100% found this document useful (1 vote)

663 views38 pagesPower Cable Engineering

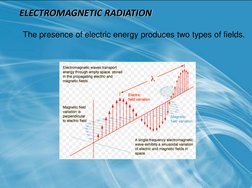

The document provides an overview of electrical power cable engineering. It discusses the historical development of electrical cables from the 19th century to present. Key developments include the introduction of insulation materials like jute, paper, polyethylene and cross-linked polyethylene. The document also outlines the basic components of cables including conductors, insulation, shields and jackets. Additionally, it covers dielectric theory and discusses termination design through methods like stress cone and voltage gradient techniques.

Uploaded by

jaimeCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

663 views38 pagesPower Cable Engineering

The document provides an overview of electrical power cable engineering. It discusses the historical development of electrical cables from the 19th century to present. Key developments include the introduction of insulation materials like jute, paper, polyethylene and cross-linked polyethylene. The document also outlines the basic components of cables including conductors, insulation, shields and jackets. Additionally, it covers dielectric theory and discusses termination design through methods like stress cone and voltage gradient techniques.

Uploaded by

jaimeCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd