Professional Documents

Culture Documents

AN043-SPI Vs Step Direction

Uploaded by

leftoverchopsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AN043-SPI Vs Step Direction

Uploaded by

leftoverchopsCopyright:

Available Formats

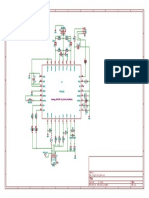

TMC 236 / 246 / 239 / 249

Family:

SPI vs. Step Direction– a

Comparison and Discussion

Trinamic Motion Control GmbH & Co. KG

Sternstraße 67

D – 20357 Hamburg, Germany

Phone +49-40-51 48 06 – 0

FAX: +49-40-51 48 06 – 60

http://www.trinamic.com

INFO@TRINAMIC.COM

SPI vs. Step / Direction – a comparison and discussion 2

1 What advantages does the SPI interface of the

drivers give you, when comparing to the simpler

Step/Direction interface?

In fact you will find that Step / Direction looks much simpler to use when compared to SPI on a first

glance, but when taking a closer look, the assumed advantages of the simpler interface diminish.

1.1 What is the background of SPI and of Step-Direction

interface?

The background for Step-Direction is industrial motion control, where you need to bridge many meters

with as few as possible control lines, while providing a simple and robust motor control interface.

However, for high-end controls in industrial applications diagnostics and bus structure connections are

new trends.

SPI is a very simple on-board interface used for communication between microprocessor and

peripherals. Typically it bridges a few centimeters. Microprocessors provide this interface in hardware

since the 30 years old 8051 and 6800 family. New CPUs and microcontrollers push SPI bandwidth up

to several 10Mbit per second, to allow control of high-bandwidth peripherals.

1.2 What does the SPI interface give you when compared

to Step-/Direction?

In comparison to SPI, Step- Direction can not give you information back from the driver, like error

signals or StallGuard information. It lacks information about the actual microstep position, and you do

not have free control over the motor current. All this is provided by SPI interface. And you have the

free choice to switch to full stepping on-the-fly in order to increase motor power temporarily.

If you would add all this to Step-/Direction, you would end up with a simple interface plus roughly 5

control lines and 10 status lines coming back from the controller. This would make up for a 17 line

interface! Of course pure Step-/Direction drivers lack this capability. The SPI interface of the TMC

driver family shift back all this status lines to the four simple control lines of SPI. We have chosen SPI,

because it is the simplest real bus interface available – it is not more than a shift register with clock

and data line. As you will see, the draw back of having shifted the Step-/Direction interface back to

within the CPU is not a hard task to solve – look up our simple software examples!

1.3 But what is the additional overhead of SPI?

You have to "play back" a stepping table in your CPU and send it via an SPI interface. As software

writers find out quickly, this is a straight-forward and simple task. Nearly all microcontrollers provide an

SPI interface, or a synchronous shift register interface.

One example: The 80 cent ATmega8 has an SPI interface with up to 8Mbit/s throughput.

1.4 What is the software load?

For a CPU with SPI interface, you need a table look up, plus two writes to the SPI interface. You can

either do this for every (micro)step, or with a fixed rate, which should be some factor higher than your

maximum full step rate, e.g. some kHz for a typical application.

Example: For the ATmega8, the routine to look up the table and send out two bytes to the driver

needs roughly 5 to 10 microseconds, e.g. when running at 2kHz it consumes 1 to 2 percent of the

processing power. This update rate is high enough for most simple positioning applications.

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

SPI vs. Step / Direction – a comparison and discussion 3

1.5 What is the real challenge when driving a stepper

motor?

The real challenge is to generate accurate acceleration and deceleration ramps, in order to stop the

motor at the target position. Quick and precise reaction to the reference and stop switches (if used) is

essential. Motion ramp generation is a hard real time task! – Unless you want to go at motor start/stop

velocity of the motor. Then everything you need is a slow few hundred hertz interrupt to do each one

step.

If you want precise and quick motor movement, look for the TMC428 motion controller IC. It comes in

a tiny SSOP16 package. If you need more than one motor - it controls up to three stepper motors!

The software load, precise motion control makes, often will be the main task for the processor.

1.6 Can I realize SPI via software?

Yes, you need to take the data word to send to the driver, shift out a bit, set and clear the clock line,

shift in the send back bit. Do this 12 times for a TMC249A. It will require around a microsecond per bit

on a low cost CPU like the ATmega8 or an up-to-date 8051 family CPU (which in fact have a hardware

interface).

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

You might also like

- Boomtown Rats - I Dont Like MondaysDocument9 pagesBoomtown Rats - I Dont Like Mondaysleftoverchops100% (1)

- Help Desk: DMX Isolation - by Wayne HowellDocument2 pagesHelp Desk: DMX Isolation - by Wayne HowellleftoverchopsNo ratings yet

- Standard For Portable Control CablesDocument16 pagesStandard For Portable Control CablesleftoverchopsNo ratings yet

- Half-Duplex Rs-485-/Rs-422-Compatible Transceiver With Autodirection ControlDocument17 pagesHalf-Duplex Rs-485-/Rs-422-Compatible Transceiver With Autodirection ControlleftoverchopsNo ratings yet

- Alanis Morrisette - You Oughta KnowDocument5 pagesAlanis Morrisette - You Oughta KnowleftoverchopsNo ratings yet

- Alanis Morisette - IronicDocument6 pagesAlanis Morisette - IronicSteven RichardAndrewLordNo ratings yet

- WS2815 LED DatasheetDocument8 pagesWS2815 LED DatasheetDaisyNo ratings yet

- Bobby McFerrin - Don't Worry Be HappyDocument7 pagesBobby McFerrin - Don't Worry Be HappyleftoverchopsNo ratings yet

- Ochure Motor Control PDFDocument60 pagesOchure Motor Control PDFeballiriNo ratings yet

- Specialist Mathematics Trial Cat 3 1998: THE Heffernan GroupDocument19 pagesSpecialist Mathematics Trial Cat 3 1998: THE Heffernan GroupleftoverchopsNo ratings yet

- The Unknown Problem With Airtight Enclosures: FeatureDocument3 pagesThe Unknown Problem With Airtight Enclosures: FeatureleftoverchopsNo ratings yet

- School For Excellence 98 Exam 2Document3 pagesSchool For Excellence 98 Exam 2leftoverchopsNo ratings yet

- Isolated Rs 485 in dmx512 Lighting PDFDocument3 pagesIsolated Rs 485 in dmx512 Lighting PDFleftoverchopsNo ratings yet

- Iartv - 1999 - E2Document2 pagesIartv - 1999 - E2leftoverchopsNo ratings yet

- 1998 Specialist Maths Exam 1 SolutionsDocument18 pages1998 Specialist Maths Exam 1 SolutionsleftoverchopsNo ratings yet

- Solutions: THE Heffernan GroupDocument11 pagesSolutions: THE Heffernan GroupleftoverchopsNo ratings yet

- Heffernan - 1998 - E2Document4 pagesHeffernan - 1998 - E2leftoverchopsNo ratings yet

- IMXRT1060IECDocument111 pagesIMXRT1060IECAntonio Madueño LunaNo ratings yet

- Qmot Qsh6018 ManualDocument14 pagesQmot Qsh6018 ManualleftoverchopsNo ratings yet

- School For Excellence 98 Exam 2 (MODIFIED)Document3 pagesSchool For Excellence 98 Exam 2 (MODIFIED)leftoverchopsNo ratings yet

- 1998 Specialist Maths Exam 1Document32 pages1998 Specialist Maths Exam 1leftoverchopsNo ratings yet

- Boardwalk LAYOUT - Ortho - 5x14: Layer 0Document1 pageBoardwalk LAYOUT - Ortho - 5x14: Layer 0leftoverchopsNo ratings yet

- MAV 1998 Exam 2Document3 pagesMAV 1998 Exam 2leftoverchopsNo ratings yet

- TMC2041-LA BOB Description: Module Top View Features and Additional ResourcesDocument2 pagesTMC2041-LA BOB Description: Module Top View Features and Additional ResourcesleftoverchopsNo ratings yet

- Atmel ICE UserGuideDocument61 pagesAtmel ICE UserGuideogom30eNo ratings yet

- SP483 SP485Document13 pagesSP483 SP485Danijel AspanNo ratings yet

- User's Guide: Dem-Pcm2912A EvmDocument43 pagesUser's Guide: Dem-Pcm2912A EvmleftoverchopsNo ratings yet

- Schematicsusb Sound CardDocument1 pageSchematicsusb Sound Cardpepe sanchezNo ratings yet

- AN043-SPI Vs Step DirectionDocument3 pagesAN043-SPI Vs Step DirectionleftoverchopsNo ratings yet

- Isolated Rs 485 in dmx512 Lighting PDFDocument3 pagesIsolated Rs 485 in dmx512 Lighting PDFleftoverchopsNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2009 Kraemer Dedrick Sharma OneLaptopPerChildDocument9 pages2009 Kraemer Dedrick Sharma OneLaptopPerChildRus FarukNo ratings yet

- Lecture 2-Computer Evolution and PerformanceDocument40 pagesLecture 2-Computer Evolution and PerformanceTahir KhanNo ratings yet

- Automation, Control To Save FfeDocument10 pagesAutomation, Control To Save Ffenghi100% (1)

- NVX-3000 Brochure-20190809Document2 pagesNVX-3000 Brochure-20190809nihal mujeebNo ratings yet

- Ap Cs Test 1aDocument3 pagesAp Cs Test 1aapi-236387090No ratings yet

- Nxbyte Arm-Legv8Document15 pagesNxbyte Arm-Legv8Jonathan Manzaki100% (1)

- Aopen Dex5350 PDFDocument2 pagesAopen Dex5350 PDFLeomark RespondeNo ratings yet

- NV Ds Quadro k600 Us PDFDocument1 pageNV Ds Quadro k600 Us PDFdusmisNo ratings yet

- ACTIVADORDocument2 pagesACTIVADORAlfredo Leon ChicomaNo ratings yet

- 13-Inch MacBook Air - Space Grey - Apple (IN)Document1 page13-Inch MacBook Air - Space Grey - Apple (IN)dummy page7007No ratings yet

- Dell PowerEdge RAID Controller (PERC) CLI GuideDocument65 pagesDell PowerEdge RAID Controller (PERC) CLI GuideharryNo ratings yet

- Cp1l - em Entradas AnalogicasDocument3 pagesCp1l - em Entradas AnalogicasMoha-med HasnaouiNo ratings yet

- UM0470 User Manual: STM8 SWIM Communication Protocol and Debug ModuleDocument39 pagesUM0470 User Manual: STM8 SWIM Communication Protocol and Debug ModuleAgustin MrqzNo ratings yet

- 08.Doa&Dap Doa&Dap PolicyDocument17 pages08.Doa&Dap Doa&Dap PolicyAymen SouddatiNo ratings yet

- Powerview: Installation ManualDocument20 pagesPowerview: Installation Manuallcsandovalr989No ratings yet

- Software Update Instruction For BW SystemDocument48 pagesSoftware Update Instruction For BW SystemШуджоадин НизомовNo ratings yet

- Chapter 2: 8255 Programmable Peripheral Interface: Department of MechatronicsDocument29 pagesChapter 2: 8255 Programmable Peripheral Interface: Department of MechatronicsTho Ho DucNo ratings yet

- LogDocument1,732 pagesLogWahyu SetyawanNo ratings yet

- CS430 Solaris and DTrace PresentationDocument8 pagesCS430 Solaris and DTrace PresentationChris HartNo ratings yet

- LRX Series Appliances: Logrhythm Appliance ModelsDocument2 pagesLRX Series Appliances: Logrhythm Appliance ModelsNhung QuachNo ratings yet

- Tabela RV CFDocument7 pagesTabela RV CFHerbert DiogenesNo ratings yet

- 16K Microwire Compatible Serial EEPROM: 93AA86A/B/C, 93LC86A/B/C, 93C86A/B/CDocument27 pages16K Microwire Compatible Serial EEPROM: 93AA86A/B/C, 93LC86A/B/C, 93C86A/B/CJesús GutiérrezNo ratings yet

- Wiseasy P3: EMV Android POSDocument2 pagesWiseasy P3: EMV Android POSBagus AditiyaNo ratings yet

- Vikmote Vx40 Flex: Remote Telemetry and Control UnitDocument6 pagesVikmote Vx40 Flex: Remote Telemetry and Control UnitPaul Ramos CarcaustoNo ratings yet

- AuditDocument261 pagesAuditKarina SilvaNo ratings yet

- VCD-D ManualDocument13 pagesVCD-D ManualnimmuhkNo ratings yet

- 4.1.3 Definition of The EE1002 and EE1002A Serial Presence Detect (SPD) EEPROMS 1. ScopeDocument24 pages4.1.3 Definition of The EE1002 and EE1002A Serial Presence Detect (SPD) EEPROMS 1. ScopemboopathiNo ratings yet

- EducationDocument94 pagesEducationPrashant KrNo ratings yet

- Digital Gauge Interface Device: For Connect All Digital Gauge or Measuring Devices To Read Measurement DataDocument2 pagesDigital Gauge Interface Device: For Connect All Digital Gauge or Measuring Devices To Read Measurement DataboonlueNo ratings yet