Professional Documents

Culture Documents

Components of Die: Ilyas Hussain-P2MFG15006

Uploaded by

kenneth loh0 ratings0% found this document useful (0 votes)

16 views15 pagesThe document summarizes the main components of a die, which is a tool used in manufacturing to cut or shape materials. It discusses the basic components such as die plates, guide pins and bushings, heel blocks, screws, dowels, keys, pads, spools, shoulder bolts, keepers, retainers, and springs. It then describes the main components and their functions, including the bolster plate, die button, guide post, guide post bushing, lower die shoe, upper die shoe, punch, ram, and stripper.

Original Description:

Original Title

componentsofdie-160414134636

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes the main components of a die, which is a tool used in manufacturing to cut or shape materials. It discusses the basic components such as die plates, guide pins and bushings, heel blocks, screws, dowels, keys, pads, spools, shoulder bolts, keepers, retainers, and springs. It then describes the main components and their functions, including the bolster plate, die button, guide post, guide post bushing, lower die shoe, upper die shoe, punch, ram, and stripper.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views15 pagesComponents of Die: Ilyas Hussain-P2MFG15006

Uploaded by

kenneth lohThe document summarizes the main components of a die, which is a tool used in manufacturing to cut or shape materials. It discusses the basic components such as die plates, guide pins and bushings, heel blocks, screws, dowels, keys, pads, spools, shoulder bolts, keepers, retainers, and springs. It then describes the main components and their functions, including the bolster plate, die button, guide post, guide post bushing, lower die shoe, upper die shoe, punch, ram, and stripper.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 15

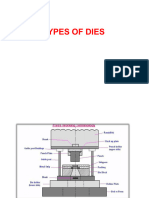

COMPONENTS OF DIE

ILYAS HUSSAIN- P2MFG15006

DIE

• A die is a specialized tool used in

manufacturing industries to cut or shape material

mostly using a press.

• Products made with dies range from simple paper

clips to complex pieces used in advanced technology.

BASIC DIE COMPONENTS

1. Die Plates, Shoes, and Die Sets

• Die plates, shoes, and die sets are steel or aluminum plates

that correspond to the size of the die and serve as the

foundation for mounting the working die components.

• The upper and lower die shoes assembled together with

guide pins create the die set.

• The die shoe thickness is based on how much force can be

expected during cutting and forming.

2. Guide Pins and Bushings

• Guide pins (guide posts or pillars) and guide bushings align

the upper and lower die shoes precisely.

• There are only two basic types of guide pins and bushings—

friction pins and ball bearing style pins.

• Friction pins are precision ground pins that are slightly

smaller than the guide bushing's inside diameter.

3. Heel Blocks and Heel Plates

• Heel blocks are special steel blocks that are precision machined,

screwed, doweled, and often welded to both the upper and lower

die shoes.

• They contain components called wear plates and function to adsorb

any side thrust that may be generated during the cutting and

forming processes.

• Heel blocks can be used to heel the die in any or all directions. Box

heels often are used to heel the die in all directions.

4. Screws, Dowels, and Keys

• Screws fasten and secure the working components to both the upper

and lower die shoes. The socket head cap screw is the most popular

fastener used in stamping dies.

• Dowels are hardened, precision ground pins that precisely locate

the die section or component in its proper location on the die shoe.

• Keys are small, rectangular blocks of precision ground steel that are

inserted into milled pockets in the die shoes and sections called

keyways.

5. Pads

• A pad is simply a pressure loaded plate, either flat or contoured,

that holds, controls, or strips the metal during the cutting and

forming processes.

• Several types of pads are used in stamping dies. Depending on

their function, pads can be made from soft low carbon steel or

hardened tool steel.

6. Spools, Shoulder Bolts, and Keepers

• Spools, shoulder bolts, and keepers are used to fasten pads to the

die shoes while allowing them to move up and down.

7. Retainers

• Retainers hold or secure cutting or forming die components to both

the upper and lower die shoes.

• One of the most popular retainers is a ball lock retainer, a high

precision, accurately manufactured die component that secures and

aligns both cutting and forming punches.

• The advantage of ball lock retainers is that they allow the die

maintenance technician to remove and reinstall punches quickly.

8. Springs

• Springs supply the force needed to hold, strip, or form metal. Many

different springs are used.

• Spring selection is based on many factors, including the required

force and travel, the spring's life expectancy, and, of course, cost.

MAIN COMPONENTS OF DIE AND

THERE FUNCTIONS

• Bolster Plate: A plate that is designed to hold in place the

lower die shoe. The bolster plate is attached to the top surface of the

press bed.

• Die Button: A hardened steel tube that provides the opening

for the punch during operation. During a shearing operation, the

slug or blank passes through this opening.

• Guide Post: A hardened rod positioned in the lower die shoe

that fits into a bushing in the upper die shoe to guide the punch

during operation.

• Guide Post Bushing: A hardened steel tube that slides over

the guide post and directs the upper die shoe during operation.

• Lower Die Shoe: The lower plate of a die set that supports

the die retainer and die button.

• Upper Die Shoe: The upper plate of a die set that secures the

punch retainer.

• Punch: The tool typically attached to the upper portion of the

die set that shapes or penetrates the sheet metal.

• Ram: The main upper portion of the press that slides up and

down within the press frame. The upper die shoe is attached to the

ram.

• Stripper : A plate designed to remove sheet metal stock from

the punch as it pulls away from the die during the operation.

THANK YOU

You might also like

- ADVANCED TOOLING LAB MANUAL - PDF NEWDocument16 pagesADVANCED TOOLING LAB MANUAL - PDF NEWHOD TD GITNo ratings yet

- PTD Module 1.5Document20 pagesPTD Module 1.5Deepak DevasagayamNo ratings yet

- Dowels and ScrewsDocument19 pagesDowels and ScrewsRaj SatoskerNo ratings yet

- 15P602-JIGS FIXTURES AND DIE DESIGN Batch 7Document24 pages15P602-JIGS FIXTURES AND DIE DESIGN Batch 7vijay AmirtharajNo ratings yet

- Chapter 4 Basic Construction PrinciplesDocument33 pagesChapter 4 Basic Construction PrinciplesMifzal Izzani0% (1)

- Press Tool DesignDocument36 pagesPress Tool DesignAmar Bhopi100% (2)

- (2ed86710 3b4f 4bc1 8799 504c7406e82a) Fasteners, Gaskets, Seals and SealantsDocument47 pages(2ed86710 3b4f 4bc1 8799 504c7406e82a) Fasteners, Gaskets, Seals and SealantsajmainNo ratings yet

- Locking DevicesDocument28 pagesLocking Devicesraj mohan100% (1)

- Tool and Die DesignDocument61 pagesTool and Die DesignAshley Kane P. Dumay100% (3)

- Progressive Report GRP DDocument12 pagesProgressive Report GRP Dbarkandaj0222222No ratings yet

- Tool Bodies (Jigs & Fixtures)Document24 pagesTool Bodies (Jigs & Fixtures)nilam0% (1)

- Types of DiesDocument99 pagesTypes of DiesMadhav ChaudharyNo ratings yet

- Presentation - JOINERY HARDWAREDocument159 pagesPresentation - JOINERY HARDWAREKeya JainNo ratings yet

- Forgingforging ProcessDocument13 pagesForgingforging Processpatel ketanNo ratings yet

- Sheet Metal ShopDocument30 pagesSheet Metal ShopAviral AkshatNo ratings yet

- Forging - Class NotesDocument51 pagesForging - Class NotesShovan KarmakarNo ratings yet

- Design and Fabrication of A Screw PressDocument8 pagesDesign and Fabrication of A Screw PressKarthikeyan Lakshmi NarasimhanNo ratings yet

- Forgingforging ProcessDocument14 pagesForgingforging ProcessShrikant BagaveNo ratings yet

- Workshop Technology Eim 118 Module 2: Hand Tools: Dzanya M.TDocument18 pagesWorkshop Technology Eim 118 Module 2: Hand Tools: Dzanya M.TBriaydon TawandaNo ratings yet

- Structural Steel Work: Structural Steelwork Is Generally Used To Form A The 'Skeleton'Document23 pagesStructural Steel Work: Structural Steelwork Is Generally Used To Form A The 'Skeleton'Status BatchNo ratings yet

- Measurement and Measuring LengthDocument101 pagesMeasurement and Measuring Lengthraymond bautistaNo ratings yet

- Smaw PPT1Document50 pagesSmaw PPT1adiksayoo12333100% (1)

- Fitting BookDocument12 pagesFitting BookOryon FooNo ratings yet

- Smithy & Forging ShopDocument24 pagesSmithy & Forging Shopashok junapudiNo ratings yet

- Lathe Accessories: Work Holding Tool HoldingDocument33 pagesLathe Accessories: Work Holding Tool HoldingSuhasNo ratings yet

- Sketching of Machine ComponentsDocument78 pagesSketching of Machine ComponentsSaurabh JadhavNo ratings yet

- GegasDocument6 pagesGegasambatarNo ratings yet

- Processes Used To Form Metallic MaterialsDocument23 pagesProcesses Used To Form Metallic MaterialsHimanshu GuptaNo ratings yet

- Boring ToolDocument15 pagesBoring Toolmuneiah100% (1)

- Tool Design TerminologyDocument5 pagesTool Design Terminologyanmol6237No ratings yet

- Module 6-5 Fasteners Pt2 PresentationDocument22 pagesModule 6-5 Fasteners Pt2 Presentationabdullahqureshi789456No ratings yet

- Drill BitDocument21 pagesDrill Bitchris loubakiNo ratings yet

- Shearing ToolsDocument21 pagesShearing Toolsメルヴリッ クズルエタNo ratings yet

- Diagram of Lathe Machine: Explanation of The Standard Components of Most LathesDocument5 pagesDiagram of Lathe Machine: Explanation of The Standard Components of Most LathesKaushik SreenivasNo ratings yet

- Fitting ShopDocument45 pagesFitting ShopRishabh SharmaNo ratings yet

- Chucks: Clamp Radial Symmetry Cylindrical Drill Bit Power Tool Bar Spindle LatheDocument14 pagesChucks: Clamp Radial Symmetry Cylindrical Drill Bit Power Tool Bar Spindle LatheIrtaza Husnain100% (1)

- Bolt and Nut Lathe MachineDocument34 pagesBolt and Nut Lathe MachineIxora My0% (2)

- Bench FittingDocument161 pagesBench FittingMichael Castro Abudu100% (2)

- Layout ToolsDocument20 pagesLayout ToolsmarlitoNo ratings yet

- Press Working OperationsDocument23 pagesPress Working OperationsKanagaraj Ganesan100% (1)

- The Bench Work Tools, Uses and ProcessesDocument11 pagesThe Bench Work Tools, Uses and Processesdockanye3No ratings yet

- Injection MoldDocument7 pagesInjection MoldServicesNo ratings yet

- DRILLBITSDocument56 pagesDRILLBITSKathrine Kate CadiangNo ratings yet

- 2 3 Basic Machine Tool Operations Drilling MachinesDocument34 pages2 3 Basic Machine Tool Operations Drilling MachinesJiggy Lawrence BathanNo ratings yet

- Rotating SystemDocument63 pagesRotating Systemmelannie adanteNo ratings yet

- Workshop Technology - Basic Measurement & BenchworkDocument77 pagesWorkshop Technology - Basic Measurement & BenchworkAbdul Munir Abdul KarimNo ratings yet

- Workshop ManualDocument13 pagesWorkshop ManualAgnivesh SharmaNo ratings yet

- Applications For Jigs and FixturesDocument10 pagesApplications For Jigs and FixturesAntay Korakot100% (1)

- Jigs and FixturesDocument75 pagesJigs and Fixturesdrsahuja0% (1)

- DieDocument6 pagesDieAditya GoelNo ratings yet

- Lathe 01 BlackDocument26 pagesLathe 01 BlackDeepak JangidNo ratings yet

- Week 6 LectureDocument3 pagesWeek 6 LectureDaniel BognotNo ratings yet

- Injection Mold Construction: August 2014Document7 pagesInjection Mold Construction: August 2014ashishNo ratings yet

- Mold and Die - PPTDocument110 pagesMold and Die - PPTThaloengsak Kucharoenpaisan100% (2)

- Tools Presentation - Module1Document80 pagesTools Presentation - Module1jishnushankarNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)

- Family Handyman Trade Secrets: Fix Your Home Like a Pro!From EverandFamily Handyman Trade Secrets: Fix Your Home Like a Pro!Rating: 4 out of 5 stars4/5 (1)

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- Curve and Freeform SurfacesDocument22 pagesCurve and Freeform Surfaceskenneth lohNo ratings yet

- Preprints201810 0249 v1Document34 pagesPreprints201810 0249 v1kenneth lohNo ratings yet

- Hydraulic Weld Force Gauge: For General Resistance Weld Compact, Lightweight, EasyDocument2 pagesHydraulic Weld Force Gauge: For General Resistance Weld Compact, Lightweight, Easykenneth lohNo ratings yet

- Resistance Welding Basics: Welding Sequence Definitions Machine Set-Up Rules For Making Good WeldsDocument17 pagesResistance Welding Basics: Welding Sequence Definitions Machine Set-Up Rules For Making Good Weldskenneth lohNo ratings yet

- 3D FE Simulations of Resistance Spot Welding: David LövebornDocument54 pages3D FE Simulations of Resistance Spot Welding: David Lövebornkenneth lohNo ratings yet

- Microsquirt Ignition Coil LS2 WS REVADocument1 pageMicrosquirt Ignition Coil LS2 WS REVARafael MendozaNo ratings yet

- Drill Press Machine: Click To Edit Master Title StyleDocument9 pagesDrill Press Machine: Click To Edit Master Title StyleRahmatullahNo ratings yet

- Cable Sizing Rev.3Document13 pagesCable Sizing Rev.3nadeem UddinNo ratings yet

- Conector Tipo C PanduitDocument1 pageConector Tipo C PanduitBrandon SarriaNo ratings yet

- Gearbox and Gear Train For Mini BMCDocument7 pagesGearbox and Gear Train For Mini BMCgermanos84No ratings yet

- Horn Sea Wind Farm 02 Offshore Substation Cooling Pipe & Instrumentation Diagrams (P&Id) All DecksDocument6 pagesHorn Sea Wind Farm 02 Offshore Substation Cooling Pipe & Instrumentation Diagrams (P&Id) All DeckskristianNo ratings yet

- 30 - Methods of Taper TurningDocument4 pages30 - Methods of Taper Turningbhagirath360100% (2)

- JDM Supra Wiring PDFDocument107 pagesJDM Supra Wiring PDFZainul Arifin100% (1)

- 807060r3 - Raw ArcDocument28 pages807060r3 - Raw ArcGonzalo MolarNo ratings yet

- FORCE INTERNATIONAL BAND SAW 3460015 - ManualDocument40 pagesFORCE INTERNATIONAL BAND SAW 3460015 - ManualAl CrosbyNo ratings yet

- Evolution Spas Manual ENG-19 PDFDocument44 pagesEvolution Spas Manual ENG-19 PDFAnonymous 0aFzcZ100% (1)

- New Standard - List Price 2023 Update - New - Ra Ac Sky VRV List Price - Updating 16 Feb'23Document73 pagesNew Standard - List Price 2023 Update - New - Ra Ac Sky VRV List Price - Updating 16 Feb'23zhuzzhiz channubinNo ratings yet

- MitsubishiDocument8 pagesMitsubishiRaheem_ka67% (3)

- Link-Belt t004 - r00431 - v0Document16 pagesLink-Belt t004 - r00431 - v0macsosaNo ratings yet

- 160-320SCV Parts ListDocument14 pages160-320SCV Parts ListjuanNo ratings yet

- Bill of Materials HSFDB-CDocument89 pagesBill of Materials HSFDB-CDBA DruidNo ratings yet

- HL770-9S Fault CodeDocument53 pagesHL770-9S Fault CodeHaidar Sareeni100% (1)

- Installation Instructions LAUFENDocument7 pagesInstallation Instructions LAUFENLapsikNo ratings yet

- Tubing and Casing Rollers: Instruction Manual 6200Document9 pagesTubing and Casing Rollers: Instruction Manual 6200Aderobaki GbengaNo ratings yet

- 8 Card Guides & Pullers PDFDocument12 pages8 Card Guides & Pullers PDFfuaunNo ratings yet

- Plumbing EstimateDocument3 pagesPlumbing Estimatepapa oforiNo ratings yet

- 6260D-Service TEDocument5 pages6260D-Service TESuporteoft SuporteoftNo ratings yet

- 3114 Entrance-Door-Sensor 10 18 18Document5 pages3114 Entrance-Door-Sensor 10 18 18Hamilton Amilcar MirandaNo ratings yet

- P94 1698Document2 pagesP94 1698JoseGarzaNo ratings yet

- Final List of Items Idenfied For Make-II - Jun 2020Document74 pagesFinal List of Items Idenfied For Make-II - Jun 2020ssinghNo ratings yet

- Service Manual: Mcculloch Chain Saw - Ms1436NavDocument17 pagesService Manual: Mcculloch Chain Saw - Ms1436NavRobNo ratings yet

- Machining Process Lab ReportDocument31 pagesMachining Process Lab ReportHafiz Hamza83% (12)

- Accessories MuellerDocument3 pagesAccessories MuellerFabio Moacir KorndoerferNo ratings yet

- Brodski Kabel BXHOZO-HFTGDocument2 pagesBrodski Kabel BXHOZO-HFTGBozo BasicNo ratings yet

- Manual TransaxleDocument136 pagesManual TransaxleGuillermo Alexamder Sanchez YbañezNo ratings yet