Professional Documents

Culture Documents

1997 ASME DTM Eubanks

Uploaded by

Alper GmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1997 ASME DTM Eubanks

Uploaded by

Alper GmCopyright:

Available Formats

Proceedings of DETC‘97

1997 ASME Design Engineering Technical Conferences and

Design Theory and Methodology Conference

September 14-17, 1997, Sacramento, California

97-DETC/DTM-02

ADVANCED FAILURE MODES AND EFFECTS ANALYSIS

USING BEHAVIOR MODELING

Charles F. Eubanks

Steven Kmenta

Kosuke Ishii

Design Division

Mechanical Engineering Dept.

Stanford University

Stanford, CA

ABSTRACT generally not available until the detailed design stage. These

This paper presents a systematic method applicable at the reliability methods are useful, however, product development

early stages of design to enhance life-cycle quality of teams need to design in quality and reliability at the beginning

ownership: Advanced Failure Modes and Effect Analysis of conceptual design, before specific components are chosen.

(AFMEA). The proposed method uses behavior modeling to This paper proposes a method to address reliability during

simulate device operations and helps identify failure and the early stages of design, influencing both future design

customer dissatisfaction modes beyond component failures. decisions and quality during customer ownership. Advanced

The behavior model reasons about conditions that cause FMEA uses behavior modeling to link desired behaviors with

departures from normal operation and provides a framework the components, operating environment, and supporting

for analyzing the consequences of failures. The paper shows systems. Qualitative behavior simulation provides the

how Advanced FMEA applies readily to the early stages of framework for generating failure modes and their effects. Key

design and captures failure modes normally missed by elements required to develop this capability include:

conventional FMEA. The result is a systematic method capable

of capturing a wider range of failure modes and effects early in •a behavior model suitable for the early stages of design

the design cycle. An automatic ice maker from a domestic •a structural model suitable for the early stages of design

refrigerator serves as an illustrative example. •a framework linking these models

KEYWORDS: behavior modeling, FMEA, reliability •inferencing methods for evaluating effects of failures

1 INTRODUCTION The proposed method builds on preliminary work by

DiMarco, et al. (1995), showing an FMEA analysis could be

extracted from a fairly simple function-to-structure mapping,

1.1 Motivation

and extends the development of behavior modeling applied to

Rising demand for quality during customer ownership has

FMEA by Eubanks (1996) and Eubanks et al. (1996). This

provided the need for design for reliability and serviceability

paper discusses some advantages of behavior modeling over

(Makino, et al., 1989; Berzak, 1991; Eubanks & Ishii, 1993).

traditional functional analysis, and shows how Advanced

Probabilistic methods for reliability assessment have been a

FMEA can capture a wider range of failure modes compared to

mainstay of engineering systems development for many years

component-based FMEA. The paper will discuss the

(Levinson, 1964). Reliability methods focus on predicting

motivation for this new approach, an overview of behavior

availability and maintainability of complex systems based on

modeling, and the implementation of AFMEA on an automatic

mean time to failure (MTBF) and mean time to repair (MTTR)

ice maker as an illustrative example.

estimations for functional components or subsystems. Failure

rate and distribution data are obtained through component life

testing or generic failure rate distribution tables; information

1 Copyright © 1997 by ASME

1.2 Failure Modes and Effects Analysis 1.3 Our Approach

Design FMEA is a powerful preventative design method This paper describes a new approach for performing

generally based on MIL-STD-1629A (Department of Defense, advanced FMEA using behavior modeling of mechanical and

1980). FMEA helps increase reliability and safety by electro-mechanical devices. Guided by the function-structure

identifying sources of failures and prioritizing design solutions relationship, one can build a behavior model describing the

or appropriate testing. A common approach to FMEA is to state changes of design variables expected during normal

analyze failed or degraded components and identify causes and device operation. The model qualitatively simulates normal

effects. Unfortunately, detailed information on the constituent operation and analyzes the effects of failures in terms of the

components is available only after completion of layout design. resulting state of the system.

At this late stage, causes of failures identified by FMEA can be Section 2 establishes the theory behind behavior modeling

very expensive or impossible to correct. by defining behaviors, describing the device simulation, and

classifying failures. Section 3 describes the application of

1.2.1 Shortcomings of Traditional FMEA behavior modeling to AFMEA. Section 4 uses an automatic

While traditional component-based FMEA is effective for ice maker to illustrate how the behavior model captures failure

identifying failure modes related to components, our industry modes not identified using traditional approaches. The paper

collaborators have reported difficulty in identifying system- concludes with specific future activities to develop, formalize,

wide failure modes, such as problems with dependent systems, and validate AFMEA.

the operating environment, and customer usage. McKinney

(1991) lists some major deficiencies with FMEA: narrowness 2 BEHAVIOR MODELING AND FAILURE SIMULATION

of scope, lack of pertinence to operation and support of the

system, timeliness, and the “box-checking” nature of the 2.1 Basic Concepts

application. According to Kara-Zaitri et al. (1991) a major Behavior modeling has received considerable attention in

problem with FMEA is treating it as a perfunctory “checklist” the Artificial Intelligence (AI) and mechanical engineering

only to satisfy contractual agreements with customers. communities. Behavior knowledge forms the link between the

Stamatis (1996) emphasizes the need to apply FMEA at an functions, structure and state of a device through a behavior-

early, system level in order to effectively impact the design and structure modeling construct (Umeda, et al., 1990). Many AI

reliability of the device. Traditional FMEA could benefit from researchers use the concept of causal chains or networks that

a systematic approach capable of capturing a wider range of are derivable either from the functional description of a device

failure modes, applicable early in the design cycle. (Chandrasekaran et al., 1993), from its structure (Kuipers,

1984), or from qualitative physics (deKleer and Brown, 1984).

1.2.2 Structured Approaches to FMEA Our work builds primarily on Chandrasekaran’s functional

Several automated FMEA systems have been used to representation, Keuneke’s device modeling (1991), and

analyze electrical systems, since electrical faults and failures Iwasaki and Simon’s behavior modeling and simulation

lend themselves to simple characterization as numerical (1994).

quantities. Ormsby et al. (1991) developed a concept for Conventional design texts use functional decomposition as

automated FMEA employing qualitative reasoning in a model- an early conceptual design tool. The design team begins by

based environment as a means of making the analysis describing the overall function of the device and progressively

extensible to other domains. Montgomery et al. (1996) decomposing the required functions in order to manage and

proposed a computer simulation of failure modes and their understand the design (Suh, 1990: Ullman, 1992). A early

effects for electrical circuits, including qualitative simulation function block diagram for an ice maker is shown in Figure 1.

at the early stages.

In the mechanical engineering domain, Umeda et al. Freeze Water

(1992) used functional representations for diagnosis and self- Create Cubes

repair of a copy machine. Morjaria et al. (1992) have

developed diagnostic systems using belief reasoning from Create Cube Shape

Make Ice Cubes

symptom to failure in large industrial systems. Clark and

Paasch (1994) showed how function-to-structure mapping can

be used in the early stages of design to assess diagnosability by Harvest Cubes

measuring the ease of isolating the cause of a malfunction. .

Palumbo (1994) uses mode variables and behavioral logic to Figure 1: Function Block Diagram for Ice Maker

automate FMEA of an actuator control system.

We use the behavior model in a manner similar to a

functional model; as a tool to hierarchically decompose and

2 Copyright © 1997 by ASME

define the design. However, the behavior model provides more c) numerically: the flow rate increases to 0.033 m3/s

information since each behavior is mapped to a specified state d) mathematically: Q = vA m3/s

transition. Suppose one recognizes a need for ice cubes in a

The design proceeds with decisions about how the device

ice bucket of a household freezer, and defines a behavior called

is to achieve its desired behavior. For example, we can

“deposit ice cubes in bucket.” In addition to the behavior, one

decompose the behavior “deposit ice cubes in bucket” into two

can define the initial and final states for this behavior. The

sub-behaviors “b11: create ice cubes” and “b12: deposit ice

initial state is a description of a condition one wishes to

change, for example: cubes in bucket,” creating state transitions:

b

Initial state: no ice cubes in ice bucket S 1 11 → S12 (3)

b12

The condition that results from the behavior of the device S12 → S2

is the final state: (4)

Behavior modeling provides a more robust basis for

Desired final state: ice cubes in ice bucket

performing early design analysis for several reasons. First,

Keuneke (1989) uses the (<variable>, <value>) construct behaviors do not rely entirely on the physical structure of the

for representing state variables. We adapted this construct by device. Although the physical elements or components may

dividing the definition of a variable into an object with one or change as the design develops, general behaviors can be

more attributes, forming the (<object>, <attribute>, <value>) defined quite early. Therefore the AFMEA is applicable

triple where: regardless of the component mix and maturity of the design.

Second, behavior modeling can reflect the customer’s

<object> can be any physical or conceptual entity desired requirements and attributes and provide a basis for

<attribute> is a distinctive quality or characteristic of the assessing “customer dissatisfaction modes.” Finally, it

object provides a systematic framework for generating failure modes

<value> is a quantification of the object attribute with an increased scope of analysis. The behavior model

This construct allows the designer to define easily various analyzes the design in the context of its supporting systems to

intensive and extensive properties of materials, components capture a more comprehensive set of failure modes.

and systems. We note that a complete description of a device The specification of pre- and post-conditions builds

is represented by the set of all state variables. However, behavior paths through the model allowing us to determine the

dealing with complete sets of state variables can be behavior interactions and the failure propagation, i.e.,

cumbersome. Chandrasekaran et al. (1993) define a partial pathways for the inferencing strategies necessary to perform

state as the values of a relevant subset of the state variables. AFMEA. A mapping between the functions and the structure

We express the partial states S1 and S2 as: forms a link between the descriptions of the device operation

and the physical entities implementing those actions (Figure

S1 = {(ice bucket, ice cube level, empty)} (1) 2).

S2 = {(ice bucket, ice cube level, not empty)} (2)

The initial and final states are quasi-static, or quasi-steady

states. The states can be identified as existing at some instance

and may serve to trigger a behavior, for example:

(switch, position, closed)

(coil, status, energized)

(cam, position, 15°)

The designer can describe a behavior several ways,

depending on the level of abstraction:

a) verbally: cause a greater amount of water to flow

b) qualitatively: the flow rate increases

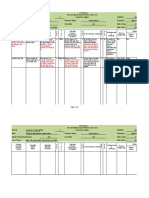

Table 1: Behavior Specification in Spreadsheet Form

Behavior Pre-condition Specification Post-condition Specification

index behavior type mapped to object attribute value object attribute value

1 deposit ice cubes in bucket desired ice maker ice bucket cube level not full ice bucket cube level full

freezer freezer temperature >8 & <15°F freezer temperature >8 & <15°F

3 Copyright © 1997 by ASME

functions structure

Step 4: Change the values in the list of current state

sense ice level

variables list to reflect the results of Step 3. This list

verify cube need close switch

represents the current partial state of the system.

activate harvest feeler arm

fill mold with water feeler arm ice cube level

Step 5: Repeat Steps 2-4 until the list of candidate behaviors

switch linkage

freeze water

sensor

from Step 2 is empty.

create cubes feeler arm switch

create nominal

deposit cubes

quality The behavior model considers failure modes as the

create nominal mold

in bucket geometry

ice creation inability to transition from an initial or intermediate state to

loosen ice in mold

freezer system system ice maker

. the desired final state, or, as the transition to an undesired

harvest cubes water delivery

remove ice from

mold

system

state. Consider two possible failures: 1) after successful

sense ice level

mold heating system ice harvesting creation of the cubes, the cubes are not deposited in the bucket;

system

verify bucket full open switch

ice harvesting system and 2) during operation, the freezer temperature rises above

de-activate harvest 32°F and remains at this level.

Failure 1 is a “non-behavior” failure since the device

Figure 2: Function-Structure Mapping remains in an expected intermediate state. Failure 2 is a

“failure behavior” which takes the system into an undesired

We can visualize a portion of the behavior model at any state to remain there until the failure is corrected. In this case,

hierarchical level by constructing a behavior fragment. The the conditions for maintaining freezer temperature have been

behavior fragment lists: the relevant initial state variables (pre- violated. We can map the failure cause to associated variables

conditions), an arrow representing the behavior, and the and systems, for example: supply power, cooling system,

relevant desired final state variables (post-conditions) and thermostat setting, freezer seal condition, external

structural elements responsible for executing the behavior are temperature, etc. In this way we can generate causes for the

listed below the behavior. Figure 3 shows an example of a failure mode by examining the requisite variables for the

behavior fragment of the high-level behavior “deposit ice cubes relevant behavior.

in bucket.” Note how the environment, in this case the freezer In addition, unwanted side effects, or misbehaviors can be

temperature, is accounted for in the pre- and post-conditions. defined as deviations from the voice of the customer, what we

behavior call the “negative VOC” (¬ VOC). For example, the customer

initial state deposit ice cubes desired final state prefers uniform sized cubes, translating into a desired post-

in bucket condition: (cube, size, equal). A side effect resulting in a

(ice bucket, cube level, not full) (ice bucket, cube level, full) “customer dissatisfaction mode” would be any behavior

(freezer, temp., >8 AND <15F) (freezer, temp., >8 AND <15 F) resulting in a final state other than (cube, size, equal). The

ice maker

same approach can identify violations in other performance

.

requirements such as noise, external heat gain, high power

Figure 3: Behavior-Structure Fragment consumption, etc. These represent side-effects, largely

unanticipated during design, that adversely impact the user’s

The modeling information can be placed in spreadsheet perception of the device even when the device still performs its

form as shown in Table 1. basic functions.

Thus, we define failure as a condition where the achieved

2.2 Behavior Simulation final state of a behavior does not match the desired final state.

Behavior simulation methods are established in the areas Similarly, we define misbehaviors as side-effects that result in

of diagnosis (Hamscher et al., 1992), design verification an annoyance or shortcoming in the eyes of the user, even

(Iwasaki & Chandrasekaran, 1992), and redesign (Goel & though the device successfully achieves the desired final state.

Chandrasekaran, 1989). The following algorithm draws on Section 3 elaborates on types of failures identified by the

the method described by Iwasaki and Low (1991). behavior model and Section 4 gives examples of each type of

failure.

Step 1: Determine the initial values for all state variables

based on the model definition and the user inputs, 3 APPLYING BEHAVIOR MODELING TO AFMEA

and list them as the current state.

This section outlines the procedure for building the

Step 2: Compile a list of candidate behaviors having current behavior model, simulating device operation, and identifying

state variable values as initial conditions, allowing failure modes. The general procedure for Advanced FMEA is

decomposition of behaviors to subsume parent shown in Figure 4.

behaviors.

Step 3: Execute the candidate behaviors by determining the

values of the state variables after the behavior’s

occurrence.

4 Copyright © 1997 by ASME

Table 2: Ice Maker: Ice Creation Behavior Model

Behavior Pre-condition Specification Post-condition Specification

index behavior type mapped to object attribute value object attribute value

1 deposit cubes in bucket desired ice maker ice bucket cube level not full ice bucket cube level full

freezer freezer temperature >8 & <15°F freezer temperature >8 & <15°F

1.1 verify cube need desired cube level sensor ice maker harvesting status inactive ice maker harvesting active

ice bucket cube level not full

1.2 create cubes desired mold mold ice cubes present no mold ice present yes

1.3 harvest cubes desired mold mold ice cubes present yes mold ice present no

ice bucket ice bucket cube level not full ice bucket cube level full

ice maker ice maker harvesting status active

1.4 de-activate harvest desired ice maker ice maker harvesting status active ice maker harvesting inactive

ice bucket ice bucket cube level full

Table 3: Decomposition of Behavior: Create Cubes

Behavior Pre-condition Specification Post-condition Specification

index behavior type mapped to object attribute value object attribute value

1.2 create cubes desired ice creation system mold ice cubes present no mold ice cubes present yes

1.2.1 fill mold with water desired water delivery system mold water level none mold water level full

mold mold ice cubes present no

1.2.2 freeze water desired freezer system water state liquid water state solid

mold freezer temperature <32°F mold ice cubes present yes

mold water level full

Customer Requirements

Identification

3.1 Procedure for Using the Behavior Model

Voice of the Customer (VOC)

We begin by looking at the key quality characteristics

V

which the device must deliver. Quality Function Deployment

Quality Function

Deployment (QFD)

O

C

(QFD) helps identify these attributes (Hauser and Clausing,

1985.) Performing QFD first is especially useful, since it both

identifies customer requirements, and relates the VOC to the

Function - Structure Functions Structure

Mapping engineering metrics and functional requirements responsible

for satisfying the customer.

Behavior Model

Constructing the behavior model for a system is similar to

Simulation

traditional functional decomposition. We start by looking at

the overall behavior of the device, then assign variable

Failure Modes attributes that identify how the system affects input and output

Identification

not(functions):

parameters. The design team examines the overall behavior

-- non-behaviors and decomposes it into sub-behaviors and assigns the

-- failure behaviors

side effects appropriate pre- and post-condition state variables. For

example, we can use input parameters and output requirements

Evaluate

for the ice maker in spreadsheet form as shown in Table 2.

FMEA table

Recommend Table 3 shows an example of decomposition of the behavior

“create cubes.”

AFMEA

3.2 Types of Failure Modes

Through qualitative simulation, the behavior model

Figure 4: Flow Chart of the AFMEA Process generates three types of failure modes: non-behaviors,

undesired behaviors, and misbehaviors.

5 Copyright © 1997 by ASME

Although we are applying AFMEA to a mature design

3.2.1 Non-behavior Failures rather than a conceptual design, the approach we take is from

While following the modeling steps given in Section 2, we a high, abstract level. We begin from the general behavior

select a behavior for investigation, consider it not to occur, and “deposit ice cubes in bucket,” and decompose the behavioral

simulate how the system responds. Once the simulation description so we can relate behaviors to general structural

process is complete, we compare the list of resulting final state elements and other systems. AFMEA applies to any

variable values with the list of desired values to indicate which hierarchical level of the behavior model, and the further the

system or component failed. decomposition progresses, the closer the behaviors map to

specific components and systems. Thus AFMEA can be

3.2.2 Undesired Behavior Failures initiated during the early design stages and updated and

In addition to failures due to non-behaviors, one may extended as the design develops.

define failure behaviors and associated state variables

corresponding to failure modes. It is important that we 4.1 Undesired Behavior Example

identify failure behaviors, as they will affect the flow of the Some problems with the ice maker are less-than-obvious

simulation algorithm. When a failure behavior appears as a failure modes, completely ignored by the component-based

candidate for execution, we execute the failure behavior only, FMEA. For example, the designers decided to use water

and recompile the list of candidate behaviors. Failure volume for the cube mold is set by adjusting the fill time

behaviors result in state variable values that generally assuming a standard water line pressure. The total fill volume

eliminate one or more desired candidates. expressed as a function of time is:

2p

3.2.3 Misbehavior Failures V= At (5)

ρ

We define misbehaviors and incorporate them into the

behavior model. Misbehaviors do not affect the flow of the where: V = volume

simulation algorithm since they do not affect the behavior

path. When a misbehavior appears as a candidate, we execute p = pressure

it first, then check the list of candidate behaviors to see if it ρ = density

remains the same, minus the misbehavior. If the list of desired A = cross-sectional area

candidate behaviors has changed, then the misbehavior has

been improperly defined. t = time

The fill time is set to 7 seconds, providing water volume of

4 VALIDATION EXAMPLE: ICE MAKER 190 cc ± 10 cc using 6.35 mm tubing and nominal water

This section illustrates specific examples of failure modes pressure of 138 kPa ± 14 kPa. Consequently, over-fill and

as they relate to the operation of an automatic ice maker. The under-fill failures occur when pressure is above or below

ice maker used in this example is shown in Figure 5. nominal conditions, respectively. Table 4 describes the filling

of the mold with water, decomposed into two sub-behaviors.

Figure 5: Ice Maker

6 Copyright © 1997 by ASME

By changing the expected pre-conditions for the “fill suspect components: thermostat

mold” behavior (e.g. water pressure) we can define failure Resulted in deviation:

behaviors from the undesired pre-conditions. We define two not(ice bucket, cube level, full) resulting from:

failure behaviors representing the under-fill and over-fill not(b1.3: harvest cubes)

conditions. Undesired behaviors create pre-conditions which not(mold, ice cubes present, no) resulting from:

can enable subsequent undesired behaviors, such as spillage in not(b1.3: harvest cubes)

the case of an over-fill, or small ice cubes in the case of an

under-fill. 4.3 Misbehavior Failure Example

Slight misalignment of the ice maker causes variations in

4.2 Non-behavior Failure Example the sizes of the ice but does not otherwise affect the operation

Failure modes can be captured by examining non- of the ice maker. We term this type of discrepancy a

behaviors of the system, for example, a thermostat that fails to misbehavior or side effect. To ensure an even fill of the mold,

close when prescribed. The analysis appears as follows: the ice maker must tilt two degrees forward with respect to the

refrigerator cabinet, and manufacturing takes special

Failure mode: not (b1.3.1.1.1: thermostat closes) precautions to meet this requirement. However, suppose the

suspect components: thermostat refrigerator is not leveled properly with respect to the floor

Resulted in deviation: during installation.

not(ice bucket, cube level, full) resulting from: Slight misalignments only cause the side effect of non-

not (b1.3.2.4: ejector pushes ice)

uniform cube size. A severe backward tilt results in shallow

not (mold, ice cubes present, no) resulting from: water level in the mold end nearest the thermostat, which

not (b1.3.2.4: ejector pushes ice)

freezes earlier than the deeper water at the opposite end of the

not (mold, water level, empty) resulting from: mold. The shallow frozen cubes trigger the thermostat and

not (b1.3.2.4: ejector pushes ice)

initiates the harvest cycle, resulting in a mixture of small cubes

not(mold, temperature, >32°) resulting from: and partially frozen cubes in the collection bucket.

not(b1.3.1.1.4: heater heats mold) If the tilt is severe enough, the larger cubes break when

Note: the subscripts indicate the level of behavioral deposited, spilling water in the collection bucket and fusing the

decompostion consistent with table 2; a period is added for cubes together. This failure is not associated with the ice

each indenture of decomposition. The list of non-behaviors is maker components or refrigerator. It is caused by an

generated by searching for discrepancies at the lowest levels of interaction with an external factor: alignment of the

abstraction. In terms of FMEA, we have generated the “local” refrigerator to the floor. A component-based FMEA would

effects. Next, we generate the “end” effects by investigating consider this to be outside the scope of the ice maker and its

the effects of the non-behavior on top level behaviors. For this components, however, this failure mode directly affects the

example, the end effect is the behavior “harvest cubes” quality of the ice cubes. Table 5 describes the effects of

behavior does not occur: misalignment as two misbehaviors and a failure behavior,

depending on the orientation and severity of the tilt.

Failure mode: not(b1.3.1.1.1: thermostat closes)

Table 4: Mold Fill Behavior Decomposition

Behavior Pre-condition Specification Post-condition Specification

index behavior type mapped to object attribute value object attribute value

1.2.1.3 fill mold desired water tube mold water level empty mold water level full

cup mold ice cubes present no

water water valve status open

water pressure <p>

1.2.1.3.1 convey water to mold desired fill switch water pressure <p> water fill volume 6.06*sqrt(p)*t

water fill switch time setting <t>

mold water level empty

mold ice cubes present no

water valve status open

1.2.1.3.2 fill mold to proper level desired water water fill volume ³180 & ²200 cc mold water level full

7 Copyright © 1997 by ASME

Table 5: Ice Maker - Alignment Misbehavior and Failure Behaviors

Behavior Pre-condition Specification Post-condition Specification

index behavior type mapped to object attribute value object attribute value

1.2.1.5m misalignment and uneven cubes misbehavior ice maker ice maker alignment >-9° AND < -4° ice cubes size non-uniform

refrigerator

1.2.1.5m misalignment and uneven cubes misbehavior ice maker ice maker alignment >0° AND <5° ice cubes size non-uniform

refrigerator

1.2.1.5.1f misalignment and hollow cubes failure ice maker ice maker alignment ³ 5° ice cubes size non-uniform

refrigerator

AFMEA is that it can be initiated much earlier in the design

4.4 Capturing More Failure Modes phase by assessing failure modes associated with high-level

AFMEA can capture a richer set of failure modes than functions and behaviors. The logical next step is to apply

traditional FMEA using the increased scope of the behavior AFMEA to a conceptual design as it develops, and future

model and analyzing many variables contributing to the applications of AFMEA to conceptual designs are discussed in

system’s function. While component failures are identified the next section.

using AFMEA, many other failure modes are addressed which

do not necessarily relate to components. These undesired 5 CONCLUSIONS AND FUTURE WORK

behaviors are found when analyzing the interaction with other This paper presented a new method for performing FMEA

mechanical, hydraulic, and electrical interfaces such as based on a device behavior model, allowing designers to

collection bucket placement, incoming water pressure, or address ownership quality at the early stages of conceptual

supply power. In addition, undesired behaviors are identified design more effectively. Using an automatic ice maker as an

by accounting for the device’s interaction with the example, the paper demonstrated how AFMEA can capture

environment, for example, freezer temperature or alignment. failures normally missed by traditional component-based

The ice maker example shows that we can obtain insight into FMEA by defining cause-and-effect relationships between

the operation of any subsystem by “violating” nominal system-wide design variables, environmental interaction, and

operating parameters. Table 6 illustrates failure modes sub-system quality measures. The result is a systematic

identified using AFMEA, providing a more comprehensive method capable of capturing a wider range of system failure

analysis of the system’s reliability at an earlier point in time. modes and effects early in the design cycle.

We are currently applying AFMEA to the development of

Table 6: Comparison of Failure Modes Captured by a new combined cycle power generation system, well before

FMEA vs. AFMEA the design of the plant and its central systems are finalized.

Applying AFMEA to a complex conceptual design helps to

refine the procedure and validate the approach as a design tool

Failure Mode FMEA AFMEA at the conceptual stage.

thermostat failure yes yes Many challenges lie ahead in the development of the

behavior model for advanced FMEA. A major challenge is to

water switch failure yes yes address failure modes in transition situations, for instance,

feeler arm damaged yes yes during the start-up of a power plant. Many failure modes

power cord disconnect yes yes occur when transitioning from one quasi steady-state mode to

high/low water pressure no yes another through a sequence of specified behaviors, what we

refer as meta-behaviors (Figure 6).

bucket misplacement no yes

refrigerator misalignment no yes

iced gears no yes Transitory Behavior Meta-behaviors

Models

high freezer temperature no yes Behavior Model A Behavior Model B Behavior Model C

mode I mode II mode III

.

This comparison was conducted between the original .

design FMEA for the ice maker and the failure modes captured

using AFMEA and the behavior model. In order to compare Figure 6: Meta-behaviors Describing Transition of

our approach to a component-based FMEA, we needed to Operational Modes

analyze a complete and detailed design. The advantage of

8 Copyright © 1997 by ASME

Using meta-behaviors we can model operations of a International Computers in Engineering Conference (CIE

system structure that causes its functional constructs to change; ‘95), Boston, MA, pp. 833-840.

that is, the function to structure mapping changes. Extending Eubanks, C. and K. Ishii (1993), “AI Methods for Life-cycle

the behavioral model to include failure modes associated with Serviceability Design of Mechanical Systems,” Artificial

non-steady state event would address, for example, sequences Intelligence, 8(2), pp. 127-140.

of switch actuation, valve operations, and sensor errors. Thus, Eubanks, C. F. (1996), "A Framework for Computer-based

meta-behavior modeling and simulation should provide the Failure Modes and Effects Analysis of Mechanical

foundation for applying AFMEA to transient operations. By Systems in the Conceptual Design Phase," Ph.D. Thesis,

focusing on behavioral transition during start-up and shut Graduate School, The Ohio State University, December,

down sequencing we can directly impact design of controls and 1996.

monitoring systems. Such an extension would complement the Eubanks, C., S. Kmenta, and K. Ishii (1996), "System

quasi-steady state or “in-mode” AFMEA described in this Behavior Modeling as a Basis for Advanced Failure

paper. Modes and Effects Analysis," ASME Computers In

Specific future activities are planned to develop further Engineering Conference, Sept. 1996, Irvine, CA.

and validate the AFMEA procedure. While continuing to Goel, A. and B. Chandrasekaran (1989), “Functional

apply AFMEA to the conceptual design of a new power Representation of Designs and Redesign Problem

generation system, Stanford's ME217 graduate life-cycle Solving,” Proc. of the 11th Int’l Joint Conf. on Artificial

design course will serve as a test-bed for AFMEA. Student Intelligence, Detroit, MI, pp. 1388-1394.

teams will use AFMEA for reliability-related industry Hamscher, W., L. Console, and de Kleer, J. (eds.) (1992),

sponsored projects and both project teams and industrial Readings in Model-based Diagnosis, Morgan Kaufmann

associates will provide feedback on the approach. Our Publishers, San Mateo, CA.

continued collaboration with Stanford Linear Accelerator Hauser, J., and D. Clausing (1985)."The House of Quality,"

(SLAC) presents an additional opportunity to use AFMEA on Harvard Business Review, May-June, pp. 63-73.

the design of the next generation linear collider. Iwasaki, Y. and B. Chandrasekaran (1992), “Design

Verification Through Function- and Behavior-Oriented

ACKNOWLEDGMENTS Representations,” Artificial Intelligence in Engineering

This research was funded by General Electric and the Design (J. Gero, ed.), Kluwer Academic Publishers,

National Science Foundation. The authors would like to Boston, pp. 597-616.

express sincere appreciation to Dr. Mahesh Morjaria for his Iwasaki, Y and C. Low (1991), "Model Generation and

continued support in the development of the behavior model, Simulation of Device Behavior with Continuous and

and to Dr. Harindra Rajiyah for his valuable feedback on the Discrete Changes," Knowledge Systems Laboratory Report

implementation of Advanced FMEA. No. KSL 91-69, Dept. of Computer Science, Stanford

University, November, 1991.

Iwasaki, Y. and H. Simon (1994), “Causality and Model

REFERENCES Extraction,” Artificial Intelligence, Kluwer Academic

Publishers, Boston, pp. 597-616.

Berzak, N. (1991), “Serviceability by Design,” Proc. of the Kara-Zaitri, C., Keller, A., Barody, I., and Fleming, P., "An

23rd Int’l SAMPE Technical Conference, October 21-24, Improved FMEA Methodology," Proceedings of the 1991

1991, pp. 1060-1071. IEEE Annual Reliability and Maintainability Symposium,

Clark, G. and R. Paasch (1994), "Diagnostic Modeling and pp. 248-252.

Diagnosability Evaluation of Mechanical Systems," Proc. Keuneke, A. (1991), “Device Representation: The Significance

of the ASME 6th International Conference on Design of Functional Knowledge,” IEEE Expert, vol. 6, no. 2,

Theory and Methodology (DTM '94), Minneapolis, MN, April, 1991, pp. 22-25.

pp. 179-189. Kuipers, B. (1984), “Commonsense Reasoning About

Chandrasekaran, B., A. Goel, and Y. Iwasaki (1993), Causality: Deriving Behavior from Structure,” Artificial

“Functional Representation as a Basis for Design Intelligence, 24(3), pp. 169-203.

Rationale,” IEEE Computer, 26(1):48-56, January, 1993. Levinson, C. (1964), "System Reliability Analysis,"

deKleer, J. and J. Brown (1984), “A Qualitative Physics Based Mechanical Design and Systems Handbook, (H. Rothbart,

on Confluences,” Artificial Intelligence, 24(3), pp. 7-83. ed.) McGraw-Hill, Inc., New York.

Department of Defense (1980), "MIL-STD-1629A: Procedures Makino, A., P. Barkan, L. Reynolds and E. Pfaff (1989), “A

for Performing a Failure Mode, Effects and Criticality Design for Serviceability Expert System,” Proc. of the

Analysis," November 24, 1980, Washington, DC. ASME Winter Annual Meeting 1989, San Francisco, CA,

Di Marco, P., C. Eubanks and K. Ishii (1995), “Service Modes pp. 213-218.

and Effect Analysis: Integration of Failure Analysis and

Serviceability Design,” Proc. of the 15th Annual

9 Copyright © 1997 by ASME

McKinney, B. (1991), "FMECA, The Right Way," Proceedings Palumbo, D. (1994) "Automating Failure Modes and Effects

of the 1991 IEEE Annual Reliability and Maintainability Analysis," Proceedings of the 1994 IEEE Annual

Symposium, pp. 253-259. Reliability and Maintainability Symposium, pp. 304-309.

Montgomery, T., Pugh, D., Leedham, S. and Twitchett, S. Stamatis, D. (1996), Failure Mode and Effect Analysis, ASQC

(1996), "FMEA Automation for the Complete Design Quality Press, Milwaukee, 1996.

Process," Proceedings of the 1996 IEEE Annual Suh, N. (1990), The Principles of Design, Oxford University

Reliability and Maintainability Symposium, pp. 30-36. Press, New York, 1990.

Morjaria, M., M. Simmons, J. Stillman (1992), "Development Ullman, D. (1992), The Mechanical Design Process, McGraw-

of Belief Networks Technology for Diagnostic Systems," Hill, Inc., New York.

General Electric Corporate Research and Development Umeda, Y., T. Tomiyama, Y. Yoshikawa (1992), "A Design

Technical Information Series, GE CR&D, Schenectady, Methodology for a Self-Maintenance Machine Based on

NY, April, 1992, 35 pages. Functional Redundancy," Proc. of the 4th Int'l. Conference

Ormsby, A., J. Hunt, M. Lee (1991), Towards an Automated on Design Theory and Methodology, Scottsdale, AZ, pp.

FMEA Assistant, Applications of Artificial Intelligence in 317-324.

Engineering VI, eds. Rzevski, G. and Adey, R.,

Computational Mechanics Publications, Southampton,

Boston, pp. 739-752.

10 Copyright © 1997 by ASME

You might also like

- 1998 ASME CIE KmentaDocument9 pages1998 ASME CIE KmentaAlper GmNo ratings yet

- FMEA For Manufacturing and Assembly Process: VJTI, Mumbai Siemens LTD., MumbaiDocument9 pagesFMEA For Manufacturing and Assembly Process: VJTI, Mumbai Siemens LTD., MumbaiKevin JordanNo ratings yet

- Modelling and Reasoning For Failure Modes and e Ects Analysis GenerationDocument12 pagesModelling and Reasoning For Failure Modes and e Ects Analysis GenerationAlper GmNo ratings yet

- An Evaluation of Failure Modes and Effects Analysis Generation Method For Conceptual DesignDocument15 pagesAn Evaluation of Failure Modes and Effects Analysis Generation Method For Conceptual DesignAlper GmNo ratings yet

- Chapter No. 1: 1.1 Problem Statement (FMEA) Failure Mode Effect Analysis of Welding Defects of Beam AssemblyDocument27 pagesChapter No. 1: 1.1 Problem Statement (FMEA) Failure Mode Effect Analysis of Welding Defects of Beam AssemblyharshalNo ratings yet

- Reliability Analysis Techniques For Aircraft CertificationDocument5 pagesReliability Analysis Techniques For Aircraft Certificationsezgin bayramNo ratings yet

- Failure Mode and Effect Analysis (FMEA) Implementation: A Literature ReviewDocument17 pagesFailure Mode and Effect Analysis (FMEA) Implementation: A Literature ReviewAdvanced Research PublicationsNo ratings yet

- 2018-Chih-Chung Chiu, Kuo-Sui Lin-A New Design Review Method For Functional Safety of Automotive Electrical SystemsDocument9 pages2018-Chih-Chung Chiu, Kuo-Sui Lin-A New Design Review Method For Functional Safety of Automotive Electrical SystemsAde Hikma TianaNo ratings yet

- Systematic Failure Mode Effect Analysis (FMEA) Using Fuzzy Linguistic ModellingDocument19 pagesSystematic Failure Mode Effect Analysis (FMEA) Using Fuzzy Linguistic ModellingSri Susilawati IslamNo ratings yet

- Recent Advancements in Aircraft Engine Health Management (EHM) Technologies and Recommendations For The Next StepDocument13 pagesRecent Advancements in Aircraft Engine Health Management (EHM) Technologies and Recommendations For The Next StepDanu MamlukatNo ratings yet

- Paper Advanced Failure Modes and Effects Analysis of Complex ProcessesDocument9 pagesPaper Advanced Failure Modes and Effects Analysis of Complex ProcessesGaetano Grana ScebbaNo ratings yet

- The Small Sample Failure Distribution Model of Diesel Engine Component Parts Using The FMECA ApproachDocument5 pagesThe Small Sample Failure Distribution Model of Diesel Engine Component Parts Using The FMECA ApproachRobbin GajadinNo ratings yet

- FMEA For Manufacturing and Assembly ProcessDocument9 pagesFMEA For Manufacturing and Assembly ProcessAsep SuryanaNo ratings yet

- Online Fault Detection for Wind Energy ConvertersDocument6 pagesOnline Fault Detection for Wind Energy ConvertersmruizbarriosNo ratings yet

- Failure Mode and Effects Analysis of A Process of Reflow Lead-Free SolderingDocument5 pagesFailure Mode and Effects Analysis of A Process of Reflow Lead-Free SolderingSRIDHAREEE61No ratings yet

- Modeling and Simulation For System Reliability Analysis: The RAMSAS MethodDocument7 pagesModeling and Simulation For System Reliability Analysis: The RAMSAS MethodDirceu NascimentoNo ratings yet

- A Systems Approach To The Development and Use of FMEA in Complex Automotive ApplicationsDocument11 pagesA Systems Approach To The Development and Use of FMEA in Complex Automotive ApplicationsArun BNo ratings yet

- Failure Analysis in Subsystem Design For Space MissionsDocument17 pagesFailure Analysis in Subsystem Design For Space Missionscary01No ratings yet

- A Model-Based Approach For Reliability Assessment in Component-Based SystemsDocument10 pagesA Model-Based Approach For Reliability Assessment in Component-Based SystemsKenneth AustinNo ratings yet

- Failure Mode and Effects AnalysisDocument10 pagesFailure Mode and Effects Analysisசரவணகுமார் மாரியப்பன்No ratings yet

- FMEA Boiler TubeDocument8 pagesFMEA Boiler TubeRituraj SinghNo ratings yet

- Analyse reliability of mechatronic systems using qualitative and quantitative approachesDocument16 pagesAnalyse reliability of mechatronic systems using qualitative and quantitative approachesRubenNo ratings yet

- Failure Mode and Effects Analysis (FMEA)Document17 pagesFailure Mode and Effects Analysis (FMEA)DME100% (1)

- FMEA MaterialDocument18 pagesFMEA MaterialKarthi ThiyagarajanNo ratings yet

- 10-1108 13552541311292682Document9 pages10-1108 13552541311292682Anonymous WoQ39NhNo ratings yet

- Application of DFMEA in Metal To PlasticDocument5 pagesApplication of DFMEA in Metal To PlasticposttopictomotiveNo ratings yet

- ACTIVIDAD1 - Practical Aspects of The Application of RCMDocument10 pagesACTIVIDAD1 - Practical Aspects of The Application of RCMeduardoperez.uniNo ratings yet

- NASA Apollo FMEADocument37 pagesNASA Apollo FMEAPaul Marshall50% (2)

- Failure Mode Effects & Criticality Analysis Workshop by TetrahedronDocument2 pagesFailure Mode Effects & Criticality Analysis Workshop by TetrahedrontetrahedronNo ratings yet

- FMEA CostDocument6 pagesFMEA CostNhan HuynhNo ratings yet

- Expert Systems With Applications: Sohag KabirDocument22 pagesExpert Systems With Applications: Sohag KabirAyşenur SancakNo ratings yet

- Ahpmaintenance3 ADocument12 pagesAhpmaintenance3 AJ.ReyesNo ratings yet

- FMEADocument12 pagesFMEAnitsugaeugeneNo ratings yet

- FMEA A Life Cycle Cost PerspectiveDocument11 pagesFMEA A Life Cycle Cost Perspectivearkaprava ghoshNo ratings yet

- MECHATRONIC BALL ON PLATE SYSTEMDocument6 pagesMECHATRONIC BALL ON PLATE SYSTEMCarlos Luis Ramos GarcíaNo ratings yet

- Integrated Approach Design Manufacturing: Simulation FlexibleDocument6 pagesIntegrated Approach Design Manufacturing: Simulation FlexibleDegaga KebedeNo ratings yet

- Failure Mode and Effects AnalysisDocument10 pagesFailure Mode and Effects AnalysisRahayu MekarNo ratings yet

- Integrating Reliability, Availability, and Maintainability Issues For Analyzing Failures in Fuel Injection PumpDocument15 pagesIntegrating Reliability, Availability, and Maintainability Issues For Analyzing Failures in Fuel Injection PumppabloNo ratings yet

- AvailabilityDocument9 pagesAvailabilityMuhd Fadzlee ZNo ratings yet

- UAV Model-Based Flight Control With Artificial Neural - SurveyDocument23 pagesUAV Model-Based Flight Control With Artificial Neural - Surveywovaj97072No ratings yet

- Vibrational Diagnostics of Rotating MachineryDocument31 pagesVibrational Diagnostics of Rotating Machineryhuliplay100% (1)

- 4207 APM Strategy RCM FMEA Course BrochureDocument2 pages4207 APM Strategy RCM FMEA Course Brochurenadal.shahidNo ratings yet

- A Framework For Intelligent Reliability Centered Maintenance AnalysisDocument9 pagesA Framework For Intelligent Reliability Centered Maintenance AnalysisErick Huaman LongobardiNo ratings yet

- Failure Mode and Effects Analysis - WikipediaDocument12 pagesFailure Mode and Effects Analysis - WikipediaNikhil PatidarNo ratings yet

- 4559 (7) System Analysis FMECADocument59 pages4559 (7) System Analysis FMECAMonika Yuliana Butar-ButarNo ratings yet

- Improve System Reliability with FMEADocument11 pagesImprove System Reliability with FMEAВладимир МалићNo ratings yet

- Hybrid Palm Oil Mills Maintenance SystemDocument10 pagesHybrid Palm Oil Mills Maintenance SystemwanameiNo ratings yet

- Computer-Aided Engineering (CAE) Is The Broad Usage of ComputerDocument4 pagesComputer-Aided Engineering (CAE) Is The Broad Usage of ComputerDavid AlexNo ratings yet

- FEMCADDocument5 pagesFEMCADdaabhiNo ratings yet

- Failure Mode and Effects Analysis of A Process of Reflow Lead-Free SolderingDocument5 pagesFailure Mode and Effects Analysis of A Process of Reflow Lead-Free SolderingMadan PrakashNo ratings yet

- An Integrated Approach To Bearing Fault Diagnostics and PrognosticsDocument6 pagesAn Integrated Approach To Bearing Fault Diagnostics and PrognosticsAaini AkashNo ratings yet

- 0026 2714 (86) 90542 1Document1 page0026 2714 (86) 90542 1Jitendra PanthiNo ratings yet

- MSC Software Product rangeDocument9 pagesMSC Software Product rangekarthikgap2No ratings yet

- 2018 ICPE Smart CPSDocument4 pages2018 ICPE Smart CPSJosé Manuel Ortiz RodriguezNo ratings yet

- EIE325 Course on Engineering Software PackagesDocument11 pagesEIE325 Course on Engineering Software PackagesnyenookeNo ratings yet

- Application of Fmea Method in A Manufacturing Organization Focused On QualityDocument7 pagesApplication of Fmea Method in A Manufacturing Organization Focused On QualityRudra DasNo ratings yet

- Foc FmeaDocument6 pagesFoc FmeaShimon PopaNo ratings yet

- Effective Measurements For Structural Dynamics TestingDocument12 pagesEffective Measurements For Structural Dynamics TestingAdeoti OladapoNo ratings yet

- Expert Systems with Applications Evaluating System Integration ProjectsDocument14 pagesExpert Systems with Applications Evaluating System Integration ProjectsRoseRose7No ratings yet

- Understanding Customer Requirements: Principles of DesignDocument30 pagesUnderstanding Customer Requirements: Principles of DesignAlper GmNo ratings yet

- Apqp - CP - QFD: Dvanced Roduct Uality Lanning Ontrol Lan Uality Unction EploymentDocument11 pagesApqp - CP - QFD: Dvanced Roduct Uality Lanning Ontrol Lan Uality Unction EploymentAlper GmNo ratings yet

- Understandinng Customer Requirements: Principles of DesignDocument30 pagesUnderstandinng Customer Requirements: Principles of DesignAlper GmNo ratings yet

- 5-s PrinciplesDocument5 pages5-s PrinciplesSasi KumarNo ratings yet

- Using 5-Step Workplace Management For Continuous ImprovementDocument3 pagesUsing 5-Step Workplace Management For Continuous ImprovementAlper GmNo ratings yet

- Apqp - CP - QFD: Dvanced Roduct Uality Lanning Ontrol Lan Uality Unction EploymentDocument11 pagesApqp - CP - QFD: Dvanced Roduct Uality Lanning Ontrol Lan Uality Unction EploymentAlper GmNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document18 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Alper GmNo ratings yet

- FmeatemplateDocument3 pagesFmeatemplateAyman AliNo ratings yet

- Using 5-Step Workplace Management For Continuous ImprovementDocument3 pagesUsing 5-Step Workplace Management For Continuous ImprovementAlper GmNo ratings yet

- Team: Project: Responsible: Manager: Product: Control Methods Failure Mode Prevention ControlDocument8 pagesTeam: Project: Responsible: Manager: Product: Control Methods Failure Mode Prevention ControlAlper GmNo ratings yet

- Product / Part: Team: Project: Engineer: Manager:: Process Functions Requirement Effects Causes Failure ModeDocument10 pagesProduct / Part: Team: Project: Engineer: Manager:: Process Functions Requirement Effects Causes Failure ModeAlper GmNo ratings yet

- Using 5-Step Workplace Management For Continuous ImprovementDocument3 pagesUsing 5-Step Workplace Management For Continuous ImprovementAlper GmNo ratings yet

- FmeatemplateDocument3 pagesFmeatemplateAyman AliNo ratings yet

- Design and Process FMEA GuideDocument4 pagesDesign and Process FMEA GuideAlper GmNo ratings yet

- Failure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleDocument1 pageFailure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleAlper GmNo ratings yet

- Paper Advanced Failure Modes and Effects Analysis of Complex ProcessesDocument9 pagesPaper Advanced Failure Modes and Effects Analysis of Complex ProcessesGaetano Grana ScebbaNo ratings yet

- Sikaflex - 256: The Primerless Windscreen Adhesive System For Direct Glazing in Automotive Glass ReplacementDocument2 pagesSikaflex - 256: The Primerless Windscreen Adhesive System For Direct Glazing in Automotive Glass ReplacementAlper GmNo ratings yet

- Print # Rev. Fmea # Item: Process Resp: Prepared: Model Year(s) /vehicle(s) Key Date Date (Orig.) Core Team: Date (Rev.)Document4 pagesPrint # Rev. Fmea # Item: Process Resp: Prepared: Model Year(s) /vehicle(s) Key Date Date (Orig.) Core Team: Date (Rev.)Alper GmNo ratings yet

- 20160323014501-20MnCr5 - 20MnCrS5Document1 page20160323014501-20MnCr5 - 20MnCrS5singaravelan narayanasamyNo ratings yet

- Alloy Steel Astm A 335 t12 PipbesDocument15 pagesAlloy Steel Astm A 335 t12 PipbesBoby SaputraNo ratings yet

- 20NiCrMoS2 2Document1 page20NiCrMoS2 2Bogdan CraciunNo ratings yet

- Star Trek Star Charts The Complete Atlas of Star Trek (Unlocked by WWW - Freemypdf.com) PDFDocument113 pagesStar Trek Star Charts The Complete Atlas of Star Trek (Unlocked by WWW - Freemypdf.com) PDFbutwhytho67% (3)

- Ultrasonic LaminationTestingDocument2 pagesUltrasonic LaminationTestingAlper GmNo ratings yet

- MT Siddhartha PDFDocument1 pageMT Siddhartha PDFAbhishek RoyNo ratings yet

- Material Spec Sheet for C45E and C45R Steel GradesDocument2 pagesMaterial Spec Sheet for C45E and C45R Steel GradesAlper GmNo ratings yet

- Low Temperature Dry-Ice Bath CompositionsDocument4 pagesLow Temperature Dry-Ice Bath CompositionsspolverinoNo ratings yet

- An RTL Power Optimization Technique Base PDFDocument4 pagesAn RTL Power Optimization Technique Base PDFmaniNo ratings yet

- Evaluación 1T1 HLDocument3 pagesEvaluación 1T1 HLIllojuanNo ratings yet

- Cadence LN ADocument68 pagesCadence LN AfocclasNo ratings yet

- Zapi H2B Autoelevador Heli PDFDocument67 pagesZapi H2B Autoelevador Heli PDFcolive1No ratings yet

- Catalog HSPDDocument8 pagesCatalog HSPDDidik SokoNo ratings yet

- Application of DerivativesDocument53 pagesApplication of DerivativesTushar PalNo ratings yet

- NotchingDocument2 pagesNotchingk.prasadNo ratings yet

- Fuel System Precautions and Disconnection StepsDocument78 pagesFuel System Precautions and Disconnection StepsOral McnarrinNo ratings yet

- RAMANUJAN Magic SquareDocument15 pagesRAMANUJAN Magic SquareDetective HomeNo ratings yet

- "Page Replacement Algorithms": - A-28 Manasi Dhote A-32 Akshat Gandhi A-63 Dhruv MistryDocument18 pages"Page Replacement Algorithms": - A-28 Manasi Dhote A-32 Akshat Gandhi A-63 Dhruv MistryManasiNo ratings yet

- Getting Started with Anypoint Platform SetupDocument2 pagesGetting Started with Anypoint Platform SetupRRR180No ratings yet

- Bloch OscillationsDocument16 pagesBloch OscillationsrkluftingerNo ratings yet

- SQL Cheat Sheet For Data Scientists by Tomi Mester 2019 PDFDocument12 pagesSQL Cheat Sheet For Data Scientists by Tomi Mester 2019 PDFVishal Shah100% (1)

- NSXT 30 AdminDocument1,028 pagesNSXT 30 AdminAlessandroNo ratings yet

- Kinematics Review Physics 11Document2 pagesKinematics Review Physics 11Raymond NguyenNo ratings yet

- (BPL12-12FR) : VRLA Rechargeable BatteryDocument1 page(BPL12-12FR) : VRLA Rechargeable BatteryAlexander PischulinNo ratings yet

- Reflect Shape TransformationsDocument2 pagesReflect Shape TransformationsannabellNo ratings yet

- Definitions: - : I) Soft PalateDocument30 pagesDefinitions: - : I) Soft PalateNikita AggarwalNo ratings yet

- 7 Stages Research process-WPS OfficeDocument4 pages7 Stages Research process-WPS OfficeSohail MirzaNo ratings yet

- Resolve ManualDocument240 pagesResolve ManualNJ333100% (1)

- Answer Ndeb Released Questions 2013 AfkDocument1 pageAnswer Ndeb Released Questions 2013 AfkKareem Shawa33% (6)

- Angular 2 Typescript support for modern browsers and Angular 2: New features over AngularjsDocument9 pagesAngular 2 Typescript support for modern browsers and Angular 2: New features over Angularjsabhijeet kulkarniNo ratings yet

- Manual Aid 2Document136 pagesManual Aid 2Luis Chinchilla CruzNo ratings yet

- 03 - Reactions Between CaO and SO2 in Carbonating and No Carbonating ConditionsDocument9 pages03 - Reactions Between CaO and SO2 in Carbonating and No Carbonating ConditionsNishantNo ratings yet

- Tutorial 8 PDFDocument16 pagesTutorial 8 PDFBharat SaiNo ratings yet

- Zapata MATHCADDocument22 pagesZapata MATHCADGonzalo Ale Olave A.No ratings yet

- Ansi B36.19Document13 pagesAnsi B36.19BimaNo ratings yet

- Lathe Machine OperationDocument68 pagesLathe Machine OperationKarthick N100% (8)

- Microsurfaces: The Role of Apis in A Microservice ArchitectureDocument11 pagesMicrosurfaces: The Role of Apis in A Microservice ArchitectureSai CharanNo ratings yet

- JUST GIVE ME A REASONDocument1 pageJUST GIVE ME A REASONS fu fuNo ratings yet