Professional Documents

Culture Documents

33 13 00 Pipeline Testing and Disinfection PDF

33 13 00 Pipeline Testing and Disinfection PDF

Uploaded by

Alberto CastilloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

33 13 00 Pipeline Testing and Disinfection PDF

33 13 00 Pipeline Testing and Disinfection PDF

Uploaded by

Alberto CastilloCopyright:

Available Formats

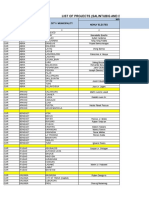

SUB WATER DEPARTMENT

STANDARD CONSTRUCTION SPECIFICATIONS

TABLE OF CONTENTS

SECTION 33 13 00

PIPELINE TESTING AND DISINFECTION

PART 1 GENERAL .............................................................................................................. 2

1.1 Description .................................................................................................................. 2

1.2 Reference Specifications, Codes, and Standards ........................................................ 2

1.3 Contractor Submittals ................................................................................................. 3

PART 2 PRODUCTS ............................................................................................................ 3

2.1 Equipment ................................................................................................................... 3

PART 3 EXECUTION .......................................................................................................... 4

3.1 Filling Mains ............................................................................................................... 4

3.2 Hydrostatic Testing of Water Mains .......................................................................... 4

3.3 Flushing ...................................................................................................................... 6

3.4 Disinfection of Water Mains ...................................................................................... 7

3.5 Bacteriological Testing ............................................................................................... 9

3.6 Disinfection of Water Main End Connections and Tie-Ins ........................................ 9

3.7 Tracer Wire Conductivity Testing ............................................................................ 10

Standard Specifications - ONLINE Pipeline Testing and Disinfection

33 13 00 - 1

PART 1 GENERAL

1.1 Description

A. This section covers field pressure testing, disinfection and purity testing of

potable water systems piping, fittings, and valves and field pressure testing of

sewage force mains. All piping shall be flushed and hydrostatically pressure

and leak tested. Defective items revealed by the testing procedures shall be

removed and replaced or otherwise corrected as directed by the Engineer. All

costs for labor and materials necessary to conduct the flushing, testing and

disinfecting procedures specified herein, and all costs of labor and materials

required to remedy defective items shall be borne by the Contractor.

B. Contractor shall provide coordination and scheduling required for SUB and

Engineer to witness and provide necessary labor for operating SUB’s existing

system during hydrostatic testing and disinfecting procedures. Contractor

shall not operate any part of the existing water.

C. The Contractor shall perform flushing and testing of all pipelines and

appurtenant piping for water and disinfection of all pipelines and appurtenant

piping for potable water, complete, including conveyance of test water to point

of use and all disposal thereof, all in accordance with the requirements of the

Contract Documents.

1.2 Reference Specifications, Codes, and Standards

Codes and Standards: Comply with the provisions of the latest edition of the

following codes, standards and specifications, except as otherwise shown and

specified:

ANSI/AWWA B300 Hypochlorites

ANSI/AWWA B301 Liquid Chlorine

ANSI/AWWA C651 Disinfecting Water Mains

ANSI/AWWA C600 Installation of Ductile Iron Water Mains and Their

Appurtenances

ANSI/AWWA C605 Underground Installation of PVC Pressure Pipe and Fittings for

Water

Standard Specifications - ONLINE Pipeline Testing and Disinfection

33 13 00 - 2

1.3 Contractor Submittals

A pipeline testing and disinfection plan will be required to be submitted by the

Contractor for review and approval by the Engineer a minimum of one month before

testing is to start. As a minimum, the Contractor’s pipeline testing and disinfection

plan shall include the following:

A. Testing schedule.

B. Proposed equipment and chemicals.

C. Proposed plan for water conveyance including flow rates.

D. Proposed plan for water control.

E. Proposed plan for water disposal including flow rates.

F. Proposed measures to be incorporated in the project to minimize erosion while

discharging water from the pipeline.

G. Proposed plan for disinfection.

H. Proposed plan for dechlorination of flushing water and superchlorinated

disinfection water including discharge points and discharge rates.

I. Proposed plan for testing chlorine levels throughout the length of the pipeline

including test locations.

PART 2 PRODUCTS

2.1 Equipment

A. All test equipment, chemicals for chlorination, temporary valves, bulkheads,

or other water control equipment and materials shall be determined and

furnished by the Contractor subject to the Engineer’s review. No materials

shall be used which would be injurious to the construction or its future

functions.

B. SUB shall furnish pressure gauges for testing. The Contractor shall furnish the

following equipment and materials for the testing:

Amount Description

2 Graduated containers approved by the Engineer

1 Hydraulic pump approved by the Engineer with hoses, valves and fittings

as needed and required for the testing and disinfection of the facilities.

C. Chlorine for disinfection shall be in the form of liquid chlorine or sodium

hypochlorite solution.

D. Sodium hypochlorite and calcium hypochlorite shall be in accordance with the

requirements of ANSI/AWWA B300. Liquid chlorine shall be in accordance

with the requirements of ANSI/AWWA B301.

Standard Specifications - ONLINE Pipeline Testing and Disinfection

33 13 00 - 3

E. All temporary thrust restraint and equipment and facilities required for

hydrostatic testing will be considered incidental.

PART 3 EXECUTION

3.1 Filling Mains

A. The Contractor shall make all necessary provisions for conveying water to the

points of use and for the proper disposal of test water.

B. Water mains shall be filled under the direction of the Engineer in such a

manner as to prevent excessive pressure reductions in the existing main and

water hammer.

3.2 Hydrostatic Testing of Water Mains

A. No section of the pipeline shall be hydrostatically tested until all field-placed

concrete or mortar has attained full strength. At the Contractor’s option, early

strength concrete may be used when the full strength requirements conflict

with schedule requirements. All such early applications shall be approved by

the Engineer prior to each installation.

B. Hydrostatic pressure tests shall be made on any valved section of all newly

laid main and service pipe in the presence of the Engineer, unless otherwise

directed by the Engineer. Reference specifications, AWWA C600 Section 5.2,

Hydrostatic Testing. All entrained air shall be expelled from the line prior to

elevating the internal pressure to the specified test pressure. The test pressure

shall be 150 psi calculated for the point of highest elevation, but shall not

exceed 200 psi at any point. The test pressure shall be applied and maintained

for a two-hour duration unless otherwise specified by the Engineer. The

allowable leakage shall not to exceed value as per Paragraph D below.

C. Testing shall be against closed hydrants with hydrant valves open. In addition,

the test shall include the service installation(s) against the closed angle meter

valve with the corporation stop open.

Standard Specifications - ONLINE Pipeline Testing and Disinfection

33 13 00 - 4

Testing allowance shall be defined as the maximum quantity of makeup water

that is added into the pipeline undergoing hydrostatic pressure testing, or any

valves section thereof, in order to maintain pressure within ±5 psi of the

specified test pressure (after the pipeline has been filled with water and the air

has been expelled). No pipe installation will be accepted if the quantity of

makeup water is greater than that determined by the following formula:

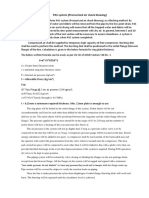

In inch-pound units,

L = SD√𝑃

148,000

Where:

L = testing allowance (makeup water), in gallons per hour

S = length of pipe tested, in feet

D = nominal diameter of pipe, in inches

P = average test pressure during the hydrostatic test, in pounds per

square inch (gauge).

The allowable leakage at various pressures for pipe of various diameters is

shown in Table 6 below from AWWA C600

AWWA C600

TABLE 6 Allowable Leakage per 1000 ft (305 m) of Pipeline*--gph

NOMINAL PIPE DIAMETER -- (inches)

Avg.

Test

Pressure 3 4 6 8 10 12 14 16 18 20 24 30 36 42 48 54

psi (bar)

200 (14) 0.29 0.38 0.57 0.76 0.96 1.15 1.34 1.53 1.72 1.91 2.29 2.87 3.44 4.01 4.59 5.16

175 (12) 0.27 0.36 0.54 0.72 0.89 1.07 1.25 1.43 1.61 1.79 2.15 2.68 3.22 3.75 4.29 4.83

150 (10) 0.25 0.33 0.50 0.66 0.83 0.99 1.16 1.32 1.49 1.66 1.99 2.48 2.98 3.48 3.97 4.47

125 (9) 0.23 0.30 0.45 0.60 0.76 0.91 1.06 1.21 1.36 1.51 1.81 2.27 2.72 3.17 3.63 4.08

100 (7) 0.20 0.27 0.41 0.54 0.68 0.81 0.95 1.08 1.22 1.35 1.62 2.03 2.43 2.84 3.24 3.65

*If the pipeline under test contains sections of various diameters, the testing allowance will be the

sum of the testing allowance for each size.

D. During the test period, operate the pump as required to maintain pressure in

the pipe within ±5 psi of the specified test pressure at all times. At the end of

test period, operate the pump until the specified maximum test pressure is

again obtained. The pump suction shall be in a graduated barrel, metered, or

similar device so that the amount of makeup water required to restore the test

pressure may be accurately measured.

Standard Specifications - ONLINE Pipeline Testing and Disinfection

33 13 00 - 5

E. If the test reveals any defects, leakage in excess of the allowable, or failure,

the Contractor shall furnish all labor, equipment and materials required to

locate and make necessary repairs. The testing of the line (and repairing of

defects, excessive leakage, and failures) shall be repeated until a test

satisfactory to the Engineer has been achieved. All visible leaks shall be

repaired regardless of the allowance used for testing. All costs for locating,

repairing, and retesting shall be borne by the Contractor.

F.

3.3 Flushing

A. Prior to chlorination, the main shall receive a complete flushing through all

hydrants and blow-offs such that a velocity of at least 2.5 feet per second is

developed in the main. If the required velocity cannot be achieved, a minimum

of three (3) pipe volumes of water shall be turned over in the lines being

tested. The flushing shall be accomplished during prearranged times under

direction and supervision of the Engineer. If sufficient outlets are not

available, a tap shall be provided large enough to develop the required velocity

in the main and to allow the removal of foam swabbing "pigs". (see Table II

below)

B. All valves shall be operated through their extreme open and closed positions

during flushing. Each hydrant shall be inspected after flushing to see that the

entire valve operating mechanism is in good, working condition.

C. Flushing water onto the street subgrade shall not be allowed at any time.

Provisions for the dechlorination and disposal of the water onto areas where no

damage will be caused shall be made by the Contractor prior to any flushing

operations. All flushing shall meet current regulatory requirements. Rate of

operation of all valves and hydrants shall be done in a manner that avoids

water hammer damage to the existing system and the improvements.

Standard Specifications - ONLINE Pipeline Testing and Disinfection

33 13 00 - 6

TABLE II

REQUIRED OPENINGS FOR 2.5 fps FLUSHING VELOCITY

(40 psi Pressure)

PIPE SIZE FLOW ORIFICE SIZE HYDRANT OUTLET NOZZLES

(inch) (gpm) (inch) Amount/Diameter (inches)

4 100 15/16 One 2-1/2

6 220 1-3/8 One 2-1/2

8 390 1-7/8 One 2-1/2

10 610 2-5/16 One 2-1/2

12 880 2-13/16 One 2-1/2

14 1200 3-1/4 Two 2-1/2

16 1565 3-5/8 Two 2-1/2

18 1908 4-3/16 Two 2-1/2

20 2450 4-5/8 Three 2-1/2

Four 2-1/2 or

24 3510 5-9/16

One 4-1/2 and One 2-1/2

Five 2-1/2 or One 4-1/2 and Two 2-

30 5500 7

1/2 or Two 4-1/2

3.4 Disinfection of Water Mains

A. After testing and repairing where necessary, all potable water systems shall be

thoroughly flushed, cleaned, and disinfected by the Contractor in accordance

with the latest version of AWWA C651.

B. Before sterilizing, flush all foreign matter from the pipeline. The Contractor is

to provide, at no additional cost to SUB, hoses, temporary pipes, ditches, etc.,

as required to dispose of flushing water without damage to adjacent properties.

Flushing water discharged to any public waters in the State of Oregon shall be

dechlorinated in accordance with Oregon Administrative Rule Chapter 340,

Division 41 – Water Quality Standards: Beneficial Uses, Policies, and Criteria

for Oregon and Oregon Department of Environmental Quality memorandum

entitled “Chlorinated Water Discharges”, Water Quality Division, DEQ, May

19, 1997.

D. Potable water shall be used for disinfection, hydrostatic pressure testing, and

flushing. Potable water piping shall be disinfected with a solution containing

an initial minimum chlorine dose of 25 parts per million (ppm) and a

maximum of 50 ppm. The chlorine solution shall remain in the piping system

for a period of 24 hours at which time the sterilizing mixture shall have a

minimum residual strength of at least 10 ppm of chlorine. If check samples

fail to produce acceptable results, the disinfection procedure shall be repeated

at the expense of the Contractor until satisfactory results are obtained.

Standard Specifications - ONLINE Pipeline Testing and Disinfection

33 13 00 - 7

E. Disposal of any water containing chlorine shall be performed in accordance

with the latest edition of AWWA C651, Section 01 10 0 Special Provisions of

this specification, and any other state or local requirements. Disposal may be

made into existing sanitary sewer systems providing approvals are obtained

from the respective systems owner prior to disposal. Any chlorinated water

discharged to open waterways must be dechlorinated prior to discharge and

conform to Section 3.4 B of this specification section.

TABLE III

Pounds of Chemicals Required to Neutralize Various Residual Chlorine

Concentrations in 100,000 gal of Water*

Residual

Chlorine Vita-D-Chlor** SodiumThiosulfate

Concentration (Ascorbic Acid) (Na2S2O35H2O)

mg/L

1 2.2 1.2

2 4.41 2.4

10 22.03 12.0

50 110.13 60.0

* Except for residual chlorine concentration, all amounts are in pounds.

**Check with local sewer department for conditions of disposal to sanitary

sewer.

***Formula for Vita-D-Chlor application: (D x D x mg/l x feet ) ÷ 1,112,300.

Where D= pipe diameter in inches, mg/l = milligrams per liter chlorine

concentration, feet = number of feet of line to be treated.

****Vita-D-Chlor tablets shall only be used for dechlorination of mains

containing 4 ppm or less of residual chlorine, and the Contractor must obtain the

approval of the Engineer prior to use.

G. The Contractor will collect samples after the pipeline is flushed in accordance

with the latest edition of AWWA C651-14 at locations directed by the

Engineer. The chlorine residual must be below 1 ppm when the sample is

taken.

H. Results of the bacteriological testing shall be satisfactory with SUB, the State

Department of Health, and/or any other appropriate regulatory agencies having

jurisdiction, or disinfection shall be repeated at the expense of the Contractor.

Standard Specifications - ONLINE Pipeline Testing and Disinfection

33 13 00 - 8

3.5 Bacteriological Testing

A. 16 hours after final flushing, and before the new water main connection is

opento the distribution system two (2) consecutive sets of bacteriological

samples shall be collected from the new main. All samples obtained from the

new main shall conform to the procedures set forth in accordance with the

latest edition of AWWA C651-14. Chlorine residual shall be tested before

sampling and must be 1 ppm or less before the sample is collected. At least

one set of samples shall be collected at intervals of 1,200 feet (366 m) from the

new water main, in addition to one set from the end of the line and at least one

set from each branch. All samples shall be tested for bacteriological quality in

accordance with Standard Methods for the Examination of Water and

Wastewater, by an Oregon State Health Division approved laboratory, and

shall show the absence of coliform organisms. A standard heterotrophic plate

count may be required as directed by the Engineer.

B. If trench water has entered the new main during construction or, if in the

opinion of the Engineer excessive quantities of dirt or debris have entered the

new main, bacteriological samples shall be taken at intervals of approximately

200 feet and shall be identified by location. Samples shall be taken of water

that has remained in the new main for at least 16 hours after final flushing has

been completed.

C. Samples for bacteriological analysis shall be collected in sterile bottles treated

with sodium thiosulfate as required by Standard Methods for the Examination

of Water and Wastewater. No hose or fire hydrant shall be used in the

collection of samples.

D. Should the initial treatment fail to produce satisfactory bacteriological results,

or if other results indicate unacceptable water quality, the main(s) may be

reflushed and shall be resampled. If the check samples fail to produce

acceptable results, the original chlorination procedure or another method

approved by SUB shall be repeated at the Contractor's expense until

satisfactory results are obtained. No extra payment or extension of Contract

time will be allowed the Contractor for the time elapsed to achieve acceptable

sterilization of the pipe. Records of all bacteriologic testing shall be provided

to Engineer by the Contractor prior to final acceptance of the new lines.

3.6 Disinfection of Water Main End Connections and Tie-Ins

Disinfection and pressure testing of potable water piping and appurtenances at end

connections which are required to remain in service due to restrictions in allowable

shutdown time shall be pressure tested and disinfected as described below:

A. Prior to connecting new potable water piping and appurtenances with existing

piping and appurtenances, the interior of all new pipe, fittings, valves and

Standard Specifications - ONLINE Pipeline Testing and Disinfection

33 13 00 - 9

appurtenances shall be swabbed or sprayed with a 1% to 5% calcium

hypochlorite solution.

B. Following the disinfection procedures described above, connection of the new

piping and appurtenances to the existing water system shall be made. During

the system startup, the Engineer and Contractor shall visually inspect all new

fittings, piping, valves and appurtenances for evidence of leakage. Any

leakage observed during this period shall be promptly repaired by the

Contractor, at Contractor’s expense as required by the Engineer.

3.7 Tracer Wire Conductivity Testing

A conductivity test shall be made on all tracer wire installed. Tests and visual

inspection shall be made at each valve box, meter box, and listening port as

applicable. Conductivity may be tested by using an electrical conductivity meter or

by attaching underground locating equipment and tracing the signal to each valve box

and meter box. No acceptance or payment will be made on any section or reach of

pipe installed that does not have a conductive electrical locator wire installed in

accordance with Standard Drawings.

END OF SECTION

Standard Specifications - ONLINE Pipeline Testing and Disinfection

33 13 00 - 10

You might also like

- Hydrostatic Testing Awwa 600Document4 pagesHydrostatic Testing Awwa 600gunsak87% (15)

- The Chess CourseDocument632 pagesThe Chess CourseAnand Ramadurai71% (34)

- RESEARCH MWTHODS M.ADocument11 pagesRESEARCH MWTHODS M.ADacosta FlectureNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Department of Genetics: Covid-19 RT PCRDocument1 pageDepartment of Genetics: Covid-19 RT PCRAswathy LNo ratings yet

- Typical Project Quality Plan & ITP CPCDocument15 pagesTypical Project Quality Plan & ITP CPCnice guy100% (1)

- ICC Masonry RequirementsDocument3 pagesICC Masonry RequirementsSuzy K Baez OrtizNo ratings yet

- AwwaDocument11 pagesAwwahuyarchitect8933% (3)

- Inspection and Test Plan For Seel StructureDocument3 pagesInspection and Test Plan For Seel StructureChris McNairNo ratings yet

- Easylog Data Logger El Wifi THDocument3 pagesEasylog Data Logger El Wifi THRohitNo ratings yet

- Method Statement Mechanical PDFDocument24 pagesMethod Statement Mechanical PDFفاعل خيرNo ratings yet

- PD 856 Sanitation Code of PhilippinesDocument28 pagesPD 856 Sanitation Code of PhilippinesJason Angel Buñag100% (2)

- 020 15140 - Testing and Disinfection Standard SpecificationDocument11 pages020 15140 - Testing and Disinfection Standard SpecificationbereketNo ratings yet

- 33 01 10 15 - Disinfecting PipelineDocument15 pages33 01 10 15 - Disinfecting PipelineBader ShrbajiNo ratings yet

- 014 Commissioning Weekly Report Template PDFDocument21 pages014 Commissioning Weekly Report Template PDFali ahmadNo ratings yet

- Hydro-Test Procedure For HDPE PipelineDocument14 pagesHydro-Test Procedure For HDPE PipelineAhmedNo ratings yet

- Infiltration and Exfiltration Acceptance Testing of Installed Corrugated High Density Polyethylene PipelinesDocument2 pagesInfiltration and Exfiltration Acceptance Testing of Installed Corrugated High Density Polyethylene PipelinesAhmad Zubair Rasuly100% (2)

- Installation of Steel Water Pipe-4 In. (100 MM) and Larger: AWWA StandardDocument48 pagesInstallation of Steel Water Pipe-4 In. (100 MM) and Larger: AWWA Standardolivares91No ratings yet

- Section 20 Horizontal Directional Drilling (HDD) /hdpe Pipe: 20.01 Scope: A. GeneralDocument6 pagesSection 20 Horizontal Directional Drilling (HDD) /hdpe Pipe: 20.01 Scope: A. GeneralRon CylNo ratings yet

- Installation Guide - Pressure Pipe - 6.26.15Document12 pagesInstallation Guide - Pressure Pipe - 6.26.15MazenNo ratings yet

- Installation, Testing, and Maintenance of Fire Hydrants: FieldDocument85 pagesInstallation, Testing, and Maintenance of Fire Hydrants: FieldCristiam MondragónNo ratings yet

- 33 05 13 Manholes and Structures 10Document4 pages33 05 13 Manholes and Structures 10salamNo ratings yet

- Qa QC Plan Facility Site Work ConstructionDocument103 pagesQa QC Plan Facility Site Work Constructionmou777No ratings yet

- Examination Procedures For Vacuum TestDocument9 pagesExamination Procedures For Vacuum TestOsilonya HenryNo ratings yet

- TrueUnion - True Union Ball ValveDocument4 pagesTrueUnion - True Union Ball ValveKarthick VenkateshNo ratings yet

- Method Statement For Carbon Steel U G Piping Fabrication ErectionDocument28 pagesMethod Statement For Carbon Steel U G Piping Fabrication ErectionAriel Anasco100% (1)

- 04 TrenchingDocument7 pages04 TrenchingkabeerdossNo ratings yet

- C.1 Method Statement For Pipeline Maintenance and Emergency RepairsDocument17 pagesC.1 Method Statement For Pipeline Maintenance and Emergency Repairsagbon johnNo ratings yet

- Upg Stream Pe100 HydrotestDocument4 pagesUpg Stream Pe100 HydrotestMoezNo ratings yet

- Inspection Report of Oceano Sewage Treatment PlantDocument34 pagesInspection Report of Oceano Sewage Treatment PlantThe Tribune100% (1)

- Typical Acid Cleaning Procedure For Compressor LinesDocument1 pageTypical Acid Cleaning Procedure For Compressor Linesrenjithv_4No ratings yet

- Page 1 of 7 1.0 Title: Method Statement For Water Chlorination TestDocument7 pagesPage 1 of 7 1.0 Title: Method Statement For Water Chlorination Testarshad iqbal100% (1)

- Section 12 - Sanitary Sewer System (PDF) - 201601061536408543Document26 pagesSection 12 - Sanitary Sewer System (PDF) - 201601061536408543Sean ChanNo ratings yet

- TSSA Fuels Safety High Pressure Piping Code, TSSA HPP-2017 November 2017Document7 pagesTSSA Fuels Safety High Pressure Piping Code, TSSA HPP-2017 November 2017Manoj SaralayaNo ratings yet

- A Color Codes For Pipe Lines ANSIDocument24 pagesA Color Codes For Pipe Lines ANSIliveconnectionz282No ratings yet

- Sewer CCTV Guidebook PDFDocument105 pagesSewer CCTV Guidebook PDFMark Anthony GaguiNo ratings yet

- Method Statement For Installation & Hydrotest of GRP & Upvc PipesDocument19 pagesMethod Statement For Installation & Hydrotest of GRP & Upvc PipesBAVA M.HNo ratings yet

- P9127 - Piping Pressure Testing - Rev 0 - GENERICDocument20 pagesP9127 - Piping Pressure Testing - Rev 0 - GENERICmengelito almonte100% (1)

- SP-1232 - HSE Specification - Public HealthDocument61 pagesSP-1232 - HSE Specification - Public Healthshashi_nspNo ratings yet

- 16 0105 Construction Method StatementDocument3 pages16 0105 Construction Method StatementChun KedNo ratings yet

- Hydro Static Test Water Management Guidelines-1Document142 pagesHydro Static Test Water Management Guidelines-1gjabyNo ratings yet

- MODEL NR3XL Pressure RegulatorDocument2 pagesMODEL NR3XL Pressure Regulator63ragtopNo ratings yet

- Pressurized Air Shock BlowingDocument3 pagesPressurized Air Shock BlowingEmir PayNo ratings yet

- MS-HKSS-Pigging Testing Drying Rev A - YNB 16''Document64 pagesMS-HKSS-Pigging Testing Drying Rev A - YNB 16''AAISATNo ratings yet

- DCP-01-005 RFI Document Control ProcDocument2 pagesDCP-01-005 RFI Document Control Prockrmchari100% (1)

- Method Statement For DI Pipe InstallationDocument7 pagesMethod Statement For DI Pipe InstallationJeffrey WeyNo ratings yet

- ITP Plan For Piping Pre-Commisioning - Rev2Document23 pagesITP Plan For Piping Pre-Commisioning - Rev2Dwikappa Asri Utama100% (1)

- 25.MOS Template - Installation of HDPE LiningDocument14 pages25.MOS Template - Installation of HDPE LiningAnantha PadmanabhanNo ratings yet

- 3 Phase SampleQualityControlPlanDocument24 pages3 Phase SampleQualityControlPlangeorgemorris777No ratings yet

- Plastic PipeDocument4 pagesPlastic Pipesethu1091No ratings yet

- Iso 20486 2017Document13 pagesIso 20486 2017ANGGI MAHARANI100% (1)

- 08-Section 2-Section 02210 HDPE Pipeline-Version 2.0Document20 pages08-Section 2-Section 02210 HDPE Pipeline-Version 2.0Avaan IvaanNo ratings yet

- Drinking Water Well ConstDocument7 pagesDrinking Water Well ConstBhuiyan RazonNo ratings yet

- Lifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneDocument7 pagesLifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneHtin Lin Aung100% (1)

- ITP Ducting Work Include Insulation Work (Rev.3)Document9 pagesITP Ducting Work Include Insulation Work (Rev.3)Researcher100% (2)

- WeldingDocument73 pagesWeldingTeodor EzaruNo ratings yet

- Ductile Cast IronDocument30 pagesDuctile Cast IrontribleprinceNo ratings yet

- HDPE Method of StatementDocument18 pagesHDPE Method of StatementKhaled NaguibNo ratings yet

- PER 2012 - Pressure EquipmentDocument35 pagesPER 2012 - Pressure EquipmentTshilidzi Irene Netselo100% (1)

- Pipeline Testing and DisinfectionDocument10 pagesPipeline Testing and DisinfectionWayjantha Sunethra Bandara JayawardhanaNo ratings yet

- Section 02760 Performance Testing of Pressure Pipelines Part 1 - GeneralDocument5 pagesSection 02760 Performance Testing of Pressure Pipelines Part 1 - Generaldương_thành_28No ratings yet

- Section 02760 Performance Testing of Pressure Pipelines Part 1 - GeneralDocument5 pagesSection 02760 Performance Testing of Pressure Pipelines Part 1 - Generaljungzki jungzkiNo ratings yet

- QCS-2010 Section 19 Part 6 Commissioning of SystemsDocument6 pagesQCS-2010 Section 19 Part 6 Commissioning of Systemsbryanpastor106No ratings yet

- Sagana at Ligtas Na Tubig Sa Lahat (Salintubig) Program: Official Gazette 871 January 6, 2020Document6 pagesSagana at Ligtas Na Tubig Sa Lahat (Salintubig) Program: Official Gazette 871 January 6, 2020Jason Angel BuñagNo ratings yet

- Am 2020 PDFDocument28 pagesAm 2020 PDFJason Angel BuñagNo ratings yet

- Sagana at Ligtas Na Tubig Sa Lahat (Salintubig) Program: Official Gazette 871 January 6, 2020Document6 pagesSagana at Ligtas Na Tubig Sa Lahat (Salintubig) Program: Official Gazette 871 January 6, 2020Jason Angel BuñagNo ratings yet

- MW4SP Submission Checklist R9Document7 pagesMW4SP Submission Checklist R9Jason Angel BuñagNo ratings yet

- How To Permanently Disable Windows Defender PDFDocument15 pagesHow To Permanently Disable Windows Defender PDFJason Angel BuñagNo ratings yet

- 1.5 Guidelines For Preparing Inspections & Test Plans (Itp) Agrarian Reform Communities ProjectDocument5 pages1.5 Guidelines For Preparing Inspections & Test Plans (Itp) Agrarian Reform Communities ProjectJason Angel BuñagNo ratings yet

- Circular 2019-04 - Internal Policy On Payment of Travel Expenses For Local & Foreign Travel of DILG LG SectorDocument8 pagesCircular 2019-04 - Internal Policy On Payment of Travel Expenses For Local & Foreign Travel of DILG LG SectorJason Angel BuñagNo ratings yet

- List of Elected LGU OfficialsDocument111 pagesList of Elected LGU OfficialsJason Angel BuñagNo ratings yet

- List of Elected LGU OfficialsDocument111 pagesList of Elected LGU OfficialsJason Angel BuñagNo ratings yet

- Admixtures by Portland CementDocument36 pagesAdmixtures by Portland CementVijayakrishna SingamsettiNo ratings yet

- Annex A - LCE Certification For Fund ReleaseDocument1 pageAnnex A - LCE Certification For Fund ReleaseJason Angel BuñagNo ratings yet

- Nietzsche and The Study of The Ancient World PDFDocument28 pagesNietzsche and The Study of The Ancient World PDFWen-Ti LiaoNo ratings yet

- Stretching Mesh Reduced FileDocument5 pagesStretching Mesh Reduced FileMerlie Fuentes Fiel ValentinoNo ratings yet

- Bitcoin Stochastic Stock To Flow ModelDocument21 pagesBitcoin Stochastic Stock To Flow ModelNathaniel FowlerNo ratings yet

- Iron Deficiency AnemiaDocument16 pagesIron Deficiency Anemiaكشخه عراقيNo ratings yet

- Knit Free by JojiDocument8 pagesKnit Free by JojipaulaNo ratings yet

- Cancer and Vitamin CDocument187 pagesCancer and Vitamin Cabdul qayyum100% (2)

- Sebahat Elif Olgun Sebahat Elif Olgun Essay Final Draft 38263 18290098Document2 pagesSebahat Elif Olgun Sebahat Elif Olgun Essay Final Draft 38263 18290098api-433221820No ratings yet

- Shmoop Summary One Flew Over The Cuckoo's NestDocument61 pagesShmoop Summary One Flew Over The Cuckoo's NestDaniela Torres Noriega100% (1)

- InheretanceDocument8 pagesInheretancefarhan.mukhtiarNo ratings yet

- Midterm Exam: University of Washington CSE 403 Software Engineering Spring 2011Document8 pagesMidterm Exam: University of Washington CSE 403 Software Engineering Spring 2011fikaduNo ratings yet

- BS en 1996-1-1 2005Document128 pagesBS en 1996-1-1 2005Project Director100% (1)

- Mock Drill PlanDocument2 pagesMock Drill Plansanjeet giriNo ratings yet

- Beverage Brochure EnglishDocument16 pagesBeverage Brochure Englishsalicurri0% (1)

- 2009 Book CloudComputing PDFDocument726 pages2009 Book CloudComputing PDFRajat Kumar YadavNo ratings yet

- Factors Affecting Onset of Puberty in Denizli Province in TurkeyDocument7 pagesFactors Affecting Onset of Puberty in Denizli Province in TurkeyAde Tiur RumondangNo ratings yet

- Motor Learning Theory: References: Cole & Tufano, Chapter 19 Reserve Article: Mathiowetz & Bass Haugen (1994) AJOTDocument23 pagesMotor Learning Theory: References: Cole & Tufano, Chapter 19 Reserve Article: Mathiowetz & Bass Haugen (1994) AJOTEdwin BedfordNo ratings yet

- Contact Lens 2 Study GuideDocument5 pagesContact Lens 2 Study GuideGenre PesselNo ratings yet

- Cement Industry - Group19Document28 pagesCement Industry - Group19swati100% (1)

- Bridge 3 Deck DesignDocument16 pagesBridge 3 Deck DesignMd MamroseNo ratings yet

- (Ebook) Valkyrie - Runes of The Elder Futhark PDFDocument21 pages(Ebook) Valkyrie - Runes of The Elder Futhark PDFJosé MarinhoNo ratings yet

- Measures of Central Tendency and DispersionDocument13 pagesMeasures of Central Tendency and DispersionArlan Joseph LopezNo ratings yet

- Ventil Preventest LTC Int v5Document3 pagesVentil Preventest LTC Int v5Teodoro Escobar Riveros100% (1)

- Asia Medical Devices Report - Q2 2019Document41 pagesAsia Medical Devices Report - Q2 2019Ân THiênNo ratings yet

- PG 511 B 1 B 1: Ordering Code Series PGP/PGM511Document7 pagesPG 511 B 1 B 1: Ordering Code Series PGP/PGM511Zoran JankovNo ratings yet

- Geometry Practice Test 7 - ACT PROBLEMSDocument7 pagesGeometry Practice Test 7 - ACT PROBLEMSCarlos OrtizNo ratings yet

- 302-1006-003 Make-Up750ml MEK-United States - ADITIVO PDFDocument8 pages302-1006-003 Make-Up750ml MEK-United States - ADITIVO PDFAlexander MamaniNo ratings yet

- Leader End of Financial Catalogue Apr-Jun 2020 - LowRez - FinalDocument16 pagesLeader End of Financial Catalogue Apr-Jun 2020 - LowRez - Finaltim chambersNo ratings yet