Professional Documents

Culture Documents

ITP-000 Piping Fabrication PDF

Uploaded by

Mahesh Kumar BandariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITP-000 Piping Fabrication PDF

Uploaded by

Mahesh Kumar BandariCopyright:

Available Formats

Inspection and Test Plan

Piping Fabrication

Document Number: XXXX XXXX XXXXX

XXXXXX—XXXX--XXXXX

Piping and Mechanical Works

Contract No. XXXXXXXXX

X

Approval and Change History

Issue Description Approval

Date Quality Proj.

Man.

0 Issued for Approval

1 Revised to Incorporate Client Comments

Piping Fabrication Page 1 of 5

Contract No. XXXXXXX Inspection & Test Plan

ITP Number XXXX XXXXX

Authorised: XXXXX XXXXX

Date: XXX XXX XXX

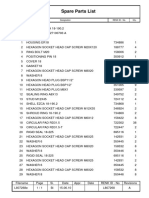

Piping Fabrication

No. Operation Standard, Verifying Inspection Remarks

Spec or Document/ Response Workshop Fabricato Client (May be used as a sign off column by xxxxxxxxxxx or the

Document Fabricator Client to indicate that the activity has been satisfactorily

Drawing Report . r

completed)

Number

1.0 Approvals

1.1 Welding Procedure Specification (WPS) approval Project Quality AS4041 Approved PE/QC H H/R R

Plan WPS/PQR

1.2 Qualify welders to approved WPS AS4041 WQR PE/QC H H/R M/R

1.3 Prepare WPS and Approved Welder Registers AS4041 Registers PE/QC H H/R R

1.4 Review Subcontractors ITP’s XXXXXXXX ITP PE/QC H H/R R Not required if this pre-approved ITP is

used

2.0 Materials

2.1 Receive materials Project Quality AS4041 D/Dkt/PO WF/ST M M M

Plan

2.1 Inspect materials: D/Dkt/PO WF/ST V/D M M

• quantities XXXXXX

• conformance to requirements

• dimensional

• damage

• material certification

Inspection Codes Responsibility

Key H Hold Point V Visual Inspection PE Project Engineer ST Storeman

W Witness D Dimension Inspection WF Workshop Foreman EX Inspection/Expeditor

M Monitor R Review & Approve Documentation TR Tradesman SC Sub-Contractor

QC Quality Inspector

Piping Fabrication Page 2 of 5

Contract No. XXXXXXX Inspection & Test Plan

ITP Number XXXX XXXXX

Authorised: XXXXX XXXXX

Date: XXX XXX XXX

Piping Fabrication

No. Operation Standard, Verifying Inspection Remarks

Spec or Document/ Response Workshop Fabricato Client (May be used as a sign off column by xxxxxxxxxxx or the

Document Fabricator Client to indicate that the activity has been satisfactorily

Drawing Report . r

completed)

Number

3.0 Shop Fabrication

3.1 Approved WPS available at work station Project Quality AS4041 Current Revision WF/QC M M M

Plan Documents

3.2 Check material for item, type, material, size, rating & unique AS4041 AFC Dwg WF/EX V/M M M

number

3.3 Check weld preparations AS4041 & AFC Dwg WF/QC V/M M M

WPS

3.4 Calculate NDT % Requirements on Piping – Confirm Piping AS4041/ EC-F-054 WF/QC V/D M R Nominate on Subcontractors NDT% Form

Class AS4037 amount and type of NDT required.

i.e PT/MT or UT/RT - Construction code

acceptance criteria shall be SPEC 000-S-0011

on all NATA NDT testing reports

3.5 Check welding consumables WPS WPS WF/QC V/M M M

3.6 Check fit up, configuration, dimension and orientation WPS AFC Dwg WF/QC V/M M M

3.7 Check for spool and sub spool identification AFC Dwg WF/QC V/M M M

AFC Drawings

3.8 Check welder qualification Welder Register/WQR WF/QC R M M

Register

3.9 Check welding parameters WPS WPS WF/QC M M M

3.10 Check weld marking (welder’s ID, date and consumable) Weld Maps WF/QC V/M M M

3.11 Check weld root and hot pass WPS WF/QC V/M M M

3.12 Check removal of slag, spatter, scale and flux AS4041 ITP WF/QC V/M M M Verify & accept by signing section 4.6 of this

ITP

3.13 Check completed weld AS4041 ITP WF/QC V/M M M Verify & accept by signing section 4.6 of this

ITP

Inspection Codes Responsibility

Key H Hold Point V Visual Inspection PE Project Engineer ST Storeman

W Witness D Dimension Inspection WF Workshop Foreman EX Inspection/Expeditor

M Monitor R Review & Approve Documentation TR Tradesman SC Sub-Contractor

QC Quality Inspector

Piping Fabrication Page 3 of 5

Contract No. XXXXXXX Inspection & Test Plan

ITP Number XXXX XXXXX

Authorised: XXXXX XXXXX

Date: XXX XXX XXX

Piping Fabrication

No. Operation Standard, Verifying Inspection Remarks

Spec or Document/ Response Workshop Fabricato Client (May be used as a sign off column by xxxxxxxxxxx or the

Document Fabricator Client to indicate that the activity has been satisfactorily

Drawing Report . r

completed)

Number

3.14 Record welding traceability information AS4041 Not Report WF/QC R M M

3.15 Final dimensional check AS4041 AFC Dwg WF/Ex V/D/M M M

4.0 Inspection and Testing

4.1 All Welds 100% Visual Project Quality AS4041 This ITP WF/QC V M M Verify & Accept by signing section 4.1 of this

Plan ITP

4.2 NDE as per AS4041 H R W

• 5% RT and MPI for Class 2A Piping NATA Report

• Exempt for Class 3 Piping

4.3 Pipework marking and identification correct Engineering Punch list M M M

Drawings

4.4 Mark up drawings as built as necessary Engineering R R

Drawing marked

in red pen

4.5 Veryify NDT% has been completed AS 4041 NDT Reports H R R

5.0 Final Inspection

5.1 Inspect delivery dockets to ensure that they record every item Project Quality AS4041 Ex/PE M M M

5.2 Final inspection and release Plan This ITP Ex/PE H H/W M Verify & Accept by signing section 5.2 of this

ITP

6.0 Delivery

6.1 Ensure that all inspections and tests are completed, all reports Project AS4041 Reports/ PE/Ex H/R H/R R

and documentation are available and all results comply with Management AFC Drwgs Checklists

requirements Plan P. O./ Scope

6.2 Check tagging/marking is in place, correct and secure AS4041 Ex M M M

6.3 Check Delivery Docket completed and forwarded to projects Delivery Docket Ex H/R M M/R Every item shall be marked and listed on the

office Delivery Docket

Inspection Codes Responsibility

Key H Hold Point V Visual Inspection PE Project Engineer ST Storeman

W Witness D Dimension Inspection WF Workshop Foreman EX Inspection/Expeditor

M Monitor R Review & Approve Documentation TR Tradesman SC Sub-Contractor

QC Quality Inspector

Piping Fabrication Page 4 of 5

Contract No. XXXXXXX Inspection & Test Plan

ITP Number XXXX XXXXX

Authorised: XXXXX XXXXX

Date: XXX XXX XXX

Piping Fabrication

No. Operation Standard, Verifying Inspection Remarks

Spec or Document/ Response Workshop Fabricato Client (May be used as a sign off column by xxxxxxxxxxx or the

Document Fabricator Client to indicate that the activity has been satisfactorily

Drawing Report . r

completed)

Number

6.4 Ensure that all items are loaded with sufficient dunnaging to Ex M M M

allow safe transport and unloading and prevent damage to

material and surface coatings

6.5 Weights and dimensions of the load shall comply with Ex M M M

statutory requirements. Compliance is the responsibility of the

approved transport contractor

6.6 Deliver product and documentation to nominated location Contract/ D/Dkt Ex/PE R R R

Purchase

Order

7.0 Records

7.1 Check MDR complete and available. Project Quality AS4041 MDR Records PE/QC R R R/H MPDJV Rep to review completed MDR at

Plan source (MEA or Subcontractor facility) covering

SEP.70

SOW

Inspection Codes Responsibility

Key H Hold Point V Visual Inspection PE Project Engineer ST Storeman

W Witness D Dimension Inspection WF Workshop Foreman EX Inspection/Expeditor

M Monitor R Review & Approve Documentation TR Tradesman SC Sub-Contractor

QC Quality Inspector

Piping Fabrication Page 5 of 5

You might also like

- Hide Tanning PDF - FINAL7.23Document32 pagesHide Tanning PDF - FINAL7.23Kevin100% (1)

- Space Policy SWAT Future Space Strategies 13 UnclassifiedDocument189 pagesSpace Policy SWAT Future Space Strategies 13 UnclassifiedSpaceStrategosNo ratings yet

- Inspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Document8 pagesInspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Santosh Kumar Bogela100% (12)

- Larsen & Toubro Limited: Ecc DivisionDocument4 pagesLarsen & Toubro Limited: Ecc Divisionmanu_gite100% (2)

- Inspection and Test Plan For Pressure VesselDocument4 pagesInspection and Test Plan For Pressure VesselNurul Amirah Princesza100% (3)

- 003 ITP UG PipingDocument4 pages003 ITP UG Pipingrvsingh70100% (1)

- Inspection Plan TemplateDocument1 pageInspection Plan Templatedennis386100% (1)

- ITP - PipingDocument7 pagesITP - PipingRiaz Rasool100% (2)

- 15 ITP Installation of Static EquipmentDocument4 pages15 ITP Installation of Static Equipmenta.hasan670No ratings yet

- Itp For Tank Fabrication & Installation Work1 - Rev02Document22 pagesItp For Tank Fabrication & Installation Work1 - Rev02mister pogi100% (3)

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankAhmed100% (5)

- ITP For Piping WorksDocument3 pagesITP For Piping WorksOrlando1949100% (3)

- Sample ItpDocument4 pagesSample ItpWijayanto BekasiNo ratings yet

- Piping Fabrication, Installation, Erection, and TestingDocument33 pagesPiping Fabrication, Installation, Erection, and Testingaop1046889% (9)

- Phased Ps Wwith P Pap Tracking FormDocument3 pagesPhased Ps Wwith P Pap Tracking FormKurt FinkNo ratings yet

- Indicative Inspection & Test Plan : Project: - Iocl PanipatDocument2 pagesIndicative Inspection & Test Plan : Project: - Iocl PanipatAshish DhokNo ratings yet

- Inspection Test Plan For Fabrication & Erection 2016Document14 pagesInspection Test Plan For Fabrication & Erection 2016Boj Mingi50% (2)

- Tank Erection Itp & Org ChartDocument34 pagesTank Erection Itp & Org Charthasan_676489616100% (2)

- Bolt Torque ReportDocument1 pageBolt Torque ReportAhmed Gomaa100% (6)

- INSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFDocument7 pagesINSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFgst ajah100% (4)

- ITP-000 Piping FabricationDocument5 pagesITP-000 Piping FabricationNatraji100% (1)

- Itp PipingDocument4 pagesItp Pipingerdemlix100% (2)

- Weld Map & NDE Extent of Pressure VesselDocument32 pagesWeld Map & NDE Extent of Pressure VesselMahesh Kumar100% (2)

- Request For InspectionDocument1 pageRequest For Inspection알안젤로No ratings yet

- ITP Installation of Static EquipmentDocument3 pagesITP Installation of Static EquipmentAwais Tariq90% (10)

- Itp For Piping Fabrication and Erection CorrectionDocument4 pagesItp For Piping Fabrication and Erection CorrectionAnand Ramachandran67% (3)

- ITP - Erection of Static EquipmentDocument4 pagesITP - Erection of Static Equipmentbhct1987No ratings yet

- Sample Itp For VesselDocument10 pagesSample Itp For VesselWijayanto BekasiNo ratings yet

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Document24 pagesItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- ITP-001 Steelwork Fabrication Rev ADocument5 pagesITP-001 Steelwork Fabrication Rev AMarcus Cox100% (2)

- 10) Itp - Tank Fabrication PDFDocument6 pages10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Piping Welding Daily Quality Control and Inspection Report FormDocument1 pagePiping Welding Daily Quality Control and Inspection Report Formenels77100% (5)

- Fahu - AhuDocument6 pagesFahu - AhuHadi AbdulkaderNo ratings yet

- ITP - Steel ErectionDocument10 pagesITP - Steel ErectionGhayas RanjhaNo ratings yet

- ITP-000 Piping Fabrication (Exemple)Document5 pagesITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- Contractor Quality Control Plan For Rotary Equipment InstallationDocument4 pagesContractor Quality Control Plan For Rotary Equipment InstallationJoel SnowNo ratings yet

- Mechanical Completion Check ListDocument6 pagesMechanical Completion Check Listmanish2089No ratings yet

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuNo ratings yet

- Attachment 6 - Piping Test Package (Manifold 206) - A4A0Z9Document44 pagesAttachment 6 - Piping Test Package (Manifold 206) - A4A0Z9Ali Hajirassouliha100% (1)

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNo ratings yet

- Sky & Telescope - February 2016 (Gnv64)Document82 pagesSky & Telescope - February 2016 (Gnv64)bogarguz100% (1)

- ITP SampleDocument2 pagesITP Sampleeiman_zerep50% (2)

- Welding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotDocument3 pagesWelding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotRicardo LourençoNo ratings yet

- Virgin Galactic Profile & Performance Business ReportDocument10 pagesVirgin Galactic Profile & Performance Business ReportLoic PitoisNo ratings yet

- Vasuanand Bba ProjectDocument66 pagesVasuanand Bba ProjectMaster PrintersNo ratings yet

- ITP For CW and ACW Piping WorkDocument8 pagesITP For CW and ACW Piping WorkPhong DoNo ratings yet

- Test Pack Flow ChartDocument1 pageTest Pack Flow ChartHum Hum100% (1)

- ITP For Fabrication & Erection of TanksDocument20 pagesITP For Fabrication & Erection of TanksosersNo ratings yet

- A05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C DDocument14 pagesA05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C Dbingmin100% (4)

- Inspection and Test Plan For Epc Gas Pipeline Project-X70mDocument15 pagesInspection and Test Plan For Epc Gas Pipeline Project-X70mFolarin Ayodeji100% (1)

- Itp For Storage TanksDocument7 pagesItp For Storage TanksHamid MansouriNo ratings yet

- Welding Consumable and Storage ProcedureDocument10 pagesWelding Consumable and Storage Procedurehasan_676489616100% (1)

- ITP Mechanical Fabrication Piping and StructureDocument7 pagesITP Mechanical Fabrication Piping and StructureAdiguna DhanaNo ratings yet

- Field Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectDocument12 pagesField Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectbasukiNo ratings yet

- H Quality and Certification Requirements-SPDocument3 pagesH Quality and Certification Requirements-SPEl_memitoNo ratings yet

- EXW-P015-0000-QM-LNT-IT-00066 Rev CADocument4 pagesEXW-P015-0000-QM-LNT-IT-00066 Rev CAbinunalukandamNo ratings yet

- AB-083 Const Data Report Piping SystemsDocument2 pagesAB-083 Const Data Report Piping Systemsjamaljamal20No ratings yet

- Use P/N PO ReviewDocument8 pagesUse P/N PO ReviewJaya ShreeNo ratings yet

- Inspection Test Plan Equipment - AFC Header Plug Seal Weld 1Document4 pagesInspection Test Plan Equipment - AFC Header Plug Seal Weld 1Mohd Shafuaaz KassimNo ratings yet

- PS 3103Document9 pagesPS 3103JayeshNo ratings yet

- Pma XT SP0009 PDFDocument15 pagesPma XT SP0009 PDFEl_memitoNo ratings yet

- Piping ReportDocument2 pagesPiping ReportcomyahoothanhNo ratings yet

- SKV-FM-QA-12 Non Conformity and Corrective ActionDocument1 pageSKV-FM-QA-12 Non Conformity and Corrective ActionSaurabh BhadouriyaNo ratings yet

- EBOOK6131f1fd1229c Unit 3 Ledger Posting and Trial Balance PDFDocument44 pagesEBOOK6131f1fd1229c Unit 3 Ledger Posting and Trial Balance PDFYaw Antwi-AddaeNo ratings yet

- Hostel Standard and Safety MeasuresDocument16 pagesHostel Standard and Safety MeasuresSadiya IqbalNo ratings yet

- Ferrites For Linear Appl - Properties - SnellingDocument10 pagesFerrites For Linear Appl - Properties - SnellingTom SebastianNo ratings yet

- Chemistry: Pearson Edexcel International GCSE (9-1)Document32 pagesChemistry: Pearson Edexcel International GCSE (9-1)YinMyat MonNo ratings yet

- Monal - An Overview of Marketing Practices: Alishba IjazDocument6 pagesMonal - An Overview of Marketing Practices: Alishba IjazAmy KhanNo ratings yet

- QP English Viii 201920Document14 pagesQP English Viii 201920Srijan ChaudharyNo ratings yet

- Smart Test Series: Q.1 Circle The Correct Answers. (6x1 6)Document1 pageSmart Test Series: Q.1 Circle The Correct Answers. (6x1 6)Eeman AkbarNo ratings yet

- Boss DD-6Document28 pagesBoss DD-6Justin Alexander SanzonENo ratings yet

- Review of The Householder's Guide To Community Defence Against Bureaucratic Aggression (1973)Document2 pagesReview of The Householder's Guide To Community Defence Against Bureaucratic Aggression (1973)Regular BookshelfNo ratings yet

- L807268EDocument1 pageL807268EsjsshipNo ratings yet

- 01 IKSP and Environmental MovementsDocument12 pages01 IKSP and Environmental MovementsGlister Diadem DolleraNo ratings yet

- Tpa6404 q1Document12 pagesTpa6404 q1siogNo ratings yet

- Embedded Modules: Pci Express Minicard and Lga Modules High-Speed Multi-Mode 3GDocument4 pagesEmbedded Modules: Pci Express Minicard and Lga Modules High-Speed Multi-Mode 3GYaSeregaNo ratings yet

- Snigdha Chaturvedi PDFDocument5 pagesSnigdha Chaturvedi PDFHitesh KohliNo ratings yet

- Geologic Report Arches NationalDocument9 pagesGeologic Report Arches NationalJacob AndersonNo ratings yet

- Technical Data Sheet: Lasteek Rwe300Document2 pagesTechnical Data Sheet: Lasteek Rwe300Engr KamalNo ratings yet

- Kitimat JRP SummaryDocument17 pagesKitimat JRP SummaryNorthwest InstituteNo ratings yet

- RK20 Power Flow SparseDocument33 pagesRK20 Power Flow Sparsejohn smithNo ratings yet

- Peter Wink Resume Aug 2019Document1 pagePeter Wink Resume Aug 2019api-471317467No ratings yet

- What Is A CodebookDocument5 pagesWhat Is A CodebookAxmed YaasiinNo ratings yet

- Phys172 S20 Lab07 FinalDocument8 pagesPhys172 S20 Lab07 FinalZhuowen YaoNo ratings yet

- Cse205 Computer-Architecture-And-Organization TH 2.00 Ac26Document2 pagesCse205 Computer-Architecture-And-Organization TH 2.00 Ac26Ravi ThejaNo ratings yet

- 344W11MidTermExamI Solution PDFDocument22 pages344W11MidTermExamI Solution PDFTrường TùngNo ratings yet