Professional Documents

Culture Documents

Textile Calculations and Equations

Uploaded by

arsh thakurCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Textile Calculations and Equations

Uploaded by

arsh thakurCopyright:

Available Formats

) * +

SlideShare Explore Search You

! Share " Like # Save

105,838

Textile Calculations and Equations views

Md. Mazadul Hasan Shishir 328 uploads $

Published on Aug 2, 2014

Production = no. of needle x no of feeder x RPM x stitch ...

length/ yarn count %

Published in: Education

& Recommended

A note of textile terms and

definitions

3 years ago

20,133 views

View in full-screen with the

SlideShare app

Designed for iOS 8

DyeManager

10 years ago

3,437 views

Yarn printing (Space dyeing)

6 years ago

4,628 views

Textile software

4 years ago

4,584 views

Scouring

6 years ago

43,367 views

Workshop on fabrics

manufacturing technology

6 years ago

3,007 views

Textile coloration

6 years ago

6,763 views

' Textile Calculations and Equations

1. TEXTILE CALCULATION & EQUATION

2. Name : MAZADUL HASAN SHESHIR ID: 2010000400008

Batch: 13th Batch (Session 2009-2013) Department: Wet

Processing Technology Email: mazadulhasan@yahoo.com Blog:

www. Textilelab.blogspot.com Southeast University Department

of Textile Engineering PREPARED BY ©right

3. Spinning Calculation and Equation

4. Basic Conversions (Spinning) No Length Weight Time 1. 1 in

= 2.54 cm 1 lb = 7000 gr 1 min = 60 sec 2. 1 yd = 36 in 1 lb =

16 oz 1 hr = 60 min 3. 1 m = 1.0936 yd 1 oz = 437.5 gr 1 shift

= 8 hr 4. 1 Hk = 840 yd 1 kg = 2.2046 lb 1 day = 24 hr 5. 1 Hk

= 7 leas 1 bag = 100 lb 1 day = 3 shifts

5. Count Conversion Table (Spinning) Ne Nm Tex Grex Denier

Ne= 1 xNe 0.5905 xNm 590.5 /Tex 5905 /Grex 5315 /Den

Nm= 1.693xNe 1 xNm 1000 /Tex 10,000/Grex 9000 /Den Tex=

590.5 /Ne 1000 /Nm 1 xTex 0.1 xGrex 0.111 xDen Grex= 5905

/Ne 10,000 /Nm 10 xTex 1 xGrex 1.111 xDen Denier= 5315

/Ne 9000 /Nm 9 xTex 0.9 xGrex 1 xDen

6. Draft & TPI Formulas

7. Efficiency Percentage (Spinning) Cleaning Efficiency (%)

Efficiency (%) Twists per inch

8. PRODUCTION CALCULATION FORMULAS

9. PRODUCTION FORMULAS

10. Yarn Count in Direct system System Unit weight Unit length

Uses Tex Grams 1,000m Polyester Denier Grams 9,000m Lycra

D-Tex Grams 10,000m Lycra Pounds/Spyndle Pounds

14400yds Jute Yarn Count in Indirect system System Unit

weight Unit length Uses English (Ne) 1 lb 840 yds Cotton yarn

Metric (Nm) 1 kg 1 km Cotton yarn Worsted 1 lb 560 yds

Worsted yarn Woolen 1 lb 256 yds Woolen yarn

11. Excellence of fiber quality by combing:

12. Fabric (Knitting & Weaving) Calculation and Equation

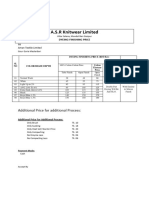

13. SIZING

14. Calculation:

15. Required Chemical &no. of Mixing of Sizing Recipe:

16. Production is calculated in accordance with the following

equation-

17. Production calculation: 1. Production = no. of needle x no

of feeder x RPM x stitch length/ yarn count Production per shift

in KG at 100% efficiency Where, Ks = knitting constant Count =

linear density of yarn GSM = gm per square meter Another

formulae is : Stitch length = (Tex × Ks) / GSM Ks is a constant.

Its value is different for different fabric structure and fabric type.

Ks is calculated and estimated as below: Ks = (GSM x Stitch

length) / Tex

18. Production calculation: Fabric type Color Value of Ks Single

jersey Average 19.55 Single lacoste Average 22.4 Double

lacoste Average 22.75 Polo pique Average 25 Plain interlock

Average 39.3 1 X 1 rib Light 24.5 1 X 1 rib Average 26.5 Ks =

(GSM x Stitch length) / Tex

19. Relation between yarn count and m/c gauge seen in

different m/c.:

20. GSM Calculation

21. DIFFERENT FABRIC GSM AND THEIR REQUIRED YARN

COUNT S/J without lycra - Fabric G.S.M Yarn Count 110 - 120

40 S – 36 S 120 - 130 36 S - 32 S 130 - 140 32 S – 28 S 140 -

150 28 S 150 - 160 26 S 170 - 210 24 S Rib without lycra -

Fabric G.S.M Yarn Count 180 - 190 36 S - 32 S 190 - 200 30 S

200 - 215 28 S 215 - 230 26 S 230 - 250 24 S 250 - 300 24 S

22. Interlock without lycra - Fabric G.S.M Yarn Count 200 - 220

34 S 220 - 230 32 S 230 - 250 30 S 250 - 300 26 S Lacoste

without lycra - Fabric G.S.M Yarn Count 180 - 190 30 S 190 -

210 28 S 210 - 230 26 S 230 – 250 26 S 40D Lycra Rib -

Fabric G.S.M Yarn Count 230 - 240 32 S 240 - 250 30 S 250 -

280 26 S 280 - 300 24 S 40D Lycra S/J – Fabric G.S.M Yarn

Count 180 - 190 34 S 190 - 210 32 S 210 - 220 30 S 220 –

240 28 S 240 - 250 26 S DIFFERENT FABRIC GSM AND

THEIR REQUIRED YARN COUNT

23. Yarn Dyeing Calculation and Equation

24. Production Calculation of Yarn singeing machine: Length =

Count * Weight = Count * Weight * 840 yards = (Count * Weight

* 840) / rpm yards per minute = (Count * Weight * 840) / rpm *

60 * 8 * 3 yards per day = (Count * Weight * 840) / rpm * 60 * 8

* 3 * 0.914 =……X…meter/day.

25. Production Calculation of reeling machine:

26. Production Calculation of hank to cone winding machine:

Machine Parameter Yarn quality Speed (rpm) 58/2, 60/2 450 All

single count 500 to 550 Length = Count Weight = Count *

Weight 840 yards = (Count Weight 840) / rpm yards per

minute = (Count Weight 840) / rpm 60 8 3 yards per

day = (Count Weight 840) / rpm 60 8 3 0.914 =……

X…meter/day.

27. GSM Calculation: WPI = 32 CPI = 45 Stitch length = 3 mm

Yarn Count = 20’S Ne

28. No. of Needle = π × Machine Diameter (D) × Machine

Gauge (N) = 3.1416 × 30 × 24 = 2262 Yarn Count = 30/1 Ne

No. of Feeder = 96 Machine RPM = 28 Stitch length = 3 mm

Efficiency = 85% = 0.85 Shift = 8 hr. = 8 × 60 = 480 min

Production Calculation Of Yarn Dyeing Machine : Production of

the machine is 146.407 Kg/Shift. Note: If any parameter in this

calculation is changed then production capacity per shift will be

changed.

29. Package Density Calculation (Yarn Dyeing): Formula

30. Density Calculation for Several Counts (Yarn dyeing):

1**Before Pressing • Yarn Quality: 30/1 cc • Package Height

(H) = 162mm = 16.2cm • Total Package Dia (D1) = 162mm =

16.2cm • Total Package Weight (W1) = 1.38kg = 1380gm •

Spring Weight (W2) = 0.185kg = 185gm • Spring Dia (D2) = 65

mm = 6.5cm

31. 2 **After Pressing Yarn Quality: 30/1 cc Package Height (H)

= 145mm = 14.5cm Total Package Dia (D1) = 165mm =

16.5cm Total Package Weight (W1) = 1.38kg = 1380gm Spring

Weight (W2) = 0.185kg = 185gm Spring Dia (D2) = 65 mm =

6.5cm **So we can sure that after pressing for every count,

yarn package density will be increase. Density Calculation for

Several Counts (Yarn dyeing):

32. Length Calculation in Package: To maintain the constant

package density same length of yarn should be wound to all

the packages of a batch or lot. The dyeing machine capacity is

calculated on weight, so it is necessary to maintain the uniform

weight throughout the packages. To do this for a definite count

of yarn following calculation is followed, In this machine length

is pre selected. For different count of yarn different length of

yarn is pre selected. This is due to maintain the constant

package weight and package density.

33. Package density Calculation We know package density ρ

=mass (m)/volume (v) gm/cc Volume= π (R2-r 2) h R= outer

radius of package R= inner radius of package h= height of

package Now we consider a sample of 40/1 cotton yarn whose

R=4.138 r= 1.59 h=15.24 Mass m=1000gm So package

density ρ=1000/π (4.1382-1.592)15.24 gm/cc =1.433 gm/cc

Production calculation: We know production= speed (m/min)

×60×24 ×1.09/(840×40×2.2045) Kg/day/head When speed is

800m/min at 80% efficiency Production=800×60×24×1.09/

(840×40×2.2045)kg/day/head =10.5976kg/day/head Total

production=10.5976×54×12kg/day =6867.2448kg/day

34. Production calculation of RF Dryer : Length of RF Dryer =

13m At 28rpm it takes 21 min 9 sec to pass this length Along

this length it can accommodate 416 package 416kgs So at 21

min9sec or 1269sec it can dry 416kgs So in 1hr or 3600sec it

can dry = 416×3600/1269 kg/hr = 1180.14 kg/hr So

Production per day = 1180.14×24kg = 22658.688 kg = 22.66

tons Production calculation of RF Dryer

35. Knit Dyeing Calculation and Equation

36. Calculations related to batch section: Now, when a gram

per linear meter is low then meters per chamber will be more.

Thus, fabric loading should be reduced to avoid jamming in the

winch. In this case 80-85% fabric loading is given. But when

gram per linear meter is more then rope length will reduce and

in this case up to 90% fabric loading can be given.

37. Calculating the chamber loading In the following table are

listed general recommendations covering rope cycle times and

speeds for a wide range of fabrics: Fabric Rope cycle times in

minutes (Cycle Time) Rope circulation speed m/min (Reel

speed) Knit fabric PES unfixed 1 250 PES heat set 1-1.5 200

PC 1-2 250 Co - reactive 2-3 225-275

38. Preparation and storage of stock dyes and chemicals

Available stock solution: 1. Red-0.1%, 0.5%, 1%, 2% 2. Yellow-

0.1%, 0.5%, 1.0%, 2.0%, 3. Blue- 0.1%, 0.5%, 1.0%, 2.0%.

Preparation: To prepare 0.1% stock solution, it necessary to

mix 0.1 gm dye with 100cc water. To prepare 0.5% stock

solution, it necessary to mix 0.5 gm dye with 100cc water. To

prepare 1.0% & 2.0% stock solution similar procedure is

followed. To prepare 10% stock solution of soda ash, it

necessary to mix 10 gm soda with 100cc water. SHADE %

STOCK SOLUTION % 0.0001-0.009 0.1 0.10-0.99 0.5 1-1.99

1 2-3.99 2 4 ( or above) 4 Stock solution preparation:

39. Stock Solution Making Procedure (Dyeing lab) For solid, X

gm chemicals/dyes/auxiliaries in the 100 ml water is called x%

stock solution. For liquid, X ml/cc chemicals/dyes/auxiliaries in

the (100 - x ml/cc) water is called x% stock solution.

Conversion formula from percentage to g/l is as g/l = Required

amount (%)× 10

40. Recipe Calculation

41. Dyes and chemicals measuring formula for laboratory: The

amount of dye solution (ml) is calculated as follow – The

amount of chemical soln (ml) is measured as follow –

42. Fabric Type GSM Pump Speed % Reel Speed(MPM) Single

Jersey Up to 140 80 250 140 – 180 85 230 180 – above 90

210 Polo Pique, Back Pique & Bubble Knit Up to 160 85 280

160 – 200 90 260 220 – above 90 240 Interlock Up to 180 85

260 180 – 220 90 240 220 – above 90 220 Machine Setup On

The Basis Of Fabric Type & GSM

43. MONTHLY EFFICIENCY OF KNITTING FLOOR: Daily

production – 6500 kgs. Approx. Daily production capacity –

10000 kgs approx. So, monthly production – 6500 x 30 kgs.

Monthly production capacity – 10000 x 30 kgs. So, Monthly

production efficiency = (6500x30x100)/ (10000x30) % = 65%

44. Garments Calculation and Equation

45. COSTING OF THE PRODUCT: Let price of yarn is $ 3.00/

kg. Process loss of yarn for knitting (10%) = $0.30 Knitting

fabric cost = $3.30 Cost of dyes & chemicals = $2.50 Process

loss for dyeing (12%) = $0.30 Dyed fabric cost = $ 6.10

Packing cost = $0.05 Production cost of fabric=$6.15 Fabric

price (with 25% margin) =$7.79 Fabric consumption/ doz. =

(Body length + Sleeve length +10) x Chest length x 2 x GSM

x12 /10000000

46. Garments specification: Body length=78 cm Sleeve

length=33 cm Chest length=62 cm GSM=210 Fabric

consumption/ doz. = {(78+33) x62x2x210x12}/ 10000000 =

3.469 kg Fabric consumption/doze (with 10% wastage) =

3.816 kg Body fabric cost / doz. =$(7.79x 3.816) = $29.73

Cost of collar& cuff/doz = $ 4.00 Cost of Trims=$ 2.25 Cost of

Trims (with 5% Process loss) = $2.36 Production Cost of

Garments/ doz=$36.09 Garments Price/doz (with 25% Profit)

=$45.12 COSTING OF THE PRODUCT:

47. Costing of Men’s shirt Fabric consumption for a dozen of

shirt π × L ═ size of basic shirt. Width of body of shirt ═ 1/2

chest ═ 24"+1"(sewing allowance) ═ 25" Body length ═ 32"+1"

(sewing allowance) ═ 33" Sleeve length ═ 23"+2.5(cost) +1.5"

(sewing allowance) ═ 27" Consumption of a body shirt: ═{1/2

chest× (body length) ×2} / 36× fabric width. (Sq. inch)

═25"×33"×2 (Sq. inch ). {Let assume fabric width 25"effective

width ═25"−1" ═ 24"} Fabric length ═25×33×2 / 44 inch

48. Fabric consumption ═25×33×2 / 44×36 yds Consumption

of sleeve ═ (length of sleeve × width sleeve) ×2 sq. inch

═27"×24"×2" (Sq. inch) Fabric consumption in length width ═

27×24×2 / 44×36 sq. inch Total fabric consumption of one

dozen shirt ═ [(25×33×2 / 44×36 + / 27×24×2 / 44×36) ×2+

wastage of 8%] ═ 22.75 yds + 8% wastage ═24.6 yds Sewing

threads consumption: It is calculated by measuring the total of

different kind of seam. Normally sewing threads consumption

per shirt , 120m. So, sewing threads consumption per dozen, ═

120 × 12 ═ 1440m Costing of Men’s shirt

49. Costing of T- shirt Fabric Type :Single jersey G.S.M :180

Yarn count :24/1 Measurement of Garments: Body length : 54

cm Chest length : 43 cm Sleeve length : 15 cm Fabric

Consumption = {(Body length + sleeve length + allowance) *

(Chest length + 3)} * 2 /10,000 * G.S.M / 1000 * 12 * 10 % (+) =

{( 54 + 15 + 10 ) * ( 43 + 3 )} * 2 / 10,000 * 180 / 1000 * 12 *

10% (+) =1.72 kg =1.72* 0.18 = 1.90 kg / doz. Costing Fabrics

cost : 17.10 Cost of making : 4.5 Print cost : 3.5 Lab cost :

0.20 Accessories cost : 2.5 Washing cost : 1 Total = $ 28.80 /

Doz. = $ 2.40 / pcs.

50. How can we get Fabric Consumption & Fabrics Price? Say:

** Body Length = 85, Chest Width = 52, Sleeve Length = 44 &

G.S.M = 240 Fabric Description: 100 % Cotton S/J Fabric

Need = [(85+5+44+5) 52+5] 2 12 240/10000000+10%

= [(90+49) 57] 2 12 240/10000000+10% = (139 57) 2

12 240/10000000+10% = 7923 12 240/10000000+10%

= 45636480/10000000 + 10% = 4.563648 +10% = 4.563648

+ .4563 = 5.02 Kgs Fabrics Say Per Kgs Price: US$ 6.00/Kgs

51. Poly bag costing : Total Length X width X Thickness =

36cm X 28cm X 10mm = 10080/72000 = 0.14pcs/lb Fabrics

Price: Total Fabric Need 5.00 Kg $ 6.00 = $ 30.00 Trim/

Accessories (Minimum Charge) = $ 2.50 Cutting & Making

Charge (C.M) = $ 5.00 Printing Charge (If any) = $ 0.00

Embroidery Charge (If any) = $ 0.00 Buying Commission (If

necessary) 5% = $ 1.97 Final/Total = $ 39.47/12 Costing of a

garment: Fabric cost + Accessories cost + Trimming cost +

Production cost + Transport cost + Commission + Profit

52. Consumption of T-Shirt: Equation: {(Body length + Sleeve

length) Chest} 2 GSM 10000 1000 5000 Solution:

Body Length = 50 + 6 (Allowance) = 56 cm Sleeve Length = 15

+ 3 (Allowance) = 18 cm Chest = 37 + 3 (Allowance) = 40 cm

GSM = 180 cm = {(56 + 18) 40} 2 180 10000 1000

5000 = 532.8 kg.

53. Consumption of Collar: Equation: {(Neck width + Front neck

drop) collar depth} 2 GSM 10000 1000 5000

Solution: Neck width =22 2 = 44 cm Front neck drop =5 cm

Collar depth =2.5 cm 2 = 5 cm GSM = 240 = {(44 + 5) 5}

2 140 10000 1000 5000 = 58.8 kg. Total = 532.8 +

58.8 kg = 591 kg

54. Collar & Cuff measurements Size Collar measurement (cm)

Cuff measurement (cm) S 40 x 9 40 x 3.5 M 42 x 9 40 x 3.5 L

44 x 9 40 x 3.5 XL 46 x 9 40 x 3.5 XXL 48 x 9 44 x 3.5 XXXL 50

x 9 44 x 3.5

55. Consumption of bottom part: Equation: Length*

(width*4)*G.S.M÷10000÷1000*12 Length=53=8=2=63cm

Width= 18*4+6= 78cm G.S.M= 260 Solution

[(63*78*260)÷10000÷1000*12 =1.53kgs

56. Consumption of Pocket: Equation:

Length*width*G.S.M÷10000÷1000*12 Length=11+2=13cm

Width=10cm G.S.M= 260 Solution (13*10)

*260÷10000÷1000*12 =0.04056kg Total= 1.53+0.04056

1.5705kg

57. Costing process: Finish fabric cost: (Yarn price + Knitting

cost + dyeing cost) Body fabric cost: (Total fabric consumption

+ Total yarn consumption) Cost of making

(CM):……………………………$ Accessories

cost:…………………………………..$ Overhead

cost………………………………………$ Others

cost:………………………………………….$ Buyer

commission:……………………………….$ Total

cost..................................................$ Costing process: PRICE

OF THE PRODUCT: Generally price of product is determined by

the required profit adding to the total expenses. So, Price of

products = (Direct expenses + Indirect expenses + Factory

Overhead) + Required profit

58. MARKER EFFICIENCY: The marker planner measures his

success by the efficiency of the marker plan. The following

formula is used to measure the efficiency: Marker

efficiency=Area of the pattern in the marker plan/ Total area of

the marker plan X 100%. MARKER EFFICIENCY:

59. STANDARD TIME = Normal time + Allowances = Normal

time + (Normal time ×Allowances) = NT (1+ Allowances). In

garments production world, the terms SMV or SAM used

frequently. SMV stands for Standard Minute Value. SAM for

Standard allocated minute or Standard Allowed Minute. SMV

CALCULATION: SMV calculation of a basic T-shirt from a time

study sheet of a garments industry. Following formulas are use-

Normal time = (Average observed time) × (Performance rating

factor). SMV (Standard Minute Value) = Basic Time +

(Allowances × Basic time). = Basic Time× (1+ Allowance).

Allowances are assumed for this calculation is 20%. SMV

60. SMV Target Production /Hour = (No Of worker -1) x 60 /

SMV SMV= standard Mean Value (the Time Required to

Complete garments by sewing ) SMV=( Basic time +Allowance )

61. To select sewing thread, thread size or number is very

important. The number which is used to express the fineness of

a sewing thread is called sewing thread number or ticket

number. It has 2 system as follows- Cotton system : It is

derived from English cotton system. Cotton ticket number in Ne

= ( Yarn count in Ne / Number of ply ) x 3 Metric system : It is

derived from Metric count system. Ticket number in Nm = (

Yarn count in Nm / Number of ply ) x 3 sewing thread number

or ticket number

62. Equation For Find Yarn Count (If GSM is Known) Single

Jersey = 4300 /GSM Pique = 5200 / GSM Fleece = 7200 /

GSM Interlock = 7200 / GSM 1x1 rib = 6000 / GSM

Locoest =5500 / GSM 2x2 rib = 6250 / GSM Terry = 6240 /

GSM

63. Find out Required Yarn Count (If GSM is Known) Equation :

S/j Ne = (0.141x GSM) + 50.22 Pique Ne = (0.146x GSM) +

57.16 Double Lacost Ne = (0.167 X GSM) + 64.36 1X1 Rib Ne

= (0.123X GSM) + 54.57 Interlock = (0.206X GSM) + 80.56

Lycra 1X1 Rib = (0.119 X GSM) + 59.12 Lycra 2X2 Rib =

(0.108X GSM) + 56.62

64. Conversion of (GSM Equation ) Kg To Yards Equation : =

GSM / 39.37 X 36 X fabric Width =Result .Kg =1000/ Result

.yds [It is converted Kg To yards ] Per Yards Fabric price

Equation : = GSM / 43” X Width / 1000 X Per kg Prize =Result .

[This the Equation define per yards Fabric price ]

65. Conversion of (GSM Equation ) Yards To meter Equation : =

Length X 36 X 2.54 /1000 =Result [It is converted yards to

Meter ] Meter To Yards Equation : = Length /36 / 2.54 X 1000

=Result [ It is converted Meter To yards ]

66. Conversion of (GSM Equation ) Find Out How many Yds /

Kg Equation : = 714//GSM =Result (yds in Kg) [Only For

58’’/60’’ Width] Price/Yards Equation : = GSM /43 / 2.54 X

Width =Result / 1000 X Price = price/yds

67. Textile Testing Calculation and Equation

68. Four point grading system Size of defects Penalty 3 inches

or less 1 point Over 3 inch but not over 6 inch 2 point Over 6

inch but not over 9 inch 3 point Over 9 inch 4 point Four point

grading system

69. Shrinkage Test:

70. Spirality test:

English Español Português Français Deutsch

About Blog Terms Privacy Copyright

You might also like

- Construcction of Woven FabricDocument8 pagesConstrucction of Woven FabricAdii ChatthaNo ratings yet

- Tetilecalculations 140802091855 Phpapp02Document86 pagesTetilecalculations 140802091855 Phpapp02Sobia Waseem100% (3)

- FMS-1 Module 2 Topic 3 Cost EstimationDocument19 pagesFMS-1 Module 2 Topic 3 Cost EstimationSrishti SanyalNo ratings yet

- Introduction to Nishat Group's Textile OperationsDocument60 pagesIntroduction to Nishat Group's Textile OperationsRana AtiqueNo ratings yet

- Quality of Yarn ControlDocument12 pagesQuality of Yarn Controlsabbir2029_310230403No ratings yet

- Textile Raw Material Inspection GuideDocument46 pagesTextile Raw Material Inspection GuideJaswant SinghNo ratings yet

- Everything You Need to Know About Fiber PropertiesDocument19 pagesEverything You Need to Know About Fiber PropertiesDhana SeelanNo ratings yet

- Fabric Check ProcedureDocument7 pagesFabric Check ProcedureEleni LanaraNo ratings yet

- International Textile Company ProfileDocument20 pagesInternational Textile Company ProfileallanbethelNo ratings yet

- Fancy YarnsDocument7 pagesFancy Yarnsiriarn100% (1)

- Yarn Numbering SystemDocument10 pagesYarn Numbering SystemRimple Goyal,25No ratings yet

- How to Control and Maintain GSM for Knitted FabricsDocument1 pageHow to Control and Maintain GSM for Knitted Fabricsদীপ্তি হুমাইরা100% (1)

- Field Technology Handbook - 2020 - V1.0Document757 pagesField Technology Handbook - 2020 - V1.0mostafa.akpbcNo ratings yet

- Essential Fabric Quality Reports For Bulk Cutting Approval of FabricsDocument7 pagesEssential Fabric Quality Reports For Bulk Cutting Approval of FabricsHarmendar S KothariNo ratings yet

- Intro To Fiber Yarn FabricDocument29 pagesIntro To Fiber Yarn FabricAbu Naser Md AbdullahNo ratings yet

- Lecture Three Natural Bast FiberDocument46 pagesLecture Three Natural Bast FiberGemeda GebinoNo ratings yet

- Manufacturing Potential and Capabilities of Indian MillsDocument20 pagesManufacturing Potential and Capabilities of Indian MillsApsara AngelNo ratings yet

- Production Methods of Fancy YarnsDocument6 pagesProduction Methods of Fancy YarnsArunraj ArumugamNo ratings yet

- Yarns: Types and CharacteristicsDocument32 pagesYarns: Types and Characteristicskartika ranaNo ratings yet

- Textile Design & Fabric Manufacturing Short CourseDocument98 pagesTextile Design & Fabric Manufacturing Short CourseMuhammad IlyasNo ratings yet

- Commonly Used Finishing Methods On FabricsDocument4 pagesCommonly Used Finishing Methods On FabricsRajesh Dwivedi100% (1)

- Textile Raw Material-II Course Code: Tex2101: Basic Concept On Textile FibreDocument63 pagesTextile Raw Material-II Course Code: Tex2101: Basic Concept On Textile FibreHrs ShihabNo ratings yet

- Recent Development in Denim ManufacturingDocument24 pagesRecent Development in Denim ManufacturingMichael LiuNo ratings yet

- BASE Textiles LimitedDocument76 pagesBASE Textiles LimitedPushpa BaruaNo ratings yet

- Amm 301Document58 pagesAmm 301asadshekhNo ratings yet

- Textile and Apparel Quality EvaluationDocument65 pagesTextile and Apparel Quality EvaluationvasineyNo ratings yet

- Denim Fabric ManufacturingDocument22 pagesDenim Fabric ManufacturingFazley Elahi100% (2)

- Mechanical Properties of Weft Knitted FabricsDocument6 pagesMechanical Properties of Weft Knitted FabricsAhmad SamerNo ratings yet

- Determination of Loop Length, Tightness Factor and Porosity of Single Jersey Knitted FabricDocument6 pagesDetermination of Loop Length, Tightness Factor and Porosity of Single Jersey Knitted FabrictanveerhusseinNo ratings yet

- Dyeing - Finishing Price - DadDocument1 pageDyeing - Finishing Price - Dadasrknit1No ratings yet

- Bi ComponentDocument13 pagesBi ComponentA.K.M. Rashedul IslamNo ratings yet

- Determining Fabric Quality: Prepared By: Riza Leigh I. FiguesDocument55 pagesDetermining Fabric Quality: Prepared By: Riza Leigh I. FiguesRizaLeighFiguesNo ratings yet

- Course Outline Weave Design Studio-II - NewDocument9 pagesCourse Outline Weave Design Studio-II - NewMudassir AbbasNo ratings yet

- Yarn FormationDocument125 pagesYarn FormationDhana SeelanNo ratings yet

- Effect of Yarn CountDocument12 pagesEffect of Yarn CountSyed Salahuddin MunnaNo ratings yet

- Minimization of Defects in Knitted Fabric 02Document7 pagesMinimization of Defects in Knitted Fabric 02Sarah SebâaNo ratings yet

- Factors Which Affect The Cost ofDocument19 pagesFactors Which Affect The Cost ofsuchi_mohan08No ratings yet

- The Effect of Fibre Blend On Comfort Characteristics of ElasticDocument7 pagesThe Effect of Fibre Blend On Comfort Characteristics of ElasticGeotamNo ratings yet

- FiberDocument9 pagesFiberAryan PatelNo ratings yet

- Publications: Fibre & YarnDocument14 pagesPublications: Fibre & YarnvigneshbalajirsNo ratings yet

- (Yarn Propertics) Joy SarkerDocument18 pages(Yarn Propertics) Joy SarkerMd Ariful IslamNo ratings yet

- Types of Knit & Woven Fabric GuideDocument2 pagesTypes of Knit & Woven Fabric GuideTanbir RahmanNo ratings yet

- Definition and Classification of Textile Neps - Count of Neps - Textile LearnerDocument1 pageDefinition and Classification of Textile Neps - Count of Neps - Textile LearnerSubrata MahapatraNo ratings yet

- Unit 1 Functional GarmentsDocument60 pagesUnit 1 Functional GarmentsSivakumar KNo ratings yet

- Primeasia UniversityDocument206 pagesPrimeasia UniversityAtik Nayon100% (2)

- Analysis of Energy Consumption in WovenDocument8 pagesAnalysis of Energy Consumption in WovenmedraizNo ratings yet

- An Overview of Knitting Industry of IndiaDocument18 pagesAn Overview of Knitting Industry of IndiaJ.N.Vohra60% (5)

- Evaluation of yarn diameter and its effect on fabric qualityDocument8 pagesEvaluation of yarn diameter and its effect on fabric qualitySabeeh Ul HassanNo ratings yet

- Textile Testing and Product EvaluationDocument64 pagesTextile Testing and Product EvaluationBhaswati PandaNo ratings yet

- Apparel standards and quality control processesDocument11 pagesApparel standards and quality control processesAman DeepNo ratings yet

- R101 Lesson 7 Fabrics, Finishes and FurnishingsDocument44 pagesR101 Lesson 7 Fabrics, Finishes and FurnishingsAman KeltaNo ratings yet

- 6 Sem. B.Tech (Fashion & Apparel Technology) : PCFT 4304 Knitting & Non WovenDocument20 pages6 Sem. B.Tech (Fashion & Apparel Technology) : PCFT 4304 Knitting & Non WovenBebi WakaNo ratings yet

- Measurement of Seam Puckering and Influence of Its Causes: Sandun Fernando Tss JayawardenaDocument7 pagesMeasurement of Seam Puckering and Influence of Its Causes: Sandun Fernando Tss JayawardenaIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Spirality of Single Jersey Knitted FabricDocument13 pagesSpirality of Single Jersey Knitted FabricKazi Saiful IslamNo ratings yet

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- Textile CalculationDocument6 pagesTextile CalculationKhandaker Sakib FarhadNo ratings yet

- TNA Prod PlanDocument2 pagesTNA Prod PlanSuhail ShaikhNo ratings yet

- Bhagwad Seva Sahitya - Vastra IntroductionDocument4 pagesBhagwad Seva Sahitya - Vastra IntroductionShivam AgrawalNo ratings yet

- Jasmine: Crochet PatternDocument23 pagesJasmine: Crochet PatternNicoleta Jauca100% (8)

- Medical Nonwoven ApplicationsDocument17 pagesMedical Nonwoven ApplicationsDipesh JainNo ratings yet

- Mypicot: Crochet Stitch Patterns Motifs #4007Document2 pagesMypicot: Crochet Stitch Patterns Motifs #4007Accesorii Lucrate Manual100% (2)

- 23 Fabric Defects To Look Out For During Fabric InspectionDocument5 pages23 Fabric Defects To Look Out For During Fabric Inspectionudi969100% (1)

- Easy Winter Beanie: A Crochet Pattern by Sarah Thompson of Rich Textures CrochetDocument3 pagesEasy Winter Beanie: A Crochet Pattern by Sarah Thompson of Rich Textures CrochetThuy DoanNo ratings yet

- 301 Hometown Girl PATTERNDocument11 pages301 Hometown Girl PATTERNPetya Kirilova Maneva100% (1)

- Diana Hobo Bag Plus Printable PatternsDocument9 pagesDiana Hobo Bag Plus Printable PatternsAngelaNo ratings yet

- FactSheet Fabrics Fiber FabricProperties PDFDocument3 pagesFactSheet Fabrics Fiber FabricProperties PDFDhilepan RajendiranNo ratings yet

- Anakaputhur WeaversDocument6 pagesAnakaputhur Weaverstweety_sylvesterNo ratings yet

- Sienna The Horse Stuffed Toy InstructionsDocument21 pagesSienna The Horse Stuffed Toy InstructionsJoshiNo ratings yet

- Ikat Weaving: Ikat and Double IkatDocument4 pagesIkat Weaving: Ikat and Double IkatDevanshi DabriwalNo ratings yet

- ENGLISH VERSION - Lactation Teaching ToolsDocument15 pagesENGLISH VERSION - Lactation Teaching ToolsXiomara Salort100% (1)

- Rajnagar MillsDocument36 pagesRajnagar Millsnikita jaiswalNo ratings yet

- Project: Christmas Snowflakes MobileDocument5 pagesProject: Christmas Snowflakes MobilecristinaNo ratings yet

- Physical Testing Requirements for Textiles and LeatherDocument20 pagesPhysical Testing Requirements for Textiles and LeatherBasto WongNo ratings yet

- Chemistry Investigatory ProjectDocument9 pagesChemistry Investigatory Projectanon_32709488156% (16)

- RovingDocument53 pagesRovingMoiz AhmadNo ratings yet

- A Demonstration Plan in EPP 6 I. Learning OutcomesDocument4 pagesA Demonstration Plan in EPP 6 I. Learning Outcomeshezil CuangueyNo ratings yet

- Fundamentals of Yarn Technology: Learning ObjectivesDocument16 pagesFundamentals of Yarn Technology: Learning Objectivesdwidha100% (1)

- RSWMDocument8 pagesRSWMSEO RSWMNo ratings yet

- English Falling StarDocument7 pagesEnglish Falling StarViviane de Medeiros GuimarãesNo ratings yet

- Fairy MaidenDocument5 pagesFairy MaidenJuan Andrés López MaesoNo ratings yet

- Idea Granny Square Month CAL 2022 Day 1Document3 pagesIdea Granny Square Month CAL 2022 Day 1Nathalie BriatoreNo ratings yet

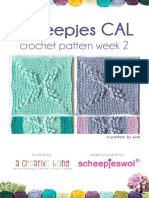

- Crochet Pattern Week 2: Scheepjes CALDocument4 pagesCrochet Pattern Week 2: Scheepjes CALHarryykhan100% (1)

- Indian Silk IndustryDocument28 pagesIndian Silk IndustryMusharaf Momin0% (1)

- Sew 3 Simple Purses - From Sew News MagazineDocument13 pagesSew 3 Simple Purses - From Sew News MagazineIread2enlighten100% (1)

- PPC GiDocument13 pagesPPC GiMeghaNo ratings yet

- TEGEWA Nomenclature of Textile AuxiliariesDocument3 pagesTEGEWA Nomenclature of Textile AuxiliariesKushagradhi DebnathNo ratings yet