Professional Documents

Culture Documents

Phase Transformations in Carbon Steels

Uploaded by

Auri Rico MartinezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phase Transformations in Carbon Steels

Uploaded by

Auri Rico MartinezCopyright:

Available Formats

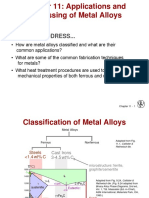

360 ● Chapter 11 / Phase Transformations

900

FIGURE 11.38 Isother- 1600

mal transformation dia-

800

gram for a 0.45 wt% C A+F

iron –carbon alloy: A , A 1400

austenite; B, bainite; F, 700

proeutectoid ferrite; M,

A+P 1200

martensite; P, pearlite.

600 P

(A dapted from A tlas of B

Temperature ( C)

Temperature ( F)

T im e-T em perature D ia- 1000

gram s for Irons and 500 A+B

Steels, G . F. Vander A

Voort, E ditor, 1991. R e- 50% 800

400

printed by permission M (start)

of A SM International,

M (50%) 600

Materials Park, O H .) 300

M (90%)

200 400

100 200

0

0.1 1 10 10 2 10 3 10 4 10 5

Time (s)

11.17 For parts a, c, d, f, and h of Problem 11.16, ure and then sketch and label continuous

determine the approximate percentages of cooling curves to yield the following micro-

the microconstituents that form. structures:

11.18 Make a copy of the isothermal transforma- (a) Fine pearlite and proeutectoid ce-

tion diagram for a 0.45 wt% C iron –carbon mentite.

alloy (Figure 11.38), and then sketch and (b) Martensite.

label on this diagram the time –temperature (c) Martensite and proeutectoid cementite.

paths to produce the following microstruc-

tures: (d) Coarse pearlite and proeutectoid ce-

mentite.

(a) 42% proeutectoid ferrite and 58%

(e) Martensite, fine pearlite, and proeutec-

coarse pearlite.

toid cementite.

(b) 50% fine pearlite and 50% bainite.

11.21 Cite two major differences between mar-

(c) 100% martensite. tensitic and pearlitic transformations.

(d) 50% martensite and 50% austenite. 11.22* Cite two important differences between

11.19* Name the microstructural products of eu- continuous cooling transformation dia-

tectoid iron –carbon alloy (0.76 wt% C) grams for plain carbon and alloy steels.

specimens that are first completely trans- 11.23* Briefly explain why there is no bainite trans-

formed to austenite, then cooled to room formation region on the continuous cooling

temperature at the following rates: (a) transformation diagram for an iron –carbon

200!C /s, (b) 100!C /s, and (c) 20!C /s. alloy of eutectoid composition.

11.20* Figure 11.39 shows the continuous cooling 11.24* Name the microstructural products of 4340

transformation diagram for a 1.13 wt% C alloy steel specimens that are first com-

iron –carbon alloy. Make a copy of this fig- pletely transformed to austenite, then

You might also like

- Metallurgy of SteelDocument4 pagesMetallurgy of SteelShakil AkhterNo ratings yet

- Bre Digest 522 Parts 1 2 Hardcore For Supporting Ground Floors of BuildingsDocument28 pagesBre Digest 522 Parts 1 2 Hardcore For Supporting Ground Floors of Buildingssyed sardar hussain shahNo ratings yet

- Iron Carbon Phase DiagramDocument4 pagesIron Carbon Phase DiagramFuhad HasanNo ratings yet

- Closed-Book Practice-Ch 10 (2017!08!08)Document12 pagesClosed-Book Practice-Ch 10 (2017!08!08)Juan0% (1)

- CH 11Document35 pagesCH 11nur afifahNo ratings yet

- GRP Lamination Processing - Instructions PDFDocument34 pagesGRP Lamination Processing - Instructions PDFmuhammadkashikNo ratings yet

- Week13 Iron Carbon Phase DiagramDocument49 pagesWeek13 Iron Carbon Phase DiagramvishalNo ratings yet

- Hardened Concrete Methods of Test: Indian StandardDocument14 pagesHardened Concrete Methods of Test: Indian Standardjitendra86% (7)

- Basic Chemical Calculations-MergedDocument184 pagesBasic Chemical Calculations-MergedVishwajeet DhanwadeNo ratings yet

- The Iron-Carbon Phase Diagram: Prof. H. K. Khaira Professor in MSME Deptt. MANIT, BhopalDocument38 pagesThe Iron-Carbon Phase Diagram: Prof. H. K. Khaira Professor in MSME Deptt. MANIT, BhopalYogesh KumbharNo ratings yet

- Iron Carbon Diagram & Heat Treatment ProcessesDocument68 pagesIron Carbon Diagram & Heat Treatment ProcessesRAJUNo ratings yet

- Kuliah 2 Diagram Kesetimbangan, TTT, CCTDocument50 pagesKuliah 2 Diagram Kesetimbangan, TTT, CCTEsti Nur AmaliaNo ratings yet

- 7B Microstructure of Iron Carbon AlloysDocument14 pages7B Microstructure of Iron Carbon AlloysAhmed AliNo ratings yet

- Microstructure of Iron Carbon Alloys (2.4 MB)Document17 pagesMicrostructure of Iron Carbon Alloys (2.4 MB)shahaljawaie87No ratings yet

- Iron-Iron Carbide Diagram: Prepared by Mr. Mukesh Kumar Assistant Professor Darbhanga College of Engineering DarbhangaDocument25 pagesIron-Iron Carbide Diagram: Prepared by Mr. Mukesh Kumar Assistant Professor Darbhanga College of Engineering Darbhangamukesh kumarNo ratings yet

- Co-Fe (Cobalt-Iron) : 1984nis 2002ohn 1 2002ohn 1 2006ust 2Document2 pagesCo-Fe (Cobalt-Iron) : 1984nis 2002ohn 1 2002ohn 1 2006ust 2Chi Nguyễn ĐanNo ratings yet

- Concept Check 11.1: Chapter 11 / Applications and Processing of Metal AlloysDocument7 pagesConcept Check 11.1: Chapter 11 / Applications and Processing of Metal AlloysSamrat BandyopadhyayNo ratings yet

- Visible Light Photocatalysis Using Metal Oxide NanoparticlesDocument45 pagesVisible Light Photocatalysis Using Metal Oxide NanoparticlesMithun PrakashNo ratings yet

- Preview - 2 of Soil EtcDocument16 pagesPreview - 2 of Soil EtcQamar SarfarazNo ratings yet

- MATERIAL SCIENCE AND ENGINEERING COURSEDocument12 pagesMATERIAL SCIENCE AND ENGINEERING COURSEnandini bhandaruNo ratings yet

- Homework 14 Solutions Spring 2001Document2 pagesHomework 14 Solutions Spring 2001Ikhwan Wf Miscellaneous AveroesNo ratings yet

- Use The Grid Below To Draw The Al-Li Phase Diagram Based Upon The ...Document24 pagesUse The Grid Below To Draw The Al-Li Phase Diagram Based Upon The ...quiqueNo ratings yet

- MAE 212 Spring 2001 Test II Study GuideDocument4 pagesMAE 212 Spring 2001 Test II Study GuideYubelgxNo ratings yet

- Chap 11Document27 pagesChap 11Qwe QNo ratings yet

- 2 KorucuDocument5 pages2 KorucuwardaNo ratings yet

- 2009_Steel Res Int_Influence of Martensite Distribution on the Mechanical Properties of Dual Phase Steels Experiments and SimulationDocument6 pages2009_Steel Res Int_Influence of Martensite Distribution on the Mechanical Properties of Dual Phase Steels Experiments and SimulationOmar S Al-AbriNo ratings yet

- Mahindra Cie - Soft Ferrite CoresDocument42 pagesMahindra Cie - Soft Ferrite CoresSatishNo ratings yet

- Phase TransformationDocument5 pagesPhase TransformationAlvin Tung Kwong Choong100% (1)

- S-EMM 3122-CH5-Phase Diagram-Part DDocument15 pagesS-EMM 3122-CH5-Phase Diagram-Part DKHAIRUL NASHRAN BIN ANUAR / UPMNo ratings yet

- Exercises Topic 4 Heat TreatmentsDocument14 pagesExercises Topic 4 Heat TreatmentsClara Barbero SánchezNo ratings yet

- Chapter 9 - HardnessDocument26 pagesChapter 9 - Hardnessnafarin4No ratings yet

- Minggu Ke 5: TTT DiagramDocument42 pagesMinggu Ke 5: TTT DiagramsyukurhsbNo ratings yet

- Improvement of Corrosion Resistance of Plasma Nitrided Stainless SteelDocument4 pagesImprovement of Corrosion Resistance of Plasma Nitrided Stainless SteelpiyupriNo ratings yet

- Letter: Ment in AIS1 4140 Low Alloy SteelDocument5 pagesLetter: Ment in AIS1 4140 Low Alloy Steeljhon ortizNo ratings yet

- Etching Stainless Steels For Delta Ferrite PDFDocument2 pagesEtching Stainless Steels For Delta Ferrite PDFAPINo ratings yet

- 2004-11-18-Effect of Martensite Volume Fraction and Its Morphology On The Tensile Properties of Ferritic Ductile Iron With Dual Matrix StructuresDocument8 pages2004-11-18-Effect of Martensite Volume Fraction and Its Morphology On The Tensile Properties of Ferritic Ductile Iron With Dual Matrix StructuresSelauco Vurobi JrNo ratings yet

- Influence of Heat Treatment On Fatigue Behafior of 4130 AISI SteelDocument8 pagesInfluence of Heat Treatment On Fatigue Behafior of 4130 AISI SteelEfvan Adhe Putra PradanaNo ratings yet

- AIEB Course: Science of MaterialsDocument16 pagesAIEB Course: Science of MaterialsKrishna SarkarNo ratings yet

- Ferrous Metals GuideDocument113 pagesFerrous Metals GuideAbhishek ChavanNo ratings yet

- Excercise 5-Chapter 8Document10 pagesExcercise 5-Chapter 8Rachel So Jia XinNo ratings yet

- Me1022 4 Sem PDFDocument2 pagesMe1022 4 Sem PDFRajiv KumarNo ratings yet

- Issues To Address... : Chapter 11 - 1Document32 pagesIssues To Address... : Chapter 11 - 1Irfan Satrio MardaniNo ratings yet

- Week 12Document30 pagesWeek 12Furkan Can ERTUĞRULNo ratings yet

- Chapter01Mat SienceDocument28 pagesChapter01Mat Sienceahmed abdel8nyNo ratings yet

- Preparation and Characterization of Supported Nickel Catalysts.Document12 pagesPreparation and Characterization of Supported Nickel Catalysts.Hugo SolìsNo ratings yet

- Metal - Designation & PropertiesDocument37 pagesMetal - Designation & Propertiesmyself_riteshNo ratings yet

- Isothermal Transformation DiagramsDocument6 pagesIsothermal Transformation DiagramsSalem GarrabNo ratings yet

- Strengthening Mechanisms For Metals and AlloysDocument15 pagesStrengthening Mechanisms For Metals and AlloysrinaldiNo ratings yet

- Metallic Material Engineering - NotesDocument56 pagesMetallic Material Engineering - NotesAshwit KumarNo ratings yet

- Iron Carbon DiagramDocument44 pagesIron Carbon DiagramThanmay B MNo ratings yet

- 1 PDFDocument1 page1 PDFYudi Candra BNo ratings yet

- 10.6 Continuous Cooling Transformation DiagramsDocument1 page10.6 Continuous Cooling Transformation DiagramsUlwan FianiNo ratings yet

- A Novel Method To Prepare Metal Oxide Electrode: Spin-Coating With Thermal DecompositionDocument4 pagesA Novel Method To Prepare Metal Oxide Electrode: Spin-Coating With Thermal Decompositionhayet debbichNo ratings yet

- CCT Phase Diagram AssignmentDocument4 pagesCCT Phase Diagram AssignmentAyu Sekar TunjungNo ratings yet

- Lecture 14 ElectroceramicsDocument29 pagesLecture 14 Electroceramicsdebayan sethNo ratings yet

- Metal Heat Treatment: D. Navaja MSE101Document21 pagesMetal Heat Treatment: D. Navaja MSE101Ebook DownloadNo ratings yet

- L-l/T-2/IPE Date: 31/03/2019: Section-ADocument16 pagesL-l/T-2/IPE Date: 31/03/2019: Section-ANazmus Sakib TntNo ratings yet

- ESO205 ProblemSheets-7 SolutionsDocument4 pagesESO205 ProblemSheets-7 SolutionsAjay chouhanNo ratings yet

- C Phase PDFDocument1 pageC Phase PDFWater VapourNo ratings yet

- C1990-EH(HC)ver 1 0英文Document6 pagesC1990-EH(HC)ver 1 0英文顏健軒No ratings yet

- Yan Sample Exam II 4016214112Document6 pagesYan Sample Exam II 4016214112christopher_spring_3No ratings yet

- Advanced Battery MaterialsFrom EverandAdvanced Battery MaterialsChunwen SunNo ratings yet

- Fundamentals of Electrocatalyst Materials and Interfacial Characterization: Energy Producing Devices and Environmental ProtectionFrom EverandFundamentals of Electrocatalyst Materials and Interfacial Characterization: Energy Producing Devices and Environmental ProtectionNo ratings yet

- Caffine in TeaDocument11 pagesCaffine in TeaPriyatosh YadavNo ratings yet

- Critical Review AdsorptionDocument111 pagesCritical Review AdsorptionMohamed ElmessoudiNo ratings yet

- 5 Rhenocure TMTD CDocument3 pages5 Rhenocure TMTD CKeremNo ratings yet

- Msds of Spray Dried LactoseDocument8 pagesMsds of Spray Dried LactoseAnandaNo ratings yet

- Pulsed Corona-Induced Degradation of Organic MaterDocument172 pagesPulsed Corona-Induced Degradation of Organic MaterFajar PriyonoNo ratings yet

- Vistalon™ 8600: Ethylene Propylene Diene Terpolymer RubberDocument1 pageVistalon™ 8600: Ethylene Propylene Diene Terpolymer RubberMaram YasserNo ratings yet

- Jota - EtchDocument3 pagesJota - EtchRidwan BaharumNo ratings yet

- The Use of The Crumb Test As A Preliminary Indicator of Dispersive SoilsDocument8 pagesThe Use of The Crumb Test As A Preliminary Indicator of Dispersive SoilsMark D VillanuevaNo ratings yet

- BS en 01905-1999Document8 pagesBS en 01905-1999mohamed guedichiNo ratings yet

- Collection of Fungal Material From Surfaces by Tape Lift: Standard Practice ForDocument3 pagesCollection of Fungal Material From Surfaces by Tape Lift: Standard Practice ForasmaNo ratings yet

- Eurostone SinkDocument24 pagesEurostone SinkDebankita MandalNo ratings yet

- Overview of Bowtie Methodology of Risk Analysis and Its ApplicationDocument6 pagesOverview of Bowtie Methodology of Risk Analysis and Its ApplicationakhyudinNo ratings yet

- Unstabilized and Stabilized Compressed Earth Blocks With Partial Incorporation of Recycled AggregatesDocument17 pagesUnstabilized and Stabilized Compressed Earth Blocks With Partial Incorporation of Recycled AggregatesqamhNo ratings yet

- Price List Hyper RB Categorized 13 02 23Document18 pagesPrice List Hyper RB Categorized 13 02 23hh6cjnnnhvNo ratings yet

- Science-10 Q4 Module-5 Week-5Document4 pagesScience-10 Q4 Module-5 Week-5Marl Rina EsperanzaNo ratings yet

- Characterization, Beneficiation and Utilization of A Kaolinite ClayDocument11 pagesCharacterization, Beneficiation and Utilization of A Kaolinite ClayArun Ebenezer100% (1)

- 04 Honey AnalysisDocument3 pages04 Honey AnalysisNaz AliNo ratings yet

- ESE GS Material Science MCQ PDFDocument175 pagesESE GS Material Science MCQ PDFPrashant ShekharNo ratings yet

- DS - Epilux - 4 - HB - Epoxy - Finish F-6BDocument2 pagesDS - Epilux - 4 - HB - Epoxy - Finish F-6Bparvez_ameenNo ratings yet

- DERIVATION OF TERM SYMBOLDocument34 pagesDERIVATION OF TERM SYMBOLAqsa AslamNo ratings yet

- The Mystery of Molten Metal: Natalia Sobczak, Jerzy Sobczak, Rajiv Asthana and Robert PurgertDocument13 pagesThe Mystery of Molten Metal: Natalia Sobczak, Jerzy Sobczak, Rajiv Asthana and Robert Purgertyosua l.rajaNo ratings yet

- A Selective Strategy For Determination of Ascorbic Acid Based On MolecularDocument6 pagesA Selective Strategy For Determination of Ascorbic Acid Based On MolecularSonyanurizkiNo ratings yet

- Biology ,,artificial Cells"Document3 pagesBiology ,,artificial Cells"Maia ZodelavaNo ratings yet

- Lab 13 - Testing For Oxidising and Reducing AgentsDocument3 pagesLab 13 - Testing For Oxidising and Reducing AgentsFina ShoNo ratings yet

- Tanzania COMPENDIUM GUIDELINES FOR MA JULY 2020Document15 pagesTanzania COMPENDIUM GUIDELINES FOR MA JULY 2020Muhammad AbbasNo ratings yet

- TGA Interpretation of Data, Sources of ErrorDocument28 pagesTGA Interpretation of Data, Sources of ErrorUsman GhaniNo ratings yet