Professional Documents

Culture Documents

Metric Handbook - Planning and Design Data - 5th Edition - Copy 21

Uploaded by

yit0rrentCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metric Handbook - Planning and Design Data - 5th Edition - Copy 21

Uploaded by

yit0rrentCopyright:

Available Formats

1-10 Design information and dimensional coordination

x expansion and contraction

x variability in manufactured size

x satisfactory joint clearance range

x variations in setting out dimensions, adjacent components, etc.

n1x 300mm x number of components in an assembly

n2x 300mm x variations in interpretation of work size from a given coordinat-

ing size.

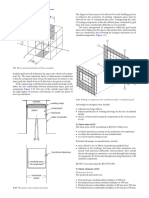

1.17 Controlling lines offset from grid

Degree of accuracy

Designers should identify where fit is critical and where not, or

Relating zones to a 300 mm grid

they must assess:

If widths of structural zones are multiples of 300 mm, the grid is

continuous, Figure 1.18. If the zone is not a multiple of 300 mm,

x where standard sizes are appropriate and readily available

however, the grid is interrupted by the dimension of that zone,

x if some components can be made to order without a significant

Figure 1.19. This is referred to as a neutral zone.

cost penalty

x whether cutting is acceptable (and the effect on performance)

x the likely order of assembly.

5.7 Boundary conditions

Some assembly and support conditions may necessitate variations

zones equal to n x 300mm in elements to allow for:

1.18 Continuous grid x an extended floor slab beyond the clear span to gain a bearing

on a wall

x reduction in size to permit the application of a finish

x an increased height of positioning to allow for building directly

off the floor slab or extending through a suspended ceiling to

reach the soffit of the floor slab.

zones not equal to n x 300mm These allowances (termed ‘boundary conditions’) should be in

multiples of 25 mm. They may be uneconomic to produce, limiting

1.19 Interrupted grid and neutral zones (tartan) the applications of the product to which they apply.

Key reference planes

Key reference planes, Figure 1.20, should generally occur at: 6 REPROGRAPHICS AND PAPER SIZES

6.1 Paper

x finished floor level Traditionally paper was the main means of information transfer.

x finished suspended ceiling level The use of CAD and BIM systems coupled with various forms of

x finished wall surface. electronic transfer now means that team collaboration can be sup-

ported by using interactive screen displays. But for many purposes

Sizes of zones indicated by key reference planes should be selected paper is still the preferred medium and the International A-series

from Table IV. Where controlling or reference lines bound floor or of paper sizes is used for all plotted drawings and printed material.

roof soffits, deflection should be allowed for in the zone.

6.2 Sizes in the A-series

B The A range is derived from a rectangle AO of area 1 m2 with sides

C x and y such that x:y = 1:√2 (i.e. x = 841 mm; y = 1189 mm). The

A

B other sizes in the series are derived downwards by progressively

C halving the size above across its larger dimension. The proportions

A

of the sizes remain constant, Figure 1.21.

1.20 Vertical control: A being floor-to-ceiling height controlling

dimension; B floor and roof zone; C floor-to-floor and floor-to-

roof controlling dimension

5.6 Size of components

Coordinating and work sizes

Controlling dimensions are coordinating sizes:

x Coordinating sizes, 1.12, make allowance for fitting and joint-

ing. They represent the overlaid grid which does not usually

coincide with actual junction lines on the face of the building.

They are indicated by open arrowheads.

x Work sizes are the specified manufactured sizes (within permis-

sible deviations). They are indicated by closed arrowheads.

Tolerance and fit

Joint sizes are critical. There are graphical aids (see References) to 1.21 A-sizes retain the same proportion (1:√2), each size being

help reconcile all the factors affecting tolerance, such as half the size above folding A1 size

You might also like

- Design dimensions and coordinationDocument1 pageDesign dimensions and coordinationyit0rrentNo ratings yet

- Made By:-Submitted ToDocument19 pagesMade By:-Submitted ToAlok Pratap SinghNo ratings yet

- Aercon AacDocument43 pagesAercon AacSITI AISYAH FKNo ratings yet

- FLU GSN 2021R1 EN WS06 Duct VanesDocument48 pagesFLU GSN 2021R1 EN WS06 Duct Vanes2nnnfhx4kqNo ratings yet

- Adaptive Slicing For The FDM Process RevisitedDocument6 pagesAdaptive Slicing For The FDM Process RevisitedNoor MalakNo ratings yet

- Wall Y+ Strategy For Dealing With Wall-Bounded Turbulent FlowsDocument7 pagesWall Y+ Strategy For Dealing With Wall-Bounded Turbulent FlowsHau TranNo ratings yet

- Metric Handbook - Planning and Design Data - 5th Edition - Copy 19Document1 pageMetric Handbook - Planning and Design Data - 5th Edition - Copy 19yit0rrentNo ratings yet

- Advantages of Measuring Surface Roughness With White Light Interferometry App Note BRUKER2Document7 pagesAdvantages of Measuring Surface Roughness With White Light Interferometry App Note BRUKER2yasminaNo ratings yet

- 4 Media: 1.7.25 ValidationDocument2 pages4 Media: 1.7.25 ValidationNickesh ShahNo ratings yet

- Wall Y+ Strategy For Dealing With Wall-Bounded Turbulent FlowsDocument7 pagesWall Y+ Strategy For Dealing With Wall-Bounded Turbulent FlowsHau TranNo ratings yet

- Wall Y Strategy For Dealing With Wall-Bounded Turbulent FlowsDocument7 pagesWall Y Strategy For Dealing With Wall-Bounded Turbulent FlowsVlad KubinyeczNo ratings yet

- Buckling Analysis of Plate GirdersDocument18 pagesBuckling Analysis of Plate Girdersup2240365No ratings yet

- Idoc Pub - Manual-Maxsurf (121-144) Es enDocument24 pagesIdoc Pub - Manual-Maxsurf (121-144) Es enAllan MarkovicNo ratings yet

- Modular Scaffolding System Offers Flexible Design OptionsDocument44 pagesModular Scaffolding System Offers Flexible Design OptionsMounir BoutaghaneNo ratings yet

- Comparison Study For Various Structural Slab SystemsDocument12 pagesComparison Study For Various Structural Slab SystemsIssam SalehNo ratings yet

- Geometrical Dimensioning and TolerancingDocument51 pagesGeometrical Dimensioning and TolerancingMahender Kumar100% (3)

- GD&T Fundamentals: Geometric Dimensioning and Tolerancing ExplainedDocument43 pagesGD&T Fundamentals: Geometric Dimensioning and Tolerancing ExplainedVictor Manuel Estrada0% (1)

- (B) (C) (D) (E) in A General Tolerance Block Referring To All Dimensions OnDocument17 pages(B) (C) (D) (E) in A General Tolerance Block Referring To All Dimensions Onavr8784No ratings yet

- Advantages of Steel Fibre Reinforced Con PDFDocument5 pagesAdvantages of Steel Fibre Reinforced Con PDFAce NovoNo ratings yet

- Modular CoordinationDocument66 pagesModular CoordinationSubhajit GoswamiNo ratings yet

- Reinforced Concrete Sections Under Moment and Axial LoadDocument5 pagesReinforced Concrete Sections Under Moment and Axial LoadAlberto CaínNo ratings yet

- Modular CoordinationDocument17 pagesModular Coordinationkavya sundaramNo ratings yet

- Computational Fluid Dynamics (CFD) Blog - LEAP Australia & New Zealand - Turbulence Part 3 - Selection of Wall Functions and Y - To Best Capture The Turbulent Boundary LayerDocument7 pagesComputational Fluid Dynamics (CFD) Blog - LEAP Australia & New Zealand - Turbulence Part 3 - Selection of Wall Functions and Y - To Best Capture The Turbulent Boundary LayerAbhiANo ratings yet

- Strut and Tie Models ACIDocument13 pagesStrut and Tie Models ACIRômulo Menck RomanichenNo ratings yet

- Astm d3917Document5 pagesAstm d3917Jorge Carreño LagosNo ratings yet

- The Chimnera Grid Concept and ApplicationDocument7 pagesThe Chimnera Grid Concept and ApplicationPutika ApphaNo ratings yet

- Basics of GD&TDocument50 pagesBasics of GD&T2023ht30006No ratings yet

- Panel Systems: Joint LocationsDocument1 pagePanel Systems: Joint LocationsscribdztNo ratings yet

- Simple Building Slab DesignDocument22 pagesSimple Building Slab Designnplasto15No ratings yet

- rc5 Module X5 Design ENDocument11 pagesrc5 Module X5 Design ENJoão Paulo SantosNo ratings yet

- Horizontal ShearDocument2 pagesHorizontal ShearJack WenNo ratings yet

- Module C-Laminar Flat Plate FlowDocument39 pagesModule C-Laminar Flat Plate FlowSandeep KadiamNo ratings yet

- Dimensional Tolerance of Thermosetting Glass-Reinforced Plastic Pultruded ShapesDocument5 pagesDimensional Tolerance of Thermosetting Glass-Reinforced Plastic Pultruded ShapesLam DesmondNo ratings yet

- Fluent-Intro 17.0 WS04 Fluid Flow Around The AirfoilDocument42 pagesFluent-Intro 17.0 WS04 Fluid Flow Around The AirfoilLuis Alfredo Perez MartinezNo ratings yet

- 1.1 WS3 - NACA0012 - AnsysMeshing PDFDocument6 pages1.1 WS3 - NACA0012 - AnsysMeshing PDFbbbNo ratings yet

- 04 GD&T IntroTutorialDocument73 pages04 GD&T IntroTutorialrust_02No ratings yet

- NADCA Product Specification Standards For Die Castings Coordinate Dimension ToleranceDocument2 pagesNADCA Product Specification Standards For Die Castings Coordinate Dimension TolerancewholenumberNo ratings yet

- Effective Span Length: 139 Concrete Deck SlabsDocument5 pagesEffective Span Length: 139 Concrete Deck SlabsJohn Royer Araúz Fuentes100% (1)

- Cad 21 (1) 2024 104-118Document15 pagesCad 21 (1) 2024 104-118Rathor SumitkumarNo ratings yet

- Artículo 31Document1 pageArtículo 31M. Cristian Pinto C.No ratings yet

- GDT TutorialDocument76 pagesGDT TutorialSivananthaa MurtheeNo ratings yet

- GDT TutorialDocument76 pagesGDT TutorialSrk ChowdaryNo ratings yet

- GD&TDocument76 pagesGD&TVictoria Indira Gandhi100% (18)

- GD&T Fundamentals in 40 CharactersDocument76 pagesGD&T Fundamentals in 40 CharactersAnish PaiNo ratings yet

- Slabs On Grade With Single Layer of Reinforcement PDFDocument2 pagesSlabs On Grade With Single Layer of Reinforcement PDFkhx2No ratings yet

- Documents: Search Books, Presentations, Business, Academics..Document105 pagesDocuments: Search Books, Presentations, Business, Academics..adwwwNo ratings yet

- Critical Changes To ASME and ISO GD&T Standards 2018Document31 pagesCritical Changes To ASME and ISO GD&T Standards 2018Juan Posada GNo ratings yet

- Wood-Armer Slab Assessment ModellingDocument20 pagesWood-Armer Slab Assessment ModellingShaileshRastogiNo ratings yet

- General tolerancing concepts for linear and angular dimensionsDocument1 pageGeneral tolerancing concepts for linear and angular dimensionsSvapnesh ParikhNo ratings yet

- Advanced Boundary Cartesian Meshing Technology in Solidworks Flow SimulationDocument31 pagesAdvanced Boundary Cartesian Meshing Technology in Solidworks Flow Simulationmlik borhenNo ratings yet

- Khaled PosterDocument1 pageKhaled PosterKhaled EmhamedNo ratings yet

- Manual of Engineering Drawing: British and International StandardsFrom EverandManual of Engineering Drawing: British and International StandardsRating: 3.5 out of 5 stars3.5/5 (4)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Metric Handbook - Planning and Design Data - 5th Edition - Copy 17Document1 pageMetric Handbook - Planning and Design Data - 5th Edition - Copy 17yit0rrentNo ratings yet

- Metric Handbook - Planning and Design Data - 5th Edition - Copy 19Document1 pageMetric Handbook - Planning and Design Data - 5th Edition - Copy 19yit0rrentNo ratings yet

- Metric Handbook - Planning and Design Data - 5th Edition - Copy 18Document1 pageMetric Handbook - Planning and Design Data - 5th Edition - Copy 18yit0rrentNo ratings yet

- External Fire Fighting GuidelinesDocument37 pagesExternal Fire Fighting Guidelinesssssgggg1968No ratings yet

- Guide To Stainless Steel Finishes PDFDocument24 pagesGuide To Stainless Steel Finishes PDFAnup George ThomasNo ratings yet

- Perkins Eastman Job OpeningsDocument50 pagesPerkins Eastman Job Openingsyit0rrentNo ratings yet

- Guide To Stainless Steel Finishes PDFDocument24 pagesGuide To Stainless Steel Finishes PDFAnup George ThomasNo ratings yet

- New York City Subway: THE BronxDocument1 pageNew York City Subway: THE Bronxnrony007No ratings yet

- Lesson PlanDocument3 pagesLesson Planapi-479604636No ratings yet

- Brain Workshop - A Dual N-Back Game: DownloadDocument2 pagesBrain Workshop - A Dual N-Back Game: DownloaddavetttapiaNo ratings yet

- 10 Steps For Avoiding Teacher BurnoutDocument3 pages10 Steps For Avoiding Teacher BurnoutSarah DeNo ratings yet

- The Ultimate Social Media Guide For Photographers in 2018 PDFDocument27 pagesThe Ultimate Social Media Guide For Photographers in 2018 PDFNicolas Mazzini CorderoNo ratings yet

- Exalted Glories of The Most High - The Maidens of Destiny 2eDocument39 pagesExalted Glories of The Most High - The Maidens of Destiny 2egercog950% (1)

- Echocardiography in Congenital Heart Disease - Expert Consult - Online and Print, 1e (Practical Echocardiography)Document239 pagesEchocardiography in Congenital Heart Disease - Expert Consult - Online and Print, 1e (Practical Echocardiography)Sofia OliveiraNo ratings yet

- Jadwal Pemeliharaan Alat Medik ICUDocument28 pagesJadwal Pemeliharaan Alat Medik ICUsarifahaniNo ratings yet

- Cs504-Midterm Solved Subjective With Refrences by Moaaz PDFDocument14 pagesCs504-Midterm Solved Subjective With Refrences by Moaaz PDFSijjusha100% (1)

- EPCC Hydrocarbon Downstream L&T 09.01.2014Document49 pagesEPCC Hydrocarbon Downstream L&T 09.01.2014shyaminannnaNo ratings yet

- Curriculum Framework of TLE for BEED Students at SLTCF PilarDocument4 pagesCurriculum Framework of TLE for BEED Students at SLTCF PilarRishane Lolo ListanaNo ratings yet

- Soft Computing IntroductionDocument29 pagesSoft Computing IntroductionHarshali Y. PatilNo ratings yet

- Chapter9E2010 PDFDocument29 pagesChapter9E2010 PDFmariahx91No ratings yet

- Zaha Hadid's Revolutionary Architecture and PhilosophyDocument4 pagesZaha Hadid's Revolutionary Architecture and PhilosophyLetu OlanaNo ratings yet

- ElectrodynamicsDocument4 pagesElectrodynamicsHarold Favian Diaz LeonisNo ratings yet

- Vaisnava Glossary PDFDocument24 pagesVaisnava Glossary PDFJulen OsorioNo ratings yet

- The Myth of Saint Thomas and The Mylapore Shiva Temple (2010) - Ishwar SharanDocument173 pagesThe Myth of Saint Thomas and The Mylapore Shiva Temple (2010) - Ishwar SharanIshwar Sharan100% (1)

- Game On! - Gamification, Gameful Design, and The Rise of The Gamer Educator PDFDocument216 pagesGame On! - Gamification, Gameful Design, and The Rise of The Gamer Educator PDFNelson LopezNo ratings yet

- Ngoveni - Mlambya - HluviDocument6 pagesNgoveni - Mlambya - HluviMorris BilaNo ratings yet

- Production Planning and Control System SynopsisDocument6 pagesProduction Planning and Control System Synopsisgvani3333No ratings yet

- Bully Kutta Price and DetailsDocument4 pagesBully Kutta Price and DetailsDr Dogs 4 UNo ratings yet

- The Stoch OscilattorDocument6 pagesThe Stoch Oscilattorapi-3831404No ratings yet

- Revisiting The Fascist Subtext of Attack On Titan - Some Notes On A Modern Reactionary AnimeDocument10 pagesRevisiting The Fascist Subtext of Attack On Titan - Some Notes On A Modern Reactionary AnimeSouthern FuturistNo ratings yet

- Simple Network Management ProtocolDocument17 pagesSimple Network Management ProtocolMallikarjuna D SNo ratings yet

- 1A A Cappuccino, Please.Document7 pages1A A Cappuccino, Please.George ZarpateNo ratings yet

- Concept of Professional Ethics and BioethicsDocument21 pagesConcept of Professional Ethics and BioethicsTina TalmadgeNo ratings yet

- Approach Paper: It-Enabled Financial InclusionDocument28 pagesApproach Paper: It-Enabled Financial InclusionAbdoul FerozeNo ratings yet

- Coconut Milk as an Effective Hair ConditionerDocument21 pagesCoconut Milk as an Effective Hair ConditionerChescka Azucena0% (1)

- 30 Day's Batch Complete Schedule PDFDocument4 pages30 Day's Batch Complete Schedule PDFAmeya GawandeNo ratings yet

- The Chess Player's Quarterly Chronicle, 1869-X, 330pDocument330 pagesThe Chess Player's Quarterly Chronicle, 1869-X, 330pJacky JopheNo ratings yet

- Caedo vs. Yu Khe ThaiDocument2 pagesCaedo vs. Yu Khe ThaiJenine QuiambaoNo ratings yet