Professional Documents

Culture Documents

The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not Contracted

Uploaded by

Remo StortiniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not Contracted

Uploaded by

Remo StortiniCopyright:

Available Formats

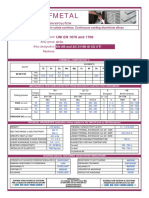

UNS C17200 EN CW101C DIN 2.

1247 - CuBe2

General Characteristics

Standard Copper-Beryllium. Machinability -

Strongly age hardenable copper alloy with excellent cold formability, high corrosion resistance, and good electrical Quench hardening no

conductivity (15 to 30% IACS). Polishing +

For pieces requiring a lot of machining operations, consider to use the variant CuBe M25.

Magnetic no

Attention: the inhalation of Beryllium is toxic. Ensure an appropriate ventilation during operations like melting, grinding,

welding or machining. Age hardening yes

Welding

MIG,TIG,WIG yes

Arc yes

Resistance no

Autogenous no

Laser yes

Chemical composition (ASTM) [wt.%]

Be Ni + Co Ni+Co+Fe Pb Cu

1.8 - 2.0 > 0.20 < 0.60 < 0.10 Saldo

Physical properties

Density Electrical resistivity Specific heat Thermal conductivity

r [kg·m-3] r [µW·m] Cp [J·kg-1·K-1] l [W·m-1·K-1]

8'250 0.057 to 0.115 at 20°C 420 105 to 130 at 20°C

Coefficient of thermal expansion Elastic modulus

a [10-6·°C-1] between 20°C and E [GPa]

100 °C 200 °C 300 °C 400 °C 500 °C 600 °C 700 °C 125 to 130 at 20°C

16.7 17.0 17.8

Mechanical properties

Yield strength Tensile Elongation Vickers

State Rp0.2 [MPa] strength Hardness

20°C 100°C 200°C 300°C Rm [MPa] A5 [%] [HV]

Solution annealed 200 - 400 420 - 550 35 - 60 90 - 130

Cold worked 40% 650 - 800 700 - 850 2-8 215 - 260

Age hardened 1000-1250 1150-1370 4 - 10 350 - 420

Worked+harden. 1150-1450 1350-1550 1-4 415 - 475

Thermal treatment

Type Temperature Time Protective atmosphere Cooling

[°C] [minutes]

Annealing 760 -790 10 - 60 Air, argon or N2 + H2 Water quenching

Age hardening 315 - 345 60 - 180 Air, argon or N2 + H2 not critical

Surface treatment

Type Solution Remarks

Pickling H2SO4 15% + 3 % H2O2 at 50°C during 30 seconds

Pickling H2SO4 25% at 70°C during 10 minutes

Pickling HNO3 20% at RT during 1 minute

Fabrication characteristics

Cold formability is good. Hot forming between 650 and 800°C. Check the state in which the alloy is delivered. Delivery often is in the solution

annealed state. This state is prerequisite for a correct age hardening. Solution annealing must be stricltly done according to the above prescriptions in

order to get the full strength in subsequent age hardening. The hardening is acccompanied by a linear shrinkage of max. 0.2% and an increase in

density of max. 0.6%. Machining is cumbersome. Machinability is estimated at 20% on a scale with the free cutting brass CuZn35.5Pb3 at 100%.

Avoid the use of sulfur containing lubricants as these will color the copper. For complex machining operations, consider to use the alloy Cu Be M25.

Welding, brazing and soldering

Brazing and soldering are suitable joining techniques; carefully clean the surface and use resin type flux. Fillers of the same material are used for

welding.

A solution anneal and age hardening must follow joining in order to restore uniform mechanical properties.

Available products

Sheets, ribbons, wires, profiles, tubes, dimensions and tolerances on request.

The indications are basically founded on our actual know-how. This technical data sheet is without

commitment and not contracted.

You might also like

- Cu Ni 18 ZN 19 PB 1Document1 pageCu Ni 18 ZN 19 PB 1Isa CatNo ratings yet

- Aisi 420 PDFDocument1 pageAisi 420 PDFJusril HidayatNo ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not Contractedlijojose1No ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedsreckoNo ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRavindra ErabattiNo ratings yet

- TitaneGrade2 PDFDocument1 pageTitaneGrade2 PDFLucho de BarNo ratings yet

- Carbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)Document7 pagesCarbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)alvida pramudiantiNo ratings yet

- Cuzn37-Pna 243 enDocument2 pagesCuzn37-Pna 243 enAbrahan Tinco PariNo ratings yet

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENjurreijndersNo ratings yet

- Cu Etp c11000 Pna - 211 sm0008 - enDocument2 pagesCu Etp c11000 Pna - 211 sm0008 - enNitin KumarNo ratings yet

- 16 MN CR 5Document2 pages16 MN CR 5bd54No ratings yet

- Cu Ofe c10100 Pna 203 - enDocument2 pagesCu Ofe c10100 Pna 203 - enNitin KumarNo ratings yet

- Cucrzr c18160 Pna 372 - enDocument2 pagesCucrzr c18160 Pna 372 - enSulistyo widiatmokoNo ratings yet

- A286 (Ficha Tecnica)Document3 pagesA286 (Ficha Tecnica)Alex Zambrana RodríguezNo ratings yet

- Nominal Composition Standard Inventory SpecificationsDocument3 pagesNominal Composition Standard Inventory Specificationssafat parNo ratings yet

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENYulwido AdiNo ratings yet

- DS Mold 4140Document3 pagesDS Mold 4140reza prasetiaNo ratings yet

- Cusn10-Pna 292 enDocument2 pagesCusn10-Pna 292 enRissi CHNo ratings yet

- CuZn30-PNA 226 - ENDocument2 pagesCuZn30-PNA 226 - ENNHadesNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- Material Datasheet Cu-OFDocument2 pagesMaterial Datasheet Cu-OFmohsen_267No ratings yet

- Material Datasheet Cuzn30Document2 pagesMaterial Datasheet Cuzn30alex94kgNo ratings yet

- Cunisi-Pna 290 enDocument2 pagesCunisi-Pna 290 enJdjoNo ratings yet

- Hussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Document1 pageHussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Michael DoyleNo ratings yet

- 100crmnsi6-4: Steel GradeDocument3 pages100crmnsi6-4: Steel GradeSama UmateNo ratings yet

- Cu-ETP-PNA 211 - ENDocument2 pagesCu-ETP-PNA 211 - ENwhoam iNo ratings yet

- Steel PropertiesDocument22 pagesSteel PropertiesMOHD SALMANNo ratings yet

- 1.7225 en PDFDocument2 pages1.7225 en PDFTheodoros AtheridisNo ratings yet

- 61 Si CR 7Document2 pages61 Si CR 7RaduIonNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- Kme STOL76 C19010 enDocument1 pageKme STOL76 C19010 enMattia Terri TerrandoNo ratings yet

- Hydro Aluminium - AlSi7Mg0 3Document2 pagesHydro Aluminium - AlSi7Mg0 3Raj PrasanthNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- Werkstoff 1.5217 (20MnV6)Document2 pagesWerkstoff 1.5217 (20MnV6)alextentwentyNo ratings yet

- 21crmov5-7: Steel GradeDocument1 page21crmov5-7: Steel GradeEdward PongracNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- Technical Datasheet PNA290Document3 pagesTechnical Datasheet PNA290nelson9746No ratings yet

- (UNS N08825) : NAS High Corrosion Resistant Nickel AlloyDocument4 pages(UNS N08825) : NAS High Corrosion Resistant Nickel AlloySunil Kumar GoudaNo ratings yet

- CuFe2p - AurubisDocument2 pagesCuFe2p - AurubisJan NoscilNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Amandeep SinghNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetreza amiriniaNo ratings yet

- 420 Martensitic Stainless Steel BarDocument4 pages420 Martensitic Stainless Steel BarAHMED FATHINo ratings yet

- 1.3505 100cr6 PDFDocument1 page1.3505 100cr6 PDFmcNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- Cusn8-Pna 283 enDocument2 pagesCusn8-Pna 283 enRahul BiradarNo ratings yet

- SINOXX 4006 Steel: Designation by StandardsDocument3 pagesSINOXX 4006 Steel: Designation by StandardsKiranNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- T - Thermanit MTS 4 - Se - en - 5Document1 pageT - Thermanit MTS 4 - Se - en - 5bhanu.kiranNo ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- 1022 Carbon Steel Bar PDFDocument3 pages1022 Carbon Steel Bar PDFjeyakumarNo ratings yet

- CLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)Document4 pagesCLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)PeterWayNo ratings yet

- Cu-ETP: C11000 Industrial RolledDocument4 pagesCu-ETP: C11000 Industrial Rolledsrsivaraman81No ratings yet

- Datasheet BOHLER DCMS-IG TIGDocument1 pageDatasheet BOHLER DCMS-IG TIGDaniele DuarteNo ratings yet

- Quality 1.4021 Chemical Composition: Lucefin GroupDocument2 pagesQuality 1.4021 Chemical Composition: Lucefin GroupSonNguyenNo ratings yet

- 1 3243hs652513 PDFDocument1 page1 3243hs652513 PDFmarko9292No ratings yet

- Datasheet Sandvik Saf 2507 en PDFDocument15 pagesDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- Six SigmaDocument15 pagesSix Sigmapravit08No ratings yet

- Phosphor Bronze CuSn6-PB103 Datasheet PDFDocument1 pagePhosphor Bronze CuSn6-PB103 Datasheet PDFRemo StortiniNo ratings yet

- Comparison of GradesDocument4 pagesComparison of GradesSourav RobinNo ratings yet

- Relaxation of Helical Springs and Spring Steel Wires PDFDocument8 pagesRelaxation of Helical Springs and Spring Steel Wires PDFRemo StortiniNo ratings yet

- Comparison of GradesDocument4 pagesComparison of GradesSourav RobinNo ratings yet

- Phosphor Bronze CuSn6-PB103 Datasheet PDFDocument1 pagePhosphor Bronze CuSn6-PB103 Datasheet PDFRemo StortiniNo ratings yet

- Special AlloyDocument1 pageSpecial AlloyRemo StortiniNo ratings yet

- Calculus Practice ExamDocument24 pagesCalculus Practice ExamRemo StortiniNo ratings yet

- Comparison of GradesDocument4 pagesComparison of GradesSourav RobinNo ratings yet

- Special Relativity With EinsteinDocument285 pagesSpecial Relativity With EinsteinRemo StortiniNo ratings yet

- Sandvik: Stainless Steel Wire ProductsDocument4 pagesSandvik: Stainless Steel Wire ProductsRemo StortiniNo ratings yet

- Sandvik: Stainless Steel Wire ProductsDocument4 pagesSandvik: Stainless Steel Wire ProductsRemo StortiniNo ratings yet

- Sandvik: Stainless Steel Wire ProductsDocument4 pagesSandvik: Stainless Steel Wire ProductsRemo StortiniNo ratings yet

- The Works of Edgar Allan Poe Volume 1Document162 pagesThe Works of Edgar Allan Poe Volume 1Remo StortiniNo ratings yet

- The Mysterious Affair at StylesDocument119 pagesThe Mysterious Affair at StylesAnnaNo ratings yet

- National Graffio - Décor (Textured Coating) : Product Code: 040Document3 pagesNational Graffio - Décor (Textured Coating) : Product Code: 040abualamalNo ratings yet

- 9883511790ENUWADocument8 pages9883511790ENUWAhalexNo ratings yet

- Welding Non-Code Specialty Equipment: NIOEC-SP-90-11Document8 pagesWelding Non-Code Specialty Equipment: NIOEC-SP-90-11aminNo ratings yet

- Struers Grinding ProductsDocument8 pagesStruers Grinding ProductsEric PangNo ratings yet

- Inconel Alloy 740 H PDFDocument24 pagesInconel Alloy 740 H PDFJosé Juan Jiménez AlejandroNo ratings yet

- Advantages and Disadvantages of Techniques Used For WastewaterDocument11 pagesAdvantages and Disadvantages of Techniques Used For WastewaterFirman JoshuaNo ratings yet

- Krar Unit 41Document14 pagesKrar Unit 41Amir AmiriNo ratings yet

- Linemans Apprentice Tool List - Clickable PDFDocument11 pagesLinemans Apprentice Tool List - Clickable PDFRoshNo ratings yet

- Fitter Iii Semester Question - New 1-4 PDFDocument11 pagesFitter Iii Semester Question - New 1-4 PDFGangadharam MademNo ratings yet

- Air Products W SHDocument22 pagesAir Products W SHNasser KhattabNo ratings yet

- Type of Monolithic Refractories PDFDocument4 pagesType of Monolithic Refractories PDFNaelNo ratings yet

- Failure of ToolDocument8 pagesFailure of ToolPROD DOPENo ratings yet

- Bharat Metal Cutting GasDocument5 pagesBharat Metal Cutting GasGitanjaliNo ratings yet

- S1301 Lamella Brochure EN 1Document8 pagesS1301 Lamella Brochure EN 1Yoto Gómez MosqueraNo ratings yet

- Project Report On Corrugated Boxes (Automatic Plant)Document6 pagesProject Report On Corrugated Boxes (Automatic Plant)EIRI Board of Consultants and PublishersNo ratings yet

- AWP Course NotesDocument320 pagesAWP Course Notesduniaadnan100% (3)

- Mass Balance CalculationDocument16 pagesMass Balance Calculationmirdza94100% (3)

- SSPDocument16 pagesSSPRaghunath Veeramani100% (1)

- WPS106 6010 WPS 107 7024 Secondary and Post SecondaryDocument1 pageWPS106 6010 WPS 107 7024 Secondary and Post SecondaryahmedNo ratings yet

- Thyssenkrupp Steel: Material SpecificationsDocument4 pagesThyssenkrupp Steel: Material Specificationsmukeshsingh6No ratings yet

- Powder Metallurgy ProjectDocument54 pagesPowder Metallurgy ProjectDhruv Raj33% (3)

- Lime - Shaft Furnaces or Rotary Furnaces - StrommashinaDocument5 pagesLime - Shaft Furnaces or Rotary Furnaces - StrommashinataghdirimNo ratings yet

- Quality Control Plan: Project: BourseDocument4 pagesQuality Control Plan: Project: Bourseroekyat hendrawanNo ratings yet

- Trickling FilterDocument26 pagesTrickling FilterMayank SaxenaNo ratings yet

- Cemwet SP 3000 (Pce 3)Document2 pagesCemwet SP 3000 (Pce 3)Angry BoyNo ratings yet

- Landing ValveDocument3 pagesLanding ValveMd. Asrafujjaman (Livon)No ratings yet

- Popravka Gumenih Camaca Od HypalonaDocument5 pagesPopravka Gumenih Camaca Od HypalonaDusanNo ratings yet

- Cheat Sheet Main RatanDocument4 pagesCheat Sheet Main RatanSushil KumarNo ratings yet

- REPORT Eng TrainingDocument11 pagesREPORT Eng TrainingTareq Al HasanNo ratings yet

- Bessemer FurnaceDocument4 pagesBessemer FurnaceHariman El EmirNo ratings yet