Professional Documents

Culture Documents

Novel Application of Post-Tensioning Solves High-Rise Design Challenges

Uploaded by

ephremOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Novel Application of Post-Tensioning Solves High-Rise Design Challenges

Uploaded by

ephremCopyright:

Available Formats

Novel Application of

Post-Tensioning Solves

High-Rise Design Challenges

Solution provides long spans and efficient transfer of horizontal and vertical forces

by Bijan O. Aalami, Florian B. Aalami, Jeffrey Smilow, and Ahmad Rahimian

P

ost-tensioning is used to reduce deflection, control estate development in the history of the United States and the

cracking, and add strength in a wide range of concrete largest development in New York City since Rockefeller

construction projects, including both new construction Center. The project covers 28 acres (11.3 ha) on the west side

and retrofit of existing structures. The two principal of Manhattan, and when it is completed in 2024, 125,000

characteristics of post-tensioning are the precompression that people per day will work at, visit, or call Hudson Yards

is applied to the concrete and the uplift that is generated to their home. The site will include more than 17 million ft2

offset gravity loads. A third characteristic of post-tensioning is (1.6 million m2) of commercial and residential space, state-of-

the generation of hyperstatic (secondary) forces in statically the-art office towers, more than 100 shops, a collection of

indeterminate structures. restaurants, approximately 4000 residences, 14 acres (5.7 ha)

Hyperstatic forces were recently used to resolve a major of public open space, and a 750-seat public school. Half of the

challenge facing the structural design of 55 Hudson Yards, a project extends over an existing rail yard; the 30 active train

high-rise in New York City, NY, that will be partially tracks are slowly being covered by a massive platform that

constructed over and supported by an existing structure. The will hold three towers, a retail complex, a 6 acre (2.4 ha)

design scheme required the columns of the existing structure public square, and a new cultural space. The construction is

to provide partial support for the new construction. The expected to be completed in 2019 and is taking place while

challenge was to match the anticipated reactions of the new the trains remain in operation.

construction, which are governed by the building’s

architectural design and construction scheme, to the location 55 Hudson Yards

and capacity of the columns of the existing structure. A prominent part of the project is a 51-story commercial

While the combined capacity of the columns of the existing office building, 55 Hudson Yards (Fig. 1). One of the first

structure could support the weight of the new construction, the fully concrete-framed high-rises of its class in New York City,

distribution of the reactions from the new construction was the tower will include over 1.3 million ft2 (120,773 m2) of

considerably different from the capacities of the existing office space. The developers wanted the building to provide

supports. Among the several options explored, the use of modern, efficient floor spaces uninterrupted by columns, and

post-tensioning, configured to generate a set of hyperstatic with floor-to-ceiling windows. The solution comprises

reactions so that the reactions from the new structure matched long-span post-tensioned flat slabs supported by a central core

the capacity of the existing supports, proved to be the most and perimeter columns (Fig. 2). The architects are Kohn

practical and effective scheme. This article presents the Pedersen Fox Associates and Kevin Roche John Dinkello and

highlights of the design challenge and details how the Associates, and the structural engineer is WSP | Parsons

hyperstatic actions associated with post-tensioning were used Brinkerhoff. ADAPT Corporation was consulted on the

to achieve the design objective. post-tensioned aspects of the design.

Using post-tensioned flat slab construction with lightweight

Hudson Yards concrete allowed floor spans of up to 45 ft (13.72 m). It also

According to its developers, Related Companies and eliminated the need for interior beams. This reduced the

Oxford Properties, Hudson Yards is the largest private real floor-to-floor height, allowing the required office space to be

58 OCTOBER 2016 | Ci | www.concreteinternational.com

Fig. 2: Plan of typical high-rise (tower) level (Note: Green designates

area of future stair opening, additional slab reinforcing is required;

yellow designates no future slab penetration is these areas, limited

small sleeves may be allowed; and white designates area for small

penetration, sleeves, and poke-throughs)

Fig. 1: Rendering of 55 Hudson Yards

accommodated within a total building height of 780 ft (237.74 m).

The building features 10 floors of larger base construction Fig. 3: Overview of tendon layout of a typical floor

topped with 41 typical levels for a total of 51 floors. A

multi-level transfer structure has been designed to direct loads

from the exterior tower columns to the offset lower column (1219 mm) wide. The specified superimposed dead load was

grid. The composite transfer structure is composed of three 35 lb/ft2 (1.68 kN/m2), and the design live load was 50 lb/ft2

floor slabs and a series of transfer walls and “walking” (2.39 kN/m2), not reduced. The specified 28-day strength was

columns. Post-tensioning in two of these slabs is used to resist 7000 psi (48 MPa) for the lightweight concrete (120 lb/ft3

the horizontal tensile forces developed in the composite [1922 kg/m3]) in the floors and 12,000 psi (83 MPa) for the

transfer levels. Profiling of the tendon ties through the transfer normalweight concrete in the columns and core walls. The

plate provide added uplift to support the load from above. design of each slab considered three zones specified by the

This unique transfer system is described in more detail later owner: areas for future large openings, areas for small

in this article. penetrations, and areas with post-tensioning that should not

The floors in the tower feature a central core and open, be penetrated in the future.

beamless unobstructed space that extends 38.5 ft (11.74 m) The floor system reinforcement consists of unbonded

from the core wall to the perimeter (Fig. 2). In the base post-tensioning tendons and conventional reinforcement. The

structure, the floors span as far as 44 ft (13.4 m). The typical tendons were grouped and configured to meet the developer’s

floors are 9 in. (229 mm) thick flat slab construction with a requirement of large tendon-free regions at the center of the

perimeter beam that is 30 in. (762 mm) deep and 48 in. floor panels (Fig. 2 and 3), allowing tenants greater flexibility

www.concreteinternational.com | Ci | OCTOBER 2016 59

for creating internal access between the floors or other

structural modifications. The 0.5 in. (13 mm), 270 ksi

(1860 MPa), seven-wire strand tendons (Fig. 4) were supplied

by Amsysco, Inc., and installed by the primary concrete

contractor Cross Country Construction, LLC.

The projection of the building beyond the central core,

shown on the right of the structural model of the building

(Fig. 5), is supported on the column ends of the existing

Metropolitan Transit Area (MTA) ventilation building. A

post-tensioned wall system was developed in the new

construction over the existing building to bring the reactions

from the new construction to within the allowable values of

the existing supports.

Post-Tensioned Wall

The existing ventilation tower had been designed with

designated support locations to accommodate future

development at the Hudson Yards project. The architectural

requirements and the massing of the proposed new

construction, however, led to a potential overloading of two of

the interior existing support locations, while the exterior

support locations were underused. WSP | Parsons Brinkerhoff

evaluated several design and construction approaches to

redistribute the loads, including the use of a large steel truss in

combination with the delayed casting of the central columns.

Load redistribution would have been achieved by initially

spanning the exterior columns with the steel truss. The central

columns would be cast only after sufficient load had been

Fig. 4: Layout of post-tensioning and nonprestressed reinforcement

transferred to the outer supports. After installation of the

central columns, the remaining construction load would have

been distributed among all supports.

Another option, developed in collaboration with ADAPT,

was to redistribute the loads using post-tensioning tendons

draped from the 10th floor at locations near the exterior

columns down to the 8th level at the two interior columns.

This alternative allowed ducts to be placed during the level-

by-level construction of a concrete wall. Multistrand tendons,

supplied by Freyssinet, Inc., would be fed through the ducts

and could be stressed from the 10th level, where segments of

the wall would terminate. Calculations showed that the proper

load rebalancing would occur if the tendons were stressed

after completing construction of the 20th floor.

Using post-tensioning in a cast-in-place wall provided a

simple solution for rebalancing the reactions on the existing

structure, with minimal requirements to manipulate the

construction sequence. It also avoided the need for mixing

structural steel construction with concrete construction and

was shown to be less expensive to implement than the steel

truss option.

The design concept of the post-tensioning alternative is

based on the hyperstatic forces from post-tensioning. In a

statically indeterminate structure, the restraint of the supports

to the movement caused by post-tensioning results in a set of

forces in the structure; these forces are referred to as

Fig. 5: Structural model of 55 Hudson Yards hyperstatic actions. In the structural design of post-tensioned

60 OCTOBER 2016 | Ci | www.concreteinternational.com

configure the reactions to act in the direction and amounts

required by design. This feature of post-tensioning was used

to alter the reactions from the building loads so that they were

within the allowable range of the existing supports.

Figure 7 illustrates the application of the concept to the

55 Hudson Yards concrete frame. The hyperstatic reactions

(a) from the post-tensioning in the wall were designed so that the

column reactions framing into the wall were within the

support capacity.

W1 through W4 are the reactions from the superstructure at

the base of the columns. Based on the elastic distribution of

(b)

loads in the proposed structure, the W2 and W3 reactions

exceeded the capacity of the existing supports, while the

reactions at W1 and W4 were less than the capacity of their

supports, but by different amounts. A total of three hundred

and sixty-seven, 0.6 in. (15 mm) strands, providing a total of

approximately 14,000 kip (62,275 kN), grouped in mostly

31 strands per tendon and arranged as shown, were used to

(c) create the hyperstatic forces H1 through H4 at the base of the

columns, where H2 and H3 are upward forces, and H1 and H4

are downward forces. The sum of the forces H1 through H4

is zero, but they transfer a load totaling over 5000 kip

(22,240 kN) from central supports to the end supports. This

(d)

Fig. 6: Hyperstatic reactions from prestressed members: (a) free member;

(b) tendon forces; (c) restrained member; and (d) hyperstatic forces

members, the hyperstatic effects must be calculated and

accounted for along with the other loads on the structure.1

Figure 6 explains the concept of support reactions in

post-tensioned members. The internal forces generated by

post-tensioning tendons deform the member that contains

them (Fig. 6(a)). Depending on the loads on the member and

the amount of post-tensioning, the post-tensioning forces can

actually lift the member off its supports. The forces generated

by the post-tensioned tendons and applied to the member that

contains them are always in static self-equilibrium (Fig. 6(b)).

That means they sum up to be zero. They will deform the

member if the member is free to deform, as shown in Fig. 6(a).

If the supports of the post-tensioned member are fixed, they

will prevent the member from deforming at the connections to

the supports (Fig. 6(c)). The resistance to the movement of the

member caused by the post-tensioning forces results in a set

of reactions at the supports (Fig. 6(d)). These reactions are

referred to as the hyperstatic forces from post-tensioning.

Because the forces that generated the reactions shown in

Fig. 6(b) are in self-equilibrium, the sum of the resulting

hyperstatic forces must also add up to be zero, but the

direction and the value of each reaction can be configured

through the post-tensioning design. Through judicious

selection of tendon profile and tendon forces, it is possible to

www.concreteinternational.com | Ci | OCTOBER 2016 61

Fig. 9: Mechanics of generation of tensile forces in the lower slab in

spreading the load from smaller to larger slab footprint

Fig. 7: Schematic elevation of the lower wall section and its supports

Fig. 10: Forces on typical span of enlarged floor (Note: DL is dead

load; LL is live load; Wp is uplift from post-tensioning (PT))

A nontraditional but beneficial aspect of post-tensioning in

the design is the extended role of the tendon ties in the

transition slab between the smaller footprint of the tower, and

the larger podium floor below. Figure 9 displays the

mechanism of generation of tensile forces in the lower slab.

Figure 10 illustrates the forces on a typical span of the lower

floor, followed by the required adjustment in the strength

design of the floor.

In-plane tension generated in the lower floor can be

Fig. 8: Partial view of construction at Level 8 resisted by adding nonprestressed reinforcement, post-

tensioning tendons, or combination of the two.

Post-tensioning to resist tension from the floor transition

results in the net building reactions R1 through R4, which do can be profiled to provide uplift (Wp) in addition to tension.

not exceed the support capacity. The uplift counteracts the effects of dead (DL) and live (LL)

Figure 8 provides a partial view of the construction of the loads, but requires an adjustment in the safety design of the

post-tensioned wall at Level 8 in the building. Ducts (white) slab from the common case.

for multistrand bonded tendons are being positioned along the While tendons have been used as tie members before,

path specified in the design. The vertical reinforcing bars on profiling of tendon ties and recognizing their participation in

each side of the wall extend up from the level below. The providing the flexural strength of the member they pass

remainder of the wall reinforcement will be placed after the through is novel. Equation (1) is the load combination

installation of the ducts has been completed. Slab commonly used for strength demand of post-tensioned

reinforcement, including unbonded reinforcement (green), is members (Sections 5.3.1 and 5.3.11 of ACI 318-142), where

also being placed. HYP is the hyperstatic effects from flexure of member caused

62 OCTOBER 2016 | Ci | www.concreteinternational.com

by post-tensioning. It is applicable to the common case when Project credits

the tendons are anchored at the slab edge, leading to Developer: The Related Companies and Oxford Properties

compression in the slab. The moments from this expression Architect: Kohn Pedersen Fox Associates and Kevin Roche

are to be resisted by the combined contributions of John Dinkello and Associates

prestressing and nonprestressed reinforcing bars. Main Contractor: Gilbane Building Company

Equation (2) is the load combination when the tendon is a Concrete Contractor: Cross Country Construction, LLC

tie and is profiled. The uplift resulting from profiling of the Structural Engineer: WSP | Parsons Brinkerhoff

tendons, and the effects of uplift on the flexure of the slab— Post-Tensioning Consultant: ADAPT Corporation

hence the hyperstatic actions—remain unchanged. However, Post-Tensioning Suppliers: Amsysco, Inc., and Freyssinet, Inc.

the tendons will not be available to resist the demand

moment, as their force P is usurped by the sloping columns. References

In this case, the applicable demand moment derived from 1. Aalami, B.O., Post-Tensioned Buildings: Design and Construction,

Eq. (2) has to be resisted by nonprestressed reinforcement first edition, PT-Structures, 2014, 396 pp.

and added post-tensioning. 2. ACI Committee 318, “Building Code Requirements for Structural

Concrete (ACI 318-14) and Commentary (ACI 318R-14),” American

U = 1.2DL + 1.6LL + 1.0HYP (1) Concrete Institute, Farmington Hills, MI, 2014, 519 pp.

U = 1.2DL + 1.6LL + 1.0Wp (2) Selected for reader interest by the editors.

ACI member Bijan O. Aalami is ACI member Jeffrey Smilow is Executive

Emeritus Professor of San Francisco Vice President, USA Director of Building

State University, San Francisco, CA; Structures at WSP | Parsons Brinkerhoff

Legend, Fellow, and Life Member of and is responsible for all building structures

the Post-Tensioning Institute (PTI); and operations throughout the United States. As

Founder and Principal of ADAPT an integral member of the firm’s leadership

Corporation. He is a recipient of the team, he also oversees all building related

ACI Design Award for application of engineering disciplines. He has over 38

advanced engineering to a notable years of design experience in steel and

concrete structure. He has published extensively on analysis concrete and has developed a portfolio of high-profile projects

and design of post-tensioned structures. A renowned educator, including the World Trade Center Tower Three, Columbia University

he has held courses on post-tensioning in more than 35 countries Manhattanville, and the Citi Field New York Mets Stadium, among

worldwide. He is an Honorary Member of the Argentine many others. His work was instrumental in renovating landmarks

Structural Engineering Association and former Vice Chancellor such as the Plaza Hotel and Grand Central Terminal. A Fellow of the

and Professor at Arya Mehr (now Sharif) University of American Society of Civil Engineers (ASCE), he is a licensed engineer

Technology, Tehran, Iran. in multiple states.

Florian B. Aalami is CEO of ADAPT ACI member Ahmad Rahimian is USA

Corporation, a structural engineering Director of Building Structures at WSP |

and software development company, Parsons Brinkerhoff. He is the recipient of

specializing in analysis and design of numerous awards from engineering societies

concrete structures with extensive for various projects, including the 2007 AISC

national and international activities. He Special Achievement Award, 2005 ASCE-

is the recipient of 2013 ACI Charles S. CERF Charles Pankow Award for innovation,

Whitney Medal, awarded to ADAPT and the ENR Excellence Award as one of the

Corporation for its contributions in the Top 25 Newsmakers of 2003. In his 30 years

area of software used to design concrete structures. He at WSP, he has engineered numerous projects worldwide ranging

received his PhD from Stanford University, Stanford, CA. He is from high-rise commercial and residential towers to stadiums and

an active member of the PTI DC-110, Building Information transportation facilities. His projects are counted among the world’s

Modeling (BIM) Committee. most iconic and award-winning structures, such as One World Trade

Center and The Shard in London, UK. He received his PhD from the

Polytechnic Institute of New York University, Brooklyn, NY. A Fellow

of ASCE, he is a licensed engineer and licensed structural engineer

in multiple states.

www.concreteinternational.com | Ci | OCTOBER 2016 63

You might also like

- Plaza 66 Tower 2 Structural Design ChallengesDocument13 pagesPlaza 66 Tower 2 Structural Design ChallengessrvshNo ratings yet

- Engineering the World's Tallest and Slenderest BuildingDocument6 pagesEngineering the World's Tallest and Slenderest Buildinglily lisaNo ratings yet

- ARTIGO - AALAMI (2007) - Critical Milestones in Development of Post-Tensioned BuildingsDocument5 pagesARTIGO - AALAMI (2007) - Critical Milestones in Development of Post-Tensioned BuildingsVenícius CiríacoNo ratings yet

- Innovative Earth Retention Underpinning and Water Control Paper SLC Ut 1 PDFDocument12 pagesInnovative Earth Retention Underpinning and Water Control Paper SLC Ut 1 PDFBajocarNo ratings yet

- Omnilife Soccer Stadium For Guadalajara's ChivasDocument7 pagesOmnilife Soccer Stadium For Guadalajara's Chivasmarvin santiNo ratings yet

- ReferpersonalDocument7 pagesReferpersonalarvindNo ratings yet

- Capitol Visitor Center Diaphragm WallDocument5 pagesCapitol Visitor Center Diaphragm WallTony ChanNo ratings yet

- Steel Shear Walls For Existing BuildingsDocument8 pagesSteel Shear Walls For Existing BuildingsOscar SanabriaNo ratings yet

- Diagrid Structural Systems For Tall Buildings: Characteristics and Methodology For Preliminary DesignDocument26 pagesDiagrid Structural Systems For Tall Buildings: Characteristics and Methodology For Preliminary DesignprahladvattikutiNo ratings yet

- Central CCTV EstructuraDocument5 pagesCentral CCTV EstructuraMartín DalmazoNo ratings yet

- Seismic Performance of A 55-Storey Steel Plate Shear Wall: Struct. Design Tall Spec. Build. 19, 139-165 (2010)Document27 pagesSeismic Performance of A 55-Storey Steel Plate Shear Wall: Struct. Design Tall Spec. Build. 19, 139-165 (2010)Aravind BhashyamNo ratings yet

- Case StudyDocument11 pagesCase StudyANUBHAV CHAUDHARYNo ratings yet

- New York Icon Tower's Unique Architecture and Engineering DesignDocument1 pageNew York Icon Tower's Unique Architecture and Engineering DesignChai Weng KuakNo ratings yet

- Mitigating Shear Lag in Tall BuildingsDocument11 pagesMitigating Shear Lag in Tall BuildingsAvanish AviNo ratings yet

- Paper de Estadio CanadaDocument10 pagesPaper de Estadio CanadaTaiwanTaiwanNo ratings yet

- Transfer TrussDocument4 pagesTransfer TrussRida Abou KaramNo ratings yet

- Report (Print Whole)Document22 pagesReport (Print Whole)rounit prashantNo ratings yet

- New Technology Spurs Market For Large Panel Precast Concrete BuildingsDocument13 pagesNew Technology Spurs Market For Large Panel Precast Concrete BuildingsBrenton ThompsonNo ratings yet

- Exzenterhaus BochumDocument7 pagesExzenterhaus BochumGonzalo NavarroNo ratings yet

- Slenderness Ratio InfluenceDocument8 pagesSlenderness Ratio InfluenceBaguma Grace GariyoNo ratings yet

- Centru cultural-ONASSIS HOUSDocument4 pagesCentru cultural-ONASSIS HOUSstefanNo ratings yet

- By John Gregerson, Managing EditorDocument4 pagesBy John Gregerson, Managing EditorMuhammad IsmaelNo ratings yet

- Atkins - Almas-TowerDocument12 pagesAtkins - Almas-TowerAshish BorkarNo ratings yet

- Applsci 10 03917 v2Document31 pagesApplsci 10 03917 v2JOHAN ESTEBAN BARACALDO PALACIONo ratings yet

- Engineering the Iconic Two IFC TowerDocument44 pagesEngineering the Iconic Two IFC TowerMuhammad Azuan TukiarNo ratings yet

- Post-Tensioning Institute Announces Winners of 2019 Pti Project AwardsDocument59 pagesPost-Tensioning Institute Announces Winners of 2019 Pti Project Awardselev lookNo ratings yet

- Metropolis Mega-Development: A Case Study in Fast-Tracked Performance-Based Seismic Design of High-Rise Concrete Towers in Los AngelesDocument14 pagesMetropolis Mega-Development: A Case Study in Fast-Tracked Performance-Based Seismic Design of High-Rise Concrete Towers in Los AngelesTorha SlevenNo ratings yet

- A Retrofitting Framework For Pre-Northridge Steel Moment-Frame BuildingsDocument10 pagesA Retrofitting Framework For Pre-Northridge Steel Moment-Frame Buildingsgorgika papandNo ratings yet

- Capitol Visitor Center..Document5 pagesCapitol Visitor Center..Tanasescu AlinNo ratings yet

- Structural Design of Dubai's Almas TowerDocument10 pagesStructural Design of Dubai's Almas Towerthanzawtun1981No ratings yet

- STRUCTURE Magazine - Stabilizing San Francisco's Leaning TowerDocument9 pagesSTRUCTURE Magazine - Stabilizing San Francisco's Leaning TowerwblackkeNo ratings yet

- Exploring Structure Systems of High-RisebuildingsDocument25 pagesExploring Structure Systems of High-Risebuildingszuhaferoz2No ratings yet

- Prgstalleretal ForcesbehindthesceneDocument9 pagesPrgstalleretal ForcesbehindthescenecelsoNo ratings yet

- 100 Storey John Hancock Center, Chicago: A Case Study of The Design ProcessDocument5 pages100 Storey John Hancock Center, Chicago: A Case Study of The Design ProcessCrimsonPoshNo ratings yet

- PR 01 Preparation of Structural Design CriteriaDocument16 pagesPR 01 Preparation of Structural Design CriteriaHans Metif LinaNo ratings yet

- 282109-F-WaveOne DelhiDocument3 pages282109-F-WaveOne DelhiVigneshKumarNo ratings yet

- The Retractable Roof and Movable Field at University of Phoenix Stadium ArizonaDocument4 pagesThe Retractable Roof and Movable Field at University of Phoenix Stadium ArizonaHeitham Bou ChahineNo ratings yet

- Moon - Diagrid Structure Reseach Paper PDFDocument26 pagesMoon - Diagrid Structure Reseach Paper PDFLaNo ratings yet

- Tallest Concrete Building in ShanghaiDocument10 pagesTallest Concrete Building in ShanghaiSergiu TaralaNo ratings yet

- BoeingDocument12 pagesBoeingMike MorrisonNo ratings yet

- The Evolution of Outrigger System in Tall BuildingsDocument11 pagesThe Evolution of Outrigger System in Tall Buildingslakko naggereynoldNo ratings yet

- Article Indoor Stadium RajkotDocument10 pagesArticle Indoor Stadium RajkotJayant LakhlaniNo ratings yet

- Role of Shear To High Rise BuildingsDocument18 pagesRole of Shear To High Rise BuildingsAxmed ShirwacNo ratings yet

- 30-Storey Office Building Reinforced Concrete DesignDocument51 pages30-Storey Office Building Reinforced Concrete DesignAyodele Oluwaseyi Dina100% (1)

- Department of Civil Engineering, NIE, MysuruDocument58 pagesDepartment of Civil Engineering, NIE, Mysuruaksh007No ratings yet

- Three Tall Buildings and Their Unique Foundation DesignsDocument10 pagesThree Tall Buildings and Their Unique Foundation DesignsKit ChinNo ratings yet

- Nonlinear Analysis Saves Partially Built 54-Story BuildingDocument6 pagesNonlinear Analysis Saves Partially Built 54-Story BuildingIngeniero Emmanuel RodriguezNo ratings yet

- Vertical Shortening Considerations in The 1 KM Tall Jeddah TowerDocument12 pagesVertical Shortening Considerations in The 1 KM Tall Jeddah TowerDevendra Pratap SinghNo ratings yet

- 13 Case Study CCTV Building Headquarters Cultural CenterDocument13 pages13 Case Study CCTV Building Headquarters Cultural CenterIbrahem HakamNo ratings yet

- 2007 SEAOC-Tall Buildings InitiativeDocument10 pages2007 SEAOC-Tall Buildings InitiativekristinorigNo ratings yet

- Concrete Slender Wall Design - Back To The Future: January 2010Document10 pagesConcrete Slender Wall Design - Back To The Future: January 2010rahuljainNo ratings yet

- Seismic Performance and Design Requirements For High1Document27 pagesSeismic Performance and Design Requirements For High1Vijay AravindNo ratings yet

- Shear Wall Constructionin BuildingsDocument7 pagesShear Wall Constructionin BuildingsVictor OmotoriogunNo ratings yet

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966From EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Introduction to Design of Building StructuresFrom EverandIntroduction to Design of Building StructuresRating: 4 out of 5 stars4/5 (22)

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresFrom EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNo ratings yet

- ADAPT-Builder 2018 Design Options PDFDocument5 pagesADAPT-Builder 2018 Design Options PDFJuan Paulo MarceloNo ratings yet

- ADAPT-Builder 2019 TutorialDocument322 pagesADAPT-Builder 2019 TutorialephremNo ratings yet

- ADAPT-Builder 2019 Tutorial - Single-Level Two-Way SlabDocument188 pagesADAPT-Builder 2019 Tutorial - Single-Level Two-Way Slabephrem100% (1)

- Top and Bottom Crack Width PlanDocument2 pagesTop and Bottom Crack Width PlanephremNo ratings yet

- ADAPT-Builder 2019 New Features SupplementDocument97 pagesADAPT-Builder 2019 New Features SupplementephremNo ratings yet

- CES 117 - 2013, Double-Capped Fluorescent Lamps-Safety SpecifiDocument48 pagesCES 117 - 2013, Double-Capped Fluorescent Lamps-Safety SpecifiephremNo ratings yet

- ADAPT-Builder 2019 Release NotesDocument4 pagesADAPT-Builder 2019 Release NotesephremNo ratings yet

- ADAPT-Builder 2019 GUI Quick Reference GuideDocument103 pagesADAPT-Builder 2019 GUI Quick Reference GuideephremNo ratings yet

- Preparation of Design Aid For Rectangular Short Columns With Symmetrical Reinforcement and Different Rebar GradeDocument21 pagesPreparation of Design Aid For Rectangular Short Columns With Symmetrical Reinforcement and Different Rebar GradeephremNo ratings yet

- Technical Notes: Safety of Concrete Members at Initiation of CrackingDocument2 pagesTechnical Notes: Safety of Concrete Members at Initiation of CrackingephremNo ratings yet

- CES 25 - 2013, Concrete Sewer PipesDocument9 pagesCES 25 - 2013, Concrete Sewer PipesephremNo ratings yet

- ClayDocument9 pagesClayephremNo ratings yet

- Hollow Concrete BlockDocument7 pagesHollow Concrete Blockephrem100% (2)

- CES 115 - 2013, Incadescent Lamps Safety SpecificationsDocument46 pagesCES 115 - 2013, Incadescent Lamps Safety SpecificationsephremNo ratings yet

- Building Drift in ETABS: 1) Maximum LimitsDocument7 pagesBuilding Drift in ETABS: 1) Maximum LimitsEngrDebashisMallickNo ratings yet

- 01we Bond Worked Example Combinations of ActionsDocument0 pages01we Bond Worked Example Combinations of ActionsPacoNo ratings yet

- Bij108 Minimum Unified RebarDocument12 pagesBij108 Minimum Unified RebarAnonymous TxhyGfNo ratings yet

- Crack Mitigation of Post Tensioned Floors TN454Document40 pagesCrack Mitigation of Post Tensioned Floors TN454Anonymous TxhyGf100% (1)

- Technical Notes: Impact of Restraint Cracks On Strength of Post-Tensioned MembersDocument13 pagesTechnical Notes: Impact of Restraint Cracks On Strength of Post-Tensioned MembersephremNo ratings yet

- Technical Notes: Permissible Cantilever DeflectionDocument2 pagesTechnical Notes: Permissible Cantilever DeflectiondvegaucentralNo ratings yet

- P 1Document10 pagesP 1ephremNo ratings yet

- Technical Notes: Safety Investigation of An Unbonded Floor System With Restraint CracksDocument11 pagesTechnical Notes: Safety Investigation of An Unbonded Floor System With Restraint CracksephremNo ratings yet

- P 13Document2 pagesP 13ephremNo ratings yet

- P 18Document10 pagesP 18ephremNo ratings yet

- p2 PDFDocument16 pagesp2 PDFtinsaeNo ratings yet

- Technical Notes: Approximate Modeling of Ramps For DesignDocument2 pagesTechnical Notes: Approximate Modeling of Ramps For DesignephremNo ratings yet

- PT DetailingDocument52 pagesPT Detailingcuongnguyen100% (4)

- Designing Post-Tensioned Beams Having Sections With Compression SteelDocument4 pagesDesigning Post-Tensioned Beams Having Sections With Compression SteelephremNo ratings yet

- Design Optimization of Post-Tensioned SLDocument6 pagesDesign Optimization of Post-Tensioned SLephremNo ratings yet

- Duza Silentioasa SIEMENSDocument6 pagesDuza Silentioasa SIEMENSIonut DeaconuNo ratings yet

- Construction and Building Materials: Banana Leaves Ashes As Pozzolan For Concrete and Mortar of Portland CementDocument7 pagesConstruction and Building Materials: Banana Leaves Ashes As Pozzolan For Concrete and Mortar of Portland CementSWAPNILNo ratings yet

- Physical Chemistry: Thermodynamics, Structure, and Change: Tenth Edition ART Powerpoint PresentationsDocument36 pagesPhysical Chemistry: Thermodynamics, Structure, and Change: Tenth Edition ART Powerpoint PresentationsVincent PradjinataNo ratings yet

- How Healing Happens Exploring The Nonlocal GapDocument11 pagesHow Healing Happens Exploring The Nonlocal GapPandaNo ratings yet

- MDR 2 DRH 4189340300i Uk 6852 Taptin0Document26 pagesMDR 2 DRH 4189340300i Uk 6852 Taptin0wan jspNo ratings yet

- A MODIFIED PENG ROBINSON EQUATION OF STATE FOR ELV 20519 FTP PDFDocument16 pagesA MODIFIED PENG ROBINSON EQUATION OF STATE FOR ELV 20519 FTP PDFalex rene cardonaNo ratings yet

- A 496 - 97 Qtq5ni05n0ffmqDocument5 pagesA 496 - 97 Qtq5ni05n0ffmqyohan172002No ratings yet

- 2019 AWRF WRSLGDocument24 pages2019 AWRF WRSLGElias JarjouraNo ratings yet

- Xenon Test Chambers: We Make Testing SimpleDocument9 pagesXenon Test Chambers: We Make Testing SimpleAman KumarNo ratings yet

- ASSIG202Document2 pagesASSIG202Carolina Ticona VargasNo ratings yet

- Mathematics January 2020 Paper 2Document34 pagesMathematics January 2020 Paper 2Tamera Green100% (1)

- Hitachi Air Cooled Screw Chiller Catalog PDFDocument12 pagesHitachi Air Cooled Screw Chiller Catalog PDFmoceNo ratings yet

- MATH223 Lecture7 With SolutionDocument17 pagesMATH223 Lecture7 With SolutionRaymond AbesamisNo ratings yet

- Circumferential Road, Bitoon-Aguada, Ozamiz City, Misamis OccidentDocument3 pagesCircumferential Road, Bitoon-Aguada, Ozamiz City, Misamis OccidentMaria Angelica Rodriguez AlonsoNo ratings yet

- Screenshot 2023-02-18 at 14.55.23Document35 pagesScreenshot 2023-02-18 at 14.55.23Christopher SleimanNo ratings yet

- Questions Bank On ElectrostaticsDocument2 pagesQuestions Bank On Electrostaticsashok PradhanNo ratings yet

- Einstein's Genealogy.Document6 pagesEinstein's Genealogy.lennysanchezNo ratings yet

- FALLSEM2020-21 MEE1003 TH VL2020210103023 Reference Material I 31-Jul-2020 First Law of Thermodynamics - IIDocument52 pagesFALLSEM2020-21 MEE1003 TH VL2020210103023 Reference Material I 31-Jul-2020 First Law of Thermodynamics - IIRahul rajelliNo ratings yet

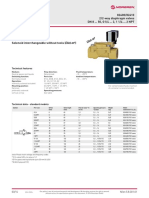

- 82400/82410 2/2-Way Diaphragm Valves DN 8 ... 50, G1/4 ... 2, 1 1/4 ... 2 NPT High Flow Rate Damped Operation Functional Compact Design Solenoid Interchangeable Without Tools (Document4 pages82400/82410 2/2-Way Diaphragm Valves DN 8 ... 50, G1/4 ... 2, 1 1/4 ... 2 NPT High Flow Rate Damped Operation Functional Compact Design Solenoid Interchangeable Without Tools (MoamenNo ratings yet

- Castle - A Theory of Normal MoveoutDocument17 pagesCastle - A Theory of Normal MoveoutNeil BariiNo ratings yet

- F 835M - 03 - Rjgznu0Document6 pagesF 835M - 03 - Rjgznu0krutikNo ratings yet

- Cone Penetration of Lubricating Grease Using One-Quarter and One-Half Scale Cone EquipmentDocument8 pagesCone Penetration of Lubricating Grease Using One-Quarter and One-Half Scale Cone EquipmentAhmedNo ratings yet

- Amineterephthalic AcidDocument3 pagesAmineterephthalic AcidVictor SeabraNo ratings yet

- Atomic Number, Mass Number, and IsotopesDocument24 pagesAtomic Number, Mass Number, and IsotopesB.Ed. Wing SundargarhNo ratings yet

- Selective Recovery of Phosphorus and Manganese From Steelmaking Slag by Carbothermic ReductionDocument4 pagesSelective Recovery of Phosphorus and Manganese From Steelmaking Slag by Carbothermic ReductionBinh NghiemNo ratings yet

- Today:: + Cos + Sin ,:, Arg Arg + Arg +Document20 pagesToday:: + Cos + Sin ,:, Arg Arg + Arg +IbrahimNo ratings yet

- VW 50136 en 2018-03Document10 pagesVW 50136 en 2018-03xu zhangNo ratings yet

- Paramagnetic Lab - Farheen & MowDocument8 pagesParamagnetic Lab - Farheen & MowFarheenNo ratings yet

- Prof DontwiDocument122 pagesProf DontwiRexford AmponsahNo ratings yet

- Poster Tesis FIKRI FAHMIDocument2 pagesPoster Tesis FIKRI FAHMIGeofisika UINo ratings yet