0% found this document useful (0 votes)

176 views23 pagesShell Services: Eng. Haitham Sedik Lubricant Technical Advisor

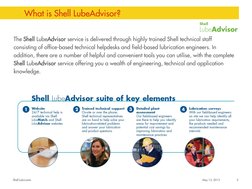

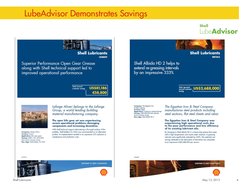

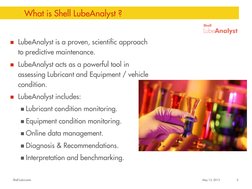

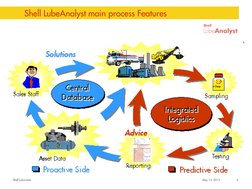

The document discusses various services provided by Shell to help customers with lubricant and equipment maintenance. It describes Shell LubeAdvisor which provides technical support and tools to customers. It also outlines Shell LubeAnalyst that uses lubricant and equipment condition monitoring to enable predictive maintenance. Further, Shell LubeVideoCheck and thermal imaging services allow inspection of equipment internals and identification of potential issues. Shell LubeCoach provides training to help customers optimize their lubrication programs. The overall aim of these services is to help customers improve equipment reliability and reduce maintenance costs.

Uploaded by

Hazem HasanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

176 views23 pagesShell Services: Eng. Haitham Sedik Lubricant Technical Advisor

The document discusses various services provided by Shell to help customers with lubricant and equipment maintenance. It describes Shell LubeAdvisor which provides technical support and tools to customers. It also outlines Shell LubeAnalyst that uses lubricant and equipment condition monitoring to enable predictive maintenance. Further, Shell LubeVideoCheck and thermal imaging services allow inspection of equipment internals and identification of potential issues. Shell LubeCoach provides training to help customers optimize their lubrication programs. The overall aim of these services is to help customers improve equipment reliability and reduce maintenance costs.

Uploaded by

Hazem HasanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd