - Tips - Novel Antiscalant Dosing Control PDFDocument8 pagesDokumen - Tips - Novel Antiscalant Dosing Control PDFAlida CuevasNo ratings yet

- 10 5923 J Materials 20140405 02 PDFDocument4 pages10 5923 J Materials 20140405 02 PDFnodyyyNo ratings yet

- Parker Alok Bible (Web) PDFDocument220 pagesParker Alok Bible (Web) PDFTamil Selvan0% (1)

- CDMCS PIP Best Practices GuideDocument40 pagesCDMCS PIP Best Practices Guidecitybizlist11No ratings yet

- UreaKnowHow - Mark Brouwer (PAPER)Document15 pagesUreaKnowHow - Mark Brouwer (PAPER)Usama JawaidNo ratings yet

- Well Abandonment - A Best Practices That Can Reduced Environmental RiskDocument7 pagesWell Abandonment - A Best Practices That Can Reduced Environmental RiskDaniel TobingNo ratings yet

- High Pressure Piping Safety Incidents in Urea Plants: Mark BrouwerDocument10 pagesHigh Pressure Piping Safety Incidents in Urea Plants: Mark Brouwervaratharajan g rNo ratings yet

- Parker Alok Bible (Web) PDFDocument224 pagesParker Alok Bible (Web) PDFmgkvprNo ratings yet

- SPE 78560 Applied Carbonate Stimulation - An Engineering ApproachDocument16 pagesSPE 78560 Applied Carbonate Stimulation - An Engineering ApproachBolsec14No ratings yet

- Vecom 0503 RustremoverDocument1 pageVecom 0503 RustremoverSPYRONo ratings yet

- Western Utilities Corporation Proposed Mine Water Reclamation Project Comment and Response ReportDocument49 pagesWestern Utilities Corporation Proposed Mine Water Reclamation Project Comment and Response Report12064100% (2)

- Parker Alok Bible WebDocument224 pagesParker Alok Bible WebRoo FaNo ratings yet

- 105-106 From TSM - Sept-Oct - 13Document2 pages105-106 From TSM - Sept-Oct - 13orlcostaNo ratings yet

- Selecting A Corrosion Inhibitor PDFDocument3 pagesSelecting A Corrosion Inhibitor PDFTariqNo ratings yet

- Storage and Handling of Welding Consumables PDFDocument20 pagesStorage and Handling of Welding Consumables PDFlth770310No ratings yet

- Pump Sealing For Hazardous Chemicals PDFDocument3 pagesPump Sealing For Hazardous Chemicals PDFBramJanssen76No ratings yet

- Mady 2020Document22 pagesMady 2020suhaimi manNo ratings yet

- He - 02 - 2020 PDFDocument92 pagesHe - 02 - 2020 PDFMarco Antonio Guevara MartínezNo ratings yet

- Belzona - Cold Curing WrapsDocument4 pagesBelzona - Cold Curing WrapsNay ThihaNo ratings yet

- Risk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3Document39 pagesRisk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3api-3752216100% (1)

- Advances in Functionalized Nanoparticles Based Drilling Inhibitors For Oil ProductionDocument12 pagesAdvances in Functionalized Nanoparticles Based Drilling Inhibitors For Oil ProductionMario Valentino DioNo ratings yet

- Binary Corrosion Inhibitors Offer Improved Corrosion ControlDocument5 pagesBinary Corrosion Inhibitors Offer Improved Corrosion ControlMoujahed FarésNo ratings yet

- Reliability of Flexible HosesDocument28 pagesReliability of Flexible HosesPakdee KammungkunNo ratings yet

- FFS For CO2 AbsorberDocument12 pagesFFS For CO2 AbsorberashwaniNo ratings yet

- 39Document26 pages39supriyo1970No ratings yet

- 1.1 What Is Piping Vibration?Document1 page1.1 What Is Piping Vibration?sheikmoinNo ratings yet

- UbiDocument15 pagesUbiOrlandoCoronelNo ratings yet

- Accident Prevention Ammonia RefrigerationDocument80 pagesAccident Prevention Ammonia Refrigerationjapganzan2186No ratings yet

- Goldmix Iwa TdsDocument1 pageGoldmix Iwa TdsRafael Obusan IINo ratings yet

- Review of Tailings Management Guidelines PDFDocument14 pagesReview of Tailings Management Guidelines PDFFelipe Ignacio Campos RodriguezNo ratings yet

- Piping Vibration Analysis & Integrity Assessment - Vibration, Dynamics and Noise - ENDocument7 pagesPiping Vibration Analysis & Integrity Assessment - Vibration, Dynamics and Noise - ENSitraka RANAIVOSONNo ratings yet

- The Benefits of Ultrasonic Testing in Determining Corrosion Rate and Service LifeDocument2 pagesThe Benefits of Ultrasonic Testing in Determining Corrosion Rate and Service Lifesooraj.cknambiarNo ratings yet

- Environmental Guidelines PetrolDocument9 pagesEnvironmental Guidelines PetrolAhmed GhawiNo ratings yet

- Corrosion and Corrosion Protection of Wind Power Structures in Marine Environments: Volume 1: Introduction and Corrosive LoadsFrom EverandCorrosion and Corrosion Protection of Wind Power Structures in Marine Environments: Volume 1: Introduction and Corrosive LoadsNo ratings yet

- Parker Twin Filter Horizontal Plate Scavenger DatasheetDocument2 pagesParker Twin Filter Horizontal Plate Scavenger Datasheetmaito2270No ratings yet

- LockNPC 11 3 315 2016Document29 pagesLockNPC 11 3 315 2016Francisco Infantes GomezNo ratings yet

- USDA Database For The Flavonoid Content of Selected Foods Release 3Document159 pagesUSDA Database For The Flavonoid Content of Selected Foods Release 3office8187No ratings yet

- Solar Panel Wash Data SheetDocument4 pagesSolar Panel Wash Data Sheetmaito2270No ratings yet

- Flavonoides en Ceboya PDFDocument34 pagesFlavonoides en Ceboya PDFmaito2270No ratings yet

- ESTRUCTURAS QUMICAS DE LOSANTIOXIDANTES Nutrients-08-00461 PDFDocument28 pagesESTRUCTURAS QUMICAS DE LOSANTIOXIDANTES Nutrients-08-00461 PDFmaito2270No ratings yet

- Estructuras de Los Flavonoides PDFDocument15 pagesEstructuras de Los Flavonoides PDFmaito2270No ratings yet

- DirectColorMarkingFinalReport PDFDocument67 pagesDirectColorMarkingFinalReport PDFmaito2270No ratings yet

- Acetite de Canela PDFDocument9 pagesAcetite de Canela PDFmaito2270No ratings yet

- Accepted Manuscript: Food ChemistryDocument31 pagesAccepted Manuscript: Food Chemistrymaito2270No ratings yet

- Yag VS Yvo4Document3 pagesYag VS Yvo4maito2270No ratings yet

- YVO4 NDDocument2 pagesYVO4 NDmaito2270No ratings yet

- Neodymium Doped Yttrium Orthavanadate (ND: YVO) Crystal: Info@lasercomponents - Co.ukDocument5 pagesNeodymium Doped Yttrium Orthavanadate (ND: YVO) Crystal: Info@lasercomponents - Co.ukmaito2270No ratings yet

- Laser Marking FundamentalsDocument4 pagesLaser Marking Fundamentalsmaito2270No ratings yet

- Todo Acido PeraceticoDocument156 pagesTodo Acido Peraceticomaito2270No ratings yet

- Sarc 2 Covid Prueba de 3 DesinfectDocument6 pagesSarc 2 Covid Prueba de 3 Desinfectmaito2270No ratings yet

- Hypochlorous Acid - Analytical Methods and Antimicrobial Activity (Pr13020.PDF)Document4 pagesHypochlorous Acid - Analytical Methods and Antimicrobial Activity (Pr13020.PDF)truetrutherNo ratings yet

- Hypochlorous Acid - Analytical Methods and Antimicrobial Activity (Pr13020.PDF)Document4 pagesHypochlorous Acid - Analytical Methods and Antimicrobial Activity (Pr13020.PDF)truetrutherNo ratings yet

- ECHA EUROPEA Peracetic Acid - PT2 - Final OpinionDocument11 pagesECHA EUROPEA Peracetic Acid - PT2 - Final Opinionmaito2270No ratings yet

- Aplicacion en Carnes y PollosDocument8 pagesAplicacion en Carnes y Pollosmaito2270No ratings yet

- Disinfection of Wastewater With Peracetic Acid: A Review: Mehmet KitisDocument9 pagesDisinfection of Wastewater With Peracetic Acid: A Review: Mehmet Kitismaito2270No ratings yet

- SARS CoV 2andanimalCoVsDocument19 pagesSARS CoV 2andanimalCoVsmaito2270No ratings yet

- Pandemic SARS Coronavirus-2 Infections in Humans-COVID-19: Nasir Mustafa, Hina Zahoor, Fuzail M. MAJOODocument17 pagesPandemic SARS Coronavirus-2 Infections in Humans-COVID-19: Nasir Mustafa, Hina Zahoor, Fuzail M. MAJOOmaito2270No ratings yet

- Aplicado A Superfices Porosas Contra Virus Epidinfect00015-0129Document13 pagesAplicado A Superfices Porosas Contra Virus Epidinfect00015-0129maito2270No ratings yet

- Pandemic SARS Coronavirus-2 Infections in Humans-COVID-19: Nasir Mustafa, Hina Zahoor, Fuzail M. MAJOODocument17 pagesPandemic SARS Coronavirus-2 Infections in Humans-COVID-19: Nasir Mustafa, Hina Zahoor, Fuzail M. MAJOOmaito2270No ratings yet

- Aplicado A Superfices Porosas Contra Virus Epidinfect00015-0129Document13 pagesAplicado A Superfices Porosas Contra Virus Epidinfect00015-0129maito2270No ratings yet

- P035-Synthesis of Dimethyl Carbonate From Urea PDFDocument2 pagesP035-Synthesis of Dimethyl Carbonate From Urea PDFmaito2270No ratings yet

- Fluidized Bed TutorialDocument10 pagesFluidized Bed TutorialAshwini SwamiNo ratings yet

- Swirl Fluiodmypapere-TransactionDocument7 pagesSwirl Fluiodmypapere-Transactionmaito2270No ratings yet

- P035-Synthesis of Dimethyl Carbonate From Urea PDFDocument2 pagesP035-Synthesis of Dimethyl Carbonate From Urea PDFmaito2270No ratings yet

- DLL - Tle 6 - Q4 - W2-2Document5 pagesDLL - Tle 6 - Q4 - W2-2Maricon ChicanoNo ratings yet

- The MoleDocument63 pagesThe MoleKennedy ChitayiNo ratings yet

- Well Head Gas Price Period July 2017Document5 pagesWell Head Gas Price Period July 2017Saad AliNo ratings yet

- The Structural Components of The Cell Membrane and Its Functions, With Transport Mechanisms.Document17 pagesThe Structural Components of The Cell Membrane and Its Functions, With Transport Mechanisms.Vieyah Angela VicenteNo ratings yet

- CodeinaDocument3 pagesCodeinaclaudiaNo ratings yet

- Hydrogen Donor Specificity of Mango Isoperoxidases: Food ChemistryDocument4 pagesHydrogen Donor Specificity of Mango Isoperoxidases: Food ChemistryGustavo HenriqueNo ratings yet

- Vulcanization of Rubber (Autosaved) .pptx234Document14 pagesVulcanization of Rubber (Autosaved) .pptx234Koundinya ManchiNo ratings yet

- Acknowledgement: M.R. Head of Civil Engineering Department, For Inspiring Take This Project. I Also ExpressedDocument18 pagesAcknowledgement: M.R. Head of Civil Engineering Department, For Inspiring Take This Project. I Also ExpressedRicky RickxNo ratings yet

- CGE653-Chapter 2-Part 1 PDFDocument79 pagesCGE653-Chapter 2-Part 1 PDFAbdul Halim AsmungiNo ratings yet

- Chemistry - Chemical Equations WorksheetDocument2 pagesChemistry - Chemical Equations WorksheetVasipalli Eshan AdityaNo ratings yet

- Chemical Kinetics Mechanism For Oxy-Fuel Combustion of Mixtures of Hydrogen Sulfide and MethaneDocument19 pagesChemical Kinetics Mechanism For Oxy-Fuel Combustion of Mixtures of Hydrogen Sulfide and MethanedanialNo ratings yet

- A Theory of The EarthDocument6 pagesA Theory of The EarthTeketel chemesaNo ratings yet

- Impression Compounds and AlginatesDocument13 pagesImpression Compounds and Alginatessourav dasNo ratings yet

- Lec 1 - MCDocument15 pagesLec 1 - MCDivyam JainNo ratings yet

- 22602-Sample-Question-Paper (Msbte Study Resources) Maintenance and Repairs of Structures (MRS)Document4 pages22602-Sample-Question-Paper (Msbte Study Resources) Maintenance and Repairs of Structures (MRS)Roshan Kinholkar100% (1)

- Taler Chemical Reactios. General Chemistry Teacher: William Alejandro Andrade BarreiroDocument8 pagesTaler Chemical Reactios. General Chemistry Teacher: William Alejandro Andrade BarreiroENITH HERRERA MONTALVONo ratings yet

- Candidate's Name:: (Do Not Write Your School/Centre Name or Number Anywhere On This Booklet)Document18 pagesCandidate's Name:: (Do Not Write Your School/Centre Name or Number Anywhere On This Booklet)OTTO OLIMANo ratings yet

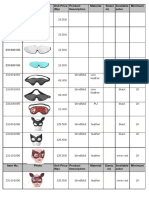

- Item No. Photo Unit Price (RP) Product Description Material Size (C M) Available Color MinimumDocument20 pagesItem No. Photo Unit Price (RP) Product Description Material Size (C M) Available Color Minimumrobiyanto wandooNo ratings yet

- Linus Pauling PublicationsDocument108 pagesLinus Pauling PublicationsFilipos ConstantinNo ratings yet

- MSDS Al2O3Document7 pagesMSDS Al2O3Mas BagusNo ratings yet

- Paper Name: Chemistry-I Code: BS-CH201 Contacts: 3L +1T Credits: 4Document5 pagesPaper Name: Chemistry-I Code: BS-CH201 Contacts: 3L +1T Credits: 4ME39Arnaw KumarNo ratings yet

- Copeland ZP24K5E PFV 830Document16 pagesCopeland ZP24K5E PFV 830Reynnier MendozaNo ratings yet

- 29 IM 240DNE XNE Service ManualDocument83 pages29 IM 240DNE XNE Service ManualSenen Geraldino JrNo ratings yet

- Jitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetDocument19 pagesJitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetabhishekNo ratings yet

- Essential Oil Chemistry HandbookDocument82 pagesEssential Oil Chemistry HandbookŁukasz Owsianko100% (1)

- HSEB Chemistry SyllabusDocument3 pagesHSEB Chemistry Syllabussudantula71% (7)

- Lab Report No. 2Document5 pagesLab Report No. 2Kouji MaedaNo ratings yet

- B.Pharmacy 2-2 Sem R15 SyllabusDocument14 pagesB.Pharmacy 2-2 Sem R15 SyllabusBhavanasi SahithiNo ratings yet