Professional Documents

Culture Documents

Part QW Welding: Article I Welding General Requirements

Part QW Welding: Article I Welding General Requirements

Uploaded by

rogel_ganaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part QW Welding: Article I Welding General Requirements

Part QW Welding: Article I Welding General Requirements

Uploaded by

rogel_ganaCopyright:

Available Formats

PART QW WELDING

ARTICLE I

WELDING GENERAL REQUIREMENTS

QW-100 GENERAL of the Code require notch toughness qualification of

the WPS, the applicable supplementary essential vari-

Section IX of the ASME Boiler and Pressure Vessel

ables must be addressed in the WPS.

Code relates to the qualification of welders, welding

The purpose for qualification of a WPS is to determine

operators, brazers, and brazing operators, and the proce-

that the weldment proposed for construction is capable

dures that they employ in welding and brazing according

of providing the required properties for its intended

to the ASME Boiler and Pressure Vessel Code and

application. Welding procedure qualification establishes

the ASME B31 Code for Pressure Piping. It is divided

the properties of the weldment, not the skill of the

into two parts: Part QW gives requirements for welding

welder or welding operator.

and Part QB contains requirements for brazing. Other

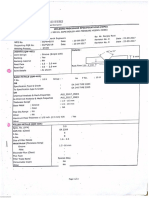

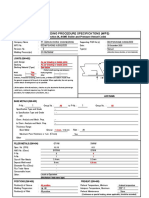

The Procedure Qualification Record (PQR) docu-

Sections of the Code may specify different requirements

ments what occurred during welding the test coupon

than those specified by this Section. Such requirements

and the results of testing of the coupon. As a minimum,

take precedence over those of this Section, and the

the PQR shall document the essential variables and

manufacturer or contractor shall comply with them.

other specific information identified in Article II for

each process used during welding the test coupon and

QW-100.1 A Welding Procedure Specification (WPS)

is a written document that provides direction to the the results of the required testing. In addition, when

welder or welding operator for making production welds notch toughness testing is required for procedure quali-

in accordance with Code requirements. Any WPSs fication, the applicable supplementary essential variables

used by a manufacturer or contractor that will have for each process shall be recorded.

responsible operational control of production welding

shall be a WPS that has been qualified by that manufac- QW-100.2 In performance qualification, the basic

turer or contractor in accordance with Article II, or it criterion established for welder qualification is to deter-

shall be an AWS Standard Welding Procedure Specifi- mine the welder’s ability to deposit sound weld metal.

cation (SWPS) listed in Appendix E and adopted by The purpose of the performance qualification test for the

that manufacturer or contractor in accordance with welding operator is to determine the welding operator’s

Article V. mechanical ability to operate the welding equipment.

Both WPSs and SWPSs specify the conditions (in-

cluding ranges, if any) under which welding must be QW-100.3 Welding Procedure Specifications (WPS)

performed. These conditions include the base metals written and qualified in accordance with the rules of

that are permitted, the filler metals that must be used this Section, and welders and welding operators of

(if any), preheat and postweld heat treatment require- automatic and machine welding equipment also qualified

ments, etc. Such conditions are referred to in this in accordance with these rules may be used in any

Section as welding “variables.” construction built to the requirements of the ASME

When a WPS is to be prepared by the manufacturer Boiler and Pressure Vessel Code or the ASME B31

or contractor, it must address, as a minimum, the Code for Pressure Piping.

specific variables, both essential and nonessential, as However, other Sections of the Code state the condi-

provided in Article II for each process to be used in tions under which Section IX requirements are manda-

production welding. In addition, when other Sections tory, in whole or in part, and give additional require-

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-100.3 2001 SECTION IX QW-122.1

ments. The reader is advised to take these provisions to qualify the welding procedures he uses in the con-

into consideration when using this Section. struction of the weldments built under this Code, and

Welding Procedure Specifications, Procedure Quali- the performance of welders and welding operators who

fication Records, and Welder /Welding Operator Per- apply these procedures.

formance Qualification made in accordance with the

QW-103.2 Records. Each manufacturer or contractor

requirements of the 1962 Edition or any later Edition

shall maintain a record of the results obtained in welding

of Section IX may be used in any construction built

procedure and welder and welding operator performance

to the ASME Boiler and Pressure Vessel Code or the

qualifications. These records shall be certified by the

ASME B31 Code for Pressure Piping.

manufacturer or contractor and shall be accessible to

Welding Procedure Specifications, Procedure Quali-

the Authorized Inspector. Refer to recommended Forms

fication Records, and Welder /Welding Operator Per-

in Nonmandatory Appendix B.

formance Qualification made in accordance with the

requirements of the Editions of Section IX prior to

1962, in which all of the requirements of the 1962

Edition or later Editions are met, may also be used. QW-110 WELD ORIENTATION

Welding Procedure Specifications and Welder/Weld- The orientations of welds are illustrated in QW-

ing Operator Performance Qualification records meeting 461.1 or QW-461.2.

the above requirements do not need to be amended to

include any variables required by later Editions and

Addenda.

QW-120 TEST POSITIONS FOR GROOVE

Qualification of new Welding Procedure Specifica-

WELDS

tions or Welders /Welding Operators and requalification

of existing Welding Procedure Specifications or Groove welds may be made in test coupons oriented

Welders /Welding Operators shall be in accordance with in any of the positions in QW-461.3 or QW-461.4 and

the current Edition (see Foreword) and Addenda of as described in the following paragraphs, except that

Section IX. an angular deviation of ±15 deg from the specified

horizontal and vertical planes, and an angular deviation

of ±5 deg from the specified inclined plane are permitted

QW-101 Scope

during welding.

The rules in this Section apply to the preparation

of Welding Procedure Specifications and the qualifica-

tion of welding procedures, welders, and welding opera- QW-121 Plate Positions

tors for all types of manual and machine welding QW-121.1 Flat Position 1G. Plate in a horizontal

processes permitted in this Section. These rules may plane with the weld metal deposited from above. Refer

also be applied, insofar as they are applicable, to other to QW-461.3 sketch (a).

manual or machine welding processes permitted in other

Sections. QW-121.2 Horizontal Position 2G. Plate in a vertical

plane with the axis of the weld horizontal. Refer to

QW-461.3 sketch (b).

QW-102 Terms and Definitions

QW-121.3 Vertical Position 3G. Plate in a vertical

Some of the more common terms relating to welding plane with the axis of the weld vertical. Refer to QW-

and brazing are defined in QW/QB-492. 461.3 sketch (c).

Wherever the word pipe is designated, tube shall

also be applicable. QW-121.4 Overhead Position 4G. Plate in a hori-

zontal plane with the weld metal deposited from under-

neath. Refer to QW-461.3 sketch (d).

QW-103 Responsibility

QW-103.1 Welding. Each manufacturer1 or contrac-

QW-122 Pipe Positions

tor1 is responsible for the welding done by his organiza-

tion and shall conduct the tests required in this Section QW-122.1 Flat Position 1G. Pipe with its axis

horizontal and rolled during welding so that the weld

1

Wherever these words are used in Section IX, they shall include metal is deposited from above. Refer to QW-461.4

installer or assembler. sketch (a).

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-122.2 GENERAL REQUIREMENTS QW-141.4

QW-122.2 Horizontal Position 2G. Pipe with its QW-132 Pipe Positions

axis vertical and the axis of the weld in a horizontal

QW-132.1 Flat Position 1F. Pipe with its axis

plane. Pipe shall not be rotated during welding. Refer

inclined at 45 deg to horizontal and rotated during

to QW-461.4 sketch (b).

welding so that the weld metal is deposited from above

QW-122.3 Multiple Position 5G. Pipe with its axis and at the point of deposition the axis of the weld is

horizontal and with the welding groove in a vertical horizontal and the throat vertical. Refer to QW-461.6

plane. Welding shall be done without rotating the pipe. sketch (a).

Refer to QW-461.4 sketch (c).

QW-132.2 Horizontal Positions 2F and 2FR

QW-122.4 Multiple Position 6G. Pipe with its axis (a) Position 2F. Pipe with its axis vertical so that

inclined at 45 deg to horizontal. Welding shall be done the weld is deposited on the upper side of the horizontal

without rotating the pipe. Refer to QW-461.4 sketch (d). surface and against the vertical surface. The axis of

the weld will be horizontal and the pipe is not to be

rotated during welding. Refer to QW-461.6 sketch (b).

QW-123 Test Positions for Stud Welds (b) Position 2FR. Pipe with its axis horizontal and

the axis of the deposited weld in the vertical plane.

QW-123.1 Stud Welding. Stud welds may be made The pipe is rotated during welding. Refer to QW-461.6

in test coupons oriented in any of the positions as sketch (c).

described in QW-121 for plate and QW-122 for pipe

(excluding QW-122.1). In all cases, the stud shall be QW-132.3 Overhead Position 4F. Pipe with its axis

perpendicular to the surface of the plate or pipe. See vertical so that the weld is deposited on the underside

QW-461.7 and QW-461.8. of the horizontal surface and against the vertical surface.

The axis of the weld will be horizontal and the pipe

is not to be rotated during welding. Refer to QW-

461.6 sketch (d).

QW-130 TEST POSITIONS FOR FILLET

WELDS QW-132.4 Multiple Position 5F. Pipe with its axis

horizontal and the axis of the deposited weld in the

Fillet welds may be made in test coupons oriented vertical plane. The pipe is not to be rotated during

in any of the positions of QW-461.5 or QW-461.6, welding. Refer to QW-461.6 sketch (e).

and as described in the following paragraphs, except

that an angular deviation of ±15 deg from the specified

horizontal and vertical planes is permitted during

welding. QW-140 TYPES AND PURPOSES OF TESTS

AND EXAMINATIONS

QW-141 Mechanical Tests

QW-131 Plate Positions

Mechanical tests used in procedure or performance

QW-131.1 Flat Position 1F. Plates so placed that qualification are as follows.

the weld is deposited with its axis horizontal and its

throat vertical. Refer to QW-461.5 sketch (a). QW-141.1 Tension Tests. Tension tests as described

in QW-150 are used to determine the ultimate strength

QW-131.2 Horizontal Position 2F. Plates so placed of groove-weld joints.

that the weld is deposited with its axis horizontal on

the upper side of the horizontal surface and against QW-141.2 Guided-Bend Tests. Guided-bend tests

the vertical surface. Refer to QW-461.5 sketch (b). as described in QW-160 are used to determine the

degree of soundness and ductility of groove-weld joints.

QW-131.3 Vertical Position 3F. Plates so placed

that the weld is deposited with its axis vertical. Refer QW-141.3 Fillet-Weld Tests. Tests as described in

to QW-461.5 sketch (c). QW-180 are used to determine the size, contour, and

degree of soundness of fillet welds.

QW-131.4 Overhead Position 4F. Plates so placed

that the weld is deposited with its axis horizontal on QW-141.4 Notch-Toughness Tests. Tests as de-

the underside of the horizontal surface and against the scribed in QW-171 and QW-172 are used to determine

vertical surface. Refer to QW-461.5 sketch (d). the notch toughness of the weldment.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-141.5 2001 SECTION IX QW-151.3

QW-141.5 Stud-Weld Test. Deflection bend, ham- number of approximately equal strips of a size that

mering, torque, or tension tests as shown in QW-466.4, can be tested in the available equipment. Each specimen

QW-466.5, and QW-466.6, and a macro-examination of the set shall be tested and meet the requirements

performed in accordance with QW-202.5, respectively, of QW-153.

are used to determine acceptability of stud welds.

QW-151.2 Reduced Section — Pipe. Reduced-sec-

tion specimens conforming to the requirements given

QW-142 Special Examinations for Welders

in QW-462.1(b) may be used for tension tests on all

Radiographic examination may be substituted for thicknesses of pipe having an outside diameter greater

mechanical testing of QW-141 for groove-weld perform- than 3 in. (76 mm).

ance qualification as permitted in QW-304 to prove (a) For thicknesses up to and including 1 in. (25 mm),

the ability of welders to make sound welds. a full thickness specimen shall be used for each required

tension test.

QW-143 Examination for Welding Operators (b) For pipe thicknesses greater than 1 in. (25 mm),

full thickness specimens or multiple specimens may

An examination of a weld by radiography may be be used, provided QW-151.2(c) and QW-151.2(d) are

substituted for mechanical testing of QW-141 for groove complied with.

weld performance qualification as permitted in QW- (c) When multiple specimens are used, in lieu of

305 to prove the ability of welding operators to make full thickness specimens, each set shall represent a

sound welds. single tension test of the full pipe thickness. Collectively,

all of the specimens required to represent the full

QW-144 Visual Examination thickness of the weld at one location shall comprise

a set.

Visual examination as described in QW-194 is used (d) When multiple specimens are necessary, the entire

to determine that the final weld surfaces meet specified thickness shall be mechanically cut into a minimum

quality conditions. number of approximately equal strips of a size that

can be tested in the available equipment. Each specimen

of the set shall be tested and meet the requirements

QW-150 TENSION TESTS of QW-153.

QW-151 Specimens For pipe having an outside diameter of 3 in. (76

mm) or less, reduced-section specimens conforming to

Tension test specimens shall conform to one of the the requirements given in QW-462.1(c) may be used

types illustrated in QW-462.1(a) through QW-462.1(e) for tension tests.

and shall meet the requirements of QW-153.

QW-151.1 Reduced Section — Plate. Reduced- QW-151.3 Turned Specimens. Turned specimens

section specimens conforming to the requirements given conforming to the requirements given in QW-462.1(d)

in QW-462.1(a) may be used for tension tests on all may be used for tension tests.

thicknesses of plate. (a) For thicknesses up to and including 1 in. (25 mm),

(a) For thicknesses up to and including 1 in. (25 mm), a single turned specimen may be used for each required

a full thickness specimen shall be used for each required tension test, which shall be a specimen of the largest

tension test. diameter D of QW-462.1(d) possible for test coupon

(b) For plate thickness greater than 1 in. (25 mm), thickness [per Note (a) of QW-462.1(d)].

full thickness specimens or multiple specimens may (b) For thicknesses over 1 in. (25 mm), multiple

be used, provided QW-151.1(c) and QW-151.1(d) are specimens shall be cut through the full thickness of

complied with. the weld with their centers parallel to the metal surface

(c) When multiple specimens are used, in lieu of and not over 1 in. (25 mm) apart. The centers of the

full thickness specimens, each set shall represent a single specimens adjacent to the metal surfaces shall not

tension test of the full plate thickness. Collectively, all exceed 5/8 in. (16 mm) from the surface.

of the specimens required to represent the full thickness (c) When multiple specimens are used, each set shall

of the weld at one location shall comprise a set. represent a single required tension test. Collectively,

(d) When multiple specimens are necessary, the entire all the specimens required to represent the full thickness

thickness shall be mechanically cut into a minimum of the weld at one location shall comprise a set.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-151.3 GENERAL REQUIREMENTS QW-161.6

(d) Each specimen of the set shall be tested and The other two surfaces shall be called the face and

meet the requirements of QW-153. root surfaces, the face surface having the greater width

of weld. The specimen thickness and bend radius

QW-151.4 Full-Section Specimens for Pipe. Ten-

are shown in QW-466.1, QW-466.2, and QW-466.3.

sion specimens conforming to the dimensions given in

Guided-bend specimens are of five types, depending

QW-462.1(e) may be used for testing pipe with an

on whether the axis of the weld is transverse or parallel

outside diameter of 3 in. (76 mm) or less.

to the longitudinal axis of the specimen, and which

surface (side, face, or root) is on the convex (outer)

QW-152 Tension Test Procedure side of bent specimen. The five types are defined as

follows.

The tension test specimen shall be ruptured under

tensile load. The tensile strength shall be computed by QW-161.1 Transverse Side Bend. The weld is

dividing the ultimate total load by the least cross- transverse to the longitudinal axis of the specimen,

sectional area of the specimen as calculated from actual which is bent so that one of the side surfaces becomes

measurements made before the load is applied. the convex surface of the bent specimen. Transverse

side-bend test specimens shall conform to the dimen-

sions shown in QW-462.2.

QW-153 Acceptance Criteria — Tension Tests

Specimens of base metal thickness over 11⁄2 in. (38

01 QW-153.1 Tensile Strength. Minimum values for mm) may be cut into approximately equal strips between

3

procedure qualification are provided under the column ⁄4 in. (19 mm) and 11⁄2 in. (38 mm) wide for testing,

heading “Minimum Specified Tensile, ksi” of QW/QB- or the specimens may be bent at full width (see

422. In order to pass the tension test, the specimen requirements on jig width in QW-466). If multiple

shall have a tensile strength that is not less than: specimens are used, one complete set shall be made

(a) the minimum specified tensile strength of the for each required test. Each specimen shall be tested

base metal; or and meet the requirements in QW-163.

(b) the minimum specified tensile strength of the

QW-161.2 Transverse Face Bend. The weld is

weaker of the two, if base metals of different minimum

transverse to the longitudinal axis of the specimen,

tensile strengths are used; or

which is bent so that the face surface becomes the

(c) the minimum specified tensile strength of the

convex surface of the bent specimen. Transverse face-

weld metal when the applicable Section provides for

bend test specimens shall conform to the dimensions

the use of weld metal having lower room temperature

shown in QW-462.3(a). For subsize transverse face

strength than the base metal;

bends, see QW-161.4.

(d) if the specimen breaks in the base metal outside

of the weld or weld interface, the test shall be accepted QW-161.3 Transverse Root Bend. The weld is

as meeting the requirements, provided the strength is transverse to the longitudinal axis of the specimen,

not more than 5% below the minimum specified tensile which is bent so that the root surface becomes the

strength of the base metal. convex surface of the bent specimen. Transverse root-

(e) the specified minimum tensile strength is for full bend test specimens shall conform to the dimensions

thickness specimens including cladding for Aluminum shown in QW-462.3(a). For subsize transverse root

Alclad materials (P-No. 21 through P-No. 23) 0.499 bends, see QW-161.4.

in. (12.5 mm) and less. For Aluminum Alclad materials

0.5 in. (13 mm) and greater, the specified minimum QW-161.4 Subsize Transverse Face and Root

tensile strength is for both full thickness specimens Bends. See Note (2) of QW-462.3(a).

that include cladding and specimens taken from the core. QW-161.5 Longitudinal-Bend Tests. Longitudinal-

bend tests may be used in lieu of the transverse side-

, face-, and root-bend tests for testing weld metal or

QW-160 GUIDED-BEND TESTS base metal combinations which differ markedly in

QW-161 Specimens bending properties between

(a) the two base metals; or

Guided-bend test specimens shall be prepared by (b) the weld metal and the base metal.

cutting the test plate or pipe to form specimens of

approximately rectangular cross section. The cut sur- QW-161.6 Longitudinal Face Bend. The weld is

faces shall be designated the sides of the specimen. parallel to the longitudinal axis of the specimen, which

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-161.6 2001 SECTION IX QW-181.1

is bent so that the face surface becomes the convex no open discontinuities exceeding 1⁄8 in. (3.2 mm) shall

surface of the bent specimen. Longitudinal face-bend be permitted along the approximate weld interface.

test specimens shall conform to the dimensions shown

in QW-462.3(b).

QW-170 NOTCH-TOUGHNESS TESTS

QW-161.7 Longitudinal Root Bend. The weld is

parallel to the longitudinal axis of the specimen, which QW-171 Notch-Toughness Tests — Charpy

is bent so that the root surface becomes the convex V-Notch

side of the bent specimen. Longitudinal root-bend test

QW-171.1 General. Charpy V-notch impact tests

specimens shall conform to the dimensions shown in

shall be made when required by other Sections.

QW-462.3(b).

Test procedures and apparatus shall conform to the

requirements of SA-370.

QW-162 Guided-Bend Test Procedure QW-171.2 Acceptance. The acceptance criteria shall

QW-162.1 Jigs. Guided-bend specimens shall be be in accordance with that Section specifying impact

bent in test jigs that are in substantial accordance with requirements.

QW-466. When using the jigs illustrated in QW-466.1 QW-171.3 Location and Orientation of Test Speci-

or QW-466.2, the side of the specimen turned toward men. The impact test specimen and notch location and

the gap of the jig shall be the face for face-bend orientation shall be as given in the Section requiring

specimens, the root for root-bend specimens, and the such tests.

side with the greater discontinuities, if any, for side- When qualifying pipe in the 5G or 6G position, the

bend specimens. The specimen shall be forced into the notch-toughness specimens shall be removed from the

die by applying load on the plunger until the curvature shaded portion of QW-463.1(f).

of the specimen is such that a 1⁄8 in. (3.2 mm) diameter

wire cannot be inserted between the specimen and the

die of QW-466.1, or the specimen is bottom ejected QW-172 Notch-Toughness Tests — Drop

if the roller type of jig (QW-466.2) is used. Weight

When using the wrap around jig (QW-466.3), the QW-172.1 General. Drop weight tests shall be made

side of the specimen turned toward the roller shall be when required by other Sections.

the face for face-bend specimens, the root for root- Test procedures and apparatus shall conform to the

bend specimens, and the side with the greater discontinu- requirements of ASTM Specification E 208.

ities, if any, for side-bend specimens.

When specimens wider than 11⁄2 in. (38 mm) are to QW-172.2 Acceptance. The acceptance criteria shall

be bent as permitted in QW-462.2, the test jig mandrel be in accordance with that Section requiring drop

must be at least 1⁄4 in. (6 mm) wider than the specimen weight tests.

width. QW-172.3 Location and Orientation of Test Speci-

men. The drop weight test specimen, the crack starter

location, and the orientation shall be as given in the

QW-163 Acceptance Criteria — Bend Tests

Section requiring such tests.

The weld and heat-affected zone of a transverse When qualifying pipe in the 5G or 6G position, the

weld-bend specimen shall be completely within the notch-toughness specimens shall be removed from the

bent portion of the specimen after testing. shaded portion of QW-463.1(f).

The guided-bend specimens shall have no open dis-

continuities in the weld or heat-affected zone exceeding

1

⁄8 in. (3.2 mm), measured in any direction on the QW-180 FILLET-WELD TESTS

convex surface of the specimen after bending. Open

QW-181 Procedure and Performance

discontinuities occurring on the corners of the specimen

Qualification Specimens

during testing shall not be considered unless there is

definite evidence that they result from lack of fusion, QW-181.1 Procedure. The dimensions and prepara-

slag inclusions, or other internal discontinuities. For tion of the fillet-weld test coupon for procedure qualifi-

corrosion-resistant weld overlay cladding, no open dis- cation as required in QW-202 shall conform to the

continuity exceeding 1⁄16 in. (1.6 mm), measured in requirements in QW-462.4(a) or QW-462.4(d). The test

any direction, shall be permitted in the cladding, and coupon for plate-to-plate shall be cut transversely to

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-181.1 GENERAL REQUIREMENTS QW-184

provide five test specimen sections, each approximately accordance with QW-184. When qualifying pipe-to-

2 in. (51 mm) long. For pipe-to-plate or pipe-to-pipe, shape in the 5F position, the fracture specimen shall

the test coupon shall be cut transversely to provide be removed from the lower 90 deg section of the

four approximately equal test specimen sections. The mockup.

test specimens shall be macro-examined to the require-

ments of QW-183.

QW-182 Fracture Tests

QW-181.1.1 Production Assembly Mockups.

Production assembly mockups may be used in lieu of The stem of the 4 in. performance specimen center

QW-181.1. The mockups for plate-to-shape shall be section in QW-462.4(b) or the stem of the quarter

cut transversely to provide five approximately equal test section in QW-462.4(c), as applicable, shall be loaded

specimens not to exceed approximately 2 in. (51 mm) in laterally in such a way that the root of the weld is in

length. For pipe-to-shape mockups, the mockup shall tension. The load shall be steadily increased until the

be cut transversely to provide four approximately equal specimen fractures or bends flat upon itself.

test specimens. For small mockups, multiple mockups If the specimen fractures, the fractured surface shall

may be required to obtain the required number of test show no evidence of cracks or incomplete root fusion,

specimens. The test specimens shall be macro-examined and the sum of the lengths of inclusions and porosity

to the requirements of QW-183. visible on the fractured surface shall not exceed 3⁄8 in.

(10 mm) in QW-462.4(b) or 10% of the quarter section

QW-181.2 Performance. The dimensions and the in QW-462.4(c).

preparation of the fillet-weld test coupon for perform-

ance qualification shall conform to the requirements in

QW-462.4(b) or QW-462.4(c). The test coupon for QW-183 Macro-Examination — Procedure

plate-to-plate shall be cut transversely to provide a Specimens

center section approximately 4 in. (102 mm) long and

One face of each cross section of the five test

two end sections, each approximately 1 in. (25 mm)

specimens in QW-462.4(a) or four test specimens in

long. For pipe-to-plate or pipe-to-pipe, the test coupon

QW-462.4(d), as applicable shall be smoothed and

shall be cut to provide two quarter sections test speci-

etched with a suitable etchant (see QW-470) to give

mens opposite to each other. One of the test specimens

a clear definition to the weld metal and heat affected

shall be fracture tested in accordance with QW-182

zone. The examination of the cross sections shall include

and the other macro-examined to the requirements of

only one side of the test specimen at the area where

QW-184. When qualifying pipe-to-plate or pipe-to-pipe

the plate or pipe is divided into sections i.e., adjacent

in the 5F position, the test specimens shall be removed

faces at the cut shall not be used. In order to pass

as indicated in QW-463.2(h).

the test:

QW-181.2.1 Production Assembly Mockups. Visual examination of the cross sections of the weld

Production assembly mockups may be used in lieu of metal and heat affected zone shall show complete fusion

the fillet-weld test coupon requirements of QW-181.2. and freedom from cracks; and

(a) Plate-to-shape There shall not be more than 1⁄8 in. (3.2 mm)

(1) The mockup for plate-to-shape shall be cut difference in the length of the legs of the fillet.

transversely to provide three approximately equal test

specimens not to exceed approximately 2 in. (51 mm)

in length. The test specimen that contains the start and QW-184 Macro-Examination — Performance

stop of the weld shall be fracture tested in accordance Specimens

with QW-182. A cut end of one of the remaining test The cut end of one of the end plate sections, approxi-

specimens shall be macro-examined in accordance with mately 1 in. long, in QW-462.4(b) or the cut end of

QW-184. one of the pipe quarter sections in QW-462.4(c), as

(b) Pipe-to-shape applicable, shall be smoothed and etched with a suitable

(1) The mockup for pipe-to-shape shall be cut etchant (see QW-470) to give a clear definition of the

transversely to provide two quarter sections approxi- weld metal and heat affected zone. In order to pass

mately opposite to each other. The test specimen that the test:

contains the start and stop of the weld shall be fracture Visual examination of the cross section of the weld

tested in accordance with QW-182. A cut end of metal and heat affected zone shall show complete fusion

the other quarter section shall be macro-examined in and freedom from cracks, except that linear indications

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-184 2001 SECTION IX QW-192.1

at the root not exceeding 1⁄32 in. (0.8 mm) shall be (a) 1⁄8 in. (3.2 mm) for t up to 3⁄8 in. (10 mm),

acceptable; and inclusive

The weld shall not have a concavity or convexity (b) 1⁄3t for t over 3⁄8 in. (10 mm) to 21⁄4 in. (57

greater than 1⁄16 in. (1.6 mm); and mm), inclusive

There shall be not more than 1⁄8 in. (3.2 mm) (c) 3⁄4 in. (19 mm) for t over 21⁄4 in. (57 mm)

difference in the lengths of the legs of the fillet. (3) any group of slag inclusions in line that have

an aggregate length greater than t in a length of

12t, except when the distance between the successive

imperfections exceeds 6L where L is the length of the

QW-190 OTHER TESTS AND

longest imperfection in the group.

EXAMINATIONS

(b) Rounded Indications

QW-191 Radiographic Examination (1) The maximum permissible dimension for

QW-191.1 Method. The radiographic examination rounded indications shall be 20% of t or 1⁄8 in. (3.2 mm),

in QW-142 for welders and in QW-143 for welding whichever is smaller.

operators shall meet the requirements of Article 2, (2) For welds in material less than 1⁄8 in. (3.2

Section V, except as follows. mm) in thickness, the maximum number of acceptable

(a) A written radiographic examination procedure is rounded indications shall not exceed 12 in a 6 in.

not required. Demonstration of density and penetrameter (152 mm) length of weld. A proportionately fewer

image requirements on production or technique radio- number of rounded indications shall be permitted in

graphs shall be considered satisfactory evidence of welds less than 6 in. (152 mm) in length.

compliance with Article 2 of Section V. (3) For welds in material 1⁄8 in. (3.2 mm) or

(b) The requirements of T-285 of Article 2 of Section greater in thickness, the charts in Appendix I represent

V are to be used only as a guide. Final acceptance of the maximum acceptable types of rounded indications

radiographs shall be based on the ability to see the illustrated in typically clustered, assorted, and randomly

prescribed penetrameter image and the specified hole dispersed configurations. Rounded indications less than

or the designated wire or a wire penetrameter. The 1

⁄32 in. (0.8 mm) in maximum diameter shall not be

acceptance standards of QW-191.2 shall be met. considered in the radiographic acceptance tests of weld-

ers and welding operators in these ranges of material

QW-191.2 Radiographic Acceptance Criteria

thicknesses.

QW-191.2.1 Terminology

Linear Indications. Cracks, incomplete fusion, inade- QW-191.2.3 Production Welds. The acceptance

quate penetration, and slag are represented on the standard for welding operators who qualify on produc-

radiograph as linear indications in which the length is tion welds shall be that specified in the referencing

more than three times the width. Code Section. The acceptance standard for welders who

Rounded Indications. Porosity and inclusions such qualify on production welds as permitted by QW-304.1

as slag or tungsten are represented on the radiograph shall be per QW-191.2.2.

as rounded indications with a length three times the

width or less. These indications may be circular, ellip-

QW-191.3 Record of Tests. The results of welder

tical, or irregular in shape; may have tails; and may

and welding operator performance tests by radiography

vary in density.

shall be recorded in accordance with QW-301.4.

QW-191.2.2 Acceptance Standards. Welder and

welding operator performance tests by radiography of

welds in test assemblies shall be judged unacceptable

when the radiograph exhibits any imperfections in

excess of the limits specified below. QW-192 Stud-Weld Tests — Procedure

(a) Linear Indications Qualification Specimens

(1) any type of crack or zone of incomplete fusion QW-192.1 Required Tests. Ten stud-weld tests are

or penetration; required to qualify each procedure. The equipment used

(2) any elongated slag inclusion which has a length for stud welding shall be completely automatic except

greater than: for manual starting.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-192.1 GENERAL REQUIREMENTS QW-193.1

Every other welding stud (five joints) shall be tested Required Torque for Testing

either by hammering over until one-fourth of its length Threaded Austenitic Stainless Steel Studs

Nominal Diameter Threads /in. Testing Torque,

is flat on the test piece, or by bending the stud to an of Studs, in. and Series Designated ft-lb

angle of at least 15 deg and returning it to its original 1

⁄4 28 UNF 4.5

position using a test jig and an adapter location dimen- 1

⁄4 20 UNC 4.0

sion that are in accordance with QW-466.4. 5

⁄16 24 UNF 9.0

The remaining five welded stud joints shall be tested 5

⁄16 18 UNC 8.0

in torque using a torque testing arrangement that is 3

⁄8 24 UNF 16.5

substantially in accordance with QW-466.5. Alterna- 3

⁄8 16 UNC 14.5

tively, where torquing is not feasible, tensile testing 7

⁄16 20 UNF 26.0

may be used, and the fixture for tensile testing shall 7

⁄16 14 UNC 23.0

be similar to that shown in QW-466.6 except that studs 1

⁄2 20 UNF 40.0

without heads may be gripped on the unwelded end 1

⁄2 13 UNC 35.5

in the jaws of the tensile testing machine. 5

⁄8 18 UNF 80.00

5

⁄8 11 UNC 71.00

QW-192.2 Acceptance Criteria — Bend and Ham- 3

⁄4 16 UNF 140.00

mer Tests. In order to pass the test(s), each of the 3

⁄4 10 UNC 125.00

five stud welds and heat affected zones shall be free 7

⁄8 14 UNF 223.00

of visible separation or fracture after bending and return 7

⁄8 9 UNC 202.00

bending or after hammering.

1 14 UNF 339.00

1 8 UNC 303.00

QW-192.3 Acceptance Criteria — Torque Tests.

In order to pass the test(s), each of the five stud welds Alternatively, where torquing to destruction is not

shall be subjected to the required torque shown in the feasible, tensile testing may be used. For carbon and

following table before failure occurs. austenitic stainless steel studs, the failure strength shall

not be less than 35,000 psi (241 MPa) and 30,000 psi

(207 MPa), respectively. For other metals, the failure

strength shall not be less than 1⁄2 of the minimum

specified tensile strength of the stud material. The

Required Torque for Testing failure strength shall be based on the minor diameter

Threaded Carbon Steel Studs of the threaded section of externally threaded studs

Nominal Diameter Threads /in. Testing Torque, except where the shank diameter is less than the minor

of Studs, in. and Series Designated ft-lb diameter, or on the original cross-sectional area where

1

⁄4 28 UNF 5.0 failure occurs in a nonthreaded, internally threaded, or

1

⁄4 20 UNC 4.2 reduced-diameter stud.

5

⁄16 24 UNF 9.5

5

⁄16 18 UNC 8.6 QW-192.4 Acceptance Criteria — Macro-Exami-

3

⁄8 24 UNF 17 nation. In order to pass the macro-examination, each

3

⁄8 16 UNC 15 of five sectioned stud welds and the heat affected zone

7

⁄16 20 UNF 27 shall be free of cracks when examined at a magnification

7

⁄16 14 UNC 24 of ×10, which is required by QW-202.5 when studs

1

⁄2 20 UNF 42 are welded to metals other than P-No. 1.

1

⁄2 13 UNC 37

9

⁄16 18 UNF 60

9

⁄16 12 UNC 54

5

QW-193 Stud-Weld Tests — Performance

⁄8 18 UNF 84 Qualification Specimens

5

⁄8 11 UNC 74

3

⁄4 16 UNF 147 QW-193.1 Required Tests. Five stud-weld tests are

3

⁄4 10 UNC 132 required to qualify each stud-welding operator. The

7

⁄8 14 UNF 234 equipment used for stud welding shall be completely

7

⁄8 9 UNC 212 automatic except for manual starting. The performance

1 12 UNF 348 test shall be welded in accordance with a qualified

1 8 UNC 318 WPS per QW-301.2.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-193.1 2001 SECTION IX QW-197.2

Each stud (five joints) shall be tested either by QW-196.1.2 The weld nugget shall be sound for

hammering over until one-fourth of its length is flat 1.25 times the thickness of the thinner member.

on the test piece or by bending the stud to an angle QW-196.1.3 For spot welds, the nugget size shall

of at least 15 deg and returning it to its original position be measured at the interface between the sheets being

using a test jig and an adapter location dimension that joined, and it shall equal or exceed 0.9冪t, where t is

are in accordance with QW-466.4. the thickness of the thinner sheet. For projection welds,

QW-193.2 Acceptance Criteria — Bend and Ham- the nugget size shall not be less than the initial size

mer Tests. In order to pass the test(s), each of the of the projection. For seam welds, the width of the

five stud welds and heat affected zones shall be free fused weld cut transverse to the seam shall be not less

of visible separation or fracture after bending and return than 0.9冪t, where t is the thickness of the thinnest sheet.

bending or after hammering.

QW-196.2 Mechanical Testing

QW-196.2.1 Shear test specimens shall be prepared

QW-194 Visual Examination — Performance

as shown on QW-462.9. For spot and projection welds,

Performance test coupons shall show complete joint each test specimen shall equal or exceed the minimum

penetration with complete fusion of weld metal and strength, and the average strength specified in QW-

base metal. 462.10 and QW-462.11 for the appropriate material.

Further, for each set, 90% shall have shear strength

values between 0.9 and 1.1 times the set average value.

QW-195 Liquid Penetrant Examination

The remaining 10% shall lie between 0.8 and 1.2 times

QW-195.1 The liquid penetrant examination in QW- the set average value.

214 for corrosion-resistant weld metal overlay shall QW-196.2.2 Peel test specimens shall be prepared

meet the requirements of Section V, Article 6. The as shown in QW-462.8. The specimens shall be peeled

acceptance standards of QW-195.2 shall be met. or separated mechanically, and fracture shall occur in

QW-195.2 Liquid Penetrant Acceptance Criteria the base metal by tearing out of the weld in order for

the specimen to be acceptable.

QW-195.2.1 Terminology

(a) relevant indications — indications with major QW-197 Laser Beam Welding (LBW) Lap

dimensions greater than 1⁄16 in. (1.6 mm). Joint Tests — Procedure Qualification

(b) linear indications — an indication having a length Specimens

greater than three times the width

QW-197.1 Required Tests. Six tension shear speci-

(c) rounded indications — an indication of circular

mens and eight macro specimens are required to qualify

or elliptical shape with the length equal to or less than

each procedure. The qualification test coupon shall be

three times the width

prepared in accordance with QW-464.1. The tension

QW-195.2.2 Acceptance Standards. Procedure shear specimens shall conform to the dimensions indi-

and performance tests examined by liquid penetrant cated in the table of QW-464.1. The longitudinal and

techniques shall be judged unacceptable when the exam- traverse sections indicated in QW-464.1 shall be cross-

ination exhibits any indication in excess of the limits sectioned as closely as possible through the centerline

specified below: of the weld. A minimum of 1 in. (25 mm) shall be

(a) relevant linear indications; provided for examination of each longitudinal specimen.

(b) relevant rounded indications greater than 3⁄16 in. The traverse specimens shall be of sufficient length to

(4.8 mm); include weld, the heat-affected zone, and portions of

(c) four or more relevant rounded indications in a the unaffected base material. Cross-sections shall be

line separated by 1⁄16 in. (1.6 mm) or less (edge-to- smoothed and etched with a suitable etchant (see QW-

edge). 470), and examined at a minimum magnification of

25X. The dimensions of the fusion zone and penetration

of each weld of the traverse specimens shall be measured

QW-196 Resistance Weld Testing

to the nearest hundredth of an inch and recorded.

QW-196.1 Metallographic Examination

QW-196.1.1 Welds shall be cross-sectioned, pol- QW-197.2 Acceptance Criteria — Tension Shear

ished, and etched to reveal the weld metal. The section Tests. In order to pass the tension shear test(s), the

shall be examined at a magnification of 10 times. requirements of QW-153 shall apply.

10

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-197.3 GENERAL REQUIREMENTS QW-198.2

QW-197.3 Acceptance Criteria — Macro-Exami- in QW-464.2 sketch (a) and macro specimens as shown

nation. In order to pass the macro-examination, each in QW-464.2 sketch (b). The peel test specimens shall

of the eight specimens shall meet the following criteria. be peeled apart to destruction and the fusion zone and

(a) The outline of the fusion zone shall be generally penetration measured to the nearest hundredth of an

consistent in size and regular in shape and uniformity inch. The end of each strip of the macro coupon shall

of penetration. be polished and etched to clearly reveal the weld metal.

(b) The examination of the weld area shall reveal The width and depth of penetration of each weld shall

sound weld metal, complete fusion along the bond line, be measured to the nearest hundredth of an inch. Each

and complete freedom from cracks in the weld metal specimen shall be examined in accordance with QW-

and heat-affected zone. 197.1.

QW-198.2 Acceptance Criteria — Peel Test and

QW-198 Laser Beam Welding (LBW) Lap

Macro-Examination. In order to pass the peel test

Joint Tests — Performance

and macro-examination, the dimensions of the fusion

Qualification Specimens

zone (averaged) and the penetration (averaged) shall

QW-198.1 Required Tests. A peel test specimen at be within the range of dimensions of those specified

least 6 in. (152 mm) long shall be prepared as shown on the WPS that was used to make the test coupon.

11

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Appendix I 2001 SECTION IX

APPENDIX I

ROUNDED INDICATION CHARTS

(See QW-191.2)

Typical Quantity and Size Permitted

in 6 in. (152 mm) Length of Weld

1/ in. (3.2 mm) to 1/ in. (6 mm)

8 4

Thickness

Typical Quantity and Size Permitted

in 6 in. (152 mm) Length of Weld

Over 1/4 in. (6 mm) to 1/2 in. (13 mm)

Thickness

Typical Quantity and Size Permitted

in 6 in. (152 mm) Length of Weld

Over 1/2 in. (13 mm) to 1 in. (25 mm)

Thickness

Typical Quantity and Size Permitted

in 6 in. (152 mm) Length of Weld

Over 1 in. (25 mm) Thickness

12

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

You might also like

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingaamirtec301100% (2)

- Pressure Vessel RT TestDocument3 pagesPressure Vessel RT TestBhavani Prasad100% (1)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Astm A923Document9 pagesAstm A923utreshwarmiskin100% (1)

- Pressure Testing of Pressure VesselDocument3 pagesPressure Testing of Pressure VesselAriq FauzanNo ratings yet

- VT Acceptance Criteria WeldsDocument14 pagesVT Acceptance Criteria WeldsCharwin Xiao100% (2)

- Pressure Vessel RT TestDocument3 pagesPressure Vessel RT TestAriq FauzanNo ratings yet

- P1 To P8Document9 pagesP1 To P8Pat AuffretNo ratings yet

- Asme Section II A Sa-435 Sa-435mDocument4 pagesAsme Section II A Sa-435 Sa-435mAnonymous GhPzn1xNo ratings yet

- ASTM C 1172 Laminated-Std PDFDocument1 pageASTM C 1172 Laminated-Std PDFpandey008No ratings yet

- Pressure Vessel Inspection Procedure Rev.2Document24 pagesPressure Vessel Inspection Procedure Rev.2Ariq Fauzan100% (7)

- RT Acceptance CriteriaDocument3 pagesRT Acceptance CriteriaRanjan Kumar100% (2)

- ASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesDocument9 pagesASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesAnnamalai Ram JGC100% (2)

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Tube To Tube Sheet WeldingDocument5 pagesTube To Tube Sheet WeldingGowrish Kumar100% (2)

- Comparision Between AWS D1.1&ASME Sec - IXDocument33 pagesComparision Between AWS D1.1&ASME Sec - IXStephen RajNo ratings yet

- Brazing Procedure Specification (BPS) : JOINTS (QB-408)Document1 pageBrazing Procedure Specification (BPS) : JOINTS (QB-408)Bernard PenuliarNo ratings yet

- ASMe Sec2 PartcDocument53 pagesASMe Sec2 PartcSARSAN NDTNo ratings yet

- Asme Sec Viii D1 Nma App RDocument2 pagesAsme Sec Viii D1 Nma App RADRIAN100% (2)

- MTC Review ChecklistDocument5 pagesMTC Review ChecklistShaheen Andre ChikkuNo ratings yet

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (2)

- Shell Petroleum Development Company: (Implemented/Issued For Review/Complete)Document17 pagesShell Petroleum Development Company: (Implemented/Issued For Review/Complete)Siva RamNo ratings yet

- Asme Sect. Ix Part QW Art. I 2005 PDFDocument12 pagesAsme Sect. Ix Part QW Art. I 2005 PDFarlyNo ratings yet

- Set-On and Set-Through Nozzle InstallationDocument3 pagesSet-On and Set-Through Nozzle InstallationLiu Yangtze100% (1)

- How To Read PWHTchartDocument10 pagesHow To Read PWHTchartAkhilesh Kumar100% (4)

- ASME P Material NumbersDocument2 pagesASME P Material NumbersAbdullah100% (1)

- Pressure Vessel DefinitionDocument2 pagesPressure Vessel DefinitionAriq FauzanNo ratings yet

- B31.3 Table 330.1.1 Preheat TempDocument1 pageB31.3 Table 330.1.1 Preheat TempHusam Ahmed100% (1)

- Guide To Astm E446Document36 pagesGuide To Astm E446ehsan hatami100% (4)

- IGC Test ASTM A261 Practice EDocument2 pagesIGC Test ASTM A261 Practice Epradeep100% (1)

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilNo ratings yet

- WPS-Tube To Tube Sheet (SS-SS)Document2 pagesWPS-Tube To Tube Sheet (SS-SS)suria qaqcNo ratings yet

- AWS D1.1 (2020) - Essential Variable For WPS & WeldersDocument7 pagesAWS D1.1 (2020) - Essential Variable For WPS & WeldersFouad OudinaNo ratings yet

- Pages de ASME VIII - DIV.1 (2019) UW-35Document1 pagePages de ASME VIII - DIV.1 (2019) UW-35HamdiMallouliNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- General Requirements For Chemical Check Analysis Limits For Nickel, Nickel Alloys and Cobalt AlloysDocument4 pagesGeneral Requirements For Chemical Check Analysis Limits For Nickel, Nickel Alloys and Cobalt Alloysanurag yadavNo ratings yet

- API 653 Exam 2 ClosedDocument5 pagesAPI 653 Exam 2 ClosedAriq FauzanNo ratings yet

- Fluke Price List - Test Equipment DepotDocument28 pagesFluke Price List - Test Equipment Depotben_splNo ratings yet

- Weld Fit Up Inspection Employee TrainingDocument10 pagesWeld Fit Up Inspection Employee TrainingBadiuzzama Azmi100% (2)

- Dissimilar Base Metal ThicknessDocument5 pagesDissimilar Base Metal ThicknessFERNANDO MIRANDA100% (2)

- En 13445 Background To The Rules in Part 3 Design (2004)Document87 pagesEn 13445 Background To The Rules in Part 3 Design (2004)David CubillosNo ratings yet

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Table UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1Document4 pagesTable UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1MechanicalNo ratings yet

- Welding Acceptance Criteria On Pipe LineDocument2 pagesWelding Acceptance Criteria On Pipe Linewahyu100% (1)

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- WPS1Document10 pagesWPS1bhavin178No ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- PART 66 ASME IX - Part 2 Essential Variable For Welder QualificationDocument13 pagesPART 66 ASME IX - Part 2 Essential Variable For Welder Qualificationravindra_jivaniNo ratings yet

- Dss 2205 Wps PQR WPQDocument8 pagesDss 2205 Wps PQR WPQAnand KesarkarNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- API 510 Questions June 02 2004 1Document10 pagesAPI 510 Questions June 02 2004 1Ariq FauzanNo ratings yet

- Qualification of Tube To Tubesheet TTJ WDocument10 pagesQualification of Tube To Tubesheet TTJ Whafiz zullaileNo ratings yet

- QW-403 6Document1 pageQW-403 6Solikhul HarisNo ratings yet

- Defect ASME Sec. I ASME B31.1 ASME Sec. VIII, Div. I, Para. UW-51 API 650 Asme Sec Viii Div. I, Paragraph UW-52Document7 pagesDefect ASME Sec. I ASME B31.1 ASME Sec. VIII, Div. I, Para. UW-51 API 650 Asme Sec Viii Div. I, Paragraph UW-52Anil100% (2)

- Astm A262 Igc Test PPTDocument50 pagesAstm A262 Igc Test PPTRakesh Mishra100% (3)

- ASME IX Interpretation-Part11Document40 pagesASME IX Interpretation-Part11kevin herryNo ratings yet

- Multiple PQR QualificationDocument4 pagesMultiple PQR QualificationKarthikeyan ShanmugavelNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- API 650 12th - 2013Document4 pagesAPI 650 12th - 2013mohamed100% (1)

- Edo Cal Coe Cor Int XXX 014 190 218 Rev A CP Calculation - Methodology For Tank Bottom ExternalsDocument17 pagesEdo Cal Coe Cor Int XXX 014 190 218 Rev A CP Calculation - Methodology For Tank Bottom ExternalsErol DAĞNo ratings yet

- Taiko - Centrifugal PumpsDocument20 pagesTaiko - Centrifugal PumpsYaman Yalçın100% (1)

- Macro-Examination: Test Code/Year Part/Section/Type Acceptance Criteria ReferenceDocument3 pagesMacro-Examination: Test Code/Year Part/Section/Type Acceptance Criteria ReferenceDelil Ozan100% (1)

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocument1 pageZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTNo ratings yet

- Definition of Buttering From ASME Section IXDocument2 pagesDefinition of Buttering From ASME Section IXsanket100% (3)

- DPT Acceptance Code ReferenceDocument5 pagesDPT Acceptance Code ReferenceMidhun K Chandrabose100% (2)

- Quality Assurance Plan For Ptfe Lined Pipes & FittingsDocument1 pageQuality Assurance Plan For Ptfe Lined Pipes & Fittingsروشان فاطمة روشانNo ratings yet

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- 6-15-0003 Rev 4Document9 pages6-15-0003 Rev 4cynideNo ratings yet

- Asme Section 1 - Pmi PDFDocument3 pagesAsme Section 1 - Pmi PDFArul Edwin VijayNo ratings yet

- A Comparison of ISO 15614 Part 1 and ASME IXDocument2 pagesA Comparison of ISO 15614 Part 1 and ASME IXtuanNo ratings yet

- Part QW Welding Article IDocument13 pagesPart QW Welding Article IHiago BragaNo ratings yet

- Hyatt Regency, Johorbahru, 30-31 October 1998Document6 pagesHyatt Regency, Johorbahru, 30-31 October 1998Ariq FauzanNo ratings yet

- Probe Eddyfi (PEC-089-G2-H05S SN.2106208)Document4 pagesProbe Eddyfi (PEC-089-G2-H05S SN.2106208)Ariq FauzanNo ratings yet

- Manual Book Hardness TesterDocument13 pagesManual Book Hardness TesterAriq FauzanNo ratings yet

- ASME Impact Test RequirementDocument5 pagesASME Impact Test RequirementAriq FauzanNo ratings yet

- Pressure Vessel HandbookDocument2 pagesPressure Vessel HandbookAriq FauzanNo ratings yet

- Pressure Vessel HeadsDocument2 pagesPressure Vessel HeadsAriq FauzanNo ratings yet

- Weng Et Al 2016 Face Stability of Large Diameter SCL Tunnel in Soil in SingaporeDocument6 pagesWeng Et Al 2016 Face Stability of Large Diameter SCL Tunnel in Soil in SingaporeNathan VincentNo ratings yet

- Nuclear Physics IgcseDocument9 pagesNuclear Physics IgcseMuhammad asifNo ratings yet

- Study of Influence of Feed Rate and Depth of Cut On Cutting Forces in Ball End Milling of Aluminum Alloy 7075-T6: Using A Mechanistic ApproachDocument9 pagesStudy of Influence of Feed Rate and Depth of Cut On Cutting Forces in Ball End Milling of Aluminum Alloy 7075-T6: Using A Mechanistic ApproachAbderrahim BelloufiNo ratings yet

- Recrystallization and Melting PointsDocument22 pagesRecrystallization and Melting Pointskiwi27_87100% (1)

- Slump TestDocument6 pagesSlump Testjoshdax2No ratings yet

- A Simulation Study On Thermal Conductivity of Glass Bead Embedded Polymeric SystemDocument15 pagesA Simulation Study On Thermal Conductivity of Glass Bead Embedded Polymeric Systembishnu ppNo ratings yet

- 2lei Chap2-The Second Law and EquilibriumDocument26 pages2lei Chap2-The Second Law and Equilibriumroramos2.rrNo ratings yet

- LangauzeDocument2 pagesLangauzeSwapnil SinhaNo ratings yet

- Window Utitlization Factor KuDocument4 pagesWindow Utitlization Factor KuJavierNo ratings yet

- Who's The BossDocument3 pagesWho's The BossSourabh DasNo ratings yet

- Physics - Unit 6 - Part 1Document7 pagesPhysics - Unit 6 - Part 1Mahdi ElfeituriNo ratings yet

- Draco Republica Checa Grosor Tejidos Blandos 2016 Facial Soft Tissue Thicknesses in The Present CzechDocument25 pagesDraco Republica Checa Grosor Tejidos Blandos 2016 Facial Soft Tissue Thicknesses in The Present CzechAdrian ToalaNo ratings yet

- Introduction To Finite Element Methods: Dr. Kiran M. CDocument47 pagesIntroduction To Finite Element Methods: Dr. Kiran M. CKiranNo ratings yet

- Publist SciexDocument129 pagesPublist SciexFroy HuancaNo ratings yet

- Optical Fibers and Waveguides: Chapter SeventeenDocument38 pagesOptical Fibers and Waveguides: Chapter SeventeenSudha MalikNo ratings yet

- Measuring The Stray Light Performance of UV-visible SpectrophotometersDocument4 pagesMeasuring The Stray Light Performance of UV-visible SpectrophotometersDiego Fernado AvendañoNo ratings yet

- Yoga 530Document90 pagesYoga 530Juan LatorreNo ratings yet

- 3 Developmental Lesson Plan: Standard - 3.3.1.B1Document11 pages3 Developmental Lesson Plan: Standard - 3.3.1.B1api-545352757No ratings yet

- اخطاء انكسار 2Document3 pagesاخطاء انكسار 2Hassan AljaberiNo ratings yet

- Module 1Document135 pagesModule 1Alesther MarianoNo ratings yet

- Fabrication Tecniques of Quantum Well, Quantum Dot and Quantum WireDocument4 pagesFabrication Tecniques of Quantum Well, Quantum Dot and Quantum WireRia Rushin Joseph100% (1)

- MR 42, 43 y 98 LámparasDocument2 pagesMR 42, 43 y 98 LámparasTecnicas Predictivas SacNo ratings yet

- 00 - Curve Packet (Rotation Test) - Questions and AnswersDocument4 pages00 - Curve Packet (Rotation Test) - Questions and AnswersA FNo ratings yet

- Analog Integrated Circuit Design: Nagendra KrishnapuraDocument26 pagesAnalog Integrated Circuit Design: Nagendra KrishnapuraAnkit Bhoomia0% (1)

- PESCODocument7 pagesPESCOSibghatullah SiyalNo ratings yet