Professional Documents

Culture Documents

Balance de Masa para El Procesamiento de 100 T RFF

Uploaded by

kennyher caballero blanco0 ratings0% found this document useful (0 votes)

13 views1 pageBalance de masa para una planta de beneficio

Original Title

Balance de Masa Para El Procesamiento de 100 t RFF

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBalance de masa para una planta de beneficio

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageBalance de Masa para El Procesamiento de 100 T RFF

Uploaded by

kennyher caballero blancoBalance de masa para una planta de beneficio

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Datasheet

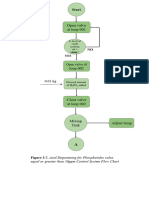

Material Balance for Processing 100 t Fresh Fruit

Bunches

N Ravi Menon

Steam admitted : 25 t CONDENSATE OUT: 20 t

Steam exhausted : 17 t STERILIZATION (Water with 1% residual oil)

(approximate values) Pressure cooking at 3 bar about 90 min TO EFFLUENT POND

Heat lost = 46 560 MJ Oil loss = 0.1% to FFB

EMPTY FRUIT BUNCH:

BUNCH STRIPPING-ROTARY DRUM: 17 rpm

23 t

Separates fruit from bunches

Oil loss: 0.52% to FB

STERILISED FRUIT: 66 t

DIGESTION

45 min: 90°C-95°C : steam heating. Stirrer 5 rpm, 5 sets of blades

CRUDE OIL: 40 t

Oil 55%, water 35%, solids PRESSING PRESS CAKE

10% 10 rpm Twin screw rotates opposite directions 26 t

NUT and FIBRE mixture

CRUDE OIL (46.5% to FFB) Water dilution (40%) 18.5% FIBRE: 13 t conveyed to the fibre cyclone

to FFB to get: Oil 39%, water: 54%, solids 7% in DCO and conveyed to boiler firing platform (oil

loss = 0.55% FFB)

VIBRATING SCREEN: (to remove fibrous tailings) NUT 13 t (oil loss: 0.05% to FFB)

Nuts dried in steam/air heated silos 70°C

DILUTED CRUDE OIL TANK (65% to FFB)

for 14 hr

Options: 1. De-sanding tanks 2. Primary clarifiers

3. Coalescence plate separator 4. horizontal clarifier

NUT CRACKERS

To remove as much oil and solids as possible to reduce

residual oil in the underflow of the final clarifier

VERTICAL CONTINUOUS CLARIFIER Cracked mixture: kernel and shell

PALM OIL 20 t CRACKED MIXTURE

SLUDGE 40 t SEPARATION

(with dirt) Waste water

1. hydro-cyclones

SLUDGE CENTRIFUGE/ about 5%

PURIFIER 2. Clay-bath separators

DECANTER 3.winnowing systems (dry)

Waste water Recovered

PURE PALM OIL SHELL: 7 t

clarification oil to WET KERNEL

(OER = 20%) sent to silos

(Oil loss: 0.55%) clarifier

PALM OIL MIL MILL VACUUM DRYER KERNEL DRYING SILOS 14 hr at 70° C

EFFLUENT

also from sterilisers 10%

nut station 5% PALM OIL PALM KERNEL

65% STORAGE TANKS BULK STORAGE SILOS

(Total oil loss = 1.77% to

FFB)

Note: Data presented here may not necessarily be the same for all mills.

PALM OIL ENGINEERING BULLETIN NO. 121 55

You might also like

- CSWIP 3.1 New Book PDFDocument590 pagesCSWIP 3.1 New Book PDFAsim90% (10)

- Ethanol Production Line Project ProposalDocument10 pagesEthanol Production Line Project ProposalDinosaur0811100% (1)

- Milling Pocketbook (Draft 3.3) Edited - 19 Apr 2018Document48 pagesMilling Pocketbook (Draft 3.3) Edited - 19 Apr 2018Ricardo Wan AgueroNo ratings yet

- Refining of Oils and Fats for Edible PurposesFrom EverandRefining of Oils and Fats for Edible PurposesRating: 3 out of 5 stars3/5 (3)

- CE155 Estimating Lecture 3 PDFDocument71 pagesCE155 Estimating Lecture 3 PDFArly Tolentino100% (1)

- Development of Groundwater Monitoring Wells in Granular AquitmentsDocument16 pagesDevelopment of Groundwater Monitoring Wells in Granular AquitmentsJose Luis Nava HernandezNo ratings yet

- Training Report HCMDocument37 pagesTraining Report HCMShubham Dubey100% (2)

- Balance de Masa para El Procesamiento de 100 T RFF PDFDocument1 pageBalance de Masa para El Procesamiento de 100 T RFF PDFkennyher caballero blancoNo ratings yet

- Desmet Ballestra GroupDocument25 pagesDesmet Ballestra GroupDesa MadukaraNo ratings yet

- Alfa Laval Crude Palm Oil Washing in The Mills Application Brochure enDocument6 pagesAlfa Laval Crude Palm Oil Washing in The Mills Application Brochure enIndra PrasetyaNo ratings yet

- Deodorization and Physical RefiningDocument45 pagesDeodorization and Physical RefiningJosé Mauricio Bonilla TobónNo ratings yet

- Oil-Mist-Presentation Dortmund Sicelub Lubritech 2016Document47 pagesOil-Mist-Presentation Dortmund Sicelub Lubritech 2016Pitipong SunkhongNo ratings yet

- 450PHL and 3000PHL and 6000PHL Double Stage Vacuum System Transformer Oil and Hydraulic Oil Purifier MachineDocument19 pages450PHL and 3000PHL and 6000PHL Double Stage Vacuum System Transformer Oil and Hydraulic Oil Purifier MachineFahadNo ratings yet

- Ghee Mill AllDocument36 pagesGhee Mill AllNuman TariqNo ratings yet

- Palm Oil TechnologyDocument24 pagesPalm Oil TechnologyHANSNo ratings yet

- Lipid ManualDocument48 pagesLipid ManualRakesh K TrivediNo ratings yet

- PMKS Mass Balance W FormDocument6 pagesPMKS Mass Balance W FormIndra SinagaNo ratings yet

- Palm Oil Fractionation Process : Lei Lei Aung, Myint Pe, Pansy Kyaw HlaDocument12 pagesPalm Oil Fractionation Process : Lei Lei Aung, Myint Pe, Pansy Kyaw Hla756fptnqzrNo ratings yet

- 10TPD Coconut Oil Project 2023Document6 pages10TPD Coconut Oil Project 2023adrian dharmalukitaNo ratings yet

- GUID - 3 en-USDocument1 pageGUID - 3 en-USDilawar BakhtNo ratings yet

- SUNJIN Surfactant Catalogue - Fabric SoftenerDocument36 pagesSUNJIN Surfactant Catalogue - Fabric SoftenerTo Ra100% (3)

- 3.oil Tests (Dec2010)Document87 pages3.oil Tests (Dec2010)Lionel MessiNo ratings yet

- Lr-I Chemtech IIDocument14 pagesLr-I Chemtech IINayan HalderNo ratings yet

- VCO Brochure EngDocument4 pagesVCO Brochure EngYuneza MutyaraNo ratings yet

- Testing Procdure For OilDocument66 pagesTesting Procdure For Oilisaiah mathengeNo ratings yet

- Miscella Refining VadkeDocument7 pagesMiscella Refining VadkeAarti ChameNo ratings yet

- Powder N1 N2-2Document41 pagesPowder N1 N2-2NamraNo ratings yet

- Poeb86 Nravi2Document8 pagesPoeb86 Nravi2Navin COYGNo ratings yet

- Oil Revised)Document78 pagesOil Revised)shhansikaNo ratings yet

- Exp 2 Dry Fractionation of RBDDocument10 pagesExp 2 Dry Fractionation of RBDaffeenaNo ratings yet

- Kurniawan 2019 J. Phys. Conf. Ser. 1321 022038 PDFDocument6 pagesKurniawan 2019 J. Phys. Conf. Ser. 1321 022038 PDFAlpin HidayatullohNo ratings yet

- HB PDFDocument1 pageHB PDFGoh Boon Tiong100% (1)

- Steam Water Condensate Balnces GSILDocument16 pagesSteam Water Condensate Balnces GSILgokulsugarmfgNo ratings yet

- Technip Separations PDFDocument47 pagesTechnip Separations PDFProcess EngineerNo ratings yet

- Oil DEODORISINGDocument28 pagesOil DEODORISINGBilli YuandaNo ratings yet

- Exp 2 Dry FractionationDocument10 pagesExp 2 Dry Fractionationtusen krishNo ratings yet

- Sacimem Steam Trap SurveyDocument40 pagesSacimem Steam Trap Surveyrakotographie zeNo ratings yet

- Seting Alarm GT-STDocument1 pageSeting Alarm GT-STfinNo ratings yet

- Control SystemDocument16 pagesControl SystemDEO SALVACIONNo ratings yet

- Top Edible Oil ProductionDocument16 pagesTop Edible Oil Productionabelteshale2244No ratings yet

- BT 0832 Rethane FWP SB 672 - InglêsDocument2 pagesBT 0832 Rethane FWP SB 672 - InglêsProtection Representacoes Valter HugoNo ratings yet

- Protections MD BFP Protections S. No. Descriptions Normal Alarm Trip RemarksDocument1 pageProtections MD BFP Protections S. No. Descriptions Normal Alarm Trip RemarksAnonymous pKsr5vNo ratings yet

- Biodiesel From JatrophaDocument17 pagesBiodiesel From JatrophamohamedNo ratings yet

- Reclamation of Transformer OilDocument39 pagesReclamation of Transformer Oilgaurang1111No ratings yet

- 43.1.14 AOAC of Fi Cial Method 962.17 Vol A Tile Oil in SpicesDocument2 pages43.1.14 AOAC of Fi Cial Method 962.17 Vol A Tile Oil in SpicespiagiopersempreNo ratings yet

- Engineering Proposal and Quotation: 50T/D Continuous Refining Workshop EquipmentDocument26 pagesEngineering Proposal and Quotation: 50T/D Continuous Refining Workshop EquipmentMuhammad aliNo ratings yet

- F03 EsterFluidsDocument38 pagesF03 EsterFluidsfabiano_projetoNo ratings yet

- Kao Corporation, S.A.: Clear Antidandruff ShampooDocument2 pagesKao Corporation, S.A.: Clear Antidandruff ShampooSerkan SivrikayaNo ratings yet

- Paramters Removal Efficiency-Pilot UnitDocument6 pagesParamters Removal Efficiency-Pilot UnitRoger T SomundohNo ratings yet

- Refining of Crude Oil For Liquid Fuels Production - NPTELDocument23 pagesRefining of Crude Oil For Liquid Fuels Production - NPTELSATHISH YENIBERANo ratings yet

- Maintenance of TransformerDocument80 pagesMaintenance of Transformerajaynmenon100% (2)

- INSTRUCTIONOF OIL PURIFIED TURBINE sçÇsîûFúàt+ S++tö¿F ÿÄS 1Document21 pagesINSTRUCTIONOF OIL PURIFIED TURBINE sçÇsîûFúàt+ S++tö¿F ÿÄS 1anon_928723433No ratings yet

- SectionX Soaps and Hand CleanersDocument14 pagesSectionX Soaps and Hand CleanersAnonymous m3Gnw1y1ENo ratings yet

- Refinery Process FlowchartDocument13 pagesRefinery Process FlowchartYanly Pattrick Fehilly100% (1)

- Distillery Industry 7Document15 pagesDistillery Industry 7gundreddy greeshmaNo ratings yet

- Ab-141 4 en PDFDocument17 pagesAb-141 4 en PDFAfthirah AmiraNo ratings yet

- AOAC 945.102 Oil Mineral in Fat (PH)Document1 pageAOAC 945.102 Oil Mineral in Fat (PH)Ressa Aja100% (1)

- US2662052Document4 pagesUS2662052DŨNG VŨ NGUYỄN TUẤNNo ratings yet

- Enhanced Oil Recovery-Slides-12Document39 pagesEnhanced Oil Recovery-Slides-12saryNo ratings yet

- Sipom: Sustainable and Intelligent Palm Oil Milling (Sipom)Document12 pagesSipom: Sustainable and Intelligent Palm Oil Milling (Sipom)Mohd Rahimi Mohmad TanuriNo ratings yet

- Nptel Chemical Engineering Petroleum Refinery Engineering9Document6 pagesNptel Chemical Engineering Petroleum Refinery Engineering9Ahmed Mohamed KhalilNo ratings yet

- Facility at Adityapur To Provide A Long Term, Pollution Free & Sustainable Solution To The Problem. Project Is To Setting Up of Used Oil Re-RefiningDocument36 pagesFacility at Adityapur To Provide A Long Term, Pollution Free & Sustainable Solution To The Problem. Project Is To Setting Up of Used Oil Re-RefiningHemant KumarNo ratings yet

- Refinery Plant 2015 EditDocument149 pagesRefinery Plant 2015 EditEnjang FathurrohmanNo ratings yet

- Oil Mist LubricationDocument22 pagesOil Mist LubricationPitipong SunkhongNo ratings yet

- Drveni Zidovi PDFDocument35 pagesDrveni Zidovi PDFMartinJankovićNo ratings yet

- Project ChemistryDocument18 pagesProject ChemistryA MNo ratings yet

- Unit 10 Thermogravimetric AnalysisDocument24 pagesUnit 10 Thermogravimetric Analysismaidhily83% (6)

- Corrioson TestDocument14 pagesCorrioson Testcombahee100% (1)

- Assignment 02Document1 pageAssignment 02parul tyagiNo ratings yet

- Portfolio Entry No. 3: Minerals and Their UsesDocument4 pagesPortfolio Entry No. 3: Minerals and Their UsesReizel Joy Borja RasonaNo ratings yet

- Engineering Services Related To Process Study: SRU RevampDocument16 pagesEngineering Services Related To Process Study: SRU RevampSiddiqui Muhammad AshfaqueNo ratings yet

- XY 168-3C Desktop Soldering StationDocument2 pagesXY 168-3C Desktop Soldering StationZach JacobNo ratings yet

- Codigos FordDocument66 pagesCodigos FordavffNo ratings yet

- Boys Book of Steam EnginesDocument282 pagesBoys Book of Steam Enginesmardukzek100% (6)

- Speed TripleDocument379 pagesSpeed TriplecsavargaNo ratings yet

- European Steel Standards PDFDocument2 pagesEuropean Steel Standards PDFMeikaNo ratings yet

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Phase Change Materials PCM For Cooling ApplicationsDocument80 pagesPhase Change Materials PCM For Cooling ApplicationsGerit LinggarNo ratings yet

- Comprehensive Report On Indian Metal Cutting Machine Tool Industry - 2019Document73 pagesComprehensive Report On Indian Metal Cutting Machine Tool Industry - 2019Dr-Prashanth GowdaNo ratings yet

- ROB StaircaseDocument21 pagesROB StaircaseSambhav PoddarNo ratings yet

- Slurry Pump The KproDocument11 pagesSlurry Pump The Kpro4lk0nNo ratings yet

- Western Cabinet Inner and Outer Forming Line Operation MannualDocument50 pagesWestern Cabinet Inner and Outer Forming Line Operation Mannualvikrant singhNo ratings yet

- 6 DZM 20 Electric MotorbikeDocument3 pages6 DZM 20 Electric Motorbikebaban aloNo ratings yet

- Croz - Beckert PDFDocument16 pagesCroz - Beckert PDFNeelakandan DNo ratings yet

- Seger Formula Glaze Calculator - Buscar Con GoogleDocument1 pageSeger Formula Glaze Calculator - Buscar Con Googlemartafrias7No ratings yet

- 3Ph Horiz Sep 2010 Weir VerA SIDocument5 pages3Ph Horiz Sep 2010 Weir VerA SIBrenda DavisNo ratings yet

- Ce04014 QaDocument49 pagesCe04014 QaekaamfNo ratings yet

- 16-Seiter BioHPP Fuer For2press 000705GB 210x297mm PDFDocument16 pages16-Seiter BioHPP Fuer For2press 000705GB 210x297mm PDFAna Mihai100% (1)

- A Banjo BuildingDocument20 pagesA Banjo BuildingRégis MoewiusNo ratings yet

- WindDocument7 pagesWindPritesh KumarNo ratings yet