Professional Documents

Culture Documents

DIP motors Category 2D variant codes guide

Uploaded by

Vilius BukysOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIP motors Category 2D variant codes guide

Uploaded by

Vilius BukysCopyright:

Available Formats

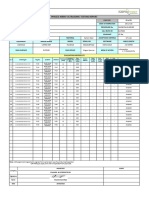

LV Dust ignition proof DIP motors, Cat 2D - Variant codes

DIP motors, Category 2D - variant codes Aluminum motors Cast iron motors

71- 90- 112- 160- 200- 80- 160- 280- 355-

Code 1) Variant 80 100 132 180 280 132 250 315 400

Balancing

052 Balancing to Grade A (IEC 60034-14). S S S S S S S S S

417 Balancing to Grade B (IEC 60034-14). NA R R R R P P P P

424 Full key balancing. P P P P P P P P P

Bearings and lubrication

036 Transport lock for bearings. NA P M M M NA M P P

037 Roller bearing at D-end. NA NA NA NA NA NA M P P

039 Cold resistant grease (-55...+100°C) M NA NA NA NA M M P P

040 Heat resistant grease (-25...+150°C) M NA NA NA NA M S S S

041 Bearings regreasable via grease nipples. NA NA NA NA NA NA S S S

042 Locked drive-end. M S S S S S S S S

043 SPM-nipples. NA R M M M NA S S S

058 Angular contact ball bearing at D-end, shaft force away from NA NA NA NA NA NA P P P

bearing.

107 Bearing mounted PT100 resistance elements. NA NA NA NA NA NA P P P

194 2Z-bearings at both ends, greased for lifetime. S NA NA NA NA S M R NA

433 Grease relief. NA NA NA NA NA NA NA P P

796 Grease nipples JIS B 1575 PT 1/8 Type A. Stainless steel. NA NA NA NA NA NA P P P

Brakes

412 Built-on brake. Branch standard designs. NA NA NA NA NA NA R R R

Branch standard designs

142 Manilla winding connection. (440VD series, 220 VD parallel, NA P P P P NA P P P

60 Hz).

178 Stainless steel/acid proof bolts. M M M M M S M P P

209 Non-standard voltage or frequency (special winding). P P P P P R P P P

425 Corrosion protected stator and rotor core. P NA NA NA NA NA S P P

786 Outdoor mounting with shaft up V3, V36, V6. NA NA NA NA NA P P NA NA

Cooling system

044 Unidirectional fan, clockwise seen from D-end. NA NA NA NA NA NA NA R R

045 Unidirectional fan, counter clockwise seen from D-end. NA NA NA NA NA NA NA R R

068 Metal fan. M S S S S S S S S

6

075 Cooling method IC 418 (without fan). P P R R R R P P P

183 Separate motor cooling (fan axial, N-end). M NA NA NA NA NA P P P

422 Separate motor cooling (fan top or side, N-end). NA NA NA NA NA NA NA P P

791 Stainless steel fan cover. NA NA NA NA NA NA R R R

Coupling

035 Assembly of customer supplied coupling-half. NA NA NA NA NA M M M M

Drain holes

065 Plugged drain holes. S NA NA NA NA NA S S S

066 Modified drain hole position (for specified IM xxxx). M NA NA NA NA NA M M M

076 Draining holes with plugs. S NA NA NA NA NA NA NA NA

1)

Certain variant codes cannot be used simultaneously. S = Included as standard. P = New manufacture only.

M = On modification of a stocked motor, R = On request.

or on new manufacture, NA = Not applicable.

the number per order may be limited.

ABB / Cat. BU / Ex-motors / Dust ignition protection GB 03-2004 143

DIP motors, Category 2D - variant codes Aluminum motors Cast iron motors

71- 90- 112- 160- 200- 80- 160- 280- 355-

Code 1) Variant 80 100 132 180 280 132 250 315 400

Heating elements

Motor size Element capacity

71-80 7W

90-160 25 W

180-280 50 W

315 2 x 50 W

355-400 2 x 65 W

450 Heating element, 110-120 V. M M R R R M M M M

451 Heating element, 220-240 V. M M R R R M M M M

Insulation system

014 Winding insulation class H. P P P P P NA R P P

405 Special winding insulation for frequency converter supply. S NA NA NA NA NA P P P

Mounting arrangements

008 IM 2101 foot/flange mounted, IEC flange, from IM 1001 M M M R/NA NA P NA NA NA

(B34 from B3). 160 = R, 180 = NA

009 IM 2001 foot/flange mounted, IEC flange, from IM 1001 M M M M M M M M M

(B35 from B3).

047 IM 3601 flange mounted, IEC flange, from IM 3001 M M M R/NA NA M NA NA NA

(B14 from B5), flange mounted with large flange.

Small flange with tapped holes. 160 = R, 180 = NA

Painting

114 Special paint colour, standard grade. M M M M M M M M M

111 Offshore two-pack polyamide cured epoxy paint 160 mm. R NA NA NA NA P P P P

115 Offshore, zinc primer painting. NA NA NA NA NA P P P P

179 Special paint specification. R R R R R R R R R

Protection

005 Protective roof, vertical motor, shaft down. M S S S S M M M M

072 Radial seal at D-end. M NA NA NA NA NA M M NA

Rating & instruction plates

002 Restamping voltage, frequency and output, continuous duty. R R R R R R R R R

095 Restamping output (maintained voltage, frequency), frequency), R NA NA NA NA NA NA NA NA

intermittent duty.

135 Mounting of additional identification plate, stainless. M M M M M M M M M

138 Mounting of additional identification plate, aluminum. M M M M M M M M M

139 Additional identification plate delivered loose. M M M M M M M M M

150 Instruction plates and maintenance instructions in NA NA NA NA NA R R R R

6

non-standard language.

161 Additional rating plate delivered loose. M M M M M M M M M

Shaft & rotor

069 Two shaft extensions as per basic catalogue. P NA NA NA NA P P P P

070 One or two special shaft extensions, standard shaft material. P P R R R R P P P

155 Cylindrical shaft extension, D-end, without key-way. NA NA NA NA NA P P P P

156 Cylindrical shaft extension, N-end, without key-way. NA NA NA NA NA R P P P

164 Shaft extension with closed key-way. S S S S S S S P P

165 Shaft extension with open key-way. P P P P P P P S S

410 Stainless steel shaft (standard or non-standard design). P P R R R NA P P P

Standards and regulations

152 Classified shaft material. NA NA NA NA NA P P P P

1)

Certain variant codes cannot be used simultaneously. S = Included as standard. P = New manufacture only.

M = On modification of a stocked motor, R = On request.

or on new manufacture, NA = Not applicable.

the number per order may be limited.

144 ABB / Cat. BU / Ex-motors / Dust ignition protection GB 03-2004

DIP motors, Category 2D - variant codes Aluminum motors Cast iron motors

71- 90- 112- 160- 200- 80- 160- 280- 355-

Code 1) Variant 80 100 132 180 280 132 250 315 400

Stator winding temperature sensors

121 Bimetal detectors, break type (NCC), (3 in series), 130°C, M NA NA NA NA P P P P

in stator winding.

122 Bimetal detectors, break type (NCC), (3 in series), 150°C, M NA NA NA NA P P P P

in stator winding.

125 Bimetal detectors, break type (NCC), (2x3 in series), 150°C, M NA NA NA NA P P P P

in stator winding.

127 Bimetal detectors, break type (NCC), (3 in series, 130°C M NA NA NA NA P P P P

and 3 in series 150°C), in stator winding.

435 PTC - thermistors (3 in series), 130°C, in stator winding. M M M M M P M M M

436 PTC - thermistors (3 in series), 150°C, in stator winding. M S S S S S S S S

439 PTC - thermistors (2x3 in series), 150°C, in stator winding. M M M M M P P P P

441 PTC - thermistors (3 in series 130°C & 3 in series 150°C), M M M M M P P P P

in stator winding.

445 PT100 resistance element (1 per phase) in stator winding. R M M M M P P P P

446 PT100 resistance element (2 per phase) in stator winding. R M M M M R P P P

Terminal box

015 D connection in terminal box (reconnection from Y). M M M M M M M M M

017 Y connection in terminal box (reconnection from D). M M M M M M M M M

021 Terminal box LHS (seen from D-end). M R NA NA R NA P P P

136 Extended cable connection, standard terminal box. P NA NA NA NA R R R R

Aluminum motors: 2 m long connection cable.

137 Extended cable connection, low terminal box. R NA NA NA NA P P P P

157 Terminal box degree of protection IP 65. R S S S S S M M M

180 Terminal box RHS (seen from D-end). NA R NA NA R NA P P P

400 4 x 90 degr turnable terminal box. NA NA NA NA NA NA S/M S S

Cast iron sizes 200-250 = S

402 Terminal box adapted for Al -cables. NA NA NA NA NA NA NA S S

413 Extended cable connection, no terminal box. NA NA NA NA NA NA NA P P

418 Separate terminal box for temperature detectors. NA NA NA NA NA NA M P P

466 Terminal box at N-end. NA NA NA NA NA NA R R R

468 Cable entry from D-end. NA NA NA NA NA P P P P

469 Cable entry from N-end. NA NA NA NA NA P P P P

731 Two standard cable glands. M M R R R NA M M M

6

736 EEx e II certified cable gland, fulfilling EN 50014 and 50019 NA NA NA NA NA S S S S

737 Standard cable gland, EEx e II with clamping device, NA NA NA NA NA M M M M

fulfilling EN 50014 and 50019.

740 Prepared for PG cable glands. NA NA NA NA NA NA P P P

743 Painted steel flange for cable glands (blind plate). NA NA NA NA NA P P P P

744 Stainless steel flange for cable glands (blind plate). NA NA NA NA NA P P P P

745 Painted steel flange equipped with brass cable glands. NA NA NA NA NA P P P P

746 Stainless steel flange equipped with standard brass cable NA NA NA NA NA P P P P

glands

1)

Certain variant codes cannot be used simultaneously. S = Included as standard. P = New manufacture only.

M = On modification of a stocked motor, R = On request.

or on new manufacture, NA = Not applicable.

the number per order may be limited.

ABB / Cat. BU / Ex-motors / Dust ignition protection GB 03-2004 145

DIP motors, Category 2D - variant codes Aluminum motors Cast iron motors

71- 90- 112- 160- 200- 80- 160- 280- 355-

Code 1) Variant 80 100 132 180 280 132 250 315 400

Testing

140 Test confirmation. M M M M M NA NA NA NA

145 Type test report from test of identical motor. M M M M M M M M M

146 Type test with report for motor from specific delivery batch. P P M M M P M P P

147 Type test with report for motor from specific delivery batch, P P M M M P M P P

customer witnessed.

148 Routine test report. P M M M M M M P P

221 Type test and multi-point load test with report for motor from R P M M M P P P P

specific delivery batch.

222 Torque/speed curve, type test and multi-point load test with R P M M M P P P P

report from specific delivery batch.

760 Vibration level test. P R M M M P M P P

761 Vibration spectrum test. R R R R R P P P P

762 Noise level test. P R M M M P P P P

763 Noise spectrum test. R R R R R P P P P

764 Complete test with ABB frequency converter. NA R R R R P P P P

Variable speed drives

181 Adapted for frequency converter, variable speed operation. NA NA NA NA NA R R R R

405 Special winding insulation for frequency converter supply, NA NA NA NA NA NA P P P

rated supply > 500 V.

701 Insulated bearing at N-end. NA NA NA NA NA NA R P P

704 EMC cable gland. NA NA NA NA NA P P P P

183 Separate motor cooling (fan axial, N-end). M NA NA NA NA NA P P P

422 Separate motor cooling (fan top or side, N-end). NA NA NA NA NA NA NA P P

747 EEx d pulse tacho. NA NA NA NA NA NA P P P

476 Separate motor cooling (fan axial, N-end) and 1024 pulse NA NA NA NA NA NA P P P

tacho (Leine & Linde equivalent) mounted.

477 Separate motor cooling (fan axial, N-end) and 2048 pulse NA NA NA NA NA NA P P P

tacho (Leine & Linde equivalent) mounted.

Y/D-starting

117 Terminals for Y/D start at both speeds (two-speed windings). NA P P P P NA R P P

118 Terminals for Y/D start at high speed (two-speed windings). NA P P P P NA R P P

119 Terminals for Y/D start at low speed (two-speed windings). NA P P P P NA R P P

1)

Certain variant codes cannot be used simultaneously. S = Included as standard. P = New manufacture only.

M = On modification of a stocked motor, R = On request.

or on new manufacture, NA = Not applicable.

the number per order may be limited.

146 ABB / Cat. BU / Ex-motors / Dust ignition protection GB 03-2004

LV Dust ignition proof DIP motors, Cat 3D - Variant codes

DIP motors, Category 3D - variant codes Aluminum motors Cast iron motors

71- 90- 112- 160- 200- 71 160- 280- 355-

Code 1) Variant 80 100 132 180 280 132 250 315 400

Balancing

052 Balancing to Grade A (IEC 60034-14). S S S S S S S S S

417 Balancing to Grade B (IEC 60034-14). NA R R R R P P P P

424 Full key balancing. P P P P P M P P P

Bearings and lubrication

036 Transport lock for bearings. NA P M M M NA M P P

037 Roller bearing at D-end. NA NA NA M M NA M P P

039 Cold resistant grease (-55...+100°C) M NA M M M M M P P

040 Heat resistant grease (-25...+150°C) M NA S S S M S S S

041 Bearings regreasable via grease nipples. NA NA M M S NA S S S

042 Locked drive-end. M S M S S NA S S S

043 SPM-nipples. NA R M M M NA S S S

058 Angular contact ball bearing at D-end, shaft force away from NA M M M M NA P P P

bearing.

107 Bearing mounted PT100 resistance elements. NA NA NA NA NA NA P P P

194 2Z-bearings at both ends, greased for lifetime. S NA S S R S M R NA

433 Grease relief. NA NA NA NA NA NA NA P P

796 Grease nipples JIS B 1575 PT 1/8 Type A. Stainless steel. NA NA M M M NA P P P

Brakes

412 Built-on brake. Branch standard designs. NA NA NA NA NA NA R R R

Branch standard designs

142 Manilla winding connection. (440VD series, 220 VD parallel, NA P P P P NA P P P

60 Hz).

178 Stainless steel/acid proof bolts. M M M M M M M P P

209 Non-standard voltage or frequency (special winding). P P P P P R P P P

425 Corrosion protected stator and rotor core. P NA P P P NA S P P

786 Outdoor mounting with shaft up V3, V36, V6. NA NA NA NA NA R P NA NA

Cooling system

044 Unidirectional fan, clockwise seen from D-end. NA NA NA NA NA NA NA R R

045 Unidirectional fan, counter clockwise seen from D-end. NA NA NA NA NA NA NA R R

068 Metal fan. M S R R R S S S S

6

075 Cooling method IC 418 (without fan). P P R R R R P P P

183 Separate motor cooling (fan axial, N-end). M NA NA NA NA NA P P P

422 Separate motor cooling (fan top or side, N-end). NA NA NA NA NA NA NA P P

791 Stainless steel fan cover. NA NA NA NA NA NA R R R

Coupling

035 Assembly of customer supplied coupling-half. NA NA R R R M M M M

Drain holes

065 Plugged drain holes. S NA S S S NA S S S

066 Modified drain hole position (for specified IM xxxx). M NA NA NA NA M M M M

076 Draining holes with plugs. S NA NA NA NA NA NA NA NA

1)

Certain variant codes cannot be used simultaneously. S = Included as standard. P = New manufacture only.

M = On modification of a stocked motor, R = On request.

or on new manufacture, NA = Not applicable.

the number per order may be limited.

ABB / Cat. BU / Ex-motors / Dust ignition protection GB 03-2004 147

DIP motors, Category 3D - variant codes Aluminum motors Cast iron motors

71- 90- 112- 160- 200- 71 160- 280- 355-

Code 1) Variant 80 100 132 180 280 132 250 315 400

Heating elements

Motor size Element capacity

71-80 7W

90-160 25 W

180-280 50 W

315 2 x 50 W

355-400 2 x 65 W

450 Heating element, 110-120 V. M M M M M M M M M

451 Heating element, 220-240 V. M M M M M M M M M

Insulation system

014 Winding insulation class H. P P P P P NA R P P

405 Special winding insulation for frequency converter supply. S NA P P P NA P P P

Mounting arrangements

008 IM 2101 foot/flange mounted, IEC flange, from IM 1001 (B34 M M M R/NA NA M NA NA NA

from B3). 160 = R, 180 = NA

009 IM 2001 foot/flange mounted, IEC flange, from IM 1001 (B35 M M M M M M M M M

from B3).

047 IM 3601 flange mounted, IEC flange, from IM 3001 M M M R/NA NA M NA NA NA

(B14 from B5), flange mounted with large flange.

Small flange with tapped holes. 160 = R, 180 = NA

Painting

114 Special paint colour, standard grade. M M M M M M M M M

111 Offshore two-pack polyamide cured epoxy paint 160 mm. R NA NA NA NA NA P P P

115 Offshore, zinc primer painting. NA NA NA NA NA NA P P P

179 Special paint specification. R R R R R R R R R

Protection

005 Protective roof, vertical motor, shaft down. M S S S S M M M M

072 Radial seal at D-end. M NA R R R S M M NA

Rating & instruction plates

002 Restamping voltage, frequency and output, continuous duty. R R R R R R R R R

095 Restamping output (maintained voltage, frequency), frequency), R R M M M NA NA NA NA

intermittent duty.

135 Mounting of additional identification plate, stainless. M M R R R M M M

138 Mounting of additional identification plate, aluminum. M M M M M M M M M

139 Additional identification plate delivered loose. M M M M M M M M M

150 Instruction plates and maintenance instructions in NA NA NA NA NA R R R R

6

non-standard language.

161 Additional rating plate delivered loose. M M M M M M M M M

Shaft & rotor

069 Two shaft extensions as per basic catalogue. P NA P P P NA P P P

070 One or two special shaft extensions, standard shaft material. P P R R R NA P P P

155 Cylindrical shaft extension, D-end, without key-way. NA NA NA NA NA NA P P P

156 Cylindrical shaft extension, N-end, without key-way. NA NA NA NA NA NA P P P

164 Shaft extension with closed key-way. S S S S S P S P P

165 Shaft extension with open key-way. P P P P P S P S S

410 Stainless steel shaft (standard or non-standard design). P P R R R NA P P P

1)

Certain variant codes cannot be used simultaneously. S = Included as standard. P = New manufacture only.

M = On modification of a stocked motor, R = On request.

or on new manufacture, NA = Not applicable.

the number per order may be limited.

148 ABB / Cat. BU / Ex-motors / Dust ignition protection GB 03-2004

DIP motors, Category 3D - variant codes Aluminum motors Cast iron motors

71- 90- 112- 160- 200- 71 160- 280- 355-

Code 1) Variant 80 100 132 180 280 132 250 315 400

Standards and regulations

152 Classified shaft material. NA NA NA NA NA NA P P P

Stator winding temperature sensors

121 Bimetal detectors, break type (NCC), (3 in series), 130°C, M NA M M M NA P P P

in stator winding.

122 Bimetal detectors, break type (NCC), (3 in series), 150°C, M NA M M M NA P P P

in stator winding.

125 Bimetal detectors, break type (NCC), (2x3 in series), 150°C, M NA M M M NA P P P

in stator winding.

127 Bimetal detectors, break type (NCC), (3 in series, 130°C M NA M M M NA P P P

and 3 in series 150°C), in stator winding.

435 PTC - thermistors (3 in series), 130°C, in stator winding. M M M M M M M M M

436 PTC - thermistors (3 in series), 150°C, in stator winding. M S M M S S S S S

439 PTC - thermistors (2x3 in series), 150°C, in stator winding. M M M M M P P P P

441 PTC - thermistors (3 in series 130°C & 3 in series 150°C), M M M M M P P P P

in stator winding.

445 PT100 resistance element (1 per phase) in stator winding. R M M M M NA P P P

446 PT100 resistance element (2 per phase) in stator winding. R M M M M NA P P P

Terminal box

015 D connection in terminal box (reconnection from Y). M M M M M M M M M

017 Y connection in terminal box (reconnection from D). M M M M M M M M M

021 Terminal box LHS (seen from D-end). M P NA NA P NA P P P

136 Extended cable connection, standard terminal box. P NA R R R NA R R R

Aluminum motors: 2 m long connection cable.

137 Extended cable connection, low terminal box. R NA NA NA NA NA P P P

157 Terminal box degree of protection IP 65. R S R R R M M M M

180 Terminal box RHS (seen from D-end). NA R NA NA P P P P P

400 4 x 90 degr turnable terminal box. NA NA NA NA NA NA S/M S S

Cast iron sizes 200-250 = S

402 Terminal box adapted for Al -cables. NA NA NA NA NA NA NA S S

413 Extended cable connection, no terminal box. NA NA NA NA NA NA NA P P

418 Separate terminal box for temperature detectors. NA NA NA NA NA NA M P P

466 Terminal box at N-end. NA NA NA NA NA NA R R R

468 Cable entry from D-end. NA NA R R R M P P P

469 Cable entry from N-end. NA NA R R R M P P P

731

736

737

Two standard cable glands.

EEx e II certified cable gland, fulfilling EN 50014 and 50019

Standard cable gland, EEx e II with clamping device,

M

NA

NA

M

NA

NA

R

NA

NA

R

NA

NA

R

NA

NA

R

R

R

M

S

M

M

S

M

M

S

M

6

fulfilling EN 50014 and 50019.

740 Prepared for PG cable glands. NA NA R R R P P P P

743 Painted steel flange for cable glands (blind plate). NA NA NA NA NA NA P P P

744 Stainless steel flange for cable glands (blind plate). NA NA NA NA NA NA P P P

745 Painted steel flange equipped with brass cable glands. NA NA NA NA NA NA P P P

746 Stainless steel flange equipped with standard brass cable glands NA NA NA NA NA NA P P P

1)

Certain variant codes cannot be used simultaneously. S = Included as standard. P = New manufacture only.

M = On modification of a stocked motor, R = On request.

or on new manufacture, NA = Not applicable.

the number per order may be limited.

ABB / Cat. BU / Ex-motors / Dust ignition protection GB 03-2004 149

DIP motors, Category 3D - variant codes Aluminum motors Cast iron motors

71- 90- 112- 160- 200- 71 160- 280- 355-

Code 1) Variant 80 100 132 180 280 132 250 315 400

Testing

140 Test confirmation. M M M M M NA NA NA NA

145 Type test report from test of identical motor. M M M M M M M M M

146 Type test with report for motor from specific delivery batch. P P M M M M M P P

147 Type test with report for motor from specific delivery batch, custo- P P M M M M M P P

mer witnessed.

148 Routine test report. P M M M M M M P P

221 Type test and multi-point load test with report for motor from R P M M M NA P P P

specific delivery batch.

222 Torque/speed curve, type test and multi-point load test with R P M M M NA P P P

report from specific delivery batch.

760 Vibration level test. P R M M M M M P P

761 Vibration spectrum test. R R R R R P P P P

762 Noise level test. P R M M M P P P P

763 Noise spectrum test. R R R R R P P P P

764 Complete test with ABB frequency converter. NA R R R R P P P P

Variable speed drives

181 Adapted for frequency converter, variable speed operation. NA NA NA NA NA R R R R

183 Separate motor cooling (fan axial, N-end). M NA NA R R NA P P P

405 Special winding insulation for frequency converter supply, rated NA NA R R R NA P P P

supply > 500 V.

422 Separate motor cooling (fan top or side, N-end). NA NA NA NA NA NA P P P

476 Separate motor cooling (fan axial, N-end) and 1024 pulse tacho NA NA R R R NA P P P

(Leine & Linde equivalent) mounted.

477 Separate motor cooling (fan axial, N-end) and 2048 pulse tacho NA NA R R R NA P P P

(Leine & Linde equivalent) mounted.

701 Insulated bearing at N-end. NA NA NA NA M NA R P P

704 EMC cable gland. NA NA M M M P P P P

Y/D-starting

117 Terminals for Y/D start at both speeds (two-speed windings). NA P NA P P NA R P P

118 Terminals for Y/D start at high speed (two-speed windings). NA P P NA NA NA R P P

119 Terminals for Y/D start at low speed (two-speed windings). NA P NA NA NA NA R P P

1)

Certain variant codes cannot be used simultaneously. S = Included as standard. P = New manufacture only.

M = On modification of a stocked motor, R = On request.

or on new manufacture, NA = Not applicable.

the number per order may be limited.

150 ABB / Cat. BU / Ex-motors / Dust ignition protection GB 03-2004

You might also like

- Overhaul Daikin screw compressor: important issuesDocument42 pagesOverhaul Daikin screw compressor: important issuesjmdc100% (3)

- Stepper Motors: Design GuideDocument12 pagesStepper Motors: Design Guidesantoshgaonkar1997100% (1)

- Manual de Partes Mustang 744Document336 pagesManual de Partes Mustang 744Humberto MartinezNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Orient Petroleum Surplus Inventory GuideDocument42 pagesOrient Petroleum Surplus Inventory GuideHANIF AKBARNo ratings yet

- Fire Hose GuideDocument22 pagesFire Hose GuideVilius BukysNo ratings yet

- Manual Valves Datasheet. Rev 1Document7 pagesManual Valves Datasheet. Rev 1eke23No ratings yet

- THYSSEN (Maquina Mini Gearless DAF-270)Document76 pagesTHYSSEN (Maquina Mini Gearless DAF-270)migmarel86% (7)

- ABB Nema MotorDocument44 pagesABB Nema MotorAlejandroInostrozaNo ratings yet

- Preboard Sept 2013 Set B SolutionDocument20 pagesPreboard Sept 2013 Set B Solutionmark ian100% (4)

- Loher Dynasys SDocument39 pagesLoher Dynasys SyounesNo ratings yet

- Limpet With Jacket Nozzle OrientationDocument1 pageLimpet With Jacket Nozzle OrientationArunkumar MyakalaNo ratings yet

- ABB Motors - General Purpose 1 PDFDocument228 pagesABB Motors - General Purpose 1 PDFVilius BukysNo ratings yet

- API 6A Gate ValveDocument16 pagesAPI 6A Gate ValveJuan PabloNo ratings yet

- Solenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Document2 pagesSolenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Ramius HamdaniNo ratings yet

- IEEE Guide For Installation of Vertical Generators and Generator/Motors For Hydroelectric ApplicationsDocument40 pagesIEEE Guide For Installation of Vertical Generators and Generator/Motors For Hydroelectric ApplicationshansamvNo ratings yet

- Cylinder Connectors - RotarexDocument40 pagesCylinder Connectors - Rotarexmanoj_sitecNo ratings yet

- General Purpose Steel Motors - Variant Codes: BalancingDocument3 pagesGeneral Purpose Steel Motors - Variant Codes: BalancingVilius BukysNo ratings yet

- SKF Bearings Master InterchangeDocument452 pagesSKF Bearings Master InterchangeAamir AshinNo ratings yet

- Apf Motor Series Ie1: Low VoltageDocument21 pagesApf Motor Series Ie1: Low VoltageWerehouse catNo ratings yet

- Brosur Katalog Valve Flange Fitting Elbow Reducer Tee JakartaDocument13 pagesBrosur Katalog Valve Flange Fitting Elbow Reducer Tee JakartaAlvindo Catur SentosaNo ratings yet

- Cherry 1900 Bulbing Blind Rivet: SPS Fastener Division, ADocument4 pagesCherry 1900 Bulbing Blind Rivet: SPS Fastener Division, AДенис СергеевичNo ratings yet

- Zurn FV-ZW4100Document3 pagesZurn FV-ZW4100Carlitos Way Golden BrainNo ratings yet

- High-Powered Air-Cooled Condensers: STULZ The Natural ChoiceDocument4 pagesHigh-Powered Air-Cooled Condensers: STULZ The Natural ChoicerobinssonNo ratings yet

- SpecDocument2 pagesSpecdesmondNo ratings yet

- Form : EIPL/WT/F-01,Rev.01 Welding Procedure SpecificationDocument2 pagesForm : EIPL/WT/F-01,Rev.01 Welding Procedure SpecificationSampath KumarNo ratings yet

- DPR - 20-06-2023Document2 pagesDPR - 20-06-2023Muhammad AftabNo ratings yet

- Owner'S Manual Supplement 600 RMK and 700 RMK PN 9914864: 700 RMK 700 RMK Opt A 600 RMK 600 RMK Opt ADocument5 pagesOwner'S Manual Supplement 600 RMK and 700 RMK PN 9914864: 700 RMK 700 RMK Opt A 600 RMK 600 RMK Opt AhundredprestonNo ratings yet

- Health Check-Up Report 2MWDocument4 pagesHealth Check-Up Report 2MWlamrininosNo ratings yet

- 2ALTERNATORDocument56 pages2ALTERNATORlilya mohNo ratings yet

- Selection PresentationDocument15 pagesSelection PresentationSteve WanNo ratings yet

- Selection PresentationDocument15 pagesSelection PresentationlightsonsNo ratings yet

- ZEXEL test values for diesel fuel-injection equipment parametersDocument4 pagesZEXEL test values for diesel fuel-injection equipment parametersBest Auto TechNo ratings yet

- Technical Information Series F: Flow Control ValvesDocument4 pagesTechnical Information Series F: Flow Control ValvesAde Indra Wijaya100% (1)

- View GB Iguzzini.Document8 pagesView GB Iguzzini.Wellington Suzini Aquino JuniorNo ratings yet

- T Screamer DatasheetDocument6 pagesT Screamer DatasheetEugy AlexNo ratings yet

- 10.piping Material Combination: Material Pipe Bw-Fitting Sw-Fitting #3000 BAR Flange WRT Class Plate ApplicationDocument1 page10.piping Material Combination: Material Pipe Bw-Fitting Sw-Fitting #3000 BAR Flange WRT Class Plate ApplicationSangram patilNo ratings yet

- Valvula Mariposa FlowsealDocument12 pagesValvula Mariposa Flowsealsakura_jNo ratings yet

- Na 928 PDFDocument68 pagesNa 928 PDFTta EngineeringNo ratings yet

- Slab Gate Valves Api 6ADocument39 pagesSlab Gate Valves Api 6AJuan Pablo100% (1)

- Product Data: CH16NA 018 - 060 Single - Stage Heat Pump With Puronr RefrigerantDocument18 pagesProduct Data: CH16NA 018 - 060 Single - Stage Heat Pump With Puronr RefrigerantNguyen DuyNo ratings yet

- Champion Dual Disc Wafer Check ValvesDocument8 pagesChampion Dual Disc Wafer Check ValvesShanghai koko ValvesNo ratings yet

- FS&SF Havells PDFDocument6 pagesFS&SF Havells PDFSureshNo ratings yet

- Coupluing DataDocument72 pagesCoupluing DataMahesh PatilNo ratings yet

- DMP PDFDocument39 pagesDMP PDFberkahharianNo ratings yet

- Alternative Price List Usa DypartsDocument20 pagesAlternative Price List Usa DypartsMarcel BaqueNo ratings yet

- Spojki Za Doktorot Vo SolidworksDocument24 pagesSpojki Za Doktorot Vo SolidworksStamen KatardzievNo ratings yet

- K2000-Serie ENDocument1 pageK2000-Serie ENbala subramaniyam TSNo ratings yet

- Roklume 380 N: WorklightsDocument1 pageRoklume 380 N: WorklightsOrlando HuillcaNo ratings yet

- CATALOGO SELLOS ECONOMOS - SKFDocument6 pagesCATALOGO SELLOS ECONOMOS - SKFdani sanNo ratings yet

- Catalogue Pressure GaugeDocument2 pagesCatalogue Pressure GaugeSupriyaRongNo ratings yet

- Hfe Pioneer Sa-710 Service AddDocument10 pagesHfe Pioneer Sa-710 Service AddAlejandro AlarcoNo ratings yet

- Hfe Pioneer Sa-710 Service AddDocument10 pagesHfe Pioneer Sa-710 Service AddAlejandro AlarcoNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- Piping, Valves, and Material Specifications for KLB Wellhead Platform ModificationDocument3 pagesPiping, Valves, and Material Specifications for KLB Wellhead Platform ModificationAnatta RahardjoNo ratings yet

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)AliZenatiNo ratings yet

- Service Instruction 1037KDocument8 pagesService Instruction 1037KLuis AmayaNo ratings yet

- Service-Parts Wp2 Catalog 10-21-21Document9 pagesService-Parts Wp2 Catalog 10-21-21dilipNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Best Auto TechNo ratings yet

- Bremach T-REX Retail PricelistDocument6 pagesBremach T-REX Retail PricelistWolfwinter ArtrashNo ratings yet

- Submersible Pump: Model S8D1 E275Document2 pagesSubmersible Pump: Model S8D1 E275frank rodriguezNo ratings yet

- Affordable Aluminum Pressure Relief ValveDocument1 pageAffordable Aluminum Pressure Relief ValveANGEL STRAGLIATINo ratings yet

- Am Radio Kit: ElencoDocument12 pagesAm Radio Kit: ElencomJ vvelascoNo ratings yet

- LHGH EvaporadoresDocument12 pagesLHGH EvaporadoresluismozoNo ratings yet

- 02 Rubber HoseDocument26 pages02 Rubber HoseVilius BukysNo ratings yet

- Aqua SignalDocument17 pagesAqua SignalVilius BukysNo ratings yet

- Part No. Description Page No.: Packing (Section IX)Document32 pagesPart No. Description Page No.: Packing (Section IX)Vilius BukysNo ratings yet

- G7 Win Metadiag Manual ARES 806Document158 pagesG7 Win Metadiag Manual ARES 806Vilius BukysNo ratings yet

- Part No. Description Page No.: Couplings (Section VIII)Document28 pagesPart No. Description Page No.: Couplings (Section VIII)Vilius BukysNo ratings yet

- 06 PVC HoseDocument19 pages06 PVC HoseVilius BukysNo ratings yet

- Indexes (Section XIIDocument9 pagesIndexes (Section XIIVilius BukysNo ratings yet

- 11 Specialty EquipmentDocument35 pages11 Specialty EquipmentVilius BukysNo ratings yet

- ABB Motors LV For Hazardous AreaDocument78 pagesABB Motors LV For Hazardous AreaVilius BukysNo ratings yet

- 07 Hydraulic HoseDocument18 pages07 Hydraulic HoseVilius BukysNo ratings yet

- 03 Composite HoseDocument23 pages03 Composite HoseVilius BukysNo ratings yet

- Part No. Description Page No.: Charts (Section XI)Document7 pagesPart No. Description Page No.: Charts (Section XI)Vilius BukysNo ratings yet

- Stainless Steel Hose Technical Data SheetsDocument10 pagesStainless Steel Hose Technical Data SheetsVilius BukysNo ratings yet

- Ducting GuideDocument6 pagesDucting GuideVilius BukysNo ratings yet

- Accord International Requisition FormDocument1 pageAccord International Requisition FormVilius BukysNo ratings yet

- 01 Table of ContentsDocument1 page01 Table of ContentsVilius BukysNo ratings yet

- General Purpose Cast Iron Motors - Variant Codes: BalancingDocument3 pagesGeneral Purpose Cast Iron Motors - Variant Codes: BalancingVilius BukysNo ratings yet

- ABB Motors - General Purpose 3Document45 pagesABB Motors - General Purpose 3Vilius BukysNo ratings yet

- ABB Motors - General Purpose 2Document47 pagesABB Motors - General Purpose 2Vilius BukysNo ratings yet

- Manual MotoresDocument72 pagesManual Motoresmodelador3dNo ratings yet

- NEMA Motors - Manual PDFDocument20 pagesNEMA Motors - Manual PDFVilius BukysNo ratings yet

- ABB Motors For Hazardous AreaDocument104 pagesABB Motors For Hazardous AreaVilius BukysNo ratings yet

- IEC Low Voltage Induction Motors 460V 60 HZ PDFDocument32 pagesIEC Low Voltage Induction Motors 460V 60 HZ PDFPedro BortotNo ratings yet

- ABB Motor KatalogDocument28 pagesABB Motor KatalogKenneth Thoft AndersenNo ratings yet

- Table Comparing ISO 8217 and BS SpecsDocument1 pageTable Comparing ISO 8217 and BS SpecsVilius BukysNo ratings yet

- TB6588FG Usage Considerations: 1. Absolute Maximum RatingsDocument10 pagesTB6588FG Usage Considerations: 1. Absolute Maximum RatingsElton RibeiroNo ratings yet

- Catalogue Brushless DC Drives GB 02 2007Document56 pagesCatalogue Brushless DC Drives GB 02 2007Bianca CerveiraNo ratings yet

- Condition Monitoring System of Wind Generators Based On The Effect of Electrical Torque Pulsations and Generator TemperatureDocument8 pagesCondition Monitoring System of Wind Generators Based On The Effect of Electrical Torque Pulsations and Generator TemperatureKhaled AbdusamadNo ratings yet

- Lec # 25 Stepper Motor NDocument16 pagesLec # 25 Stepper Motor NBuriro HayatNo ratings yet

- Electro Masgnetic Propulsion SystemDocument2 pagesElectro Masgnetic Propulsion Systemfsilassie8012No ratings yet

- 3-Phase Induction Motor FundamentalsDocument26 pages3-Phase Induction Motor FundamentalsSOBIT KUMARNo ratings yet

- Machine Transformations: J. MccalleyDocument24 pagesMachine Transformations: J. MccalleymansoorNo ratings yet

- Motoranalyzer1: Universal Tester For Electric Motors and WindingsDocument8 pagesMotoranalyzer1: Universal Tester For Electric Motors and WindingsMohamedNo ratings yet

- Harvesting Energy With Hand-Crank Generators To Support Dismounted Soldier MissionsDocument9 pagesHarvesting Energy With Hand-Crank Generators To Support Dismounted Soldier MissionsAlexander J RokowetzNo ratings yet

- EE-260 Lecture 19 Synchronous Generators IntroductionDocument24 pagesEE-260 Lecture 19 Synchronous Generators IntroductionRehan BasharatNo ratings yet

- Lecture (SM Construction, Types and Operation)Document32 pagesLecture (SM Construction, Types and Operation)kyaw winNo ratings yet

- PEconverter Topologiesusedin EVsDocument80 pagesPEconverter Topologiesusedin EVsAnkit BhattNo ratings yet

- MT Series - ServiceDocument8 pagesMT Series - ServiceВаня БойкоNo ratings yet

- Concept of Sinusoidal Distributed Windings: Appendix ADocument9 pagesConcept of Sinusoidal Distributed Windings: Appendix ASarvasaisrinathNo ratings yet

- Suggested Answer PowerDocument60 pagesSuggested Answer Powerengineeraina2460100% (1)

- Pt C, Ch 2, Sec 4 Rotating MachinesDocument5 pagesPt C, Ch 2, Sec 4 Rotating MachinesJon LopezNo ratings yet

- A 2-D Model of The Induction Machine An Extension of The Modified Winding Function ApproachDocument7 pagesA 2-D Model of The Induction Machine An Extension of The Modified Winding Function ApproachFaiza OuiddirNo ratings yet

- Synchronous MotorsDocument25 pagesSynchronous MotorsParvesh NainNo ratings yet

- General X RayDocument185 pagesGeneral X RayEwicck WackwickwackwickNo ratings yet

- Electrical Actuation SystemDocument8 pagesElectrical Actuation SystemShriyash KamatNo ratings yet

- Slip Ring or Wound Rotor MotorsDocument12 pagesSlip Ring or Wound Rotor Motorskuwar_raiNo ratings yet

- Demostracion de Arranque Por Inversion de Polaridad PDFDocument3 pagesDemostracion de Arranque Por Inversion de Polaridad PDFAlejandro Roldan MolinaNo ratings yet

- Maintenance Manual: Rotary Valves RV-SDocument25 pagesMaintenance Manual: Rotary Valves RV-Saloknayak123No ratings yet

- Flyer TR Nrs NP 110315Document2 pagesFlyer TR Nrs NP 110315Le Thanh HaiNo ratings yet