Professional Documents

Culture Documents

Test Bank Cost Accounting 14e by Carter ch14

Uploaded by

Mary Anne HermosaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Bank Cost Accounting 14e by Carter ch14

Uploaded by

Mary Anne HermosaCopyright:

Available Formats

lOMoARcPSD|4609482

TEST BANK Cost Accounting 14E by Carter Ch14

Accounting (Hanoi University)

StuDocu is not sponsored or endorsed by any college or university

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

lOMoARcPSD|4609482

Chapter 14

ACTIVITY ACCOUNTING: ACTIVITY-BASED COSTING

AND ACTIVITY-BASED MANAGEMENT

MULTIPLE CHOICE

A 1. A base used to allocate the cost of a resource to the different activities using

that resource is a(n):

A. resource driver

B. activity driver

C. final cost object

D. driver

E. none of the above

B 2. A base used to allocate the cost of products, customers, or other final cost

objects is a(n):

A. resource driver

B. activity driver

C. final cost object

D. driver

E. none of the above

B 3. Examples of activities at the batch level of costs include:

A. cutting, painting, and packaging

B. scheduling, setting up, and moving

C. designing, changing, and advertising

D. heating, lighting, and security

E. none of the above

C 4. Examples of activities at the product level of costs include:

A. cutting, painting, and packaging

B. scheduling, setting up, and moving

C. designing, changing, and advertising

D. heating, lighting, and security

E. none of the above

D 5. Examples of activities at the plant level of costs include:

A. cutting, painting, and packaging

B. scheduling, setting up, and moving

C. designing, changing, and advertising

D. heating, lighting, and security

E. none of the above

197

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

lOMoARcPSD|4609482

198 Chapter 14

A 6. Examples of activities at the unit level of costs include:

A. cutting, painting, and packaging

B. scheduling, setting up, and moving

C. designing, changing, and advertising

D. heating, lighting, and security

E. none of the above

A 7. Examples of unit-level costs are:

A. portions of electricity and indirect materials

B. salaries of schedulers and setup personnel

C. salaries of designers and programmers

D. depreciation and insurance on buildings

E. none of the above

C 8. Examples of product-level costs are:

A. portions of electricity and indirect materials

B. salaries of schedulers and setup personnel

C. salaries of designers and programmers

D. depreciation and insurance on buildings

E. none of the above

D 9. Examples of plant-level costs are:

A. portions of electricity and indirect materials

B. salaries of schedulers and setup personnel

C. salaries of designers and programmers

D. depreciation and insurance on buildings

E. none of the above

B 10. Examples of batch-level costs are:

A. portions of electricity and indirect materials

B. salaries of schedulers and setup personnel

C. salaries of designers and programmers

D. depreciation and insurance on buildings

E. none of the above

A 11. Examples of unit-level activity drivers include:

A. units of output and direct labor hours

B. number of batches and material moves

C. number of products and design changes

D. square footage occupied

E. all of the above

B 12. Examples of batch-level activity drivers include:

A. units of output and direct labor hours

B. number of batches and material moves

C. number of products and design changes

D. square footage occupied

E. all of the above

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

lOMoARcPSD|4609482

Activity Accounting: Activity-Based Costing and Activity-Based Management 199

C 13. Examples of product-level activity drivers include:

A. units of output and direct labor hours

B. number of batches and material moves

C. number of products and design changes

D. square footage occupied

E. all of the above

D 14. Examples of plant-level activity drivers include:

A. units of output and direct labor hours

B. number of batches and material moves

C. number of products and design changes

D. square footage occupied

E. all of the above

A 15. Unit-level costs are costs that:

A. inevitably increase whenever a unit is produced

B. are caused by the number of batches produced and sold

C. are incurred to support the number of different products produced

D. are incurred to sustain capacity at a production site

E. none of the above

D 16. Plant-level costs are costs that:

A. inevitably increase whenever a unit is produced

B. are caused by the number of batches produced and sold

C. are incurred to support the number of different products produced

D. are incurred to sustain capacity at a production site

E. none of the above

E 17. Unit-level drivers are:

A. inversely proportional to the volume of output

B. measures of activities that vary with the number of batches produced and

sold

C. measures of activity that vary with the number of different products

produced and sold

D. for assigning plant-level costs

E. none of the above

A 18. Traditional costing systems are characterized by their use of which of the

following measures as bases for allocating overhead to output:

A. unit-level drivers

B. batch-level drivers

C. product-level drivers

D. plant-level drivers

E. none of the above

E 19. ABC systems are characterized by their use of which of the following measures

as bases for allocating overhead to output:

A. unit-level drivers

B. batch-level drivers

C. product-level drivers

D. plant-level drivers

E. all of the above

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

lOMoARcPSD|4609482

200 Chapter 14

A 20. All of the following are distinctions that usually exist between traditional and

ABC costing systems, except that:

A. the number of overhead cost pools tends to be lower in ABC systems

B. the number of allocation bases tend to be higher in ABC systems

C. costs within an ABC cost pool tend to be more homogeneous than the costs

within a traditional system's cost pool

D. all ABC systems are two-stage costing systems, while traditional systems

may be one- or two-stage

E. all of the above are distinctions

D 21. All of the following are distinctions that usually exist between traditional and

ABC costing systems, except that:

A. the number of overhead cost pools tends to be higher in ABC systems

B. the number of allocation bases tend to be higher in ABC systems

C. costs within an ABC cost pool tend to be more homogeneous than the costs

within a traditional system's cost pool

D. all ABC systems are one-stage costing systems, while traditional systems

may be one- or two-stage

E. all of the above are distinctions

B 22. Compared to an ABC system, a traditional costing system reports:

A. a lower unit cost for high-volume products and a higher unit cost for low-

volume products

B. a higher unit cost for high-volume products and a lower unit cost for low-

volume products

C. the same unit costs for high- and low-volume products as does an ABC

system

D. either higher or lower unit cost for high-volume products than an ABC

system depending upon the level of fixed costs

E. none of the above

C 23. Activity-based management (ABM) is:

A. a costing system in which multiple overhead cost pools are allocated using

bases that include one or more nonvolume related factors

B. a base used to allocate the cost of a resource to the different activities

using it

C. the use of information obtained from ABC to make improvements in the

firm

D. a base used to allocate the cost of an activity to products and customers

E. none of the above

A 24. All of the following are ways that activities can be managed to achieve

improvements in a process, except:

A. activity induction

B. activity elimination

C. activity selection

D. activity sharing

E. all of the above are ways in which activities may be managed

C 25. All of the following are examples of non-value-added activities except:

A. ordering

B. receiving

C. assembling

D. inspections

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

lOMoARcPSD|4609482

Activity Accounting: Activity-Based Costing and Activity-Based Management 201

E. setting up

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

lOMoARcPSD|4609482

202 Chapter 14

PROBLEMS

PROBLEM

1.

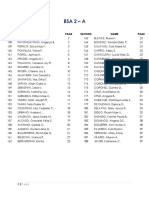

Levels of Activity Drivers

Required: Each of the following is a potential activity driver. Identify the most likely level

of each activity driver by writing U for a unit-level driver, B for a batch-level driver, and P

for a product-level driver.

1.Number of setups

2.Number of work orders

3.Machine hours

4.Pounds of product

5.Number of part numbers

6.Design hours

7.Number of design changes

8.Marketing promotions

9.Direct materials dollars

10.Loads of materials moved

SOLUTION

1. B 2. B 3. U 4. U 5. P

6. P 7. P 8. P 9. U 10. B

PROBLEM

2.

Distortion of Batch-Level Costs. Maupin Company's existing cost system accumulates

all overhead in a single cost pool and allocates it based on direct labor hours. Last year,

overhead costs totaled $1,500,000, and Product A used 3,000 of the 30,000 total direct

labor hours. An ABC study revealed that of the total overhead cost for last year, $100,000

represented batch-level costs; these batch-level costs are driven by work orders; and a

total of 500 work orders were issued, of which 25 were for Product A.

Required: With respect to batch-level costs only, calculate the existing cost system's

direction and amount of cost distortion for Product A.

SOLUTION

The existing system allocated 3,000/30,000 = 10% of all overhead to Product A last year;

but A accounted for only 25/500 = 5% of batch-level activity. So, with respect to batch-

level costs only, the existing system overstated A's cost last year by a total of:

(10% - 5%) x $100,000 = $5,000 overstatement

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

lOMoARcPSD|4609482

Activity Accounting: Activity-Based Costing and Activity-Based Management 203

PROBLEM

3.

Value-Added and Non-Value-Added Activities. Sequential Company's sole product, a

unique end table made from lumber, is produced and sold in the following sequence of

steps:

(a) wood received and inspected at receiving dock

(b) wood moved to stores inventory

(c) wood moved to Cutting Department

(d) wood cut to size

(e) moved to Planing Department

(f) placed in queue to await planing

(g) wood smoothed and shaped

(h) moved to Inspection Department

(i) inspected

(j) moved to in-process storage area

(k) moved to Assembly Department

(l) various parts of the table are assembled

(m) placed on hand truck to await material handler

(n) moved to Staining Department

(o) tables stained

(p) moved to Inspection Department

(q) inspected

(r) moved to Shipping Department

(s) tables shipped

Required: Which of the steps add value to the product?

SOLUTION

Activities (d), (g), (l), and (o) are the only ones which add value.

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

lOMoARcPSD|4609482

204 Chapter 14

PROBLEM

4.

Allocation Rates and Driver Rates. The Barre Division of Scranton Company

manufactures many high-volume products and many low-volume products. Selected

information follows for Barre's most recent year of operations:

Indirect costs:

Machine related:

Machine operation........................................................................................... $ 75,000

Machine setup................................................................................................. 50,000

Total machine overhead............................................................................ $ 125,000

Materials related:

Materials handling........................................................................................... $ 45,000

Other materials-related................................................................................... 60,000

Total materials overhead.......................................................................... $ 105,000

Other overhead............................................................................................... $ 190,000

Total overhead................................................................................................ $ 420,000

Machine hours....................................................................................................... 10,000

Pounds of materials.............................................................................................. 50,000

Setup hours........................................................................................................... 1,000

Purchase orders.................................................................................................... 1,200

Direct labor hours................................................................................................. 25,000

Barre's existing cost system allocates all machine-related overhead based on machine

hours and all the remaining overhead based on direct labor hours. However, a recent study

determined that machine setup costs and material handling costs are primarily related to

setup hours, and other materials-related costs are primarily related to the number of

purchase orders issued. Barre does not keep significant materials inventories on hand.

Required:

(1) Calculate the two overhead rates in Barre's existing cost system for the most recent

year.

(2) Calculate the overhead (driver) rates that an ABC system would use for the most

recent year, making only the changes suggested by the results of the recent study.

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

lOMoARcPSD|4609482

Activity Accounting: Activity-Based Costing and Activity-Based Management 205

SOLUTION

$125,000 of machine- related overhead

= $12.50 per machine hour

10,000 machine hours

$295,000 of remaining overhead costs

= $11.80 per direct labor hour

25,000 DLH

(1)

$75,000 of machine operation overhead

= $7.50 per machine hour

10,000 machine hours

$50,000 of machine- setup overhead + $45,000 of materials handling overhead

= $95 per s

1,000 setup hours

$60,000 of other materials- related cost

= $50 per purchase order

1,200 purchase orders

$190,000 of _ other overhead _

= $7.60 per direct labor hour

25,000 DLH

(2)

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

lOMoARcPSD|4609482

206 Chapter 14

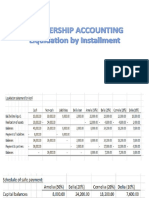

PROBLEM

5.

Comparison of ABC and Traditional Costing; Two Products. Blaine Company

produces two products, Nifty and So-So, and uses a costing system in which all overhead is

accumulated in a single cost pool and allocated based on machine hours. Blaine's

management has decided to implement ABC because a cost study has revealed significant

amounts of overhead cost related to setup activity and design activity. The number of

setups and the number of design hours will be the activity drivers for the two new cost

pools, and machine hours will continue as the base for allocating the remaining overhead.

Selected information follows for Blaine Company's most recent year of operations:

Nifty So-So Total

Units produced.......................................................... 500 15,500 16,000

Direct material cost:

Per unit................................................................ $ 200 $ 20

Total.................................................................... $100,000 $310,000 $410,000

Machine hours........................................................... 3,000 47,000 50,000

Direct labor cost........................................................ $50,000 $350,000 $400,000

Setups....................................................................... 120 80 200

Design hours............................................................. 6,000 4,000 10,000

Overhead:

Setup-related....................................................... $250,000

Design-related..................................................... 350,000

Other................................................................... 900,000

Total overhead.................................................... $

1,500,000

Required:

(1) Calculate the total and per-unit costs reported for the two products by the existing

costing system.

(2) Calculate the total and per-unit costs reported for the two products by the ABC

system.

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

lOMoARcPSD|4609482

Activity Accounting: Activity-Based Costing and Activity-Based Management 207

SOLUTION

(1) Blaine Company

Product Costs from Existing Cost System

Overhead Rate:

$1,500,000 of overhead divided by 50,000 machine hours = $30 per machine hour

Nifty So-So Total

Direct material........................................................... $100,000 $310,000 $410,000

Direct labor................................................................ 50,000 350,000 400,000

Overhead:

$30 x 3,000......................................................... 90,000

$30 x 47,000....................................................... 1,410,000

1,500,000

Total cost................................................................... $240,000 $2,070,000 $

2,310,000

Units produced.......................................................... 500 15,500

Cost per unit.............................................................. $480.00 $ 133.55

(2) Blaine Company

Product Costs from Activity-Based Costing System

Overhead Rate:

$250,000 setup-related costs divided by 200 setups = 1,250 per setup

$350,000 design-related costs divided by 10,000 design hours = $35 per design hour

$900,000 of other overhead divided by 50,000 machine hours = $18 per machine hour

Nifty So-So Total

Direct material........................................................... $100,000 $310,000 $410,000

Direct labor................................................................ 50,000 350,000 400,000

Overhead:

$1,250 x 120 setups............................................ 150,000

$1,250 x 80 setups.............................................. 100,000 250,000

$35 x 6,000 design hours.................................... 210,000

$35 x 4,000 design hours.................................... 140,000 350,000

$18 x 3,000 machine hours................................. 54,000

$18 x 47,000 machine hours............................... 846,000 900,000

Total cost................................................................... $564,000 $1,746,000 $

2,310,000

Units produced.......................................................... 500 15,500

Cost per unit.............................................................. $1,128.00 $ 112.65

Downloaded by Joseph Mangahas (josephmangahas013100@gmail.com)

You might also like

- 14 Activity-Accounting - Activity-Based Costing & Activity-Based ManagementDocument10 pages14 Activity-Accounting - Activity-Based Costing & Activity-Based ManagementJonna Lynne0% (1)

- CompTIA A+ Certification All-in-One Exam Questions Prep (220-701 & 220-702)From EverandCompTIA A+ Certification All-in-One Exam Questions Prep (220-701 & 220-702)Rating: 2.5 out of 5 stars2.5/5 (6)

- Chapter 14 Activity Accounting: Activity Based Costing and Activity Based ManagementDocument12 pagesChapter 14 Activity Accounting: Activity Based Costing and Activity Based ManagementcykablyatNo ratings yet

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Accounting 106Document19 pagesAccounting 106Sports savageNo ratings yet

- Data-Driven Design and Construction: 25 Strategies for Capturing, Analyzing and Applying Building DataFrom EverandData-Driven Design and Construction: 25 Strategies for Capturing, Analyzing and Applying Building DataNo ratings yet

- Chapter 4 Cost SystemsDocument26 pagesChapter 4 Cost SystemsAdnan KhanNo ratings yet

- Improving Energy Efficiency and Reducing Emissions through Intelligent Railway Station BuildingsFrom EverandImproving Energy Efficiency and Reducing Emissions through Intelligent Railway Station BuildingsNo ratings yet

- MAS Compilation of QuestionsDocument21 pagesMAS Compilation of QuestionsHazel Joy GaboNo ratings yet

- Handbook on Construction Techniques: A Practical Field Review of Environmental Impacts in Power Transmission/Distribution, Run-of-River Hydropower and Solar Photovoltaic Power Generation ProjectsFrom EverandHandbook on Construction Techniques: A Practical Field Review of Environmental Impacts in Power Transmission/Distribution, Run-of-River Hydropower and Solar Photovoltaic Power Generation ProjectsRating: 2 out of 5 stars2/5 (1)

- Quiz ABMDocument3 pagesQuiz ABMBeatrice ErilloNo ratings yet

- MANAGEMENT ADVISORY SERVICES Q&ADocument21 pagesMANAGEMENT ADVISORY SERVICES Q&ATom Dominguez100% (1)

- Guidelines for Estimating Greenhouse Gas Emissions of ADB Projects: Additional Guidance for Clean Energy ProjectsFrom EverandGuidelines for Estimating Greenhouse Gas Emissions of ADB Projects: Additional Guidance for Clean Energy ProjectsNo ratings yet

- MAS.M-1414.Cost Concepts ClassificationDocument10 pagesMAS.M-1414.Cost Concepts Classificationchowchow123No ratings yet

- Management Accounting Strategy Study Resource for CIMA Students: CIMA Study ResourcesFrom EverandManagement Accounting Strategy Study Resource for CIMA Students: CIMA Study ResourcesNo ratings yet

- ABC - ReviewerDocument9 pagesABC - ReviewerAndrea Nicole MASANGKAYNo ratings yet

- Chapter 03 TestbankDocument108 pagesChapter 03 TestbankanukshaNo ratings yet

- Formal Methods Applied to Complex Systems: Implementation of the B MethodFrom EverandFormal Methods Applied to Complex Systems: Implementation of the B MethodNo ratings yet

- Theory: Management Advisory Services Questions and Answers Compiled By: Ma. Cristina P. Obeso, CpaDocument21 pagesTheory: Management Advisory Services Questions and Answers Compiled By: Ma. Cristina P. Obeso, CpaJyasmine Aura V. AgustinNo ratings yet

- Schaum's Easy Outline: Programming with C++From EverandSchaum's Easy Outline: Programming with C++Rating: 3.5 out of 5 stars3.5/5 (4)

- 04 Cost Systems - Cost AccumulationDocument14 pages04 Cost Systems - Cost AccumulationNerissa Bangui100% (2)

- Integration of Demand Response into the Electricity Chain: Challenges, Opportunities, and Smart Grid SolutionsFrom EverandIntegration of Demand Response into the Electricity Chain: Challenges, Opportunities, and Smart Grid SolutionsNo ratings yet

- Cost Accounting SystemsDocument24 pagesCost Accounting SystemsQueenie ValleNo ratings yet

- The 123s of ABC in SAP: Using SAP R/3 to Support Activity-Based CostingFrom EverandThe 123s of ABC in SAP: Using SAP R/3 to Support Activity-Based CostingNo ratings yet

- MAS Compilation of Questions PDFDocument17 pagesMAS Compilation of Questions PDFARISNo ratings yet

- MAS Compilation of QuestionsDocument10 pagesMAS Compilation of QuestionsArianne LlorenteNo ratings yet

- Cost TB C02 CarterDocument23 pagesCost TB C02 CarterArya Stark100% (1)

- Chapter 02 TestbankDocument372 pagesChapter 02 TestbankAvisha SinghNo ratings yet

- MAS Compilation of QuestionsDocument21 pagesMAS Compilation of QuestionsInocencio Tiburcio67% (3)

- Cost Accounting Systems A. Traditional Cost Accounting TheoriesDocument47 pagesCost Accounting Systems A. Traditional Cost Accounting TheoriesalabwalaNo ratings yet

- ABC Quiz With SolutionDocument13 pagesABC Quiz With Solutionlou-924No ratings yet

- ABC QuizDocument11 pagesABC Quizlou-924No ratings yet

- 18 x12 ABC ADocument12 pages18 x12 ABC AKM MacatangayNo ratings yet

- Cost concepts and cost accounting informationDocument7 pagesCost concepts and cost accounting informationAkiNo ratings yet

- 18 x12 ABC A Traditional Cost AccountingDocument13 pages18 x12 ABC A Traditional Cost AccountingQueenie ValleNo ratings yet

- 02 - Costacctng 02 - CostacctngDocument12 pages02 - Costacctng 02 - CostacctngClarisse PelayoNo ratings yet

- MIDTERM-IN-AE23 (1)Document5 pagesMIDTERM-IN-AE23 (1)Ladignon IvyNo ratings yet

- Cost Accounting 1-2 FinalDocument29 pagesCost Accounting 1-2 FinalChristian Blanza LlevaNo ratings yet

- Is A Two-Stage Overhead Cost Allocation System That Identifies Activity Cost Pools and Cost DriversDocument16 pagesIs A Two-Stage Overhead Cost Allocation System That Identifies Activity Cost Pools and Cost DriversDhaboy PeñarandaNo ratings yet

- Chapter 12&13 Variance AnalysisDocument3 pagesChapter 12&13 Variance AnalysisCh KingNo ratings yet

- COSTACCTGDocument112 pagesCOSTACCTGMaria Emarla Grace CanozaNo ratings yet

- MULTIPLE CHOICE. Choose The One Alternative That Best Completes The Statement or Answers The QuestionDocument19 pagesMULTIPLE CHOICE. Choose The One Alternative That Best Completes The Statement or Answers The QuestionKang ChulNo ratings yet

- Management Accounting 6th Edition Smith Test BankDocument38 pagesManagement Accounting 6th Edition Smith Test Banklevi95scott100% (13)

- COST ACCOUNTING 1-4 FinalDocument28 pagesCOST ACCOUNTING 1-4 FinalChristian Blanza Lleva100% (1)

- 0 Out of 25 CorrectDocument18 pages0 Out of 25 CorrectMika Abucay ReyesNo ratings yet

- Management Advisory Services and Accounting OverviewDocument150 pagesManagement Advisory Services and Accounting OverviewJamaica DavidNo ratings yet

- Ans: D: Multiple ChoiceDocument14 pagesAns: D: Multiple ChoiceNah HamzaNo ratings yet

- Activity Based CostingDocument13 pagesActivity Based CostingJoshNo ratings yet

- Cost Accounting Chapter 2 ReviewDocument18 pagesCost Accounting Chapter 2 ReviewMaryane AngelaNo ratings yet

- MANAGEMENT ADVISORY SERVICES Q&ADocument14 pagesMANAGEMENT ADVISORY SERVICES Q&AKatrina AngelicaNo ratings yet

- MAS.m-1414. Cost Concepts, Classification and Segregation - MCDocument10 pagesMAS.m-1414. Cost Concepts, Classification and Segregation - MCCharry Ramos100% (2)

- Management Accounting 6th Edition Smith Test Bank Full Chapter PDFDocument67 pagesManagement Accounting 6th Edition Smith Test Bank Full Chapter PDFlilyhubertovkxxb100% (9)

- University of Caloocan City Cost Accounting & Control Midterm ExaminationDocument8 pagesUniversity of Caloocan City Cost Accounting & Control Midterm ExaminationAlexandra Nicole IsaacNo ratings yet

- Activity Based CostingDocument13 pagesActivity Based CostingJoshNo ratings yet

- Cost Accounting Practice TestDocument27 pagesCost Accounting Practice Testaiswift100% (1)

- ABC Methods for Improved Costing and ManagementDocument26 pagesABC Methods for Improved Costing and ManagementPeter Angelo BangaanNo ratings yet

- CH 04Document20 pagesCH 04Chronos ChronosNo ratings yet

- Auditing Theory Test BankDocument7 pagesAuditing Theory Test BankMary Anne HermosaNo ratings yet

- Swimming History and Basic KnowledgeDocument4 pagesSwimming History and Basic KnowledgeMary Anne HermosaNo ratings yet

- Project in ObliconDocument2 pagesProject in ObliconCathy ManahanNo ratings yet

- Digital Age, Information Age and Computer Age ExplainedDocument10 pagesDigital Age, Information Age and Computer Age ExplainedMary Anne Hermosa100% (9)

- Chap 005Document62 pagesChap 005AhsanNo ratings yet

- R.A. No. 10173 Data Privacy Act of 2012Document9 pagesR.A. No. 10173 Data Privacy Act of 2012Rovan Gionald LimNo ratings yet

- Basic Accounting: Accounts Titles Date Debit CreditDocument5 pagesBasic Accounting: Accounts Titles Date Debit CreditJamel torres82% (17)

- Partial Philippine Corporation Code SummaryDocument39 pagesPartial Philippine Corporation Code SummaryMary Anne HermosaNo ratings yet

- Cbea Ais Lecture 03Document5 pagesCbea Ais Lecture 03Ericka SantiagoNo ratings yet

- Solution Manual Keiso 9-1 To 9-15Document9 pagesSolution Manual Keiso 9-1 To 9-15Mary Anne HermosaNo ratings yet

- Cbea Partn Actg Lecture 07Document11 pagesCbea Partn Actg Lecture 07Mary Anne HermosaNo ratings yet

- CH 05 SMDocument22 pagesCH 05 SMRyan James B. Aban100% (4)

- Ch01 - Auditing, Attestation, and AssuranceDocument9 pagesCh01 - Auditing, Attestation, and AssuranceRamon Jonathan Sapalaran100% (2)

- Mitch Fryling and Linda Hayes - Motivation in Behavior Analysis A Critique PDFDocument9 pagesMitch Fryling and Linda Hayes - Motivation in Behavior Analysis A Critique PDFIrving Pérez Méndez0% (1)

- Extending NAS Web App MobileDocument2 pagesExtending NAS Web App MobileD2VNo ratings yet

- Ds 311 2 General Pre-Start Check List (B)Document4 pagesDs 311 2 General Pre-Start Check List (B)Miguel RomoNo ratings yet

- TUDelft Clay Suction PDFDocument8 pagesTUDelft Clay Suction PDFDing LiuNo ratings yet

- The Origins Development and Possible Decline of The Modern StateDocument65 pagesThe Origins Development and Possible Decline of The Modern StateJasper Jade MartinNo ratings yet

- Compendium 2004jan RadiographyDocument11 pagesCompendium 2004jan RadiographyAgus SusilaNo ratings yet

- Disney's Strategic HRM: Training, Recruitment and HR PlanningDocument9 pagesDisney's Strategic HRM: Training, Recruitment and HR PlanningNgân NgânNo ratings yet

- Container Generator Qac Qec Leaflet EnglishDocument8 pagesContainer Generator Qac Qec Leaflet EnglishGem RNo ratings yet

- SCAQMD Method 3.1Document27 pagesSCAQMD Method 3.1Jonathan Aviso MendozaNo ratings yet

- 2018 General Education Reviewer Part 10 - 50 Questions With Answers - LET EXAM - Questions & AnswersDocument10 pages2018 General Education Reviewer Part 10 - 50 Questions With Answers - LET EXAM - Questions & AnswersScribdNo ratings yet

- Spreadsheet Practice Exercises-2017Document43 pagesSpreadsheet Practice Exercises-2017Sur Velan100% (1)

- Surveyquestionnaire 1Document6 pagesSurveyquestionnaire 1Almira IbarraNo ratings yet

- Building Materials Purchase ListDocument123 pagesBuilding Materials Purchase ListRizki AmrullahNo ratings yet

- Part IIDocument281 pagesPart IILeng SovannarithNo ratings yet

- Pics Dany and Camy Preteen Models Checked PDFDocument3 pagesPics Dany and Camy Preteen Models Checked PDFChris0% (2)

- Handbook Valve Technology 03.04.2020Document132 pagesHandbook Valve Technology 03.04.2020Ramazan YaşarNo ratings yet

- Micro-operations and the CPU ClockDocument28 pagesMicro-operations and the CPU ClockchandraNo ratings yet

- Solution Manual For Macroeconomics 13th Edition Michael ParkinDocument24 pagesSolution Manual For Macroeconomics 13th Edition Michael ParkinBonnieGoodmanxajb100% (45)

- ch9 MKT 301 Quiz ReviewDocument4 pagesch9 MKT 301 Quiz ReviewSergio HoffmanNo ratings yet

- CHAPTER 9 Microsoft Excel 2016 Back ExerciseDocument3 pagesCHAPTER 9 Microsoft Excel 2016 Back ExerciseGargi SinghNo ratings yet

- A Knowledge Management Approach To Organizational Competitive Advantage Evidence From The Food SectorDocument13 pagesA Knowledge Management Approach To Organizational Competitive Advantage Evidence From The Food SectorJack WenNo ratings yet

- Operation and Safety Manual: Ansi As/NzsDocument116 pagesOperation and Safety Manual: Ansi As/NzsMuhammad AwaisNo ratings yet

- Katalog Ag-700 To Ag-800Document1 pageKatalog Ag-700 To Ag-800Iqbal AbugindaNo ratings yet

- Class Note 2 - Rain GaugesDocument6 pagesClass Note 2 - Rain GaugesPrakash PatelNo ratings yet

- Risktec Drilling Soc 0.3 PDFDocument16 pagesRisktec Drilling Soc 0.3 PDF1sNo ratings yet

- Comparative ratings of heavy duty cablesDocument1 pageComparative ratings of heavy duty cablesshivani76% (25)

- Hydrology Notes 4 PDFDocument12 pagesHydrology Notes 4 PDFSudin PradhanNo ratings yet

- OM Sample QPDocument8 pagesOM Sample QPChandra ShekarNo ratings yet

- Lisa Van Krieken CVDocument1 pageLisa Van Krieken CVapi-525455549No ratings yet

- Geotechnical Scope of Work For ERL Unit-2Document75 pagesGeotechnical Scope of Work For ERL Unit-2smjohirNo ratings yet

- How to Start a Business: Mastering Small Business, What You Need to Know to Build and Grow It, from Scratch to Launch and How to Deal With LLC Taxes and Accounting (2 in 1)From EverandHow to Start a Business: Mastering Small Business, What You Need to Know to Build and Grow It, from Scratch to Launch and How to Deal With LLC Taxes and Accounting (2 in 1)Rating: 4.5 out of 5 stars4.5/5 (5)

- The Science of Prosperity: How to Attract Wealth, Health, and Happiness Through the Power of Your MindFrom EverandThe Science of Prosperity: How to Attract Wealth, Health, and Happiness Through the Power of Your MindRating: 5 out of 5 stars5/5 (231)

- I Will Teach You to Be Rich: No Guilt. No Excuses. No B.S. Just a 6-Week Program That Works (Second Edition)From EverandI Will Teach You to Be Rich: No Guilt. No Excuses. No B.S. Just a 6-Week Program That Works (Second Edition)Rating: 4.5 out of 5 stars4.5/5 (13)

- Love Your Life Not Theirs: 7 Money Habits for Living the Life You WantFrom EverandLove Your Life Not Theirs: 7 Money Habits for Living the Life You WantRating: 4.5 out of 5 stars4.5/5 (146)

- Profit First for Therapists: A Simple Framework for Financial FreedomFrom EverandProfit First for Therapists: A Simple Framework for Financial FreedomNo ratings yet

- Tax-Free Wealth: How to Build Massive Wealth by Permanently Lowering Your TaxesFrom EverandTax-Free Wealth: How to Build Massive Wealth by Permanently Lowering Your TaxesNo ratings yet

- Getting to Yes: How to Negotiate Agreement Without Giving InFrom EverandGetting to Yes: How to Negotiate Agreement Without Giving InRating: 4 out of 5 stars4/5 (652)

- The One-Page Financial Plan: A Simple Way to Be Smart About Your MoneyFrom EverandThe One-Page Financial Plan: A Simple Way to Be Smart About Your MoneyRating: 4.5 out of 5 stars4.5/5 (37)

- 7 Financial Models for Analysts, Investors and Finance Professionals: Theory and practical tools to help investors analyse businesses using ExcelFrom Everand7 Financial Models for Analysts, Investors and Finance Professionals: Theory and practical tools to help investors analyse businesses using ExcelNo ratings yet

- Financial Intelligence: A Manager's Guide to Knowing What the Numbers Really MeanFrom EverandFinancial Intelligence: A Manager's Guide to Knowing What the Numbers Really MeanRating: 4.5 out of 5 stars4.5/5 (79)

- Finance Basics (HBR 20-Minute Manager Series)From EverandFinance Basics (HBR 20-Minute Manager Series)Rating: 4.5 out of 5 stars4.5/5 (32)

- Bookkeeping: A Beginner’s Guide to Accounting and Bookkeeping for Small BusinessesFrom EverandBookkeeping: A Beginner’s Guide to Accounting and Bookkeeping for Small BusinessesRating: 5 out of 5 stars5/5 (4)

- Ledger Legends: A Bookkeeper's Handbook for Financial Success: Navigating the World of Business Finances with ConfidenceFrom EverandLedger Legends: A Bookkeeper's Handbook for Financial Success: Navigating the World of Business Finances with ConfidenceNo ratings yet

- Accounting Principles: Learn The Simple and Effective Methods of Basic Accounting And Bookkeeping Using This comprehensive Guide for Beginners(quick-books,made simple,easy,managerial,finance)From EverandAccounting Principles: Learn The Simple and Effective Methods of Basic Accounting And Bookkeeping Using This comprehensive Guide for Beginners(quick-books,made simple,easy,managerial,finance)Rating: 4.5 out of 5 stars4.5/5 (5)

- The Accounting Game: Learn the Basics of Financial Accounting - As Easy as Running a Lemonade Stand (Basics for Entrepreneurs and Small Business Owners)From EverandThe Accounting Game: Learn the Basics of Financial Accounting - As Easy as Running a Lemonade Stand (Basics for Entrepreneurs and Small Business Owners)Rating: 4 out of 5 stars4/5 (33)

- I'll Make You an Offer You Can't Refuse: Insider Business Tips from a Former Mob Boss (NelsonFree)From EverandI'll Make You an Offer You Can't Refuse: Insider Business Tips from a Former Mob Boss (NelsonFree)Rating: 4.5 out of 5 stars4.5/5 (24)

- Accounting 101: From Calculating Revenues and Profits to Determining Assets and Liabilities, an Essential Guide to Accounting BasicsFrom EverandAccounting 101: From Calculating Revenues and Profits to Determining Assets and Liabilities, an Essential Guide to Accounting BasicsRating: 4 out of 5 stars4/5 (7)

- Overcoming Underearning(TM): A Simple Guide to a Richer LifeFrom EverandOvercoming Underearning(TM): A Simple Guide to a Richer LifeRating: 4 out of 5 stars4/5 (21)

- Warren Buffett and the Interpretation of Financial Statements: The Search for the Company with a Durable Competitive AdvantageFrom EverandWarren Buffett and the Interpretation of Financial Statements: The Search for the Company with a Durable Competitive AdvantageRating: 4.5 out of 5 stars4.5/5 (109)

- Financial Accounting - Want to Become Financial Accountant in 30 Days?From EverandFinancial Accounting - Want to Become Financial Accountant in 30 Days?Rating: 5 out of 5 stars5/5 (1)

- LLC Beginner's Guide: The Most Updated Guide on How to Start, Grow, and Run your Single-Member Limited Liability CompanyFrom EverandLLC Beginner's Guide: The Most Updated Guide on How to Start, Grow, and Run your Single-Member Limited Liability CompanyRating: 5 out of 5 stars5/5 (1)