Professional Documents

Culture Documents

DSM-FRM-0001-27-0, HDPE PE-100 Pipe Installation

Uploaded by

kadir tanzaniaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DSM-FRM-0001-27-0, HDPE PE-100 Pipe Installation

Uploaded by

kadir tanzaniaCopyright:

Available Formats

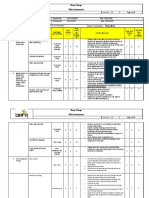

Dar Es Salaam - Morogoro

SGR Line Project

Document type: Hazard Identification and Risk assessment Ref.: DSM-FRM-0001-27-0

Activity: HDPE PE-100 Pipe Installation Revision: 00

For internal use only Location: Site Date: 02.01.2019

Work Area: All Work Areas Issued by: HSE Department

Document Preliminary Handling: For YM internal use only

Persons Affected (e.g. operators, maintenance, visitors, public etc.):

Status: Review: Following any significant legislation or

Operators, Welders, Plumber, Foreman(s), other

employees near the workplace

Final procedure changes but no later than: - 12 Months

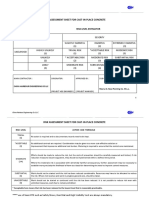

The Risk Assessment Severity (S) Likelihood of harm (L) Risk Rating (R) = S x L

1. Identify and record for each hazard/risk 1 = No Injury 1= Rare 1 to 6 = Low Risk (L) (Acceptable, Monitor & Review)

identified the appropriate rating for

LIKELIHOOD

severity and likelihood without controls. 2 = Minor Injury 2 = Unlikely 8 to 12 = Medium Risk (M) (Acceptable with controls)

3 = Lost time Injury 3 = Possible >12 = High Risk (H) Unacceptable

2. Identify and record the control 4 = Major Injury 4 = Likely

measures to be used then repeat the SEVERITY

5 = Death or Permanent Disability

5 = Certain

assessment with the controls in place 1 2 3 4 5

NOTE: If after 1

risk evaluation

1 2 3 and4 with5 all the necessary controls in place; the risk rating (R) is HIGH,

the HSE department are to be contacted for guidance on the task/process.

2 2 4 6 8 10

3 3 6 9 12 15

4 4 8 12 16 20

5 Before Agreed Controls After

Code Task Steps Hazards 5 10 15 20 25

Consequences of

Monitoring Monitoring

Hazards

S L R S L R

•Handling material 4 3 M •All precautionary signs will placed where and when 4 2 M

Stock the pipes in •Trip fall needed.

designated areas or •House keeping •Access should always be free from obstacles.

remove pipes from •No proper signing •Injury to personnel •Supervisor, foreman and all workers are responsible

1 area. •Lack of •Property Damage for housekeeping.

communication and •When handling the material, it should be carried as

instruction per manufacturer’s instructions

Communicate with co-workers to coordinate

Risk Assessment for HDPE PE-100 Pipe Installation DSM-FRM-0001-27-0 02.01.2019

This report must not be either loaned, copied or otherwise reproduced in whole or in part or used for any purpose without the prior written permission of YME

© Yapi Merkezi & Mota Engil Africa JV. Page: 1 / 4

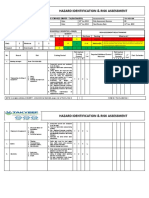

Dar Es Salaam - Morogoro

SGR Line Project

movements when working as a team

•Pre-task instruction must be conducted by

supervisor / foreman

•Heavy equipment’s daily check list shall be

completed prior the task

•All heavy-equipment to have properly operating

•Excavation collapse back-up signals, lights, reverse alarm must be

Working In •Fall into the •Injury to person, controlled

2 4 4 H 4 2 M

Excavations excavation •Serious injury, •Access/egress shall be designated and barricaded

•Serious injury •Property damage •Excavator’s counterweight and boom swing area

shall be clear

•Equipment operators shall be experienced and only

qualified and certified operators can operate

•Spotter / signalman for the safe movement of traffic

shall be separated from pedestrian and other zones

•Ensure all equipment/machinery are in proper

working condition prior to operating.

•Injury from struck by •Be aware of surroundings

equipment •Minor injury •All operators must be certified to operate individual

Back filling activity •Lack of experience •Fracture and sprain 3 3 M pieces of equipment 3 2 L

2

and information •Hand injury •Follow all safety requirements for vehicle operation

•Serious injury •Obey all project requirements.

Utilize required PPE

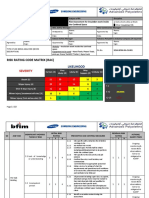

Welding process •Health illness-burns- 5 3 H •Hot works permit should be followed 5 2 M

injury •Flammable materials should be removed from the

•Failure can cause out welding operations area.

brake of fires •Fire Extinguisher or fire blanket should be used to

•Fire and explosion •Slip, trips and falls protect the surrounding areas from flame and

3 from the ignition of gas •Serious injury spatter.

cylinders. •Burn •The placing of a fire watcher on stand-by in case of

•Ignition of other •Fire emergency should be considered.

flammable materials •Fatality •Ensure equipment is installed properly,

whilst hot work •Ensure equipment is serviceable

•Gases and fumes •Consider hazards associated with wet area

Risk Assessment for HDPE PE-100 Pipe Installation DSM-FRM-0001-27-0 02.01.2019

This report must not be either loaned, copied or otherwise reproduced in whole or in part or used for any purpose without the prior written permission of YME

© Yapi Merkezi & Mota Engil Africa JV. Page: 2 / 4

Dar Es Salaam - Morogoro

SGR Line Project

•Safely dispose of electrode stubs

•Do not weld near degreasing operations

•Remove paints or coatings from welding surface

•Weather Conditions

•Reduced time exposure should be considered.

•Where other people are working adjacent to the

welding area, e.g. painting, the combined effect

•Provide exit and egress signs

•Pre task information should be done by supervisor

or foreman

•Keep work areas clean and tidy.

•All work areas should be kept orderly and clean.

•Keep walking aisles and roadways clear.

•Storage yards should be kept tidy and orderly

manners.

•Workers slip, trip and

4 •Slip, trips and falls •It is the responsibility of all workers and site

Housekeeping falls, 4 3 M 4 2 M

•Serious injury management to ensure that's work area is cleared

•Fire hazards

•Fire regularly and free of hidden hazards.

•When handling sharp tools e.g. scarpers, it should

be carried in holders and the use of gloves.

•Follow safety instruction

•Segregate the trash, general waste / hazardous

waste in appropriate bins.

•The correct PPE that suits to work will be used.

The cigarettes shall smoke only in designated area

Night Time Work •Poor visibility leading 3 3 M •Toolbox talk will be conduct for night shift by 3 2 L

to incident supervisor or foreman

•Lack of supervision •Employees will be made familiar about the

•Lack of communication •Minor injury emergency procedures by foreman or supervisor

•With and •Serious injury •As long as the lighting is needed and it must be

5 miscommunication •Fatality enough,

work force. •HSE to be informed by foreman, supervisor or

•Lack of communication engineer,

with security team •Verify existing light provisions at work site,

•Working alone •Additional lighting will be available if required,

Risk Assessment for HDPE PE-100 Pipe Installation DSM-FRM-0001-27-0 02.01.2019

This report must not be either loaned, copied or otherwise reproduced in whole or in part or used for any purpose without the prior written permission of YME

© Yapi Merkezi & Mota Engil Africa JV. Page: 3 / 4

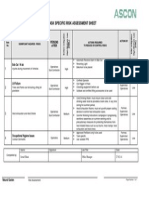

Dar Es Salaam - Morogoro

SGR Line Project

•No permission •Night Work Permit will be in place.

•Pressure testing of pipe will only be carried out by

competent and experienced personnel.

•The duct work under test and the surrounding area

will be barricaded off and suitable warning signs will

•Potential personnel •Slip, trips and falls be displayed.

injuries due to failure of •Serious injury •Personnel will be instructed not to enter areas

pressure testing where pressure testing is being undertaken.

Testing and

6 •Lack of communication 3 3 M •Unauthorized people shall be excluded from the test 3 2 L

commissioning

and instruction area.

•Lack of knowledge •Suitable communication facilities shall be available

and experience during testing.

•Padlock and tag is placed on the appropriate energy

isolating device that is in the off or closed position.

•Lockout technique used to prevent the release of

hazardous energy

Primary Legislation: Associated Documentation:

For further information relating to legislative requirements please refer to Risk Management Procedure (DSM-YME-AL-GL00X-G-HS-PRO-0001-0)

the HSE register of legislation. Method Statement for HDPE PE-100 Pipe Installation

Lifting Plan if Required

Construction Safety Management Plan (DSM–YMME–AL–GL00–G–HS–

MGP–0001–0)

Local Management Instruction(s)

Assessed by: Serkan OZTURHAN Date: 02.01.2019 Checked by: Tahir TUMER Date: 02.01.2019

Approved by : Kemal ARTÜZ Date: 02.01.2019

Risk Assessment for HDPE PE-100 Pipe Installation DSM-FRM-0001-27-0 02.01.2019

This report must not be either loaned, copied or otherwise reproduced in whole or in part or used for any purpose without the prior written permission of YME

© Yapi Merkezi & Mota Engil Africa JV. Page: 4 / 4

You might also like

- Risk Assessment & Control Register - Grease Trap CleaningDocument7 pagesRisk Assessment & Control Register - Grease Trap CleaningAbdul RahmanNo ratings yet

- Risk Assessment - House and BuildingDocument1 pageRisk Assessment - House and Buildingnayanahari0% (1)

- Risk Assessment - Site Establishment - 2021Document6 pagesRisk Assessment - Site Establishment - 2021Asakundwi Mukhwa100% (1)

- Risk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingDocument3 pagesRisk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingSafety Professional0% (1)

- Brick Masonry - EHS Risk AssessmentDocument2 pagesBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- Ooredoo: Title of Job: FO Cable Pulling, Installation of FAT & TerminationDocument6 pagesOoredoo: Title of Job: FO Cable Pulling, Installation of FAT & TerminationYousaf RichuNo ratings yet

- RA-for Glass Installation 30-04-2022Document6 pagesRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- 009 Installation of Pumps Risk AssessmentDocument2 pages009 Installation of Pumps Risk AssessmentRadhaKrishnan RNo ratings yet

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Fencing Installation Risk AssessmentDocument6 pagesFencing Installation Risk AssessmentVictorNo ratings yet

- Risk Assessment LoaderDocument3 pagesRisk Assessment Loadermohamed ghalyNo ratings yet

- Risk Assesssment-Vinyl & Tile Floor InstallationDocument2 pagesRisk Assesssment-Vinyl & Tile Floor InstallationMunaku TafadzwaNo ratings yet

- Critical Steps Analysis - Risk Assessment: 28/06/2018 Welding OperationsDocument2 pagesCritical Steps Analysis - Risk Assessment: 28/06/2018 Welding OperationsdnmuleNo ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentSam HodgsonNo ratings yet

- Skillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayingDocument6 pagesSkillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayinguknandiNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- Screeding WorksDocument2 pagesScreeding WorksSaleem Basha100% (1)

- Risk Assessment - Installation of Air CurtainDocument25 pagesRisk Assessment - Installation of Air CurtainMohsin MohdNo ratings yet

- Job Hazard AssessmentDocument26 pagesJob Hazard AssessmentGeherson AbustanNo ratings yet

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Manual HandlingDocument4 pagesManual HandlingJeffersonDeGuiaNo ratings yet

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul WasayNo ratings yet

- DewateringDocument1 pageDewateringChandruNo ratings yet

- CALACA POWER COMPLEX RISK ASSESSMENTDocument14 pagesCALACA POWER COMPLEX RISK ASSESSMENTJayson Escamillan100% (1)

- RISK ASESSMENT For SKYLIGHTDocument23 pagesRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)

- Risk Assessment MasonryDocument1 pageRisk Assessment Masonrymohamed ghalyNo ratings yet

- App-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair RoadDocument15 pagesApp-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair Roadloveson709No ratings yet

- Cleaning Risks AssessedDocument6 pagesCleaning Risks Assessedjulius0% (1)

- Soft Landscaping Risk Assessment SheetDocument1 pageSoft Landscaping Risk Assessment SheetMuhammad Ibrahim100% (3)

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- Risk assessment for 300MW Masinloc coal-fired power plant plumbing worksDocument8 pagesRisk assessment for 300MW Masinloc coal-fired power plant plumbing worksResearcherNo ratings yet

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- Electric Hand Drill Risk AssessmentDocument4 pagesElectric Hand Drill Risk AssessmentTariq AkhtarNo ratings yet

- Hazard Identification PlanDocument11 pagesHazard Identification PlanjavithNo ratings yet

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- Safe Work Method StatementDocument11 pagesSafe Work Method StatementJNo ratings yet

- Risk Assessment For Installation of Fire Fighting SystemDocument12 pagesRisk Assessment For Installation of Fire Fighting Systemطارق رضوان100% (3)

- Risk Assessment For Material Handling PDFDocument15 pagesRisk Assessment For Material Handling PDFHein Sithu KyawNo ratings yet

- RA, COSHH, MSDS Screed & Waterproofing PDFDocument27 pagesRA, COSHH, MSDS Screed & Waterproofing PDFテレブリコ ジェファーソン60% (5)

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 pagesIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisNo ratings yet

- Risk assessment for night shift activitiesDocument16 pagesRisk assessment for night shift activitiesthomson100% (1)

- Activity Hazard AnalysisDocument4 pagesActivity Hazard AnalysisGerrard Singh100% (1)

- Heavy Lifting Safety ChecklistDocument1 pageHeavy Lifting Safety ChecklistMock ProjectNo ratings yet

- 2.8c Risk Assessment - 007 Excavation Work Using Heavy Equipment Rev. HSE AsadDocument9 pages2.8c Risk Assessment - 007 Excavation Work Using Heavy Equipment Rev. HSE AsadAsad Raza100% (1)

- Risk Assessment For Drainage uPVC PipesDocument1 pageRisk Assessment For Drainage uPVC PipesZameer Basha Navzath AliNo ratings yet

- F5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionDocument11 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionTaiwo OshinNo ratings yet

- Risk Assessment of Fire Pipe Flange T ConnectionDocument5 pagesRisk Assessment of Fire Pipe Flange T Connectionimran aliNo ratings yet

- Cast-In Place Concrete - Risk Assessment SheetDocument3 pagesCast-In Place Concrete - Risk Assessment SheetYash SharmaNo ratings yet

- Excavation Risk Assessment KTPS - 8 PAGESDocument7 pagesExcavation Risk Assessment KTPS - 8 PAGESrajalingam100% (1)

- HAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBDocument7 pagesHAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBCharles LambNo ratings yet

- Risk Assessment for Overhead Line Relocation ProjectDocument5 pagesRisk Assessment for Overhead Line Relocation Projectghada gattouchNo ratings yet

- RA For Nitoflor FC150Document4 pagesRA For Nitoflor FC150kkhafajiNo ratings yet

- Project HS Risk Assessment for Sandvik Pvt Ltd Ceiling WorkDocument8 pagesProject HS Risk Assessment for Sandvik Pvt Ltd Ceiling WorkParasNo ratings yet

- Risk Assess Plastering 2006 Tcm17 26368Document2 pagesRisk Assess Plastering 2006 Tcm17 26368Anonymous QGHbz92uNo ratings yet

- Installing Cladding Risk AssessmentDocument3 pagesInstalling Cladding Risk AssessmentAhmed Tarek67% (3)

- Ev05 - Safety Task Analysis Reduction - Star Card in Different LanguageDocument3 pagesEv05 - Safety Task Analysis Reduction - Star Card in Different LanguageFrancis Enriquez TanNo ratings yet

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor50% (4)

- Risk Assessment For BricklayingDocument7 pagesRisk Assessment For BricklayingSathishKumar SkNo ratings yet

- SRA-GEN Risk Assessment for Turbine MaintenanceDocument3 pagesSRA-GEN Risk Assessment for Turbine Maintenanceacanbasri1980No ratings yet

- K 150 XL Sileo: Technical ParametersDocument8 pagesK 150 XL Sileo: Technical Parameterskadir tanzaniaNo ratings yet

- İlk Sayfa LG BİREBİR SPLİT GENEL KATOLOK (11-12-13-14 SAYFALAR 1Document1 pageİlk Sayfa LG BİREBİR SPLİT GENEL KATOLOK (11-12-13-14 SAYFALAR 1kadir tanzaniaNo ratings yet

- LG Ai̇r Conditions Catalouge - 11Document1 pageLG Ai̇r Conditions Catalouge - 11kadir tanzaniaNo ratings yet

- Stock Name Project Code Stock Code: DesignerDocument1 pageStock Name Project Code Stock Code: Designerkadir tanzaniaNo ratings yet

- K 100 XL Sileo: Technical ParametersDocument9 pagesK 100 XL Sileo: Technical Parameterskadir tanzaniaNo ratings yet

- K 100 XL Sileo: Technical ParametersDocument9 pagesK 100 XL Sileo: Technical Parameterskadir tanzaniaNo ratings yet

- MS - HDPE PE 100 Piping InstallationDocument14 pagesMS - HDPE PE 100 Piping Installationkadir tanzaniaNo ratings yet

- Essential checklist for water system O&MDocument3 pagesEssential checklist for water system O&Mkadir tanzaniaNo ratings yet

- Storage Tank MaintainDocument2 pagesStorage Tank Maintainkadir tanzaniaNo ratings yet

- Cupss Users GuideDocument180 pagesCupss Users Guidekadir tanzaniaNo ratings yet

- DSM - YME - AL - GL00X - G - AL - ITP - 0XXX - 0X Inspection PlanDocument1 pageDSM - YME - AL - GL00X - G - AL - ITP - 0XXX - 0X Inspection Plankadir tanzania100% (2)

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping System InspectionDocument1 pageDSM-xxx-0xxx-xx, Checklist For HDPE Piping System Inspectionkadir tanzaniaNo ratings yet

- DSM-FRM-0001-27-0, HDPE PE-100 Pipe InstallationDocument4 pagesDSM-FRM-0001-27-0, HDPE PE-100 Pipe Installationkadir tanzaniaNo ratings yet

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping InstallationDocument1 pageDSM-xxx-0xxx-xx, Checklist For HDPE Piping Installationkadir tanzaniaNo ratings yet

- MS - HDPE PE 100 Piping InstallationDocument14 pagesMS - HDPE PE 100 Piping Installationkadir tanzaniaNo ratings yet

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping InstallationDocument1 pageDSM-xxx-0xxx-xx, Checklist For HDPE Piping Installationkadir tanzania100% (4)

- DSM - YME - AL - GL00X - G - AL - ITP - 0XXX - 0X Inspection PlanDocument1 pageDSM - YME - AL - GL00X - G - AL - ITP - 0XXX - 0X Inspection Plankadir tanzania100% (2)

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping System InspectionDocument1 pageDSM-xxx-0xxx-xx, Checklist For HDPE Piping System Inspectionkadir tanzaniaNo ratings yet

- GPSForex Robot V2 User GuideDocument40 pagesGPSForex Robot V2 User GuideMiguel Angel PerezNo ratings yet

- PEC ReviewerDocument17 pagesPEC ReviewerJunallyn ManigbasNo ratings yet

- Types of Air Conditioning UnitsDocument10 pagesTypes of Air Conditioning Unitssnowgalvez44No ratings yet

- Company Profile ASIA ONE - 2022Document15 pagesCompany Profile ASIA ONE - 2022Nur SiswantoNo ratings yet

- Graphics Hardware Terminology, Displays and ArchitectureDocument35 pagesGraphics Hardware Terminology, Displays and ArchitectureBinoNo ratings yet

- Surgical Aspects of Pulmonary Infections: Kibrom Gebreselassie, MD, FCS-ECSA Cardiovascular and Thoracic SurgeonDocument60 pagesSurgical Aspects of Pulmonary Infections: Kibrom Gebreselassie, MD, FCS-ECSA Cardiovascular and Thoracic SurgeonVincent SerNo ratings yet

- Case 26 Star River Electronics - Group Thạch Trung Chương HiểnDocument12 pagesCase 26 Star River Electronics - Group Thạch Trung Chương HiểnTrương ThạchNo ratings yet

- Chap 7Document35 pagesChap 7Nizar TayemNo ratings yet

- Cellular ManufacturingDocument61 pagesCellular Manufacturingapi-3852736100% (1)

- Karla Maganda PDFDocument29 pagesKarla Maganda PDFKalay Tolentino CedoNo ratings yet

- Overcoming The Service Paradox in Manufacturing CompaniesDocument13 pagesOvercoming The Service Paradox in Manufacturing CompaniesErfanNo ratings yet

- The Teacher and Student Relationship of Haydn and BeethovenDocument10 pagesThe Teacher and Student Relationship of Haydn and BeethovenVinny MuscarellaNo ratings yet

- (Historical Materialism Book Series 32) Lapavitsas, Costas - Financialisation in Crisis (2012, Brill Academic Pub)Document276 pages(Historical Materialism Book Series 32) Lapavitsas, Costas - Financialisation in Crisis (2012, Brill Academic Pub)monikaNo ratings yet

- Lippo Karawaci Review 30 September 2019 FINAL PDFDocument149 pagesLippo Karawaci Review 30 September 2019 FINAL PDFAndy AghastaNo ratings yet

- DQFAQsDocument8 pagesDQFAQsBhagyashree kawaleNo ratings yet

- Laptops and Desktop-MAY PRICE 2011Document8 pagesLaptops and Desktop-MAY PRICE 2011Innocent StrangerNo ratings yet

- Title of Training Presentation: Presented by Your NameDocument14 pagesTitle of Training Presentation: Presented by Your NameJudy UnreinNo ratings yet

- University Library Management SystemDocument10 pagesUniversity Library Management Systemkochi jerryNo ratings yet

- Korepox Topcoat ET6572Document2 pagesKorepox Topcoat ET6572Isabelo AbaoNo ratings yet

- CMG STARS Guide PDFDocument1,136 pagesCMG STARS Guide PDFAastha91% (11)

- 3-IBM-RB - Sales - Selling Ibm Innovative SolutionsDocument226 pages3-IBM-RB - Sales - Selling Ibm Innovative Solutionsjusak131No ratings yet

- Rossetto Et AlDocument21 pagesRossetto Et AlEunice FiecasNo ratings yet

- Biology of Tooth MovementDocument22 pagesBiology of Tooth MovementsakshiNo ratings yet

- Cilegon-Order Material Pt. Quantum Radja Perkasa-280823Document1 pageCilegon-Order Material Pt. Quantum Radja Perkasa-280823Ria Maretta DewiNo ratings yet

- Duoc Dien Duoc Lieu Dai Loan - 3rd - 2019Document639 pagesDuoc Dien Duoc Lieu Dai Loan - 3rd - 2019Hương Nguyễn100% (1)

- Gpfs Overview v33Document54 pagesGpfs Overview v33Farha AzadNo ratings yet

- Compact NSX - Micrologic 5-6-7 - User Guide 11Document1 pageCompact NSX - Micrologic 5-6-7 - User Guide 11amnd amorNo ratings yet

- Activity 2EE56L FINALDocument6 pagesActivity 2EE56L FINALLUAÑA ALMARTNo ratings yet

- E44 - Wet Cooling Tower: InstructionsDocument3 pagesE44 - Wet Cooling Tower: InstructionsMarc AnmellaNo ratings yet

- A Study of Impact of FMCG Product Packaging On Consumer Behaviour With Reference To Food Items - IOPDocument37 pagesA Study of Impact of FMCG Product Packaging On Consumer Behaviour With Reference To Food Items - IOPvaibhav rajputNo ratings yet