Professional Documents

Culture Documents

Ozone Control (Ballasting) : Operating Manuals

Uploaded by

larina20049273Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ozone Control (Ballasting) : Operating Manuals

Uploaded by

larina20049273Copyright:

Available Formats

Operating Manuals

NK-O3 BlueBallast System

1.2.3 Control of the System

(1) Ozone control (Ballasting)

The following parameters affect the production of ozone;

• Cooling water temperature and quantity

• Ambient pressure (height above sea level)

• Feed gas (Oxygen) pressure and flow-rate

• Feed gas (Oxygen) purity and temperature

• Ozone Concentration

• Electrical power applied on the HV dielectrics

The higher is the cooling water temperature the lower is the ozone generator efficiency goes down. The

higher is the gas pressure the lower is the ozone generator efficiency.

The lower is the gas flow the higher will go the ozone concentration (for the same load). The higher is the

ozone concentration (low gas flow) the lower is the ozone generator production capacity. The higher is the

gas flow (low ozone concentration) the higher is the ozone generator production capacity.

The higher is the power density on the HV electrodes the higher is the ozone production.

The contractual performance of an ozone generator must be fixed in the customer’s order and is always

pending on the above parameters which must clearly be stated in the contract. Deviations from the

contractual parameter values will entail changes to the ozone quantity and concentration.

This also applies when the unit is installed at altitudes 1,000 m above sea level. The built in pressure

gauge indicates the relative system pressure in relation to the respective ambient pressure. Adapt the

setting accordingly in these cases.

The operating parameters for which this plant is designed for and limited to, are shown in the drawings.

The unit will only operate safely, reliable and economical within these parameters. The pressure switches

and the safety valve in the feed gas line are preset and leaded.

The demanded ozone production is determined as follow:

3 3

O3 Prod. (g/hr) = B.W Flow (m /hr) ⅹ O3 Dose (g/m )

a. O3 Prod.: Ozone production will be adjusted to meet the demand by varying the ozone concentration

and ozone flow through the ozone generator.

b. B.W Flow: Ballast water flow is coming from the ballast water flow meter or ballast water flow

signal.

3

c. O3 Dose: Ozone dose = 2.4 g/m , controlled via ozone dose control loop.

The desired ozone flow will be determined based on the O3 Prod.:

3 3

O3 Flow (Nm /hr) = O3 Prod. (g/hr) / O3 Conc. (g/Nm )

a. O3 Flow: Ozone flow is controlled by using the flow control valve and flow meter at the outlet of the

ozone generator. This gas flow will be injected into the ballast water using ozone injector.

Saving Our Seas for Future Generations NK_290.001.01a (2011.09) 7

Operating Manuals

NK-O3 BlueBallast System

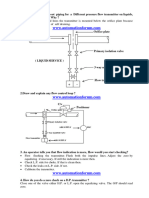

① Ozone Line: The statuses and values of equipments located at the ozone line are represented here.

• PT: The ozone pressure values as measured by the sensors located on the inlet of control valve and

suction of ozone injector.

• CONTROL VALVE: The ozone flow control valve output value (0~100%).

The output of control valve is derived from the Ozone flow controller via PLC.

• FLOW METER: The ozone gas flow value as measured by the flow meter.

• 3-WAY Valve: The status of the 3-way valve for ozone injection or destruction is represented here.

• DESTRUCTOR: The status of the Ozone destructor is represented here.

• Ozone INLET Valve: The status of the Ozone inlet valve for ozone injection is represented here.

② Side Stream Line: The status of the Circulation pump and valve for ozone injection are represented

here.

③ Main Ballast Line: The ballast water flow and ozone dose value is represented here.

The initial set point is 2.4 mg/L and this is automatically calculated as follow:

Ozone concentration × Ozone flow-rate

• Ozone dose =

Ballast water flow-rate

④ TRO: The status and valves of TRO are represented here.

• TRO: The TRO values as measured by the analyzers.

⑤ TRO Air, Water: Used to control and indicate TRO sampling pump status.

Saving Our Seas for Future Generations NK_290.001.01a (2011.09) 33

Operating Manuals

NK-O3 BlueBallast System

Message Comment Reference

Oxygen_Generator_Power & Mode Breakdown malfunction Check oxygen generator

Fault

Ozone_Generator_Power_Fault Breakdown malfunction Check ozone generator

(2) Ozone equipment alarm

Message Comment Reference

Ozone_generator_mode_Fault Operation mode “Local” O3 generator manual, p.48

Ozone_generator_operation_Fault Collective fault O3 generator manual, p.60

Water_chiller_Fault Collective fault Water chiller manual, p.16

PORT 3-Way Mode Fault Breakdown malfunction Check I/O and 3way-valve

STBD 3-Way Mode Fault

PORT L/G_Separator_Fault Ozone skid Check I/O, sensor and check valve

STBD L/G_Separator_Fault of Liquid/gas Separator

Compressor Fault Collective fault Air compressor manual, p.103

Ship_Emergency_Fault Remote interlock Check signal and deactivate

Circulation_pump_mode_Fault Breakdown malfunction Check I/O and mode button

PORT C.Pump_E.O.C.R_Fault MCP EOCR trip Check EOCR and C.pump

STBD C.Pump_E.O.C.R_Fault

Emergency_stop_fault Emergency button activated Check E_stop button & reset

(3) Neutralizer equipment alarm

Message Comment Reference

Agitator_EOCR_Trip MCP EOCR trip Check EOCR and agitator

Discharge_Pump_EOCR_Trip MCP EOCR trip Check EOCR and discharge pump

NO1_Drain_Pump_EOCR_Trip MCP EOCR trip Check EOCR and drain pump

• Operating alarm

• Ballasting alarm

Message Comment Reference

P-Dose _low_warning Ozone dose ≤ 2.2 ppm Check ballast water flow and

S-Dose _low_warning ozone production

P-Dose _low_fault Ozone dose ≤ 2.1 ppm Check sensors

S-Dose _ low_ fault

P-Dose _high_warning Ozone dose ≥ 2.5 ppm

Saving Our Seas for Future Generations NK_290.001.01a (2011.09) 52

You might also like

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Rev Quiz All PDFDocument46 pagesRev Quiz All PDFNota Belz82% (17)

- Performance and Efficiency Test of A Refrigeration Plant Test ProcedurDocument4 pagesPerformance and Efficiency Test of A Refrigeration Plant Test ProcedurEJ TolentinoNo ratings yet

- Compressible flow study across varying area passagesDocument4 pagesCompressible flow study across varying area passagesGaurav VaibhavNo ratings yet

- Polish Words Minimum To Learn DictionaryDocument69 pagesPolish Words Minimum To Learn DictionaryAndras KondratNo ratings yet

- Control ValvesDocument50 pagesControl ValvesReaderRRGHT93% (15)

- Wood Turning NotesDocument36 pagesWood Turning Notestheodrosyo0% (1)

- MANAURITE XM Material PDFDocument8 pagesMANAURITE XM Material PDFkbc404No ratings yet

- Doe Fundamentals Handbook Instrumentation and ControlDocument34 pagesDoe Fundamentals Handbook Instrumentation and Controlmoath1No ratings yet

- Cooling Tower Process CalculationDocument4 pagesCooling Tower Process CalculationDevita AmeliaNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Operation Principal of Sewage Treatmentplant and Point of MDocument12 pagesOperation Principal of Sewage Treatmentplant and Point of MKo Gyi BakaNo ratings yet

- VXD Old SMC 0900766b8094a5b0Document32 pagesVXD Old SMC 0900766b8094a5b0FranzKafkaNo ratings yet

- Liugong 938l Wheel Loader Parts ManualDocument20 pagesLiugong 938l Wheel Loader Parts Manualviolet100% (56)

- Instrumentation Systems: Wärtsilä V50Df Standard EngineDocument30 pagesInstrumentation Systems: Wärtsilä V50Df Standard Enginelarina20049273100% (1)

- Control Chapter 5 - RemoteDocument87 pagesControl Chapter 5 - RemoteJhonny PerezNo ratings yet

- ES - BlowOut User ManualDocument11 pagesES - BlowOut User Manualleekiangyen79No ratings yet

- Control Valves and SensorsDocument86 pagesControl Valves and SensorsWilmar Antonio Zuluaga ArangoNo ratings yet

- Steven Churchill, Jack Reynolds (Eds.) - Jean-Paul Sartre - Key Concepts-Routledge (2014)Document257 pagesSteven Churchill, Jack Reynolds (Eds.) - Jean-Paul Sartre - Key Concepts-Routledge (2014)Leonardo Grana100% (3)

- General Smart Manual PDFDocument62 pagesGeneral Smart Manual PDFGiurca FlorinNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Flow Meter MeasurementDocument12 pagesFlow Meter Measurementrahman75% (8)

- Control Valve Characteristics PDFDocument20 pagesControl Valve Characteristics PDFPrem SagarNo ratings yet

- Flow Measurements Using Orifice: ObjectivesDocument4 pagesFlow Measurements Using Orifice: ObjectivesRashid Al MuhannadiNo ratings yet

- M200A NOx Analyzer: Measuring NO, NOx, and NO2Document4 pagesM200A NOx Analyzer: Measuring NO, NOx, and NO2Farooq ALiNo ratings yet

- DBD StandartDocument7 pagesDBD StandartFeyza KaragözNo ratings yet

- Ozone - What Is ItDocument29 pagesOzone - What Is ItRoberto Hijosa GarciaNo ratings yet

- Flow Measurements Using OrificeDocument4 pagesFlow Measurements Using OrificeKovačević DarkoNo ratings yet

- SMP - O2 AnalyserDocument5 pagesSMP - O2 AnalyserPragneshNo ratings yet

- 2.20 Purge Flow Regulators: E. L. Szonntagh B. G. LiptákDocument3 pages2.20 Purge Flow Regulators: E. L. Szonntagh B. G. Liptáktiffanyyy00No ratings yet

- Optimized SOP for NOx MeasurementsDocument17 pagesOptimized SOP for NOx MeasurementsDienNo ratings yet

- HYdraulics LabDocument55 pagesHYdraulics LabAbu Bakar DaudNo ratings yet

- Vcone To Orifice Plate Noise ComparisonDocument8 pagesVcone To Orifice Plate Noise ComparisonDavid P. MonjureNo ratings yet

- Pneumatic FloatDocument4 pagesPneumatic Floatalamsyah_syamNo ratings yet

- Flow Meter Measurement Apparatus FM-1849-10Document19 pagesFlow Meter Measurement Apparatus FM-1849-10ArslanNo ratings yet

- Lab ManualDocument11 pagesLab ManualSujith SurapaneniNo ratings yet

- Instrumentation Question and AnswerDocument7 pagesInstrumentation Question and AnswerYounis MolayNo ratings yet

- Lab 7Document3 pagesLab 7Ankit PatelNo ratings yet

- Cop of Re Frie Ration SystemDocument5 pagesCop of Re Frie Ration SystemSachin BorseNo ratings yet

- Bio-Med Air-Oxygen Blender - Service ManualDocument33 pagesBio-Med Air-Oxygen Blender - Service ManualKittiwat WongsuwanNo ratings yet

- Sistema de OzonoDocument47 pagesSistema de OzonoPedro Aguirre BandaNo ratings yet

- Gas Absorption Column DesignDocument4 pagesGas Absorption Column DesignAuzaNo ratings yet

- ERT 321 Process Control & DynamicsDocument49 pagesERT 321 Process Control & Dynamicshakita86No ratings yet

- Vapor Recovery Test Procedure Pressure DropDocument10 pagesVapor Recovery Test Procedure Pressure Droppondpawee_337421255No ratings yet

- A Conventional Activated Sludge Treatment Conventional AerationDocument6 pagesA Conventional Activated Sludge Treatment Conventional AerationHashem Mohamed HashemNo ratings yet

- PN 455 Understanding A Pressure Regulator CV ValueDocument3 pagesPN 455 Understanding A Pressure Regulator CV ValuenicaiNo ratings yet

- Vehicle Sensor and Driver Instrumentation Air Flow Sensor FunctionDocument16 pagesVehicle Sensor and Driver Instrumentation Air Flow Sensor FunctionBharathiraja MoorthyNo ratings yet

- Calibration of Water Flow Rate in An Ultrasonic Flow Meter Using The MAX35101Document10 pagesCalibration of Water Flow Rate in An Ultrasonic Flow Meter Using The MAX35101lailiNo ratings yet

- 6.anesthesia MachineDocument61 pages6.anesthesia MachineM7md Al-HuwaitiNo ratings yet

- Flow Measurement in Closed ConduitDocument65 pagesFlow Measurement in Closed ConduitjohnmayardNo ratings yet

- Three Element Drum Level ControlDocument3 pagesThree Element Drum Level ControlSatish SohaniNo ratings yet

- Droplet Size and Spray Pattern Characteristics of An Electronic Flow Controller For Spray NozzlesDocument19 pagesDroplet Size and Spray Pattern Characteristics of An Electronic Flow Controller For Spray Nozzlesrobert.cesarNo ratings yet

- PCP TdaDocument25 pagesPCP TdaJose Miguel GonzalezNo ratings yet

- Advanced Techniques For Acoustic Liquid Level DeterminationDocument14 pagesAdvanced Techniques For Acoustic Liquid Level Determinationmáté_galambosiNo ratings yet

- CaptureRayWaterWash CJUVWW 062011Document23 pagesCaptureRayWaterWash CJUVWW 062011ed saudiNo ratings yet

- Tsi 127Document4 pagesTsi 127kadiravanNo ratings yet

- AerationDocument92 pagesAerationcumpio425428No ratings yet

- Project PLCDocument18 pagesProject PLCnarendramohan22No ratings yet

- Dissolved Oxygen MeasurementDocument5 pagesDissolved Oxygen Measurementraju1559405No ratings yet

- Orifice Flow Meter (Series KOP/KOE) : AXI LODocument16 pagesOrifice Flow Meter (Series KOP/KOE) : AXI LOmounrNo ratings yet

- Analysis and Design of Multicell DC/DC Converters Using Vectorized ModelsFrom EverandAnalysis and Design of Multicell DC/DC Converters Using Vectorized ModelsNo ratings yet

- GMDSS Batteries: Tests and Checks Mariners Must Know: Written by On January 31, 2016Document22 pagesGMDSS Batteries: Tests and Checks Mariners Must Know: Written by On January 31, 2016larina20049273No ratings yet

- MGE Safety Test ResultsDocument1 pageMGE Safety Test Resultslarina20049273No ratings yet

- GMDSS Batteries: Tests and Checks Mariners Must Know: Written by On January 31, 2016Document22 pagesGMDSS Batteries: Tests and Checks Mariners Must Know: Written by On January 31, 2016larina20049273No ratings yet

- Ballast Flow High Alarm: Ballast Warning Alarm Fault: Section.9.4Document2 pagesBallast Flow High Alarm: Ballast Warning Alarm Fault: Section.9.4larina20049273No ratings yet

- Engineering Mathematics For Gate Chapter1Document1 pageEngineering Mathematics For Gate Chapter1Sai VeerendraNo ratings yet

- Tle Grade7 8 - CARPENTRYDocument10 pagesTle Grade7 8 - CARPENTRYdonna geroleoNo ratings yet

- SP HousekeepingDocument4 pagesSP HousekeepingLomunyak SaruniNo ratings yet

- 2021 SC Hurricane GuideDocument16 pages2021 SC Hurricane GuideWMBF News100% (1)

- CIA Patho 1Document23 pagesCIA Patho 1Suhas H GNo ratings yet

- FIITJEE SAMPLE PAPER – 2018 (Big Bang Edge Test / Talent Recognition Exam) for Class 10 (Paper 2Document17 pagesFIITJEE SAMPLE PAPER – 2018 (Big Bang Edge Test / Talent Recognition Exam) for Class 10 (Paper 2msreddy86No ratings yet

- Water Transport Studies in Stone Masonry With Soil Cement MortarDocument10 pagesWater Transport Studies in Stone Masonry With Soil Cement MortarTJPRC PublicationsNo ratings yet

- Philosophy, Logic, & Rhetoric SyllabusDocument3 pagesPhilosophy, Logic, & Rhetoric SyllabusBrynja KnappNo ratings yet

- Chapter 2Document21 pagesChapter 2mlyth1668No ratings yet

- 09a50205 PowerelectronicsDocument8 pages09a50205 PowerelectronicsPaone KalyanNo ratings yet

- Sample Weekly Home Learning PlansDocument2 pagesSample Weekly Home Learning PlansJINGKY HUMAMOYNo ratings yet

- Economic Growth, Environment and SustainabilityDocument3 pagesEconomic Growth, Environment and Sustainability140 - MANEESHA ST AGNESNo ratings yet

- Flaxseed Paper PublishedDocument4 pagesFlaxseed Paper PublishedValentina GarzonNo ratings yet

- Public List Programs by Specialty 460Document9 pagesPublic List Programs by Specialty 460Enta SyngNo ratings yet

- Mktech PDFDocument7 pagesMktech PDFAlexander WieseNo ratings yet

- Mapsco Street GuidesDocument5 pagesMapsco Street Guidesapi-256961360No ratings yet

- Ch02 World Trade An Overview 1Document32 pagesCh02 World Trade An Overview 1XIKAMNo ratings yet

- DR Vatsal Patel AhmedabadDocument30 pagesDR Vatsal Patel AhmedabadSayali PhansekarNo ratings yet

- Special Report 205 Chemical Weekly 1 4-B PDFDocument7 pagesSpecial Report 205 Chemical Weekly 1 4-B PDFsifrmoroNo ratings yet

- Angles of Elevation and Depression, Bearings NotesDocument4 pagesAngles of Elevation and Depression, Bearings Notesroddyeal100% (2)

- Vivo Device Log File with Input Method and Networking DetailsDocument133 pagesVivo Device Log File with Input Method and Networking DetailsSheilaNo ratings yet

- Industrial Training IntroductionDocument1 pageIndustrial Training Introductionsgurjar07No ratings yet

- Katalog Single Split Packaged AC 2015-2016 PanasonicDocument32 pagesKatalog Single Split Packaged AC 2015-2016 Panasonicdoris0% (1)

- Chords ListDocument5 pagesChords ListakshayNo ratings yet