Professional Documents

Culture Documents

Saudi Aramco bracket scaffold inspection

Uploaded by

HaleemUrRashidBangashOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco bracket scaffold inspection

Uploaded by

HaleemUrRashidBangashCopyright:

Available Formats

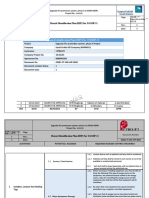

Saudi Aramco 9617 (11/01) Page 1 of 1

BRACKET SCAFFOLD FIELD INSPECTION CHECKLIST BRACKET SCAFFOLD

SCAFFOLD DESCRIPTION / LOCATION: DIMENSIONS (meters)

INSPECTED BY: (Signature) Print Name: Certificate / Badge #: Platform Width Platform Length

SCAFFOLD ACCEPTED & TAGGED WITH: DATE (M/D/Y):

(Please check the appropriate box) 䡺 Green Tag 䡺 Yellow Tag

FIELD INSPECTION CHECKLIST FOR BRACKET (TANK BUILDER’S) SCAFFOLD Yes No NA

Are all bracket scaffold components (including brackets, planks, and ladders) free from detrimental corrosion, damage, or other defects?

Have all bracket straps been welded to the tank wall by Saudi Aramco certified welder(s)?

Have the completed bracket strap welds to the tank wall been inspected and approved by a Saudi Aramco certified welding inspector?

Are bracket straps at least 250 x 75 x 10 mm (10 x 3 x 3/8 inch) in size?

Do brackets fit inside bracket strap gaps with not more than a 3 mm (1/8") clearance at the front or back faces?

Are brackets installed in a vertical and plumb position?

Are the supports (bearers/board bearers) for wood planks with a thickness of 38 mm (1-1/2 inches) not over 1.5 meters (5 feet) apart?

Are the supports (bearers/board bearers) for wood planks with a thickness of 50 mm (2 inches) not over 2.4 meters (8 feet) apart?

GENERAL REQUIREMENTS

Is a guardrail system (including toprails and midrails) installed along the outside edge of all platforms?

Is a guardrail system provided along the inside edge of all platforms that are more than 360 mm (14 inches) from the face of the tank?

Are guardrails constructed from scaffold tubes or wire ropes at least 10 mm (3/8-inch) in diameter?

If toprails are made of scaffold tubes, are connections made only at support uprights (no mid-span end-to-end connections)?

If wire rope guardrails are used, are they securely fixed and kept tight?

Are toprails between 0.95 meters and 1.15 meters (38 inches – 45 inches) above the platform walking/working surface?

Are guardrail support uprights made of scaffold grade tube or structural angle welded or adequately secured to the brackets?

If guardrail support uprights are not welded to brackets, are their support sleeves at least 150 mm (6 inches) in height and welded in place?

Is falling object protection provided (i.e., toeboards, barricades, wire screen, nets, etc.)?

Is the working platform between 450 mm – 680 mm (18" - 27") wide and fully planked, with no gaps larger than 25 mm (1 inch)?

Are planks or platform units secured to the brackets to prevent movement?

If plank ends are split, are cracks less than 300 mm (12 inches) long if the end is banded or less than 25 mm (1 inch) without banding?

Are all wood scaffold planks at least 38 mm (1-1/2 inches) thick and at least 225 mm (9 inches) wide?

For solid sawn wood planks, is a “Scaffold Grade” stamp from an accepted lumber grading/inspection association visible?

For laminated veneer lumber (LVL) planks, is “Proof Tested Scaffold Plank” and “OSHA” continuously embossed along both edges?

Are planks overlapped in one direction only and overlapped a minimum of 300 mm (12 inches)?

Note: NA means the requirement is not applicable to the scaffold being inspected.

You might also like

- Inspect suspended scaffold checklistDocument2 pagesInspect suspended scaffold checklistKiran Reddy100% (2)

- Tube Coupler Poster1Document1 pageTube Coupler Poster1Kiran Reddy100% (1)

- Bracket Scaffold Field Inspection ChecklistDocument3 pagesBracket Scaffold Field Inspection ChecklistShams Tabrez100% (1)

- Saudi Aramco Field ChecklistDocument6 pagesSaudi Aramco Field Checklistjaslin78% (9)

- Underhung (Suspended) Scaffold PDFDocument2 pagesUnderhung (Suspended) Scaffold PDFShams Tabrez100% (1)

- SABIC Site Project Scaffold InspectionDocument2 pagesSABIC Site Project Scaffold InspectionTamoor Mirza100% (2)

- Scaffold Inspection ChecklistDocument2 pagesScaffold Inspection ChecklistMikael Naqib75% (4)

- Aramco ChecklistDocument2 pagesAramco ChecklistMahadevan Somasundaram100% (1)

- Scaffold Checklist LocationDocument2 pagesScaffold Checklist LocationMikael NaqibNo ratings yet

- Scaffolding Inspection ChecklistDocument2 pagesScaffolding Inspection ChecklistBorislav VulićNo ratings yet

- Scaffolding Test Supervisor & Inspector of Saudi AramcoDocument16 pagesScaffolding Test Supervisor & Inspector of Saudi Aramcoeyas vp100% (3)

- 0008 - 001 Safety Requirements For ScaffoldsDocument16 pages0008 - 001 Safety Requirements For Scaffoldsshahid zaheer100% (1)

- Mobile Scaffold-2 PracticalDocument8 pagesMobile Scaffold-2 Practicalsamim100% (3)

- CSM II-3 Ladders and StepladdersDocument7 pagesCSM II-3 Ladders and StepladdersTasasdaq khanNo ratings yet

- Set 2Document21 pagesSet 2Tamilmani K100% (1)

- G.I. 8.001 Issue Date 10-01-2011Document17 pagesG.I. 8.001 Issue Date 10-01-2011Ruben Vasquez Laurente82% (17)

- SCOFFOLD CERT GUIDEDocument9 pagesSCOFFOLD CERT GUIDEFrancis Reyes100% (6)

- Scaffold Inspector Exam at 14-01-15Document2 pagesScaffold Inspector Exam at 14-01-15Altamas RehanNo ratings yet

- User Manual Cuplok NewDocument16 pagesUser Manual Cuplok NewSomu MahadevanNo ratings yet

- CISRS Overseas 3 Day Scaffolding Supervisor PDFDocument1 pageCISRS Overseas 3 Day Scaffolding Supervisor PDFkrishna kumr100% (1)

- Set 4Document8 pagesSet 4Tamilmani KNo ratings yet

- Overview of New Scaffold Safety RequirementsDocument4 pagesOverview of New Scaffold Safety RequirementsTehman AlamNo ratings yet

- Questions For Scaffolding GI 8.001Document20 pagesQuestions For Scaffolding GI 8.001Aftab Yaqoob100% (4)

- Scaffold VOC Questions & AnswersDocument4 pagesScaffold VOC Questions & AnswersMohamed Adel100% (2)

- Scaffold CSM Image BookDocument32 pagesScaffold CSM Image BooksamimNo ratings yet

- Method Statement - TF CUPLOK and Birdcage To SG4 - April 2005 PDFDocument10 pagesMethod Statement - TF CUPLOK and Birdcage To SG4 - April 2005 PDFMuhammed MahrousNo ratings yet

- Non-GBS Specialized Scaffolding Prequal Questionnaire1Document13 pagesNon-GBS Specialized Scaffolding Prequal Questionnaire1RAMIL100% (3)

- Scaffold Safety GuideDocument9 pagesScaffold Safety GuideHaleemUrRashidBangashNo ratings yet

- 9.15 Underhung Scaffold.Document3 pages9.15 Underhung Scaffold.AfshadNo ratings yet

- Scaffolding ExamDocument4 pagesScaffolding ExamSandeep Kumar100% (2)

- Solved PaperDocument6 pagesSolved Paperhasnainkhattak100% (2)

- Scaffold ChecklistDocument2 pagesScaffold ChecklistHaleem Ur Rashid Bangash100% (1)

- Part I - 04 Work Permit SystemDocument7 pagesPart I - 04 Work Permit Systemsalah abddayemNo ratings yet

- Set 3Document17 pagesSet 3Tamilmani KNo ratings yet

- Access Birdcage ScaffoldsDocument22 pagesAccess Birdcage ScaffoldsJitendra Kumar AnandNo ratings yet

- Scaffold Inspection Report 1Document2 pagesScaffold Inspection Report 1ronachaif3191100% (2)

- Tube and Coupler Scaffold GuideDocument11 pagesTube and Coupler Scaffold GuideAfshad100% (1)

- Method Statement For Scaffolding Erection - Docx R3Document14 pagesMethod Statement For Scaffolding Erection - Docx R3magramya100% (1)

- 11scaffolds Ladders Fall ProtectionDocument7 pages11scaffolds Ladders Fall ProtectionYoga Raja100% (1)

- ScaffoldingDocument86 pagesScaffoldingAristotel C. Cabais, RN100% (6)

- SAUDI ARAMCO SCAFFOLDING CERTIFICATION SUPERVISOR QUESTIONNAIREDocument38 pagesSAUDI ARAMCO SCAFFOLDING CERTIFICATION SUPERVISOR QUESTIONNAIREAftab Yaqoob89% (70)

- Scaffolding Supervisor I: Certification Study GuideDocument27 pagesScaffolding Supervisor I: Certification Study GuideTeodoro Esquillo100% (10)

- Rigger Level LLL: Prepared by Sagar ChiliveriDocument15 pagesRigger Level LLL: Prepared by Sagar ChiliveriAbdus Samad100% (1)

- Test Paper - SCAFFOLDINGDocument9 pagesTest Paper - SCAFFOLDINGmohsin khan100% (1)

- Scaffolding Notes PDFDocument30 pagesScaffolding Notes PDFzia68080% (10)

- Pile driving checklistDocument2 pagesPile driving checklistTrevor Emb67% (3)

- Cuplock Scaffolding SystemDocument6 pagesCuplock Scaffolding SystemJyles Sirab100% (1)

- Scaffold Inspection ChecklistDocument1 pageScaffold Inspection ChecklistAlves Edattukaran100% (4)

- 2 Scaffolding Inspector Training - VelosiDocument98 pages2 Scaffolding Inspector Training - Velosishahbaz akram100% (5)

- Excavation and Trenching Safety Program Construction Material Handeling ProgramDocument9 pagesExcavation and Trenching Safety Program Construction Material Handeling ProgramARSHI ASLAMNo ratings yet

- Scaffold BasisDocument19 pagesScaffold Basiswisdom ukuejeNo ratings yet

- Saudi Aramco Scaffold Safety RequirementsDocument21 pagesSaudi Aramco Scaffold Safety RequirementsKashmir Ka Bata Abdul GHAFFAR LAL DIN CHNo ratings yet

- Guide To Appointing A Scaffolding ContractorDocument20 pagesGuide To Appointing A Scaffolding ContractorMohammed HafizNo ratings yet

- Underhung (Suspended) Scaffold Field Inspection ChecklistDocument2 pagesUnderhung (Suspended) Scaffold Field Inspection ChecklistHaleemUrRashidBangashNo ratings yet

- Underhung (Suspended) ScaffoldDocument5 pagesUnderhung (Suspended) ScaffoldShams TabrezNo ratings yet

- 008 SA9614 Scaffold - NO NEED FOR UPDATEDocument4 pages008 SA9614 Scaffold - NO NEED FOR UPDATELijo JohnNo ratings yet

- 2018 Scaffold and Access Inspection Checklist FDocument6 pages2018 Scaffold and Access Inspection Checklist FTaufiq YahayaNo ratings yet

- Base SP Scaffold CHECK LIST-1Document4 pagesBase SP Scaffold CHECK LIST-1sameeralibabar00000786No ratings yet

- Scaffold Inspection ChecklistDocument3 pagesScaffold Inspection Checklistengrabbas75No ratings yet

- Scaffold Inspection ChecklistDocument2 pagesScaffold Inspection Checklistjeffrey90% (10)

- 01 Safety Statistics by Haleem Ur Rashid, BI 10-02185Document3 pages01 Safety Statistics by Haleem Ur Rashid, BI 10-02185HaleemUrRashidBangashNo ratings yet

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Document1 pageBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashNo ratings yet

- BI 10-02133, WEEK 06, Safety Statistics Reoport NDocument1 pageBI 10-02133, WEEK 06, Safety Statistics Reoport NHaleemUrRashidBangash100% (1)

- BI 10-02133, March 23 2020, SAFETY STATISTICSDocument2 pagesBI 10-02133, March 23 2020, SAFETY STATISTICSHaleemUrRashidBangashNo ratings yet

- Weekly Safety Meeting Minutes & StatsDocument3 pagesWeekly Safety Meeting Minutes & StatsHaleemUrRashidBangash100% (2)

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Document36 pages5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashNo ratings yet

- Weekly Safety Meeting Minutes & StatsDocument3 pagesWeekly Safety Meeting Minutes & StatsHaleemUrRashidBangash100% (2)

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Document1 pageBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashNo ratings yet

- Weekly Safety Meeting Minutes & StatsDocument3 pagesWeekly Safety Meeting Minutes & StatsHaleemUrRashidBangash100% (2)

- 13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020Document31 pages13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020HaleemUrRashidBangashNo ratings yet

- 20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020Document27 pages20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020HaleemUrRashidBangash100% (2)

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 pagesHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 pagesHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 pagesHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNo ratings yet

- 13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020Document31 pages13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDocument31 pagesHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashNo ratings yet

- 14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020Document31 pages14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020HaleemUrRashidBangash100% (1)

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Document36 pages4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 pagesHazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNo ratings yet

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pages9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- 11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020Document36 pages11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pages9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Document36 pages5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashNo ratings yet

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pages9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Document36 pages4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashNo ratings yet

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Document36 pages5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashNo ratings yet

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pages9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pages9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDocument31 pagesHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashNo ratings yet

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Document36 pages4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashNo ratings yet

- How To Decode METARDocument14 pagesHow To Decode METARkikiNo ratings yet

- Marketing DB ModelDocument2 pagesMarketing DB Modeld j goraNo ratings yet

- Chapter5ExceptionHandling IIDocument30 pagesChapter5ExceptionHandling IISaya WaniNo ratings yet

- Ieee 1578-2007 PDFDocument32 pagesIeee 1578-2007 PDFNataGBNo ratings yet

- Byv10ed 600pDocument10 pagesByv10ed 600pdavid.gjeorgevskiNo ratings yet

- HX2-100 2V AGM battery specsDocument2 pagesHX2-100 2V AGM battery specsdarwin gualotoNo ratings yet

- Chapter 09 Flow Measurement Applications Aps Compatibility ModeDocument12 pagesChapter 09 Flow Measurement Applications Aps Compatibility ModeBig BangNo ratings yet

- No. Description ApplicationDocument50 pagesNo. Description ApplicationMihes AdrianNo ratings yet

- Bil Jax 2622T - ManualDocument60 pagesBil Jax 2622T - ManualDuynamndk100% (1)

- Tremie SealsDocument12 pagesTremie SealsWalid MghazliNo ratings yet

- 3 Voter CounterDocument12 pages3 Voter CounterSheikh Abdul Wahab100% (2)

- Structural CalculationDocument5 pagesStructural CalculationEze NonsoNo ratings yet

- Name of Work: Estimation For Proposed Construction of Tara Ramesh, Tangali, Kadur Taluk, Chikkamagalur DistrictDocument25 pagesName of Work: Estimation For Proposed Construction of Tara Ramesh, Tangali, Kadur Taluk, Chikkamagalur DistrictDEEPIKANo ratings yet

- Park Residence BrochureDocument86 pagesPark Residence Brochureahmed ahmedNo ratings yet

- EGCP-2 Engine Generator Control PackageDocument226 pagesEGCP-2 Engine Generator Control PackageJorge EspinozaNo ratings yet

- OP100 D & OC 100 D - Spare Parts Manual 12 - 2002 - ENGDocument76 pagesOP100 D & OC 100 D - Spare Parts Manual 12 - 2002 - ENGRafael CastroNo ratings yet

- Kyocera FS-600 Parts Manual PDFDocument19 pagesKyocera FS-600 Parts Manual PDFliviumaraNo ratings yet

- W101 V2 Ebook 0831Document37 pagesW101 V2 Ebook 0831papagajkoNo ratings yet

- Notifier Compatible EquipmentDocument2 pagesNotifier Compatible EquipmentHesams EnamoradoNo ratings yet

- Frame Generator PDFDocument13 pagesFrame Generator PDFWilly PeralesNo ratings yet

- Check Valve VickersDocument15 pagesCheck Valve Vickersعلي عائشة100% (1)

- Robin Grayson Gold Recovery Method73Document1 pageRobin Grayson Gold Recovery Method73Senthilkumar PragasamNo ratings yet

- Python3 Tutorial PDFDocument26 pagesPython3 Tutorial PDFferronatto11100% (1)

- Safety PrecautionDocument1 pageSafety PrecautionSJ Chua100% (1)

- Calculating masonry costs for a residential structureDocument7 pagesCalculating masonry costs for a residential structureSean Franz VilardoNo ratings yet

- Ettus B100Document2 pagesEttus B100Philip GaddiNo ratings yet

- In XXX Project in YYY Country VOLTE Call Failure Due To Insufficient Bearer ResourceDocument10 pagesIn XXX Project in YYY Country VOLTE Call Failure Due To Insufficient Bearer ResourceAchmad Amrulloh100% (1)

- Accomplishment of SB 72-1074Document7 pagesAccomplishment of SB 72-1074aliNo ratings yet

- Las 2Document3 pagesLas 2James Honrubia (titobibot)No ratings yet