Professional Documents

Culture Documents

How to Control and Maintain GSM for Knitted Fabrics

Uploaded by

দীপ্তি হুমাইরাOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How to Control and Maintain GSM for Knitted Fabrics

Uploaded by

দীপ্তি হুমাইরাCopyright:

Available Formats

GSM means gram per square meter.

It is very important

factor for both knitting and dyeing section. If we can’t

properly maintain GSM according to buyer’s requirements

then he may not accept produced goods.

We can control GSM by controlling stitch length (SL)

which is controlled by VDQ pulley diameter.

If we increase diameter of VDQ pulley then increase yarn

feed, stitch length and decrease GSM and vice verse.

Diameter of Yarn feed S.L GSM

VDQ Pulley

↑ ↑ ↑ ↓

↓ ↓ ↓ ↑

Calculation:

CPI × WPI × Stitch Length (mm) × 0.91 Yarn Count CPI= Course Per Inch WPI= Wells Per Inch

Some points are needed to maintain for high quality fabric:

M/cs are separated from m/c to m/c by using poly bag or fabric.

Knitting floor should be cleaned for high quality fabric

Operator should be skilled.

Good quality fabric depends on good quality yarn.

Before production m/c is oiled and greased properly

G.S.M, Stitch length, Tensions must be controlled.

Grey Fabrics are checked by 4- point system

Changing of GSM:

Major control by QAP pulley.

Minor control by stitch length adjustment.

Altering the position of the tension pulley changes the G.S.M. of the fabric. If pulley moves

towards the positive direction then the G.S.M. is decrease. And in the reverse direction G.S.M will

increase.

You might also like

- Indian Journal Examines Spirality in Weft-Knitted FabricsDocument5 pagesIndian Journal Examines Spirality in Weft-Knitted FabricsObak Prithibi100% (1)

- Agrotextiles: Submitted By: Hema Upadhayay I.D:34594 Dept. of Clothing and TextilesDocument31 pagesAgrotextiles: Submitted By: Hema Upadhayay I.D:34594 Dept. of Clothing and Textilesদীপ্তি হুমাইরাNo ratings yet

- Defects and Quality Optimisation of Core-Spun Yarn Containing SpandexDocument9 pagesDefects and Quality Optimisation of Core-Spun Yarn Containing SpandexMohammed Atiqul Hoque Chowdhury100% (1)

- Evaluation of yarn diameter and its effect on fabric qualityDocument8 pagesEvaluation of yarn diameter and its effect on fabric qualitySabeeh Ul HassanNo ratings yet

- Textile Calculations and EquationsDocument1 pageTextile Calculations and Equationsarsh thakurNo ratings yet

- Recent Development of Circular KnittingDocument32 pagesRecent Development of Circular KnittingHarshitha A100% (1)

- Determining Fabric Quality: Prepared By: Riza Leigh I. FiguesDocument55 pagesDetermining Fabric Quality: Prepared By: Riza Leigh I. FiguesRizaLeighFiguesNo ratings yet

- Tetilecalculations 140802091855 Phpapp02Document86 pagesTetilecalculations 140802091855 Phpapp02Sobia Waseem100% (3)

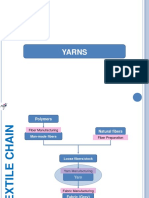

- Yarns: Types and CharacteristicsDocument32 pagesYarns: Types and Characteristicskartika ranaNo ratings yet

- Construcction of Woven FabricDocument8 pagesConstrucction of Woven FabricAdii ChatthaNo ratings yet

- Weaving Calculation & Useful Formulas:: 1. CountDocument13 pagesWeaving Calculation & Useful Formulas:: 1. CountMusa Miah0% (1)

- Efficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionDocument4 pagesEfficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionElias KhalilNo ratings yet

- 2.1 Quailty Control in SpinningDocument31 pages2.1 Quailty Control in SpinningRounoque ShishirNo ratings yet

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- Draw FrameDocument50 pagesDraw FrameDev Narayan KushwahaNo ratings yet

- Factors Affecting Production in Spinning MillDocument38 pagesFactors Affecting Production in Spinning MillSivam Ravi67% (3)

- Training Report of Gcti Tarinees MS WORDDocument55 pagesTraining Report of Gcti Tarinees MS WORDAakash NagpalNo ratings yet

- Airjet PracDocument12 pagesAirjet PracJunaid SuhailNo ratings yet

- Yarn Realization and Control of Waste in SpinningDocument16 pagesYarn Realization and Control of Waste in SpinningRameshkumar SNo ratings yet

- New Development of A Swatch Given by BuyerDocument11 pagesNew Development of A Swatch Given by BuyerNaimul Hasan0% (1)

- Knitting ScienceDocument24 pagesKnitting ScienceKathirrveluSubramainanNo ratings yet

- Yarn FaultsDocument69 pagesYarn Faultssitu_tex8594100% (2)

- Study of Loop Formation Process On 1x1 V-Bed Rib Knitting MachineDocument12 pagesStudy of Loop Formation Process On 1x1 V-Bed Rib Knitting MachineIAEME PublicationNo ratings yet

- Unit - IiDocument27 pagesUnit - IiJoseph KuruvilaNo ratings yet

- Ornamantation in SelvagesDocument18 pagesOrnamantation in SelvagesSatish Kulkarni100% (1)

- Fabric IV PPT MahasinDocument12 pagesFabric IV PPT MahasinS.m. MahasinNo ratings yet

- Yarn Defect-Final - ReadyDocument47 pagesYarn Defect-Final - Readyparash rajNo ratings yet

- Fabric Check ProcedureDocument7 pagesFabric Check ProcedureEleni LanaraNo ratings yet

- Analysis of Weft Knitted Jersey FabricDocument6 pagesAnalysis of Weft Knitted Jersey FabricNaimul HasanNo ratings yet

- Patterning in Weft Knitting: Waqas AshrafDocument33 pagesPatterning in Weft Knitting: Waqas AshrafHifza khalidNo ratings yet

- Weft Knitting (Suza)Document16 pagesWeft Knitting (Suza)Suza Ahmed AuporboNo ratings yet

- Welcome To Our PresentationDocument40 pagesWelcome To Our PresentationAbdul AzizNo ratings yet

- Elements of Circular KnittingDocument5 pagesElements of Circular KnittingSanika JoshiNo ratings yet

- Nannu Spinning Mills Quality Control Melange Yarn ProcessDocument10 pagesNannu Spinning Mills Quality Control Melange Yarn ProcessAhmed LikhonNo ratings yet

- Quality of Yarn ControlDocument12 pagesQuality of Yarn Controlsabbir2029_310230403No ratings yet

- Textile Technology:: "Spinning": Rings and TravellersDocument10 pagesTextile Technology:: "Spinning": Rings and TravellersKuldeep SinghNo ratings yet

- Spinpact Fine Tuning HandbookDocument10 pagesSpinpact Fine Tuning Handbookselvakumar100% (1)

- SelvedgeDocument16 pagesSelvedgejony_nsu022No ratings yet

- Process Parameter in Blow RoomDocument19 pagesProcess Parameter in Blow RoomakmaluzirNo ratings yet

- Fabric Spec KnittedDocument2 pagesFabric Spec KnittedakshatgargmoderniteNo ratings yet

- Projectile Loom Projectile Weaving Machines Working Procedure of Projectile LoomDocument3 pagesProjectile Loom Projectile Weaving Machines Working Procedure of Projectile LoomObak PrithibiNo ratings yet

- Improving productivity of ring framesDocument8 pagesImproving productivity of ring framesAmrit virkNo ratings yet

- I K G TDocument37 pagesI K G TAbhishek kushwahaNo ratings yet

- Fabric Booking, Accessories Booking & Production Planning StepsDocument12 pagesFabric Booking, Accessories Booking & Production Planning StepsKhandaker Sakib FarhadNo ratings yet

- Prevention of BarreDocument5 pagesPrevention of BarreKavi DhingraNo ratings yet

- Yarn EvennessDocument8 pagesYarn EvennessMuhammad Qamar TusiefNo ratings yet

- Spirality of Single Jersey Knitted FabricDocument13 pagesSpirality of Single Jersey Knitted FabricKazi Saiful IslamNo ratings yet

- Pattern and Selection DevicesDocument18 pagesPattern and Selection DevicesAtaur RahmanNo ratings yet

- Modern Developments in WeavingDocument13 pagesModern Developments in WeavingRakeahkumarDabkeyaNo ratings yet

- Chapter-7 - Knitting DerivativesDocument39 pagesChapter-7 - Knitting DerivativesMD Shakil Khan0% (1)

- Spinning Process Flow ChartDocument5 pagesSpinning Process Flow ChartShantnu MittalNo ratings yet

- Single Jersey FabricDocument4 pagesSingle Jersey FabricMrcr Kapzap0% (1)

- Raymond UCO DenimDocument25 pagesRaymond UCO DenimChaitanya Gajbhiye100% (1)

- Cut & sew knitwear manufacturing processDocument4 pagesCut & sew knitwear manufacturing processshponNo ratings yet

- Modern Cotton Spinning Machinery, Its Principles and ConstructionFrom EverandModern Cotton Spinning Machinery, Its Principles and ConstructionNo ratings yet

- Assignment On How We Can Increase The GSMDocument4 pagesAssignment On How We Can Increase The GSMZAyedNo ratings yet

- Increase Fabric GSM: 6 Key Factors (38 charactersDocument5 pagesIncrease Fabric GSM: 6 Key Factors (38 charactersZAyedNo ratings yet

- This Is Your Presentatio N TitleDocument28 pagesThis Is Your Presentatio N TitleMedia GuruNo ratings yet

- Business Assignment Cover Page 4Document1 pageBusiness Assignment Cover Page 4দীপ্তি হুমাইরাNo ratings yet

- Industrial Report On Opex and Sinha Textile Group: Nasif ChowdhoaryDocument95 pagesIndustrial Report On Opex and Sinha Textile Group: Nasif Chowdhoaryদীপ্তি হুমাইরাNo ratings yet

- Business Assignment Cover Page 4Document1 pageBusiness Assignment Cover Page 4দীপ্তি হুমাইরাNo ratings yet

- This Is Your Presentatio N TitleDocument28 pagesThis Is Your Presentatio N TitleMedia GuruNo ratings yet

- OpheliaDocument28 pagesOpheliaSila Maribel Laboriano MiliânNo ratings yet

- On Circular Knitting Machine Parts and FunctionsDocument21 pagesOn Circular Knitting Machine Parts and Functionsদীপ্তি হুমাইরাNo ratings yet

- Knitting:: Differences in Warp and Weft KnittingDocument22 pagesKnitting:: Differences in Warp and Weft KnittingjennygraceshaliniNo ratings yet

- Knitting:: Differences in Warp and Weft KnittingDocument22 pagesKnitting:: Differences in Warp and Weft KnittingjennygraceshaliniNo ratings yet

- Belal 151128152242 Lva1 App6892Document203 pagesBelal 151128152242 Lva1 App6892দীপ্তি হুমাইরাNo ratings yet

- Reactive Dye Mechanism and PropertiesDocument19 pagesReactive Dye Mechanism and Propertiesদীপ্তি হুমাইরাNo ratings yet

- Wetprocessingtechnology Internshipreport 151230113524 PDFDocument258 pagesWetprocessingtechnology Internshipreport 151230113524 PDFদীপ্তি হুমাইরাNo ratings yet

- Professional Institute of Science & Fashion Technology (PISFT)Document58 pagesProfessional Institute of Science & Fashion Technology (PISFT)দীপ্তি হুমাইরাNo ratings yet