Professional Documents

Culture Documents

Polarity in Arc Welding

Uploaded by

Babuli KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polarity in Arc Welding

Uploaded by

Babuli KumarCopyright:

Available Formats

Polarity in Arc Welding – Straight, Reverse & Alternating Polarity

Arc welding is one type of fusion welding process where base metals are fused by applying

heat in order to form coalescence. Required heat is supplied by an electric arc constituted

between positive and negative terminals of an electric circuit inbuilt with a power source. For

welding purpose work metal is made one terminal and the electrode is made another, and thus

arc constitutes in between them in the external circuit. Since electrons always flow from

negative terminal to positive terminal of any external circuit, so based on the connection

made, two cases are possible:

1. Electrode is connected with negative terminal of the power source;

whereas, base metals are connected with positive terminal.

2. Base metals are connected with the negative terminal of the power

source; whereas, electrode is connected with positive terminal.

However, if the power source provides alternating current (AC) then both

conditions occur one after another in every cycle. Basically arc welding

power sources can provide either DC or AC type current. Some modern

power sources also contain facility to convert one from another

(integrated with AC-DC converter), so these sources can supply both AC

and DC power. Therefore, arc welding can be carried out in any of the

following three polarities; however, each has certain advantages over

others as elaborated in the successive sections.

Polarity indicates direction of flow of current (in other word – electrons) between base plates

and electrode in the external circuit. Remember, current flow direction is considered as

opposite to flow of electrons.

Three different polarities used in arc

welding

Direct Current Straight Polarity—occurs when electrode is made

negative and base plates are made positive. Thus electrons flow

from electrode tip to base plates.

Direct Current Reverse Polarity—occurs when electrode is made

positive and base plates are made negative. Thus electrons flow

from base plates to electrode.

Alternating Current Polarity—if power source provides AC

current then above two cases will occur one after another in every

cycle. In one half of the cycle, electrode will be negative (so base

plates will be positive) and in the next half, electrode will be positive

(so base plate will be negative). Number of cycles per second

depends on frequency of supply. For example, with a 60Hz supply,

60 cycles occur in every second.

Direct Current Electrode Positive (DCEP)

polarity in arc welding

With direct current (DC) power supply, when electrode is connected with

positive terminal and base plates with the negative terminal, then it is

termed as Direct Current Electrode Positive (DCEP) or Direct Current

Reverse Polarity (DCRP). So electrons liberate from base plate and flow

towards electrode via the outer circuit. Continuous flow of avalanche of

electrons in a small passage produces the arc (source of heat).

Electrons, emitting from the base plates (negative polarity), are accelerated due

to presence of potential difference and are allowed to strike the electrode

(positive polarity) at a very high velocity. Upon striking, kinetic energy of

electrons is converted to thermal energy, which ultimately results in high heat

generation at the vicinity of electrode tip. As a thumb rule, it is considered that

two-third (66%) of the entire arc heat is generated at electrode; whereas, only

one-third (33%) heat is generated at base plate. As a result, electrode melts

down quickly and metal deposition rate increases (for consumable electrodes

only). On the other hand, base plates do not fuse properly due to lack of

sufficient heat and thus various defects arise, such as insufficient fusion, lack of

penetration, high reinforcement, etc. However, stream of electron flow from base

plate remove oil, coating, oxide layer or dust particles present on the base plate

surface (termed as oxide cleaning action).

Direct Current Reverse Polarity (DCRP) in Arc Welding:

Arc welding power sources can supply either AC or DC or both forms of

current. In case of DC polarity, current flows only in one direction;

whereas, in case of AC, current flow direction reverses in every cycle

(number of cycles per second depends on the frequency of supply). Now,

in arc welding, base metals are connected with one terminal and the

electrode is connected with other terminal. Under presence of sufficient

potential difference, continuous flow of electrons between them through a

small gap constitutes the arc (prime source of heat in arc welding).

Depending on the connection of base metals and electrode with the ports

of power supply, DC polarity can be subdivided into two categories—

Direct Current Straight Polarity (DCSP) and Direct Current Reverse Polarity

(DCRP). It is to be noted that for AC supply, both polarities occur one after

another in every cycle for a number of times (equals to frequency of

supply).

DCSP or DCEN—Base plate is positive and electrode is negative.

DCRP or DCEP—Base plate is negative and electrode is positive.

Advantages of DCEP polarity in arc welding

Better arc cleaning action so less chance of inclusion defects.

High volume deposition rate for consumable electrode, so faster welding.

Better performance for welding thin plates. It reduces distortion level,

residual stress, complete cutting, etc.

Suitable for joining metals with low melting points, such as copper and

aluminum.

Disadvantages of DCEP polarity in arc welding

Shorter electrode life for non-consumable electrodes.

Higher level of reinforcement if speed is not adjusted properly.

Insufficient melting and incomplete penetration.

Cannot fuse properly thick plates or metals having high melting point.

You might also like

- Iron Carbon DiagramDocument10 pagesIron Carbon DiagramsivakumarNo ratings yet

- Iron Carbon DiagramDocument8 pagesIron Carbon Diagramashok pradhanNo ratings yet

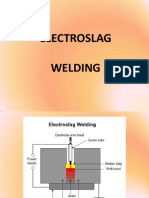

- Electroslag WeldingDocument9 pagesElectroslag WeldingGopal Jetani100% (1)

- Manual Electric Arc Welding Automatic Welding Processes, Electro-Slag, Electro-Ga S, TIG, MIG, SAW, Resistance WeldingDocument132 pagesManual Electric Arc Welding Automatic Welding Processes, Electro-Slag, Electro-Ga S, TIG, MIG, SAW, Resistance WeldingRajesh PatroNo ratings yet

- Welding Lecture 5 Solid State Welding Processes ( - )Document20 pagesWelding Lecture 5 Solid State Welding Processes ( - )Adel AbdelmaboudNo ratings yet

- ARC WELDING POWER SOURCES EXPLAINEDDocument16 pagesARC WELDING POWER SOURCES EXPLAINEDFahad AliNo ratings yet

- Electrical Fundamentals in Arc WeldingDocument34 pagesElectrical Fundamentals in Arc WeldingPeter ThomasNo ratings yet

- Welding Electrode Complete Guide (Includes Charts)Document15 pagesWelding Electrode Complete Guide (Includes Charts)Robert DelafosseNo ratings yet

- 1 - MMAW Process - PPT (Compatibility Mode)Document44 pages1 - MMAW Process - PPT (Compatibility Mode)Kumawat Prakash100% (1)

- PAM Process GuideDocument16 pagesPAM Process GuideParanthaman RamanNo ratings yet

- Types of Electric WeldingDocument7 pagesTypes of Electric WeldingSUKhanNo ratings yet

- MIG Vs TIG Vs Stick Vs Flux Core Welding ProcessesDocument8 pagesMIG Vs TIG Vs Stick Vs Flux Core Welding ProcessesCalvin YeohNo ratings yet

- On Plasma Arc WeldingDocument12 pagesOn Plasma Arc WeldingSandeep MauryaNo ratings yet

- Gas Tungsten Arc Welding: by L D PoyyaraDocument37 pagesGas Tungsten Arc Welding: by L D PoyyaraRajeeb MohammedNo ratings yet

- 2 2 Ultrasonic Welding PDFDocument43 pages2 2 Ultrasonic Welding PDFErick Venegas HerreraNo ratings yet

- Guide to Welding Types and TechniquesDocument15 pagesGuide to Welding Types and TechniquesArslan100% (1)

- Welding & Cutting ProcessDocument16 pagesWelding & Cutting ProcesscvNo ratings yet

- Manufacturing Technology: Unit - IDocument12 pagesManufacturing Technology: Unit - Iapi-271354682No ratings yet

- Plasma Arc MachiningDocument18 pagesPlasma Arc MachiningStephen WeiNo ratings yet

- Introducing Cold Pilger Mill Technology - Tube and Pipe ProductionDocument4 pagesIntroducing Cold Pilger Mill Technology - Tube and Pipe Productionribeiro30No ratings yet

- Iron Carbon Phase DiagramDocument7 pagesIron Carbon Phase Diagrampratap biswasNo ratings yet

- 3 ElectricArcWeldingDocument35 pages3 ElectricArcWeldingKirandeep GandhamNo ratings yet

- CSWIP Module Re-ExamDocument2 pagesCSWIP Module Re-ExamAhmad Khalimi Ilmawan100% (1)

- Bolt Feeder Operation Manual: 11570001 BM12-1699/1701 Date 6.12.2017Document39 pagesBolt Feeder Operation Manual: 11570001 BM12-1699/1701 Date 6.12.2017tyler0% (1)

- Fundamentals of Welding TechDocument29 pagesFundamentals of Welding TechAshwani DograNo ratings yet

- Certilas CW CAT EN PDFDocument44 pagesCertilas CW CAT EN PDFwindsurferke007No ratings yet

- Welding ParametersDocument11 pagesWelding Parametershuze_nedian100% (1)

- The Manual Metal Arc ProcessDocument4 pagesThe Manual Metal Arc ProcessMehmet SoysalNo ratings yet

- Presented By, Uma .B. S Ii Sem Mtech (1MS11MSC013) Department of Mechanical EngineeringDocument18 pagesPresented By, Uma .B. S Ii Sem Mtech (1MS11MSC013) Department of Mechanical EngineeringJyoti Sharma100% (1)

- Como Soldar 4140Document4 pagesComo Soldar 4140Luis Jose DuranNo ratings yet

- Gtaw WeldingDocument37 pagesGtaw WeldingSadhasivam VeluNo ratings yet

- Arc-Air Gouging (Air - Carbon Arc Gouging) PDFDocument1 pageArc-Air Gouging (Air - Carbon Arc Gouging) PDFcarlosNo ratings yet

- MIG Welding Guide for Welding Mild SteelDocument9 pagesMIG Welding Guide for Welding Mild SteelIsaiahNo ratings yet

- Alloy Steel and Cast IronDocument16 pagesAlloy Steel and Cast IronDennis AlvarezNo ratings yet

- Introduction To Arc Welding: Information Sheet - "Document14 pagesIntroduction To Arc Welding: Information Sheet - "Eahbm KaduNo ratings yet

- Weld TestingDocument51 pagesWeld TestingYuki FongNo ratings yet

- Submerged Arc Welding: by L D PoyyaraDocument29 pagesSubmerged Arc Welding: by L D PoyyaraSapan KansaraNo ratings yet

- Unified numbering system identifies metal alloysDocument2 pagesUnified numbering system identifies metal alloyscal2_uniNo ratings yet

- Welding Lecture1 2Document34 pagesWelding Lecture1 2Dr Abhijeet GangulyNo ratings yet

- Physics of WeldingDocument3 pagesPhysics of WeldingKhurram RehmanNo ratings yet

- PowerPoint Presentation Classification of SteelDocument6 pagesPowerPoint Presentation Classification of SteelDaniel Dowding100% (2)

- Usability Designators FCAWDocument5 pagesUsability Designators FCAWAnonymous dh6DITNo ratings yet

- Non Destructive Testing: CMR Institute of TechnologyDocument32 pagesNon Destructive Testing: CMR Institute of TechnologyrajNo ratings yet

- Module 3 Metal Joining and Cutting Process 15Document89 pagesModule 3 Metal Joining and Cutting Process 15Miki JaksicNo ratings yet

- Solid State Welding ProcessDocument17 pagesSolid State Welding ProcessRathnakrajaNo ratings yet

- WeldingDocument23 pagesWeldingBilal TayyabNo ratings yet

- Heat Treatment ProcessesDocument7 pagesHeat Treatment Processessonu100% (1)

- Unit 1 Physics of Welding Arc WeldingDocument106 pagesUnit 1 Physics of Welding Arc WeldingyashNo ratings yet

- Rail WeldingDocument4 pagesRail WeldingOlga Sandoval RomeroNo ratings yet

- Welding SymbolsDocument17 pagesWelding SymbolsJustine WilliamsNo ratings yet

- Stainless Steel Technical GuideDocument50 pagesStainless Steel Technical GuideHuỳnh TrươngNo ratings yet

- Resistance WeldingDocument19 pagesResistance WeldingJustin McClendon100% (1)

- On Plasma Arc WeldingDocument13 pagesOn Plasma Arc WeldingDUKENo ratings yet

- Advanced Welding Process (Welding)Document58 pagesAdvanced Welding Process (Welding)Sk SamsuddinNo ratings yet

- 11 Mma Welding-6Document1 page11 Mma Welding-6Dipesh PatelNo ratings yet

- 5.arc WeldDocument40 pages5.arc Weldalinader20022No ratings yet

- Types of Welding ArcsDocument14 pagesTypes of Welding ArcsArnab GoswamiNo ratings yet

- Electricity and MagnetismDocument12 pagesElectricity and MagnetismVanita Shetty BhoolaNo ratings yet

- Motor Circuit Analysis Concept and PrincipleDocument13 pagesMotor Circuit Analysis Concept and Principleclide_050793No ratings yet

- Schottky DiodeDocument9 pagesSchottky DiodePranaliNo ratings yet

- Polarity in Arc WeldingDocument3 pagesPolarity in Arc WeldingBabuli KumarNo ratings yet

- Centurion University of Technology and Management: Recent Developments in Mechanical Engineering (Rdme - 2019)Document5 pagesCenturion University of Technology and Management: Recent Developments in Mechanical Engineering (Rdme - 2019)Babuli KumarNo ratings yet

- Selection &optimization of Spot Welding Process Parameters Using Taguchi MethodDocument40 pagesSelection &optimization of Spot Welding Process Parameters Using Taguchi MethodBabuli KumarNo ratings yet

- FDP 12Document2 pagesFDP 12Babuli KumarNo ratings yet

- Mentor ListDocument1 pageMentor ListBabuli KumarNo ratings yet

- 2nd Internal 7th Semester Mechanical Jigs & FixturesDocument1 page2nd Internal 7th Semester Mechanical Jigs & FixturesBabuli KumarNo ratings yet

- Manual Serial Arm PDFDocument19 pagesManual Serial Arm PDFPIYUSH KULKARNINo ratings yet

- Mid Semester Exam Paper Contains 02 PagesDocument2 pagesMid Semester Exam Paper Contains 02 PagesBabuli KumarNo ratings yet

- Regression Analysis: T Off Versus Out Put RaDocument3 pagesRegression Analysis: T Off Versus Out Put RaBabuli KumarNo ratings yet

- Effects of Welding Parameters on TIG Welding of Aluminum PlateDocument48 pagesEffects of Welding Parameters on TIG Welding of Aluminum PlatekarthickNo ratings yet

- Irjet V5i415 PDFDocument4 pagesIrjet V5i415 PDFvidit sharmaNo ratings yet

- Question M.TechDocument5 pagesQuestion M.TechBabuli KumarNo ratings yet

- Milling, Shaping and GrindingDocument19 pagesMilling, Shaping and Grindingdema_dias100% (1)

- FULLTEXT02Document101 pagesFULLTEXT02Babuli KumarNo ratings yet

- FixtureDocument20 pagesFixturesrinivaskurmapu9101No ratings yet

- 09 Chapter 1Document15 pages09 Chapter 1Suraj MuktiNo ratings yet

- ManufacturingDocument4 pagesManufacturingBabuli KumarNo ratings yet

- Elements of Jigs and FixturesDocument5 pagesElements of Jigs and FixturesBabuli KumarNo ratings yet

- 59f6f95f3c9011509357919 PDFDocument5 pages59f6f95f3c9011509357919 PDFRaja RajaNo ratings yet

- Milling, Shaping and GrindingDocument19 pagesMilling, Shaping and Grindingdema_dias100% (1)

- 2nd Internal Question Rapid PrototypingDocument1 page2nd Internal Question Rapid PrototypingBabuli KumarNo ratings yet

- Chapter 9 - Welding DefectsDocument18 pagesChapter 9 - Welding Defectsbibin2010100% (1)

- Ansarangi AY19-20Document1 pageAnsarangi AY19-20Babuli KumarNo ratings yet

- Physics: Michelle Lao NMAT Review 2020 July 2020 Trans 01Document6 pagesPhysics: Michelle Lao NMAT Review 2020 July 2020 Trans 01Klee KazuhaNo ratings yet

- Glider Aerobatics ManualDocument36 pagesGlider Aerobatics ManualmichetraviNo ratings yet

- VLSI Digital Design Issues: Clock Skew, Distribution, Jitter and Power OptimizationDocument94 pagesVLSI Digital Design Issues: Clock Skew, Distribution, Jitter and Power Optimizationraghava06No ratings yet

- Magnetic Fields From High Voltage Power CablesDocument4 pagesMagnetic Fields From High Voltage Power CablesDejanNo ratings yet

- Environmental friendly, energy saving LED well luminaireDocument9 pagesEnvironmental friendly, energy saving LED well luminaireAbhishek KumarNo ratings yet

- Worksheet - Accumulation FunctionsDocument3 pagesWorksheet - Accumulation FunctionssteveNo ratings yet

- Understanding Moores LawDocument136 pagesUnderstanding Moores Lawsasi kiran sNo ratings yet

- Ranon, Lyan Anacleto Q M12 PMDocument7 pagesRanon, Lyan Anacleto Q M12 PMHan NahNo ratings yet

- Form 3 Angles subtended at arc circumference are equalDocument2 pagesForm 3 Angles subtended at arc circumference are equalRita Lau50% (4)

- Product and Performance Task: Basic CalculusDocument23 pagesProduct and Performance Task: Basic CalculusYvez Vyanka CastilloNo ratings yet

- Manual Viscosimetro Fungilab Viscolead ONE enDocument49 pagesManual Viscosimetro Fungilab Viscolead ONE enWilfrank BadilloNo ratings yet

- Course Schedule - 14080167 - 2022 - 12 - 18 - 09 - 02Document1 pageCourse Schedule - 14080167 - 2022 - 12 - 18 - 09 - 02KevinNo ratings yet

- 4FE-28Y-40P With FHU+60Document17 pages4FE-28Y-40P With FHU+60tedychrNo ratings yet

- Western Region-Ordinary Members PDFDocument21 pagesWestern Region-Ordinary Members PDFjaydeep daveNo ratings yet

- 06.GTA-06 (p1) Question Paper S60Document20 pages06.GTA-06 (p1) Question Paper S60Motivational BabaNo ratings yet

- Philips Master Ledtube 30W 4000Lm Mains T8: Signify Classified - InternalDocument5 pagesPhilips Master Ledtube 30W 4000Lm Mains T8: Signify Classified - InternalMANDAR LITESNo ratings yet

- Kruss Techdata SDT en PDFDocument4 pagesKruss Techdata SDT en PDFTravis HNo ratings yet

- QSD 1976Document10 pagesQSD 1976Felipe ChagasNo ratings yet

- Upgrade As You Grow Aesthetic Platform: LuminaDocument2 pagesUpgrade As You Grow Aesthetic Platform: Luminachash75No ratings yet

- Chapter 3 256857Document45 pagesChapter 3 256857신재우No ratings yet

- Brønsted-Lowry Theory of Acids and BasesDocument4 pagesBrønsted-Lowry Theory of Acids and Basescayla mae carlosNo ratings yet

- 0580 IGCSE Mathematics - Useful FormulaeDocument3 pages0580 IGCSE Mathematics - Useful FormulaeSupermartin767No ratings yet

- Dice Vault - PARAGONDocument5 pagesDice Vault - PARAGONWolfcreed87No ratings yet

- Experiment 12:: SCR CharacteristicsDocument3 pagesExperiment 12:: SCR CharacteristicsPerumal NamasivayamNo ratings yet

- Inkjet Nozzle Simulation Using Level Set MethodDocument18 pagesInkjet Nozzle Simulation Using Level Set MethodNEHA THAKUR 1982605No ratings yet

- SPE 125581 Global Laboratory Experience of CO2-EOR Flooding: V D V A I 1Document15 pagesSPE 125581 Global Laboratory Experience of CO2-EOR Flooding: V D V A I 1shayanepmNo ratings yet

- Statics of Forces and VectorsDocument14 pagesStatics of Forces and VectorstoxicjjNo ratings yet

- Matarbari Ultra Super Critical Coal-Fired Power ProjectDocument1 pageMatarbari Ultra Super Critical Coal-Fired Power ProjectHasan al MahmudNo ratings yet

- Air Cooled Mini Chiller Ex. Teco-2Document5 pagesAir Cooled Mini Chiller Ex. Teco-2Bagus TVNo ratings yet

- Footwork EnglishDocument13 pagesFootwork EnglishYel Balmediano Dela CruzNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)

- Grid-Scale Energy Storage Systems and ApplicationsFrom EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNo ratings yet

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)

- DIY Free Home Energy Solutions: How to Design and Build Your own Domestic Free Energy SolutionFrom EverandDIY Free Home Energy Solutions: How to Design and Build Your own Domestic Free Energy SolutionRating: 5 out of 5 stars5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Power Quality in Power Systems and Electrical MachinesFrom EverandPower Quality in Power Systems and Electrical MachinesRating: 4.5 out of 5 stars4.5/5 (11)

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)