Professional Documents

Culture Documents

1998 ASME CIE Kmenta

Uploaded by

Alper GmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1998 ASME CIE Kmenta

Uploaded by

Alper GmCopyright:

Available Formats

Proceedings of DETC ’98

1998 ASME Design Engineering Technical Conferences

September 13 - 16, 1998, Atlanta, GA

DETC98/CIE-5702

ADVANCED FMEA USING META BEHAVIOR MODELING

FOR CONCURRENT DESIGN OF PRODUCTS AND CONTROLS

Steven Kmenta Kosuke Ishii

Design Division Design Division

Mechanical Engineering Dept. Mechanical Engineering Dept.

Stanford University Stanford University

Stanford, CA 94305-4022 Stanford, CA 94305-4022

kmenta@cdr.stanford.edu ishii@cdr.stanford.edu

ABSTRACT

This paper presents the use of Advanced Failure Modes Probabilistic methods for reliability assessment have been

and Effects Analysis (AFMEA) as a methodology for the a mainstay of engineering systems development for many years

concurrent design of electro-mechanical products and their (Levinson, 1964: Leemis, 1995). While statistical approaches

control systems. The past two years have seen the extension of are useful, they require information available late in the

AFMEA to simulate dynamic changes of device operations detailed design stage. Product development teams need to

using meta-behavior modeling. This approach can help build-in reliability at the early stages of design and Failure

engineers identify failure modes associated with controls and Modes and Effects Analysis (FMEA) can help address this

their interaction with physical systems and drive system design challenge.

toward more reliable solutions. The proposed method uses

behavior modeling to map control functions to physical entities 1.2 Background and Shortcomings of FMEA

and identifies failure modes as the departure from intended Failure Modes and Effects Analysis is a key design

control functions. AFMEA provides a framework for controls method to help engineers improve quality of ownership.

and hardware developers to discuss and understand the FMEA is an engineering technique used to define, identify, and

relationship between sub-systems, controls, and overall system eliminate known and/or potential failures, problems, and

performance. An example of a power generation system errors from the system, design, or process before they reach the

illustrates how AFMEA applies to the early stages of layout customer (Omdahl, 1992). What is a failure mode? A failure

and controls design. mode is essentially an undesired cause-effect chain of events.

KEYWORDS: behavior modeling, FMEA, reliability, Once the development teams identify and prioritize failure

concurrent engineering, systems engineering modes, they can make design decisions leading to improved

reliability, quality, and safety (Stamatis, 1995). Table 1

1. INTRODUCTION explains the three main phases of FMEA.

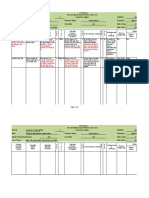

Table 1. Three aspects of FMEA

1.1 Ownership Quality

Ownership quality is the customers' perspective of quality Phase Question Output

during the use of the product. Reliability, maintainability, and

Identify What can go wrong? Failure Modes

serviceability are essential attributes of ownership quality and

customer satisfaction (Makino, et al., 1989; Berzak, 1991; Analyze How likely is a failure Risk Priority Evaluation

Eubanks & Ishii, 1993). Ullman (1992) reports on a survey mode and what are the (likelihood × severity ×

(Time, November 13, 1989) which asked customers, “What consequences? detection difficulty)

determines quality?” He responds “...quality is a composite of

factors that are the responsibility of the design engineer” and Act What can be done to Design solutions, test plans,

highlights basic functionality, reliability, and ease of service eliminate the cause or manufacturing changes,

alleviate the severity? error proofing, etc.

as key quality indicators.

1 Copyright ©1998 by ASME

challenging to understand operational interactions between

McKinney (1991) emphasizes the need to apply FMEA at systems and to facilitate continuous communication among

an early, system level in order to effectively impact the design groups. For example, a new gas/steam turbine (combined-

and reliability of the device. FMEA teams frequently identify cycle) plant design uses exhaust steam to help cool the gas

failure modes by assessing component failures and their turbine. This interaction of the gas and steam turbine systems

effects. Unfortunately, detailed information on the constituent leads to a new complexity in both plant and controls design

components is available only after completion of layout design. (Figure 2.) Advanced FMEA provide an means for discussing

At this late stage, causes of failures identified by FMEA can be the interface between independent design teams.

very expensive or impossible to correct. According to Kara-

Zaitri et al. (1991) FMEA is almost useless when treated as an Gas Turbine Steam Turbine

after-the-fact “checklist” to satisfy management or contractual Design Design

agreements with customers. Figure 1 compares the early and

continuous application of FMEA to what often happens:

performing the FMEA late or not at all. Controls Controls

Failure Failure Failure

Modes Modes

Ideal Modes

FMEA Hardware Hardware

System, Design, Process, Service ...

Functional Layout Detailed Manufacturing

Design Design Design

Figure 2. Interfaces between functional teams lead to

Actual FMEA failure modes that are difficult to anticipate

Design Process

Functional Layout Detailed Manufacturing

Design Design Design 1.3 Advanced FMEA Using Behavior Modeling

Problems with timing and execution lead to one of the

biggest problems with FMEA: not identifying critical failure

Figure 1. Comparison of ideal and actual deployment of

modes that occur during use. It is impossible to assess the

FMEA

probability and consequences − much less provide design

The literature does not prescribe detailed procedures for solutions − for a failure scenario that engineers do not

identifying failure modes. A crucial step in predicting the anticipate. Our goal in developing “Advanced FMEA” is to

overall reliability of a system is formulating an extensive list of provide a systematic approach to identify a comprehensive set

failure modes identifying what might go wrong. While FMEA of failure modes early in the design process.

has the potential to predict and mitigate failure modes during Advanced FMEA uses behavior modeling to link desired

design, our industry collaborators have reported difficulty behaviors with the components, operating environment, related

using FMEA to identify system-wide failure modes. Without a systems, and control logic. Qualitative behavior simulation

systematic approach, engineers produce a subjective analysis provides the framework for identifying failure modes and

depending on their experience level. Some failure modes are estimating their effects. The proposed method builds on

difficult to anticipate during the pre-manufacturing stages, preliminary work by Eubanks (1996) and Eubanks et al. (1997)

including: which used behavior-based AFMEA on an automatic ice maker

design. In this paper, we extend the scope of AFMEA to

include control systems and their interaction with physical

•interfaces with other systems

systems. This study illustrates how AFMEA can (1) drive

•interaction with controls

concurrent engineering of products and their corresponding

•unexpected operating conditions

control systems, and (2) provide the foundation for computer

•unanticipated customer use support of a structured design method.

•assembly and service errors Several automated FMEA systems exist particularly in the

•manufacturing variation field of electrical circuit design. Ormsby et al. (1991)

proposed a concept for automated FMEA employing

Failure modes particularly difficult to identify are those qualitative reasoning in a model-based environment to make

which fall between development teams, especially when teams the analysis extensible to other domains. Price et al. (1995)

correspond to systems with functional interdependence. It is developed an automated FMEA that combines intended

2 Copyright ©1998 by ASME

functions of a circuit with a proposed model and analyzes the Using the function-structure map, designers can easily

design’s safety. Montgomery et al. (1996) performed a establish cause-effect failure scenarios. A failure in the

computer simulation of failure modes and their effects for hardware or supporting systems (such as power) could result in

electrical circuits, including qualitative simulation at the early a sub-function not occurring as intended. We define a failure

stages. Pelaez et al. (1994) introduced a fuzzy cognitive map as the negation of a function, or “not(function).” Using this

to facilitate automated FMEA in mechanical systems. definition, we can capture outright failures where the function

Palumbo (1994) used mode variables and behavioral logic to does not occur at all, as well as deviations from the intended

automate FMEA of an actuator control system. Russomanno et functions. Figure 4 uses the a function-structure map of a hair

al. (1994) related the FMEA process to various artificial dryer to generate two failure scenarios.

intelligence techniques. These approaches, while powerful,

generally require domain specific system models, particularly major mapped

main function sub-function sub-function elements

when modeling electrical circuits and logic.

The next section reviews the concepts of behavior not(convert fan

modeling used for Advanced FMEA. Section 3 describes the rotation to flow) obstructed

application of AFMEA to a conceptual design and its not(dry hair) not(provide

airflow) not(convert

corresponding control system. The paper introduces “meta- electricity motor

behavior” modeling as a framework for evaluating systems to rotation) failure

whose behavior-to-structure constructs are changing in time. potential

end effect local effect failure mode causes

A gas turbine cooling system for a conceptual power plant

serves as an illustrative example. Section 4 discusses

opportunities for AFMEA as an automated concurrent Figure 4. Two failure scenarios from the function-

engineering tool, and Section 5 relays specific future activities. structure map

2. BASIC CONCEPTS OF BEHAVIOR MODELING Similar to a functional decomposition, the behavior model

Conventional design texts use functional decomposition as hierarchically decomposes intended behaviors and maps them

an early conceptual design tool. The design team describes the to physical entities. This definition of behavior modeling

overall function of the device and progressively decomposes builds on functional and causal representation described by

the required functions in order to manage and understand the Iwasaki and Simon’s behavior modeling and simulation

design (Suh, 1990: Ullman, 1992). A mapping between the (1994). The behavior model provides more information than

functions and the structure forms a link between the normal functional representations. Each behavior maps to a

descriptions of the device operation and the physical entities specified state transition as well as to the physical systems

implementing those actions. Figure 3 is an example of a responsible for the execution of the behavior. State variables

hierarchical function decomposition mapped to the structure. are objects with one or more attributes, forming the (<object>,

<attribute>, <value>) triple (Eubanks et al., 1997).

provide ambient air

Function electricity Structure

switch

supply air

<object> can be any physical or conceptual entity

fan housing

convert elec.

fan

assy

<attribute> is an identifiable quality or measurable

motor

to rotation

characteristic of the object

provide convert rotation fan blade

airflow to flow <value> is a quantification or discrete qualification of

heating

support flow

generation element the attribute

springs

convey flow heating

thermocouple assy

Dry

control flow temperature

switch Hair

This construct allows the designer to define easily various

Hair

supply

electicity heat shield

Dryer

properties of materials, flows, components and systems. To

convert elec.

to heat

front grid simplify modeling, we have adapted a partial state description

heat air

control front case

front

housing as described by Chandrasekaran et al. (1993) as a relevant

temperature

transfer heat

power cord subset of the variables.

to air

switch

actuator

provide handle

rear housing

provide user provide rear

interface controls screen housing

protect user ground wire

power source

Figure 3. Function-structure mapping for a hair dryer

3 Copyright ©1998 by ASME

behavior: dry hair Cooling Air System

Air from

Compressor pipe 1 pipe 2 pipe 3 pipe 4

initial state desired final state

post-conditions control Air to

pre-conditions Combustor

valve 1

<obj.><attribute><value> <obj.><attribute><value>

pipe 5 pipe 6

Heat Exchanger

{hair, dry, no} {hair, dry, yes}

Cooling control Air to Gas

Water valve 2 Turbine

mapped to:

to pipe 7

hair dryer, Condenser pipe 8

power source,

ambient air

Figure 7. An example design schematic

Figure 5. A behavior-structure fragment for a hair dryer After setting overall system requirements for the highest

level of the behavior model, we can decompose the model into

The specification of steady-state pre- and post- conditions sub-behaviors with physical elements and state changes.

builds behavior paths through the model. The behavior paths Figure 8 shows a simplified example of a behavior model

facilitate reasoning about failure propagation through the based on the Cooling Air System schematic diagram.

system. Failure propagation leads to the assignment of effects

for a specific failure mode. pre-conditions cool air post-conditions

and split flow

(combustor_air, flow_rate, D)

(combustor_air, pressure, E)

initial state behavior final state (compressor_air, flow_rate, A)

(combustor_air, temperature, F)

(compressor_air, pressure, B)

(compressor_air, temperature, C) (GT_cooling_air, flow_rate, H)

cv

(GT_cooling_air, pressure, J)

(GT_cooling_air, temperature, K)

sub-behavior

System Boundary

behaviors convey air control flow convey air

convey air & elements split air

pipe 3 control pipe 4

valve 1

pipe 1 pipe 2 convey air

cv cool air convey air

. convey pipe 1 control pipe 1

heat

water convey valve2

exchanger

water

pipe 7

pipe 8

Figure 6. Decomposition of behaviors and intermediate state variables

states form inferencing paths

Figure 8. Overview of a behavior model

Behavior modeling provides a robust basis for performing

AFMEA early during the design analysis for several reasons. Behavior modeling provides a systematic framework for

Behaviors do not rely entirely on the physical structure of the generating failure modes compared to brainstorming and other

device. Although physical elements or components change as techniques. Moreover, behavior modeling has a greater scope

the design develops, one can use behavior modeling for the of analysis than a component based failure mode analysis.

following:

3. APPLICATION OF AFMEA FOR CONCEPTUAL

• to define general behaviors at the early stages of design, DESIGNS & CONTROLS

• to decompose into more specific sub-behaviors, and

• to map to physical systems and components as the 3.1 Power Plant Gas Turbine Cooling System

design develops. This section describes AFMEA as applied to a gas turbine

cooling system of a combined cycle power plant. This

Figure 7 is an example of an early design schematic, in conceptual design uses steam to cool the gas turbine in order to

this case, an air cooling system. Even this basic level of design increase thermal efficiency. Figure 9 shows a schematic

detail can lead to a behavior model of the system. diagram of the proposed design.

4 Copyright ©1998 by ASME

Legend failures associated with the transition from one mode to the

HP - High Pressure IP - Intermediate Pressure next.

LP - Low Pressure GT - Gas Turbine

C - Combustor C - Compressor

- High Temp. - Low Temp

3.2 Concurrent Engineering Challenges

- Valve - One-way Check Valve In previous combined cycle power plants, the gas and

steam turbines operated almost independently of each other.

Boiler The only functional interaction between the two systems was

GT Exhaust the gas turbine exhaust heated steam in the boilers. Design

IP Steam engineers understood this configuration and its failure modes

well and the designs had not changed much from year to year.

Cold Reheat The controls for the gas turbines and the controls for the

Steam

GT Cooling Hot Reheat

steam turbines were largely independent as were the

HP

Steam Steam engineering groups. Because the design was not evolving

Steam

LP Steam rapidly, controls engineers could adapt easily to design

Comb changes when they occurred. Design changes in the steam

turbine configuration did not effect performance or controls of

gas turbines and vice versa. For the new concept in plant

T C HP IP / LP Generator

design, the gas turbine’s performance is intimately inter-

related with the steam turbine system (Figure 10).

Gas Turbine Air Steam Turbine

Traditional Design

Figure 9. Conceptual power plant using steam to cool

the gas turbine Cold

Reheat

Steam LP Steam

The target example is a single-shaft combined-cycle plant. Hot Reheat

HP

The unique function of the new design is cooling of the gas Steam Steam

turbine blades with exhaust steam from the high pressure (HP) Comb

steam turbine. The gas turbine blades, in turn, heat the

cooling steam in parallel with the reheater before powering the GT C HP IP / LP Generator

intermediate pressure (IP) steam turbine. Unfortunately, there Gas

is no cooling steam available when starting-up the plant. Air Steam Turbine

Turbine

Thus, the development team proposed three distinct cooling

modes during plant start-up. Initially, air from the compressor GT Cooling

cools the gas turbine blades. After the gas turbine exhaust has sensing & control points

created sufficient boiler pressure, the boiler will provide

cooling steam for the blades. When the high pressure steam

turbine reaches steady state operating pressure, the GT blades Proposed Design

will use the HP exhaust steam for cooling. These distinct

cooling modes resulted in three steady state behavior models:

IP

LP Steam

Steam

• Air Cooling Mode

HP

• Intermediate Steam Mode Steam

• HP Steam Cooling Mode

Comb

The schematic diagrams − used by the gas turbine, steam GT C HP IP / LP Generator

turbine, and controls engineers − provided the basis for the

behavior models. Input parameters and output requirements Air

provided an overall system behavior used for decomposition

into detailed sub-behaviors. The behavior models helped GT Cooling

identify potential failure modes, causes, and effects. Sub- sensing & control points

system engineers, and component specialists, used AFMEA as

a basis for discussing design rationale and potential Figure 10. The new GT cooling system is intertwined

improvements. However, these three analyses did not address with the steam system

5 Copyright ©1998 by ASME

The controls engineers must now understand both systems decision making and the sensing / reasoning / actuating

and their functional interaction. The authors observed that the sequence of a control system.

controls people were struggling to stay up-to-date with the

frequent design changes. The design of the controls followed Meta-behavior:

the system layout design and component selection. establish intermediate steam cooling

Conventional engineering efforts, such as periodic design behavior model behavior model

reviews, were not adequate. Design reviews typically consisted Air Cooling Intermediate Steam

Exhaust sensing actuating Exhaust

of one functional group while other groups and controls Cold Reheat

to Stack

IP SteamLP Steam

reasoning

to Stack

IP SteamLP Steam

Cooling

Cold Reheat

Steam

Steam HP Hot Reheat

HP Hot Reheat

engineers learned of design changes after-the-fact. T

Comb

C HP

Steam Steam

IP / LP Generator T

Comb

C HP

Steam Steam

IP / LP Generator

Gas Turbine Steam Turbine Gas Turbine Steam Turbine

Air Air

{meta-behavior sensors actuators {meta-behavior

controls valves

pre-conditions} post-conditions}

3.3 AFMEA for Controls-Hardware Interaction

The performance of the control system is critical to plant

performance and safety. A major challenge for the controls Figure 12. Meta-behaviors transition from one behavior

engineer is to identify failure modes during the start-up of the model to the next

power plant when the cooling of the gas turbine (GT) is not at

steady state. During start-up, the behavior “cool the gas The control system essentially acts as the brains or logic of

turbine” goes through three distinct modes: Air Cooling, a system, gathering information from the sensors, making

Intermediate Steam Cooling, and HP Steam Cooling. Within decisions, and sending impulses to actuators. In order for a

each mode, the behavior model does not change since the system to operate as desired, the control system must receive

source of cooling is constant for each mode. accurate information and reason correctly. In addition, the

Since the development teams were concerned about actuators must receive the control command and act upon the

potential failures when changing from one mode to another, command. As with behaviors, meta-behaviors have pre-

we felt the need to augment the existing behavior models. The conditions described by a set of state variables: requirements

model should address discrepancies during the transient start- that must exist in order to enable the meta behavior. When the

up sequence. In order to extend the scope of the behavior meta behavior executes, the variable-set updates to reflect the

model, we introduce the concept of “meta-behaviors” as new state of the system. Figure 13 shows the changing of

behaviors that change behavior-structure relationship. During modes through meta behaviors as governed by the control

start-up, the overall behavior “cool the gas turbine” remains system.

constant but the medium responsible for the cooling is

changing. Figure 11 illustrates the use of meta-behavior to If flow in pipe 1

behavior model A meta-

> min_flow

move from one mode to the next desired mode. behavior

Air Cooling

Exhaust

to Stack

IP SteamLP Steam Exhaust

Meta-Behaviors Meta-Behaviors Cold Reheat IP Steam

to Stack

open

Steam LP Steam

HP Hot Reheat

Steam Steam

Cold Reheat

Steam Exhaust valve B

Comb to Stack

IP SteamLP Steam

T C HP IP / LP Generator

Cold Reheat

Gas Turbine Steam Turbine Steam Exhaust

Transient Behaviors Air HP Hot Reheat

Steam Steam

to Stack

IP SteamLP Steam

Behavior Comb valve B open

Behavior Model: Behavior Model: Behavior Model: Cold Reheat

Exhaust

Models Intermediate Steam HP Steam

T C HP IPHP Steam

/ LP Hot ReheatGenerator

to Stack

Air Cooling Cooling Cooling

Gas Turbine

Air Comb

Steam TurbineSteam Steam IP SteamLP Steam

Cold Reheat

T C Intermediate Steam

HP IP / LP Steam

Generator

Gas Turbine Steam Turbine Exhaust

Air Cooling to Stack

IP Steam

LP Steam

Figure 11. Meta-behaviors describe transition of

Co

Cold Reheat

Steam

HP Hot Reheat

nt

operational modes Steam Steam

ro

Comb

lA

T C HP IP / LP Generator

lgo

Gas Turbine Steam Turbine

Air

rith

Meta-behaviors represent changes in the governing behavior model B

m

behavior model of the system. Changing from one behavior

model to another generally requires the following:

Figure 13. The control algorithm corresponds to meta-

•gathering information about the state of the system, behaviors.

•using that information to make a decision,

•acting on the decision.

3.4 Steps for AFMEA using Meta-behaviors

A human might be responsible for this decision making Our approach for Advanced FMEA of the combined cycle

process or, as in this example, a control system. Figure 12 plants’start-up sequence is as follows

shows the relationship between the see / think / do process of

6 Copyright ©1998 by ASME

Step 1: Define the initial behavior model and its outputs result in a pre-condition failure. Theoretically, a steady-state

(post-conditions) behavior model can identify these failures at that instance.

Step 2: Define the final desired “target” behavior model Sensing failures occur when sensing agents do not report

and its inputs (pre-conditions) accurately the true state of the systems. Sensing failures

include Type I errors (false positives) and Type II errors (false

Step 3: Identify all intermediate control decisions

negatives). Other sensing failure could include the lack of a

Step 4: Translate control decisions into meta behaviors: signal or an operator mis-reading a gauge. These failures can

list the purpose of the control action result in an improper control action such as a premature

Step 5: For each, identify the requisite trigger parameters action, or no action when the control system intends one.

for the control decision, or pre-conditions (e.g., Reasoning failures occur when the information is

steam temperature) and list the responsible physical available to make a prescribed decision but the control system

systems (e.g., steam supply system, steam responsible does not execute the appropriate command. These

temperature sensors) are essentially control logic flaws to test extensively during

Step 6: Identify the desired resultant state of the control software validation and debugging.

action, or post-conditions (e.g., valve position) and Actuating failures occur when the mechanical or

the responsible agents (e.g., valve, actuator) electrical system fails to receive or execute the control

command, e.g., if a solenoid does not activate or a valve sticks.

Step 7: For each meta-behavior, tabulate potential failure Intrinsic failures are failures of the systems or hardware

modes based on pre-conditions, sensing, reasoning, that do not relate directly to the sensing, reasoning, or

and acting and undesired post-conditions actuation of the meta-behavior. These failures are problems

with the behavior of supporting hardware and systems. As

3.5 Identifying Failure Modes with pre-condition failures, a behavior model for the entire

For the meta-behaviors to execute successfully, the system system can help identify these failure modes at quasi steady

must satisfy all pre-conditions, sensing accurately, reasoning state “snapshots” of the system state between meta-behaviors.

properly, actuating appropriately, all while being supported by Intrinsic failures might include a valve that changes position

intrinsic systems and hardware. Specifically: when it is not expected or a check valve not closing on positive

pressure.

• system state variables must reach specified values (pre- Table 2 summarizes failure categories and corresponding

conditions.) These variables can be intrinsic (e.g., valve examples. Once the engineers tabulate these failures, they can

position) or extrinsic (system inputs such as supply steam) reason about the effects based on the undesired state of the

• current state of the system must be sensed and reported system. In an actuation failure, for example, if a valve is stuck

correctly (sensing) closed, the system will operate with the valve in the closed

• control system must recognize sensor signals and other position. If a sensor gives a false “high” reading then the

logical inputs (reasoning) controls will act as if the requisite condition were attained.

• control logic should reason as prescribed (reasoning) From these failures, one can identify the causes and effects.

• control system must issue appropriate signals (reasoning)

• signals must be received correctly by the associated Table 2. Meta-behavior Failure Categories

systems (actuating) Failure Responsible System Example

• associated hardware should comply with the actuation Pre-condition input to the system, insufficient steam flow

signal (actuating) previous meta-behavior

• supporting hardware & systems must function properly

Sensing sensors steam flow sensor fails

(intrinsic)

Reasoning control system no signal to open valve A

Each meta-behavior can fail if any of the above mechanical valve stuck closed

Actuating

requirements breakdown. This study classifies failures into

five different categories depending on the nature and timing. Intrinsic mechanical pipe failure

Pre-condition failures result from a requisite “trigger”

variable not reaching the state required for the control system

to execute an action. If pre-conditions for the action (or meta- 3.6 Results of AFMEA Analysis

behavior) do not exist, then there is no trigger for the control A team of gas turbine, steam turbine, controls, component

system to take action. For example, sufficient steam flow might engineers, and managers discussed the potential failure modes

serve as a pre-condition for a meta-behavior. If a failure in the associated with each meta-behavior and rated each for severity

boiler system provides in inadequate steam flow, this would

7 Copyright ©1998 by ASME

and likelihood. The discussion and ensuing ratings resulted in Component &

the following: Sub-system

Design

Controls Design

• determined “trip” or shut-down protection logic

during start-up

• prioritized sensor placement and redundancy for high System Design

risk control actions IP Steam

Exhaust

to Stack

• initiated detailed FMEA’s for critical components

LP Steam

Cold Reheat

Steam

HP Hot Reheat

based upon the risk evaluation Comb

Steam Steam

• established the basis for a diagnostic engine used for T

Gas Turbine

C HP

Steam Turbine

IP / LP Generator

real-time monitoring Air

In addition to these specific results, Advanced FMEA

proved valuable as communication tool. AFMEA facilitated cv •Systems integration

• Concurrent engineering

key discussions and information exchange between different •Semi automated FMEA

groups which might not have happened until much later in the •Shortened development

cv

development process. The methodology helped engineers •Improved quality

understand their systems’ impact on others as well as on Behavior Modeling

overall performance.

4. OPPORTUNITY FOR COMPUTER SUPPORT Figure 14. Automation of AFMEA can facilitate

AFMEA is a powerful method for addressing failure communication and expedite product development

modes in the early stages of design. However, the AFMEA is

tedious in its present form and the authors see an opportunity

for automating the process. The goal of automation should not 5. CONCLUSIONS AND FUTURE WORK

be to replace face-to-face communication, nor to under- Behavior modeling facilitates concurrent engineering

emphasize careful engineering analysis, but rather to enhance efforts between controls and hardware design. AFMEA is a

both. Careful implementation of an automated approach could flexible yet systematic approach, applicable at the early stages

hold significant advantages: of design and throughout development. In addition, the

method lends itself to automation as a product development

• information management: linking behavior, design, tool. Further extensions of AFMEA include detailed budgeting

and controls of reliability, manufacturing process design, prioritization of

• semi-automated generation of meta-behaviors from testing, development of diagnostics and service logistics

control logic (Figure 15).

• formalized logic and reasoning

• knowledge and model retention

• speed of analysis Advanced FMEA

• integration of sub-system analysis and performance

• Reliability Budgeting

• Mfg Process Design

with the overall system

• Service Strategy

• Controls Design

• System Design

• Error Proofing

Some level of automation of the process is critical for

• Testing Plan

• Diagnostics

implementing the AFMEA as a product development tool. If

automation increases the speed of analysis, then it will provide

extra motivation for using the tool at the early stages of

product development. Figure 14 shows the relationship of

automated AFMEA with design of controls, functional design

of hardware, and their interaction. Product Development Process

Figure 15. AFMEA benefits parallel aspects of product

development

To extend and validate AFMEA as a design methodology,

we plan on the following activities:

8 Copyright ©1998 by ASME

Makino, A., P. Barkan, L. Reynolds and E. Pfaff (1989), “A

• extend the behavior model to manufacturing processes Design for Serviceability Expert System,” Proceedings. of

• link AFMEA with design and process Error Proofing the ASME Winter Annual Meeting 1989, San Francisco,

• automate the procedure using software CA, pp. 213-218.

• document additional case examples McKinney, B. (1991), "FMECA, The Right Way," Proceedings

• develop Advanced FMEA training modules of the 1991 IEEE Annual Reliability and Maintainability

Symposium, pp. 253-259.

ACKNOWLEDGMENTS Montgomery, T., Pugh, D., Leedham, S. and Twitchett, S.

We would like to thank General Electric and the (1996), “FMEA Automation for the Complete Design

Department of Energy for providing motivation and funding Process,” Proceedings of the 1996 IEEE Annual Reliability

for this research. The authors would like to express sincere and Maintainability Symposium, pp. 30-36.

appreciation to Dr. Harindra Rajiyah and Brian Ray for Ormsby, A., J. Hunt, M. Lee (1991), Towards an Automated

facilitating the application of our AFMEA and providing FMEA Assistant, Applications of Artificial Intelligence in

valuable feedback. A special thanks to Dr. C. Fritz Eubanks Engineering VI, eds. Rzevski, G. and Adey, R.,

for his guidance during the development and application of Computational Mechanics Publications, Southampton,

behavior modeling, and to Mark Martin and Jason Grant for Boston, pp. 739-752.

comments and help putting this paper together. Palumbo, D. (1994) "Automating Failure Modes and Effects

Analysis," Proceedings of the 1994 IEEE Annual Reliability

REFERENCES and Maintainability Symposium, pp. 304-309.

Berzak, N. (1991), "Serviceability by Design," Proceedings. of Pelaez, C. E., J. B. Bowles, (1994) "Using Fuzzy Cognitive

the 23rd Int’l SAMPE Technical Conference, October 21- Maps as a System Model for Failure Modes Effects Analysis

24, 1991, pp. 1060-1071. (FMEA)", Third Annual FT&T, International Conference,

Chandrasekaran, B., A. Goel, and Y. Iwasaki (1993), November 1994.

"Functional Representation as a Basis for Design Rationale," Price, C. J., D. R. Pugh, N. Snooke, J. E. Hunt, M. S. Wilson

IEEE Computer, 26(1):48-56, January, 1993. (1997), “Combining Functional and Structural Reasoning

Eubanks, C. and K. Ishii (1993), "AI Methods for Life-cycle for Safety Analysis of Electrical Designs,” Knowledge

Serviceability Design of Mechanical Systems," Artificial Engineering Review vol. 12(3), pp271-287, 1997.

Intelligence, 8(2), pp. 127-140. Russomanno, D. J, R. D. Bonnell and J. B. Bowles (1994),

Eubanks, C. F. (1996), "A Framework for Computer-based “Viewing Computer-aided Failure Mode and Effects

Failure Modes and Effects Analysis of Mechanical Systems Analysis from an Artificial Intelligence Perspective,”

in the Conceptual Design Phase," Ph.D. Thesis, Graduate Integrated Computer Aided Design, Vol. 1 (3), pp. 209-228,

School, The Ohio State University, December, 1996. 1994.

Eubanks, C., S. Kmenta, and K. Ishii, (1997) "Advanced Stamatis, D.H., Failure Mode and Effect Analysis: FMEA

Failure Modes and Effects Analysis Using Behavior from Theory to Execution, ASQC Quality Press,

Modeling," Proceedings of the ASME 9th International Milwaukee, WI, 1995.

Design Theory & Methodology Conference, Sept. 1997, Suh, N. (1990), The Principles of Design, Oxford University

Sacramento, CA. Press, New York, 1990.

Eubanks, C., S. Kmenta, and K. Ishii (1996), "System Ullman, D. (1992), The Mechanical Design Process, McGraw-

Behavior Modeling as a Basis for Advanced Failure Modes Hill, Inc., New York.

and Effects Analysis," ASME Computers In Engineering

Conference, Sept. 1996, Irvine, CA.

Iwasaki, Y. and H. Simon (1994), "Causality and Model

Extraction," Artificial Intelligence, Kluwer Academic

Publishers, Boston, pp. 597-616.

Kara-Zaitri, C., Keller, A., Barody, I., and Fleming, P., "An

Improved FMEA Methodology," Proceedings of the 1991

IEEE Annual Reliability and Maintainability Symposium,

pp. 248-252.

Leemis, L. A. (1995), Reliability: Probabalistic Models and

Statistical Methods,” Prentice-Hall, NJ, 1995.

Levinson, C. (1964), "System Reliability Analysis,"

Mechanical Design and Systems Handbook, (H. Rothbart,

ed.) McGraw-Hill, Inc., New York.

9 Copyright ©1998 by ASME

You might also like

- Configuration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingFrom EverandConfiguration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingNo ratings yet

- 1997 ASME DTM EubanksDocument10 pages1997 ASME DTM EubanksAlper GmNo ratings yet

- Paper Advanced Failure Modes and Effects Analysis of Complex ProcessesDocument9 pagesPaper Advanced Failure Modes and Effects Analysis of Complex ProcessesGaetano Grana ScebbaNo ratings yet

- Chapter No. 1: 1.1 Problem Statement (FMEA) Failure Mode Effect Analysis of Welding Defects of Beam AssemblyDocument27 pagesChapter No. 1: 1.1 Problem Statement (FMEA) Failure Mode Effect Analysis of Welding Defects of Beam AssemblyharshalNo ratings yet

- FMEA For Manufacturing and Assembly Process: VJTI, Mumbai Siemens LTD., MumbaiDocument9 pagesFMEA For Manufacturing and Assembly Process: VJTI, Mumbai Siemens LTD., MumbaiKevin JordanNo ratings yet

- Failure Mode and Effects Analysis of A Process of Reflow Lead-Free SolderingDocument5 pagesFailure Mode and Effects Analysis of A Process of Reflow Lead-Free SolderingSRIDHAREEE61No ratings yet

- Hair DryerDocument27 pagesHair Dryerjazzyblue100% (2)

- Failure Mode and Effect Analysis (FMEA) Implementation: A Literature ReviewDocument17 pagesFailure Mode and Effect Analysis (FMEA) Implementation: A Literature ReviewAdvanced Research PublicationsNo ratings yet

- Application of Fmea Method in A Manufacturing Organization Focused On QualityDocument7 pagesApplication of Fmea Method in A Manufacturing Organization Focused On QualityRudra DasNo ratings yet

- FMEA MaterialDocument18 pagesFMEA MaterialKarthi ThiyagarajanNo ratings yet

- Fmea and FmecaDocument14 pagesFmea and FmecaLindsay SleijpenNo ratings yet

- Pfmea For Small Scale IndustriesDocument4 pagesPfmea For Small Scale IndustriesshivkeshNo ratings yet

- FMEA For Manufacturing and Assembly ProcessDocument9 pagesFMEA For Manufacturing and Assembly ProcessAsep SuryanaNo ratings yet

- An Evaluation of Failure Modes and Effects Analysis Generation Method For Conceptual DesignDocument15 pagesAn Evaluation of Failure Modes and Effects Analysis Generation Method For Conceptual DesignAlper GmNo ratings yet

- Benefits of FMEADocument9 pagesBenefits of FMEAbaranirajsalem100% (2)

- Failure Mode Effects & Criticality Analysis Workshop by TetrahedronDocument2 pagesFailure Mode Effects & Criticality Analysis Workshop by TetrahedrontetrahedronNo ratings yet

- Quality Analysis Using Fmea Method On Assembly Processes of Washing Machine (Case Study in Panasonic Manufacturing Indonesia)Document5 pagesQuality Analysis Using Fmea Method On Assembly Processes of Washing Machine (Case Study in Panasonic Manufacturing Indonesia)gadhang dewanggaNo ratings yet

- FMEA Master PresentationDocument63 pagesFMEA Master Presentationnigeldouch100% (1)

- Failure Modes and Effects Analysis (FMEA)Document43 pagesFailure Modes and Effects Analysis (FMEA)Muhammad Bilal100% (4)

- TQM Assignment On Failure Mode Effect Analysis: Srideep Kumar Mohanta 215112033 2013-14Document13 pagesTQM Assignment On Failure Mode Effect Analysis: Srideep Kumar Mohanta 215112033 2013-14mechatronicsmkNo ratings yet

- Failure Mode and Effects AnalysisDocument19 pagesFailure Mode and Effects AnalysispatnaikpsNo ratings yet

- Fmeca: Jins Abraham Roll No:29Document8 pagesFmeca: Jins Abraham Roll No:29Alvin ThariyathNo ratings yet

- Failure Mode and Effects Analysis of A Process of Reflow Lead-Free SolderingDocument5 pagesFailure Mode and Effects Analysis of A Process of Reflow Lead-Free SolderingMadan PrakashNo ratings yet

- FMEA A Life Cycle Cost PerspectiveDocument11 pagesFMEA A Life Cycle Cost Perspectivearkaprava ghoshNo ratings yet

- Foc FmeaDocument6 pagesFoc FmeaShimon PopaNo ratings yet

- Fmea SoproDocument9 pagesFmea SoprofernandoNo ratings yet

- History of FMEA: FMEA Cause and Effect DiagramDocument8 pagesHistory of FMEA: FMEA Cause and Effect Diagramervikas34No ratings yet

- Quality Management AnswersDocument42 pagesQuality Management AnswersVrushali Nayak100% (1)

- Failure Mode and Effects AnalysisDocument10 pagesFailure Mode and Effects Analysisசரவணகுமார் மாரியப்பன்No ratings yet

- Failure Modes and Effect AnalysisDocument17 pagesFailure Modes and Effect AnalysisWahid KdrtNo ratings yet

- Failure Mode and Effects Analysis (FMEA)Document17 pagesFailure Mode and Effects Analysis (FMEA)DME100% (1)

- Modelling and Reasoning For Failure Modes and e Ects Analysis GenerationDocument12 pagesModelling and Reasoning For Failure Modes and e Ects Analysis GenerationAlper GmNo ratings yet

- Failure Modes and Effects Analysis (FMEA)Document47 pagesFailure Modes and Effects Analysis (FMEA)Dushyant Sarvaiya100% (1)

- Failure Mode and Effects AnalysisDocument10 pagesFailure Mode and Effects AnalysisRahayu MekarNo ratings yet

- Failure Mode and Effects AnalysisDocument11 pagesFailure Mode and Effects AnalysisВладимир МалићNo ratings yet

- 2018-Chih-Chung Chiu, Kuo-Sui Lin-A New Design Review Method For Functional Safety of Automotive Electrical SystemsDocument9 pages2018-Chih-Chung Chiu, Kuo-Sui Lin-A New Design Review Method For Functional Safety of Automotive Electrical SystemsAde Hikma TianaNo ratings yet

- FMEA Failure Modes Effects Analysis PDFDocument32 pagesFMEA Failure Modes Effects Analysis PDFVILLANUEVA_DANIEL2064100% (1)

- FMEADocument12 pagesFMEAnitsugaeugeneNo ratings yet

- FmeaDocument23 pagesFmeaSaif UllahNo ratings yet

- System Analysis: Failure Modes, Effects, and Criticality AnalysisDocument41 pagesSystem Analysis: Failure Modes, Effects, and Criticality AnalysisJuan Sebastian RodriguezNo ratings yet

- (International Journal of Quality and Reliability Management) Failure Mode and Effects AnalysisDocument19 pages(International Journal of Quality and Reliability Management) Failure Mode and Effects AnalysisLuis Gustavo PachecoNo ratings yet

- FmeaDocument2 pagesFmeaNitheeshNo ratings yet

- Application of DFMEA in Metal To PlasticDocument5 pagesApplication of DFMEA in Metal To PlasticposttopictomotiveNo ratings yet

- Failure Mode and Effects AnalysisDocument25 pagesFailure Mode and Effects AnalysisabrahamNo ratings yet

- FMEA CostDocument6 pagesFMEA CostNhan HuynhNo ratings yet

- Fmea VviDocument52 pagesFmea VviBobby Edwin100% (2)

- Reliability Analysis Techniques For Aircraft CertificationDocument5 pagesReliability Analysis Techniques For Aircraft Certificationsezgin bayramNo ratings yet

- Fmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123Document5 pagesFmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123DanistergladwinNo ratings yet

- A Systems Approach To The Development and Use of FMEA in Complex Automotive ApplicationsDocument11 pagesA Systems Approach To The Development and Use of FMEA in Complex Automotive ApplicationsArun BNo ratings yet

- Innovative Approach To FMEA Facilitation: Govind RamuDocument34 pagesInnovative Approach To FMEA Facilitation: Govind Ramukskr_44No ratings yet

- FMEA Types and Their UsageDocument4 pagesFMEA Types and Their UsageAnder GaragorriNo ratings yet

- GS-0002D, Design FMEADocument26 pagesGS-0002D, Design FMEAmesa142100% (1)

- Failure Mode Effect Analysis Process Capability Enhancement A Case Study IJERTV2IS4793Document10 pagesFailure Mode Effect Analysis Process Capability Enhancement A Case Study IJERTV2IS4793mn1938No ratings yet

- FEMCADDocument5 pagesFEMCADdaabhiNo ratings yet

- FMEA Methodology Design, Implementation and Integration With HACCP System in A Food CompanyDocument7 pagesFMEA Methodology Design, Implementation and Integration With HACCP System in A Food CompanyTri Handayani TulungNo ratings yet

- Failure Mode and Effects Analysis 2Document15 pagesFailure Mode and Effects Analysis 2Oyebanji SurajNo ratings yet

- FMEA Applications Machinery FMEA: Continued On Next PageDocument10 pagesFMEA Applications Machinery FMEA: Continued On Next Pagenelson.rodriguezm6142100% (1)

- A Case Study: A Process FMEA Tool To Enhance Quality and Efficiency of Manufacturing IndustryDocument9 pagesA Case Study: A Process FMEA Tool To Enhance Quality and Efficiency of Manufacturing Industrysanjay chamoliNo ratings yet

- 1 CT AmefDocument23 pages1 CT AmefCuenta PokemonNo ratings yet

- FMEA Methodology Design and Implementation in A Fo PDFDocument10 pagesFMEA Methodology Design and Implementation in A Fo PDFsureshkumar silvernitzNo ratings yet

- Understandinng Customer Requirements: Principles of DesignDocument30 pagesUnderstandinng Customer Requirements: Principles of DesignAlper GmNo ratings yet

- Understanding Customer Requirements: Principles of DesignDocument30 pagesUnderstanding Customer Requirements: Principles of DesignAlper GmNo ratings yet

- Apqp - CP - QFD: Dvanced Roduct Uality Lanning Ontrol Lan Uality Unction EploymentDocument11 pagesApqp - CP - QFD: Dvanced Roduct Uality Lanning Ontrol Lan Uality Unction EploymentAlper GmNo ratings yet

- Apqp - CP - QFD: Dvanced Roduct Uality Lanning Ontrol Lan Uality Unction EploymentDocument11 pagesApqp - CP - QFD: Dvanced Roduct Uality Lanning Ontrol Lan Uality Unction EploymentAlper GmNo ratings yet

- Team: Project: Responsible: Manager: Product: Control Methods Failure Mode Prevention ControlDocument8 pagesTeam: Project: Responsible: Manager: Product: Control Methods Failure Mode Prevention ControlAlper GmNo ratings yet

- Item Name: FMEA Team: Prepared By: FMEA Date (Orig) : Revision #Document4 pagesItem Name: FMEA Team: Prepared By: FMEA Date (Orig) : Revision #Alper GmNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document18 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Alper GmNo ratings yet

- Modelling and Reasoning For Failure Modes and e Ects Analysis GenerationDocument12 pagesModelling and Reasoning For Failure Modes and e Ects Analysis GenerationAlper GmNo ratings yet

- Failure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleDocument1 pageFailure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleAlper GmNo ratings yet

- Print # Rev. Fmea # Item: Process Resp: Prepared: Model Year(s) /vehicle(s) Key Date Date (Orig.) Core Team: Date (Rev.)Document4 pagesPrint # Rev. Fmea # Item: Process Resp: Prepared: Model Year(s) /vehicle(s) Key Date Date (Orig.) Core Team: Date (Rev.)Alper GmNo ratings yet

- Star Trek Star Charts The Complete Atlas of Star Trek (Unlocked by WWW - Freemypdf.com) PDFDocument113 pagesStar Trek Star Charts The Complete Atlas of Star Trek (Unlocked by WWW - Freemypdf.com) PDFbutwhytho67% (3)

- An Evaluation of Failure Modes and Effects Analysis Generation Method For Conceptual DesignDocument15 pagesAn Evaluation of Failure Modes and Effects Analysis Generation Method For Conceptual DesignAlper GmNo ratings yet

- Sikaflex - 256: The Primerless Windscreen Adhesive System For Direct Glazing in Automotive Glass ReplacementDocument2 pagesSikaflex - 256: The Primerless Windscreen Adhesive System For Direct Glazing in Automotive Glass ReplacementAlper GmNo ratings yet

- 20160323010627-C45E (Ck45) - C45R (Cm45)Document2 pages20160323010627-C45E (Ck45) - C45R (Cm45)Alper GmNo ratings yet

- 34P S4hana1909 BPD en UsDocument18 pages34P S4hana1909 BPD en UsBiji RoyNo ratings yet

- National Industrial Policy 2010 (Bangla)Document46 pagesNational Industrial Policy 2010 (Bangla)Md.Abdulla All Shafi0% (1)

- Pit Viper 351Document6 pagesPit Viper 351Sebastian Robles100% (2)

- Attention: 6R60/6R75/6R80 Installation GuideDocument4 pagesAttention: 6R60/6R75/6R80 Installation GuideEdwinferNo ratings yet

- Parkinson Hoehn and Yahr ScaleDocument3 pagesParkinson Hoehn and Yahr ScaleCarol Artigas GómezNo ratings yet

- Semi Formal Asking To Borrow BooksDocument75 pagesSemi Formal Asking To Borrow BooksPei Cheng WuNo ratings yet

- Likert Scale Video Presentation RubricsDocument1 pageLikert Scale Video Presentation RubricsALDWIN B. BAYLONNo ratings yet

- A-Health Advance - Application Form With InstructionsDocument14 pagesA-Health Advance - Application Form With InstructionsExsan OthmanNo ratings yet

- TOS 1st QuarterDocument6 pagesTOS 1st QuarterQuerisa Ingrid MortelNo ratings yet

- Case For Overhead and DistributionDocument2 pagesCase For Overhead and DistributionBhargav D.S.No ratings yet

- Iraqi Portal of Knowledge and Heritage With Format Edits - 11-21-2023Document6 pagesIraqi Portal of Knowledge and Heritage With Format Edits - 11-21-2023محمد الكربلائيNo ratings yet

- Description Features: Maximizing IC PerformanceDocument1 pageDescription Features: Maximizing IC Performanceledaurora123No ratings yet

- Smartpilot s1 s1g Service ManualDocument30 pagesSmartpilot s1 s1g Service Manualmalte winbaldNo ratings yet

- GE2410 Student Booklet (UpdatedDec27)Document88 pagesGE2410 Student Booklet (UpdatedDec27)markhoNo ratings yet

- Specification For Neoprene Coating On The Riser CasingDocument17 pagesSpecification For Neoprene Coating On The Riser CasingLambang AsmaraNo ratings yet

- Building Interactive AppsDocument17 pagesBuilding Interactive AppsJRoman OrtizNo ratings yet

- Oxford Math AA SL Exam Practise Additional ResourcesDocument172 pagesOxford Math AA SL Exam Practise Additional ResourcesSıla DenizNo ratings yet

- CV (Martin A Johnson)Document7 pagesCV (Martin A Johnson)kganesanNo ratings yet

- The Normal DistributionDocument9 pagesThe Normal DistributionElfren BulongNo ratings yet

- Logical Database Design ModelingDocument2 pagesLogical Database Design ModelingGio Agudo100% (1)

- Chapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16Document81 pagesChapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16mohamed hemdanNo ratings yet

- 310 311 320 321 Toilet Warranty Codes PDFDocument11 pages310 311 320 321 Toilet Warranty Codes PDFTerri MartinNo ratings yet

- EEE Sofware Lab Experiment 1, PDFDocument11 pagesEEE Sofware Lab Experiment 1, PDF240 Sadman ShafiNo ratings yet

- Dragon Ball Z Project: R1 and R2J Dragon Boxes Merge: AcknowledgementsDocument11 pagesDragon Ball Z Project: R1 and R2J Dragon Boxes Merge: Acknowledgements8ASergio GamarraNo ratings yet

- Unit-I Basic Concepts: Course Code: BTCS9504 Course Name: Network Operating SystemsDocument17 pagesUnit-I Basic Concepts: Course Code: BTCS9504 Course Name: Network Operating SystemsPradeep BediNo ratings yet

- Ebook Essentials of Kumar Clarks Clinical Medicine PDF Full Chapter PDFDocument67 pagesEbook Essentials of Kumar Clarks Clinical Medicine PDF Full Chapter PDFjanet.cochran431100% (19)

- ASWP Manual - Section 1 - IntroductionDocument17 pagesASWP Manual - Section 1 - Introductionjmvm56No ratings yet

- Catalogue Colorants TextilesDocument5 pagesCatalogue Colorants TextilesAs Des As BenedictionNo ratings yet

- 44Document2 pages44menakadevieceNo ratings yet

- Caribbean Examination Council: School Based AssessmentDocument17 pagesCaribbean Examination Council: School Based AssessmentDiana FrillsNo ratings yet