Professional Documents

Culture Documents

Design and Analysis of Multi Operation Automatic Machine

Uploaded by

KKOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Analysis of Multi Operation Automatic Machine

Uploaded by

KKCopyright:

Available Formats

Design and Analysis of Multi Operation Automatic Machine

I.Rajkumar1,N.Rajini1, Ramesh Babu.S2, Nagulraaj.J2, Alexander.M2 , Suresh Jayaraman3

1

Asisstant professor, 2Third year students Department of Mechanical Engineering,

Kalasalingam University, Srivilliputtur, Virudhunagar, Tamil Nadu, India.

3

Italia Components Suppliers, Narasimhanaickenpalayam,

Coimbatore, Tamil Nadu, India.

Abstract:

The purpose of this research work is to design and construct an semi-auto machine

doing multiple operation in a single machine with loss of man power and resulting in

minimum lead time order to increase the production rate. Major work of the research is to

design the machine in minimum production cast with good efficiency and using pneumatic

powers to drive the machine rather using the electrical stepper motors in order to reduce the

machine cast and also to save the electrical energy. The machine is designed with use of

Solid works software as, to collect to coolant oil and cycled again for the process, burrs

produced is collected in the burr tank for the re-usage of the coolant oil and to separate the

burr easily. This chamfering, tapping machining process are used to manufacture automatic

machine. The chamfering is nothing but an essential operation before thread cutting so that

nut may pass freely on the threaded work piece, and tapping is a process of cutting or forming

threads using a tap. The main concept of this project is to reduce to production time and easy

to handle the small components which is not get easy for man and also reduce the man power.

Key words: Pneumatic power, Solidworks, Automatic machine, Cost efficient, Coolant oil.

You might also like

- Fabrication of Dual Side Shaper Machine Using Scotch Yoke Mechanism IJERTV8IS070088Document4 pagesFabrication of Dual Side Shaper Machine Using Scotch Yoke Mechanism IJERTV8IS070088Mikyas BelayNo ratings yet

- Project PPPT 2 ReviewDocument14 pagesProject PPPT 2 ReviewanuNo ratings yet

- Literature Review On Coconut Peeling MachineDocument8 pagesLiterature Review On Coconut Peeling MachineIJRASETPublications100% (1)

- ArunReddy CE3Document5 pagesArunReddy CE3John CornerNo ratings yet

- Low Cost Automation (LCA) : A Case Study: December 2014Document11 pagesLow Cost Automation (LCA) : A Case Study: December 2014Robinson PrabuNo ratings yet

- Design and Fabrication of Multipurpose Mechanical Machine - A ReviewDocument8 pagesDesign and Fabrication of Multipurpose Mechanical Machine - A ReviewM.HARISHANKARNo ratings yet

- PD ReportDocument6 pagesPD Reportbitish commectNo ratings yet

- Proceedings FinalDocument31 pagesProceedings FinalPalaniVelRajanNo ratings yet

- Journalnx DesignDocument2 pagesJournalnx DesignJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- A Project Report On Automatic Hammering MachineDocument17 pagesA Project Report On Automatic Hammering MachineLipsha75% (12)

- Semi Automatic Ceramic Sleeve Surface Finishing MachineDocument2 pagesSemi Automatic Ceramic Sleeve Surface Finishing MachineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Project 2Document5 pagesProject 2Delinda DimpleNo ratings yet

- Design and Fabrication of Multipurpose Agriculture Vehicle - Shaan Narjinary - 26100718001Document13 pagesDesign and Fabrication of Multipurpose Agriculture Vehicle - Shaan Narjinary - 26100718001Ringkhang MushahariNo ratings yet

- Groundnut Sheller Machine Project ReportDocument40 pagesGroundnut Sheller Machine Project ReportTanvi Khurana88% (8)

- Design and Fabrication of Motorised Portable Multipurpose Machine Ijariie10167Document10 pagesDesign and Fabrication of Motorised Portable Multipurpose Machine Ijariie10167127 -ME 54-Sumit SinghNo ratings yet

- Low Cost Automationlca A Case Study PDF Download A - 59822ea21723ddec5675c5bfDocument10 pagesLow Cost Automationlca A Case Study PDF Download A - 59822ea21723ddec5675c5bfRobinson PrabuNo ratings yet

- Design and Performance Analysis of Pneumatic 3 Axes Robotic Arm For Mechanical ComponentsDocument6 pagesDesign and Performance Analysis of Pneumatic 3 Axes Robotic Arm For Mechanical ComponentsurveshNo ratings yet

- Design and Development of Mini Plastic Shredder MaDocument7 pagesDesign and Development of Mini Plastic Shredder MaRishok0% (1)

- PD Report 2Document10 pagesPD Report 2bitish commectNo ratings yet

- Design and Fabrication of Solar Operated Portable Type Coolant SystemDocument49 pagesDesign and Fabrication of Solar Operated Portable Type Coolant SystemGokul GocoolNo ratings yet

- Balancing Tak T TimeDocument6 pagesBalancing Tak T TimeKomangNo ratings yet

- Miniprojectreport 210820223654Document16 pagesMiniprojectreport 210820223654Deepak KNo ratings yet

- Automatic Coconut Harvesting SystemDocument7 pagesAutomatic Coconut Harvesting SystemAdvanced Research PublicationsNo ratings yet

- Design and Fabrication of Pneumatic Sheet Metal Cutting MachineDocument34 pagesDesign and Fabrication of Pneumatic Sheet Metal Cutting Machine4008- Manoj KumarNo ratings yet

- Literature Review For Designing of Portable CNC MachineDocument3 pagesLiterature Review For Designing of Portable CNC MachineIJIRSTNo ratings yet

- 2.auto Indexing Drilling MachineDocument7 pages2.auto Indexing Drilling Machinesasitharan33No ratings yet

- PDF - Report Automatc Portable Hammering Machine 111Document44 pagesPDF - Report Automatc Portable Hammering Machine 111mmv 7100% (6)

- Design and Development of Automatic Lamination Cutting MachineDocument9 pagesDesign and Development of Automatic Lamination Cutting MachineIJRASETPublicationsNo ratings yet

- Department of Mechanical Engineering Project Review Design and Analysis of Compact Paddy Harvester MachineDocument30 pagesDepartment of Mechanical Engineering Project Review Design and Analysis of Compact Paddy Harvester MachineMAGESH KUMARNo ratings yet

- Design and Fabrication of An Oldham Coupling Mechanism: Term ProjectDocument20 pagesDesign and Fabrication of An Oldham Coupling Mechanism: Term ProjectSidharth MalohtraNo ratings yet

- Vishal Chandrasekar Resume FinalDocument3 pagesVishal Chandrasekar Resume FinalVishal ChandrasekharNo ratings yet

- Automatic Pipe Cutting MachineDocument7 pagesAutomatic Pipe Cutting MachineMectrosoft Creative technologyNo ratings yet

- Pulvizer Ak-IjaiemDocument19 pagesPulvizer Ak-Ijaiemthirunivedhan0708No ratings yet

- Improvement in Productivity Through Design and Development of Special Purpose Machine Tool - A Case StudyDocument7 pagesImprovement in Productivity Through Design and Development of Special Purpose Machine Tool - A Case StudytimrompiescommunityNo ratings yet

- Design and Fabrication of Automatic Sand Sieving Machine (ICAIEA 2018)Document2 pagesDesign and Fabrication of Automatic Sand Sieving Machine (ICAIEA 2018)mmk.mech59No ratings yet

- Tool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesDocument8 pagesTool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesODEH ABU YAHIANo ratings yet

- Project Seminar On: Mechanical EngineeringDocument27 pagesProject Seminar On: Mechanical EngineeringJayadeep DeepuNo ratings yet

- Study On Tool Life and Its Failure MechanismsDocument6 pagesStudy On Tool Life and Its Failure MechanismsjaninaNo ratings yet

- Group DDocument21 pagesGroup Dmtariqsuleman5No ratings yet

- Multipurpose Agricultural EquipmentDocument8 pagesMultipurpose Agricultural EquipmentManiranjan KumarNo ratings yet

- Design and Development of Multioperational Mechanical SystemDocument8 pagesDesign and Development of Multioperational Mechanical SystemKamlakar WaghNo ratings yet

- Semi - Outer Thread Cutting MachineDocument4 pagesSemi - Outer Thread Cutting MachineTechnico TechnocratsNo ratings yet

- Study On Tool Life and Its Failure Mechanisms: September 2015Document7 pagesStudy On Tool Life and Its Failure Mechanisms: September 2015Mohammed EndrisNo ratings yet

- REPORT Eng TrainingDocument11 pagesREPORT Eng TrainingTareq Al HasanNo ratings yet

- IJCRT1892205Document8 pagesIJCRT1892205automobpc5031No ratings yet

- Project Semester Report: Dy Auto India Pvt. LTDDocument55 pagesProject Semester Report: Dy Auto India Pvt. LTDAchint GuptaNo ratings yet

- Multipurpose Cutting Machine: A Project ReportDocument25 pagesMultipurpose Cutting Machine: A Project ReportSYED'SNo ratings yet

- Under The Guidance ofDocument40 pagesUnder The Guidance ofnaveen mylapilliNo ratings yet

- Machine Design Chap1 2012Document16 pagesMachine Design Chap1 2012Anirban SardarNo ratings yet

- FireeDocument7 pagesFireeBINIYAM ALAMREWNo ratings yet

- Ijmet 10 07 024Document8 pagesIjmet 10 07 024chiranjitdceNo ratings yet

- Automatic Paper Cutting Machine Using Geneva MechanismDocument33 pagesAutomatic Paper Cutting Machine Using Geneva MechanismSuraj KadamNo ratings yet

- Mini Report3 1Document24 pagesMini Report3 1AKASH RNo ratings yet

- ExDocument59 pagesExHilary SangkanNo ratings yet

- Design & Fabrication of Pedal Operated Multi-Purpose MachineDocument5 pagesDesign & Fabrication of Pedal Operated Multi-Purpose MachineDeepak ChaurasiaNo ratings yet

- PROJECT Mini Saw MachineDocument32 pagesPROJECT Mini Saw MachineGolu Sam75% (4)

- Pneumatic Speed Breaker With Day Night Control (PSB)Document40 pagesPneumatic Speed Breaker With Day Night Control (PSB)Giri TharanNo ratings yet

- Ijetae 0415 85Document4 pagesIjetae 0415 85ifyNo ratings yet

- Five Slot Geneva Wheel MechanismDocument22 pagesFive Slot Geneva Wheel MechanismSURAJ SINGHNo ratings yet

- 12th of June 2020-Webinar On Stress ManagementDocument1 page12th of June 2020-Webinar On Stress ManagementKKNo ratings yet

- WWW - Manaresults.Co - In: Code: 13A03301Document1 pageWWW - Manaresults.Co - In: Code: 13A03301KKNo ratings yet

- Manufacturing: ProcessDocument22 pagesManufacturing: ProcessKKNo ratings yet

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)KKNo ratings yet

- WWW - Manaresults.Co - In: Material Science & EngineeringDocument1 pageWWW - Manaresults.Co - In: Material Science & EngineeringKKNo ratings yet

- WWW - Manaresults.Co - In: B.Tech Ii Year I Semester (R13) Supplementary Examinations June 2017Document2 pagesWWW - Manaresults.Co - In: B.Tech Ii Year I Semester (R13) Supplementary Examinations June 2017KKNo ratings yet

- 134BK042018Document2 pages134BK042018KKNo ratings yet

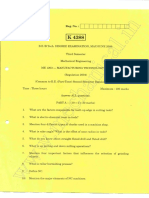

- Me6602 PDFDocument2 pagesMe6602 PDFKKNo ratings yet

- MEC18R443 Automatic Guided Vehicle 3 0 0 3: L T P CDocument2 pagesMEC18R443 Automatic Guided Vehicle 3 0 0 3: L T P CKKNo ratings yet

- Asme ListDocument3 pagesAsme ListKKNo ratings yet

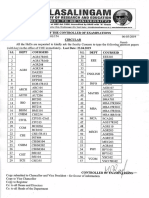

- 174 Arrear QP Pending List - Apr May 2019Document1 page174 Arrear QP Pending List - Apr May 2019KKNo ratings yet

- ME6302-SCAD-MSM-by WWW - LearnEngineering.inDocument130 pagesME6302-SCAD-MSM-by WWW - LearnEngineering.inKKNo ratings yet

- Curriculum Syllabi 2015 PDFDocument298 pagesCurriculum Syllabi 2015 PDFKKNo ratings yet

- ICEEIS 2018 Proceedings BookDocument261 pagesICEEIS 2018 Proceedings BookRaj KumarNo ratings yet

- Manufacturing Technology2 (Ap - May2008) R2004 PDFDocument3 pagesManufacturing Technology2 (Ap - May2008) R2004 PDFKKNo ratings yet

- Applied Hydraulics and Pneumatics (Nov - Dec2009) R2004 PDFDocument3 pagesApplied Hydraulics and Pneumatics (Nov - Dec2009) R2004 PDFKKNo ratings yet

- WWW - Mechanical.in: Unit-I Concepts of MeasurementDocument33 pagesWWW - Mechanical.in: Unit-I Concepts of Measurementharim_meNo ratings yet

- Mec18r151 Engineering GraphicsDocument2 pagesMec18r151 Engineering GraphicsKKNo ratings yet

- Manufacturing Technology2 (May - June2009) R2004 PDFDocument3 pagesManufacturing Technology2 (May - June2009) R2004 PDFKKNo ratings yet

- Applied Hydraulics and Pneumatics (Nov - Dec2012) PDFDocument3 pagesApplied Hydraulics and Pneumatics (Nov - Dec2012) PDFKKNo ratings yet

- 28 Design of Riveted JointsDocument9 pages28 Design of Riveted JointsPRASAD326100% (1)

- Emm 2marksDocument12 pagesEmm 2marksStalin DavidNo ratings yet

- 34 Design of Joints With Variable LoadingDocument8 pages34 Design of Joints With Variable LoadingPRASAD326100% (1)

- 27 Riveted Joints Types and UsesDocument11 pages27 Riveted Joints Types and UsesPRASAD326100% (1)

- 29 Welded Joints Types and UsesDocument10 pages29 Welded Joints Types and UsesPRASAD326100% (1)

- 33 Design of Eccentrically Loaded Welded JointsDocument10 pages33 Design of Eccentrically Loaded Welded JointsPRASAD326No ratings yet

- 20 Design of Helical Springs For Variable LoadDocument16 pages20 Design of Helical Springs For Variable LoadPRASAD326No ratings yet

- 30 Design of Welded JointsDocument8 pages30 Design of Welded JointsPRASAD326No ratings yet

- 27 Riveted Joints Types and UsesDocument11 pages27 Riveted Joints Types and UsesPRASAD326100% (1)