Professional Documents

Culture Documents

ME 155L DESIGN PROBLEM 2nd Sem2020 PDF

Uploaded by

Rhoy MunarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ME 155L DESIGN PROBLEM 2nd Sem2020 PDF

Uploaded by

Rhoy MunarCopyright:

Available Formats

ME 155L POWER PLANT ENGINEERING LAB

Design No. 1

Design of Diesel Electric Power Plant

PROBLEM:

Design a Diesel Electric Power Plant to supply a certain community having a

metered data from the National Grid Corporation of the Philippines. Plot and

determine the following:

A. Daily load curve for weekdays

B. Daily load curve for Sundays

C. Annual duration curve

D. Average Load

E. Load Factor

F. Plant Capacity Factor

G. Plant Use Factor

DESIGN REQUIREMENTS AND SPAECIFICATIONS:

1. Plant capacity based on the given data.

2. Plant location must be based on the transmission of energy, fuel delivery, water

supply and realty value.

3. Equipment selection must be done to make the plant operate economical and

efficient considering the number of units to be installed and their speed.

4. A provision for future expansion is necessary.

5. Cold reserve is provided for emergencies and additional loads through out the

year.

6. Consider the prevailing coast of diesel generator set and manpower availability to

operate the plant economically and efficiently.

DETAILS:

1. Load curves must be separate for weekdays and Sundays.

2. Number of units of Diesel-Generator set.

3. Graphical representation of schedule of operation super-imposed on the daily

load curve.

4. Design Of machine foundation:

- Use foundation weight recommended

- Specify all materials to be used including construction materials.

5. Design of cooling system:

- Use a closed type cooling system if possible using limited temperature of plant

location.

- Specify the type, capacity, power rating, etc. of all equipment.

- Make a schematic diagram indicating and labeling the major parts.

- Design all the heat exchangers and showing all the detailed specifications of

parts such as materials, working stresses, etc., necessary in the design.

Abraham P. Apilado 2020

PME 0005075

6. Design the fuel and lubricating system with complete specifications as in the

cooling system.

7. Select and specify units for starting system. Use recommended starting pressures.

8. Discuss how to start and stop the plant.

9. Design and make a complete specification of silencer and muffler for all units.

10. Estimate the cost of generating 1 kw-hr at switchboard.

11. Design and select an overhead crane. Give specifications.

12. Prepare a good plant layout in accordance with required procedures, safety

and engineering specifications.

13. Discuss the procedure of installation, erection, and testing to be considered and

conducted by future contractor and commissioning the plant.

14. Prepare the bill of materials.

15. Submit all preliminary and final drawings, computations, assumptions, and

catalogs (photocopy).

16. Prepare all letters necessary in accordance with contracts, laws, and

specifications of engineering works and projects.

17. Prepare all engineering documents as prescribed by the Department of Labor

and Employment and the Department of Environment and Natural Resources and

in accordance with contracts, laws, and specifications of engineering works and

projects.

18. Computations, drawings and specifications must be done in metric system. Use

tracing paper for your layout using 530 mm x 750 mm. Use the same drawing

format used in Air Conditioning design.

19. Use long bond paper in the final design. Use engineering lettering, 3mm height

and 6mm spacing, black ink only.

Abraham P. Apilado 2020

PME 0005075

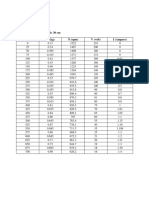

METERED DATA FROM NATIONAL GRID CORPORATION OF THE PHILIPPINES

A. Weekdays (Monday to Saturday)

TIME Current (ave.) Voltage (ave.)

Power Factor

hours amperes volts

2400 191 0.97 26,987.64

0100 179 0.98 6,840.73

0200 172 0.98 7,415.76

0300 162 0.99 18,082.06

0400 153 0.99 23,106.89

0500 150 0.99 33,670.04

0600 139 0.99 42,874.80

0700 136 0.99 46,791.45

0800 144 0.96 50,636.58

0900 166 0.95 47,558.66

1000 184 0.95 45,766.60

1100 204 0.94 42,761.79

1200 206 0.94 43,895.89

1300 216 0.95 43,859.65

1400 218 0.95 44,422.99

1500 212 0.95 50,148.96

1600 207 0.95 55,936.9

1700 223 0.95 56,974.28

1800 257 0.93 49,370.32

1900 303 0.92 39,460.47

2000 292 0.93 38,665.49

2100 273 0.93 35,448.43

2200 247 0.95 34,093.34

2300 215 0.96 29,069.77

2400 195 0.98 24,071.17

Abraham P. Apilado 2020

PME 0005075

B. Sundays

TIME Current (ave.) Voltage (ave.)

Power Factor

hours amperes volts

2400 175 0.97 17,673.05

0100 167 0.98 15,275.58

0200 159 0.98 12,835.33

0300 154 0.98 19,878.09

0400 149 0.98 41,090.27

0500 157 0.98 38,996.50

0600 160 0.95 36,184.22

0700 162 0.96 41,795.27

0800 206 0.94 40,280.94

0900 271 0.92 30,081.83

1000 295 0.92 25,792.19

1100 316 0.92 25,798.02

1200 315 0.92 26,570.05

1300 316 0.92 26,657.96

1400 325 0.92 26,086.96

1500 320 0.91 25,755.50

1600 307 0.91 25,235.36

1700 275 0.91 31,168.84

1800 293 0.91 25,878.56

1900 303 0.91 25,387.16

2000 292 0.92 22,334.73

2100 272 0.93 19,765.98

2200 240 0.94 30,141.85

2300 206 0.95 20,439.45

2400 186 0.97 14,965.09

Abraham P. Apilado 2020

PME 0005075

You might also like

- BDocument80 pagesBNovan Ediwibowo100% (1)

- Error Code List Ergopower-Est37/A: ZF Passau GMBHDocument56 pagesError Code List Ergopower-Est37/A: ZF Passau GMBHTogu Marnaek SiagianNo ratings yet

- DBA Strategy Roadmap (Amazon)Document28 pagesDBA Strategy Roadmap (Amazon)Muhammad Sajid SaeedNo ratings yet

- BGA Land Rover Steering Suspension Brochure PDFDocument37 pagesBGA Land Rover Steering Suspension Brochure PDFbit xozNo ratings yet

- 14) Chilled Water Plant Efficiency 1Document33 pages14) Chilled Water Plant Efficiency 1Ooi Tze HoongNo ratings yet

- History of Social CaseworkDocument14 pagesHistory of Social Caseworknirmaljoy60% (5)

- Hydrogen Power Handbook (3206)Document34 pagesHydrogen Power Handbook (3206)cesar baranda100% (2)

- Oshkosh M AtvDocument28 pagesOshkosh M AtvUsNdaomanu100% (1)

- Accc InstallationDocument4 pagesAccc InstallationARCC2030No ratings yet

- HP LaserJet MFP M72625-M72630 Series Service Training - V0.94 - 20180206Document130 pagesHP LaserJet MFP M72625-M72630 Series Service Training - V0.94 - 20180206smrizalNo ratings yet

- 03 Analisa HydografDocument139 pages03 Analisa Hydograflos pollosNo ratings yet

- Me 155L Design Problem PDFDocument3 pagesMe 155L Design Problem PDFjohn guinyangNo ratings yet

- Nama: Andi Nurslamat NIM: 1713005 Prodi: Teknik Sipil (A) : UTS Rekayasa Drainase Mata KuliahDocument2 pagesNama: Andi Nurslamat NIM: 1713005 Prodi: Teknik Sipil (A) : UTS Rekayasa Drainase Mata KuliahAndi Nurslamat Putra AmpueNo ratings yet

- Northeast Power Systems, Inc.: 66 Carey Road, Queensbury, NYDocument12 pagesNortheast Power Systems, Inc.: 66 Carey Road, Queensbury, NYkponramNo ratings yet

- Short Time Current Rating of ConductorDocument12 pagesShort Time Current Rating of ConductorAbhinav SinhaNo ratings yet

- Tablas R134a MORANDocument5 pagesTablas R134a MORANBlasNo ratings yet

- RTD Thermistor Z202030 0NDocument1 pageRTD Thermistor Z202030 0NcesarNo ratings yet

- Volume Report: Project: C:/Users/ Usuario/a Ppdata/lo Cal/temp /chaupib Anda N - 1 - 3 - 28 45.sv$Document4 pagesVolume Report: Project: C:/Users/ Usuario/a Ppdata/lo Cal/temp /chaupib Anda N - 1 - 3 - 28 45.sv$davidNo ratings yet

- Alloy 600 Resistance Heating Nickel Chrome: ASTM: B344 & B267 (7.9 G/CM)Document5 pagesAlloy 600 Resistance Heating Nickel Chrome: ASTM: B344 & B267 (7.9 G/CM)SachinNo ratings yet

- Tabla VC TP2Document15 pagesTabla VC TP2Julio TorresNo ratings yet

- Tablas R134aDocument5 pagesTablas R134azulma9solano-1100% (1)

- Shavneel HydraulicsDocument7 pagesShavneel HydraulicsDrakeGAMINGNo ratings yet

- 100W 5700kphotometric Test ReportDocument10 pages100W 5700kphotometric Test ReportGonzalo LunaNo ratings yet

- ACCC Conductor List 2019 v1.6Document6 pagesACCC Conductor List 2019 v1.6Mauricio MoralesNo ratings yet

- 1 ACCC-Conductor-List-M356010-01-REV-A-120921-reduced-v4Document8 pages1 ACCC-Conductor-List-M356010-01-REV-A-120921-reduced-v4jdserpa.0617No ratings yet

- Holman 10th Edition Appindix ADocument18 pagesHolman 10th Edition Appindix AAbod AbodNo ratings yet

- UntitledDocument11 pagesUntitledksarawanNo ratings yet

- Pseudo PressureDocument199 pagesPseudo PressureKalou BoniNo ratings yet

- (S, Co To) Versus To Including Wellbore Storage and Skin (S +10)Document10 pages(S, Co To) Versus To Including Wellbore Storage and Skin (S +10)سحر سلامتیانNo ratings yet

- AERO3000 Equation ListDocument19 pagesAERO3000 Equation ListlalalallkjdlfjlkNo ratings yet

- Garantii Cu Sold 1670 Noiembrie 2014Document24 pagesGarantii Cu Sold 1670 Noiembrie 2014danaNo ratings yet

- Turbine Cable Aw G 1Document2 pagesTurbine Cable Aw G 1Umamaheshwarrao VarmaNo ratings yet

- Fortlight Fledss09-P-150W 1X: Luminous Emittance 1 / Polar LDCDocument8 pagesFortlight Fledss09-P-150W 1X: Luminous Emittance 1 / Polar LDCCarlosNo ratings yet

- Fortlight Fledss09-P-150W 1X: Luminous Emittance 1 / Polar LDCDocument8 pagesFortlight Fledss09-P-150W 1X: Luminous Emittance 1 / Polar LDCCarlosNo ratings yet

- Tables of R 134a From NistDocument6 pagesTables of R 134a From NistMarel8980% (1)

- Txy Diagram For Ethanol/Water at 760MmhgDocument2 pagesTxy Diagram For Ethanol/Water at 760MmhgAsilahNo ratings yet

- Txy Diagram For Ethanol/Water at 760MmhgDocument2 pagesTxy Diagram For Ethanol/Water at 760MmhgAsilahNo ratings yet

- Dist GumbelDocument3 pagesDist Gumbelelvin20012No ratings yet

- Project Name: Al Shahad Tower Consultant: MZP W.L.L Main Contractor: Al Bandary EngineeringDocument6 pagesProject Name: Al Shahad Tower Consultant: MZP W.L.L Main Contractor: Al Bandary EngineeringFranklyn GenoveNo ratings yet

- Packed Stripper SizingDocument16 pagesPacked Stripper SizingAriesNo ratings yet

- Packed Stripper SizingDocument16 pagesPacked Stripper SizingAriesNo ratings yet

- Motors Cable SelectionDocument1 pageMotors Cable SelectionAhmad HamoudaNo ratings yet

- Mechanical Properties: QT-900 Technical Data SheetDocument2 pagesMechanical Properties: QT-900 Technical Data SheetIshmael WoolooNo ratings yet

- PR1 Tekres-NmappyDocument4 pagesPR1 Tekres-NmappyJenyver LappyNo ratings yet

- Perfiles IPE EntregableDocument19 pagesPerfiles IPE EntregableJazmín NopeNo ratings yet

- Ac Resistances: Table 3.26 Multi Conductor Cables - AC Resistances (M /M)Document1 pageAc Resistances: Table 3.26 Multi Conductor Cables - AC Resistances (M /M)subramanyaNo ratings yet

- Volume Report (Alignment 1)Document3 pagesVolume Report (Alignment 1)Yvonne YveNo ratings yet

- Transito de AvenidasDocument11 pagesTransito de AvenidasJhonatan Christian Guinea PerezNo ratings yet

- 06 22Document18 pages06 22MustaminNo ratings yet

- R 134a PDFDocument1 pageR 134a PDFFabian de Jesus Orozco MartinezNo ratings yet

- H 0.9 CM, HT 2.3 Bar, L 30 CM Beban M (KG) N (RPM) V (Volt) I (Ampere)Document4 pagesH 0.9 CM, HT 2.3 Bar, L 30 CM Beban M (KG) N (RPM) V (Volt) I (Ampere)fadel albasithNo ratings yet

- H 0.9 CM, HT 2.3 Bar, L 30 CM Beban M (KG) N (RPM) V (Volt) I (Ampere)Document4 pagesH 0.9 CM, HT 2.3 Bar, L 30 CM Beban M (KG) N (RPM) V (Volt) I (Ampere)fadel albasithNo ratings yet

- CTC AcccDocument2 pagesCTC AcccJALIR ANDRE HUAYLLAS SOTONo ratings yet

- AR 303 Vol 1 DDocument968 pagesAR 303 Vol 1 DAnonymous gM6RZL5lYdNo ratings yet

- Perhitungan CFRDocument4 pagesPerhitungan CFRRizal FauziNo ratings yet

- Geothermal Power Plants: Principles, Applications, Case Studies and Environmental ImpactDocument1 pageGeothermal Power Plants: Principles, Applications, Case Studies and Environmental ImpactJuan Ponce ManríquezNo ratings yet

- 2019 04 17 - Draft - Hydraulic Analysis - Talchwok Begnas - AmitDocument19 pages2019 04 17 - Draft - Hydraulic Analysis - Talchwok Begnas - AmitDeepak YadavNo ratings yet

- 19 OutDocument32 pages19 Outarby rezkiansyahNo ratings yet

- Shear Stress Vs Shear StrainDocument12 pagesShear Stress Vs Shear StrainAbrar AfzalNo ratings yet

- Dayco Tensiometer InstructionsDocument13 pagesDayco Tensiometer InstructionsJoseph ChamiNo ratings yet

- Electrical Wire Sizes AWG Diameter Cross-Sectional Area Mils Inches MM Cmils MMDocument1 pageElectrical Wire Sizes AWG Diameter Cross-Sectional Area Mils Inches MM Cmils MMccorp0089No ratings yet

- UCT Kalibrasi Dial Vertikal 0.010 Mm2/div Diameter 4.355 A0 14.888 Tinggi 8.000 LRC 0.129Document4 pagesUCT Kalibrasi Dial Vertikal 0.010 Mm2/div Diameter 4.355 A0 14.888 Tinggi 8.000 LRC 0.129CAECILIA PRAYITNA WELENDNo ratings yet

- Jack %Document21 pagesJack %Aly Arquillano JrNo ratings yet

- Lo Ad (P) : KG N (MM)Document9 pagesLo Ad (P) : KG N (MM)Muhammad Husnain IjazNo ratings yet

- Levas Acel ConstanteDocument6 pagesLevas Acel ConstanteAnthony Gabriel LescanoNo ratings yet

- GT DURACOIL 130 DATASHEET US 3-22 v2Document3 pagesGT DURACOIL 130 DATASHEET US 3-22 v2Ahmed BenayadNo ratings yet

- Raled I 16 LedDocument20 pagesRaled I 16 LedPineda SuárezNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- English 109 Informative SpeechDocument16 pagesEnglish 109 Informative SpeechRoberto GuzmanNo ratings yet

- (Notes) Financial Management FundamentalsDocument65 pages(Notes) Financial Management FundamentalsJoanna Danielle AngNo ratings yet

- Lesson Plan - WebDocument3 pagesLesson Plan - WebAbinaya87No ratings yet

- Catalogo Level OneDocument80 pagesCatalogo Level Onemedo amgdNo ratings yet

- Estimation of An OfficeDocument29 pagesEstimation of An OfficeJincy JohnsonNo ratings yet

- Fabric EJDocument20 pagesFabric EJOctama RizkyNo ratings yet

- Advance Transportation Management Technologies (Abridged)Document326 pagesAdvance Transportation Management Technologies (Abridged)Pablo Chan100% (1)

- NetstatDocument1 pageNetstatM Faaiq Al AzharNo ratings yet

- ALLEN Ball ValveDocument1 pageALLEN Ball ValveShaffiqNo ratings yet

- E147478 BMW 5GT F07 NF FpoDocument9 pagesE147478 BMW 5GT F07 NF FpoInventyourselfNo ratings yet

- Make A Battery Level Indicator Using LM339 ICDocument13 pagesMake A Battery Level Indicator Using LM339 ICnelson100% (1)

- Request Form For Postponement of Return DateDocument4 pagesRequest Form For Postponement of Return DateAzimah MustafaNo ratings yet

- Project CoordinatorDocument2 pagesProject Coordinatorapi-78653370No ratings yet

- Applying Organizational Routines in Understanding Organizational ChangeDocument17 pagesApplying Organizational Routines in Understanding Organizational ChangeJack000123No ratings yet

- Walmart CaseDocument1 pageWalmart Casemaria clara drzeviechi silvaNo ratings yet

- Skilled Worker EC Application Questionnaire..Document11 pagesSkilled Worker EC Application Questionnaire..Courage MlamboNo ratings yet

- 06 - SCM Academy - Purchasing Overview-EditedDocument15 pages06 - SCM Academy - Purchasing Overview-Editedalice.9No ratings yet

- 26 Indian Police Service Structure and FunctioningDocument13 pages26 Indian Police Service Structure and FunctioningHardik PatelNo ratings yet

- E Directory Project ReportDocument11 pagesE Directory Project ReportVidhimanya Chamber of Commerce and IndustryNo ratings yet

- Class - 20200904 Restore - Recovery Using Keystore (My Practice)Document23 pagesClass - 20200904 Restore - Recovery Using Keystore (My Practice)RaihanNo ratings yet

- Flight International 13 November 2018Document52 pagesFlight International 13 November 2018Adrian BistreanuNo ratings yet

- Slack Operations Management 6e Chapter1Document7 pagesSlack Operations Management 6e Chapter1dorislianNo ratings yet